Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Uniform exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food product surface sterilization apparatus and method

InactiveUS20040052702A1Increase temperatureReduce food product temperature changeFood preservationIndirect heat exchangersUnsafe conditionUltraviolet

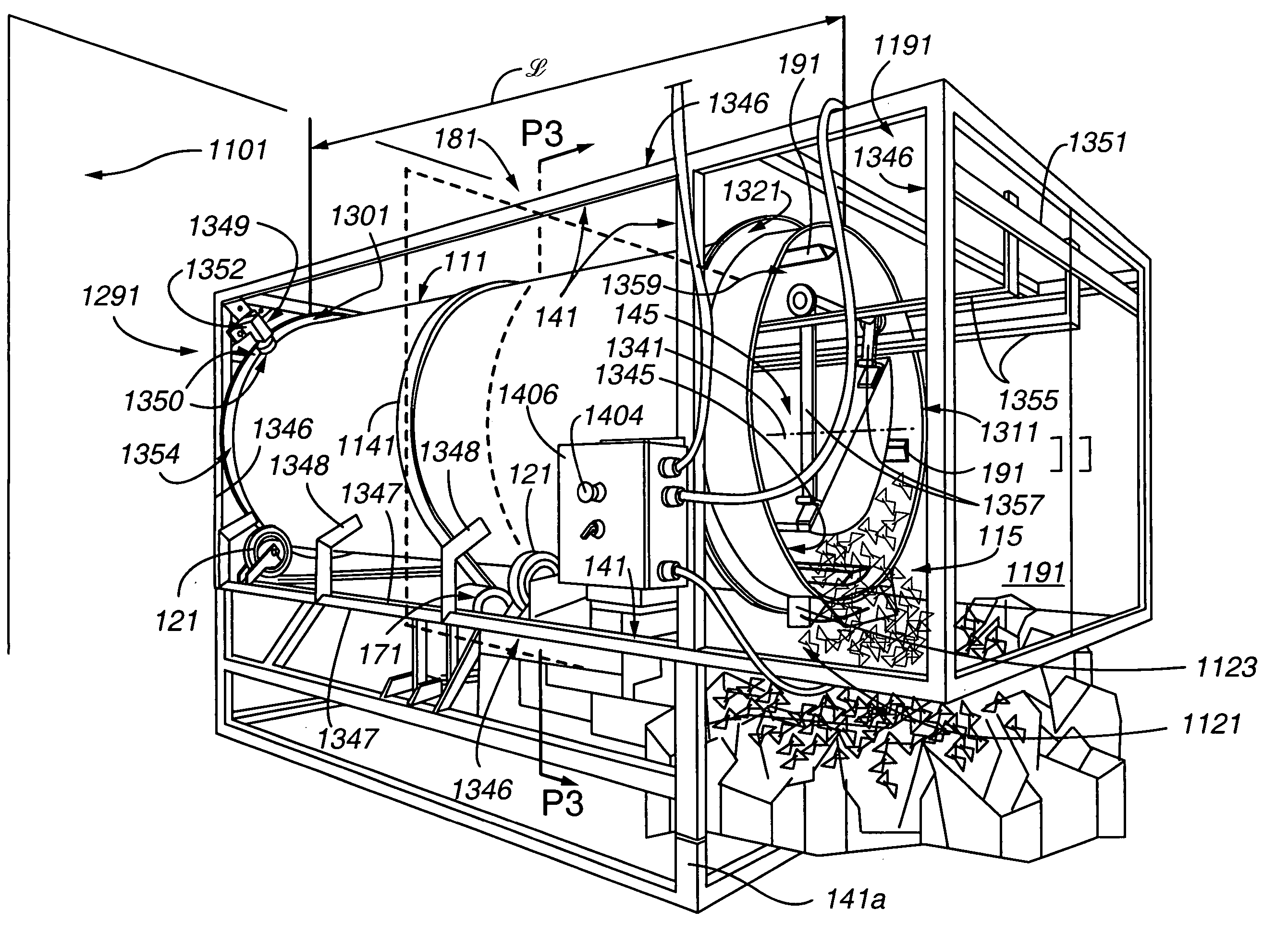

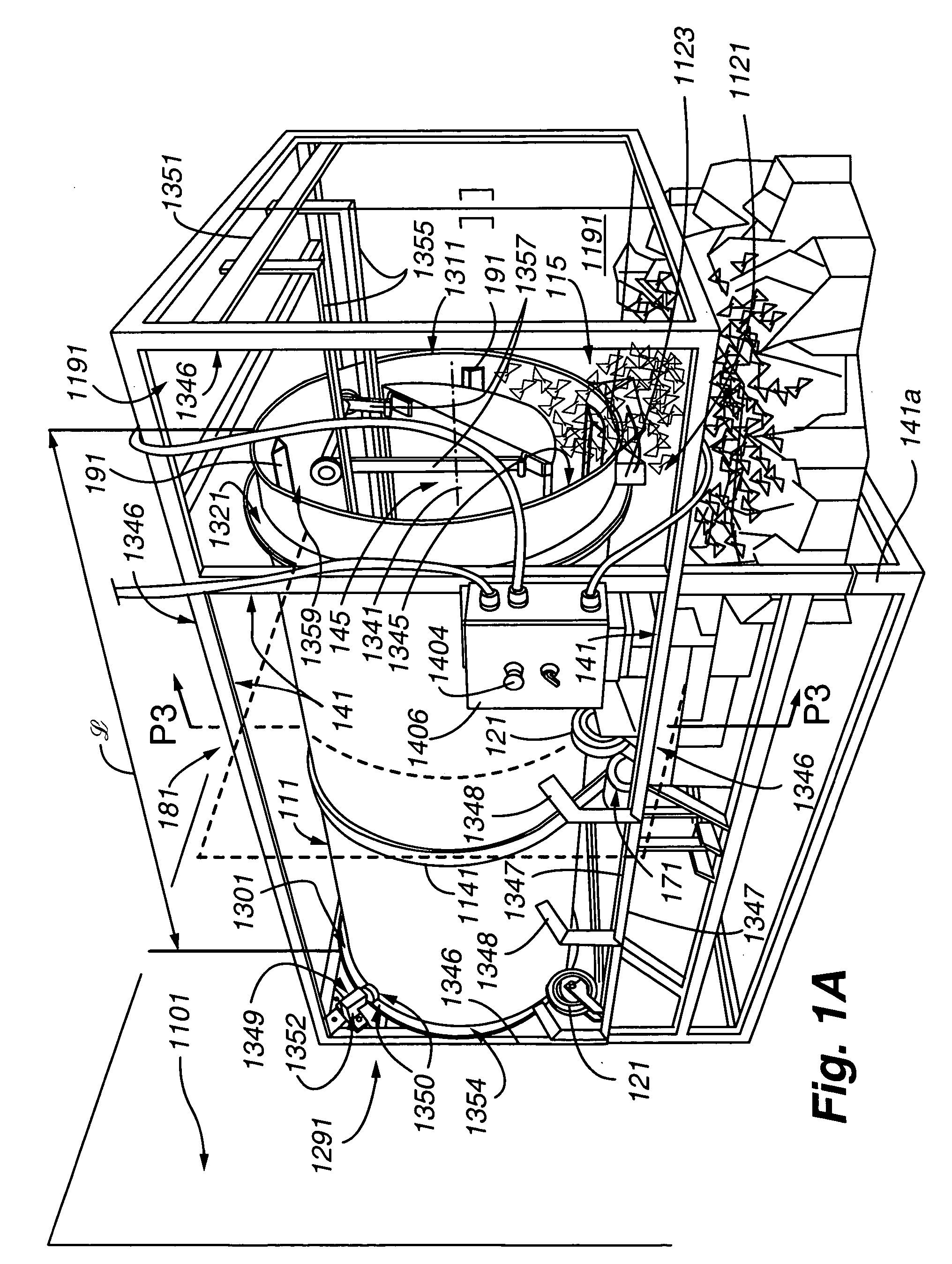

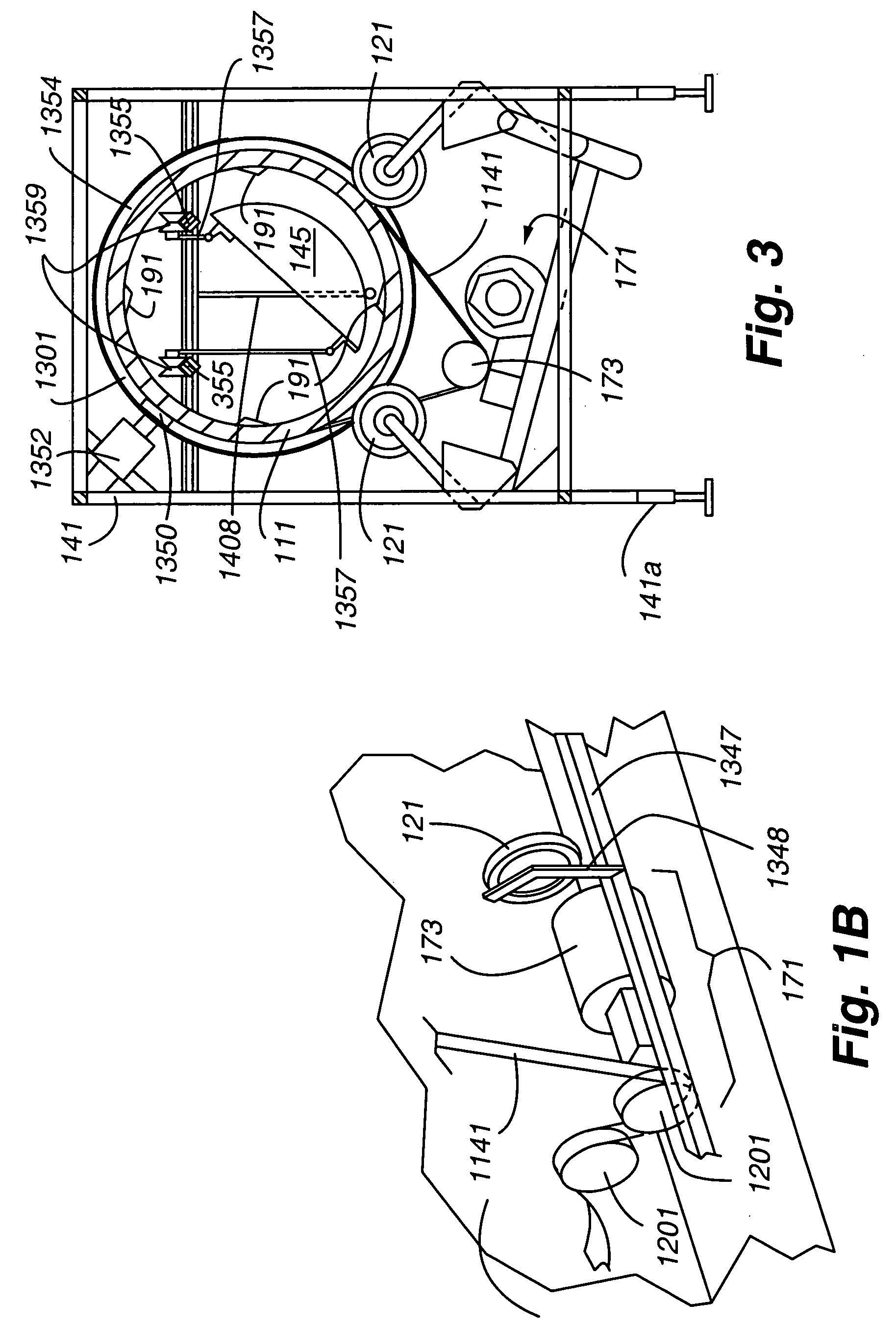

An apparatus is disclosed for the micro-organism surface sterilization of foods using, a "germicidal" such as light waves (e.g., ultraviolet), and in some cases in combination with (or replaced by) one or more of sound waves and ozone. The surface sterilizer apparatus may include a plurality of germicidal (e.g., ultraviolet) emitters for surface sterilization of foods that are, e.g., rotated in a drum or rotated via a screw auger. Assemblies of emitters for the germicidal may be constructed to be watertight (i.e., withstand a high pressure, heated water spray), and movable relative to the drum or screw conveyor for easy cleaning and maintenance. The apparatus may also include a controller (e.g., programmable logic controller) for controlling the sterilization process so that the apparatus does not endanger personnel nearby, and so that the food is properly sterilized. The controller may vary the amount of germicidal used, the rate that food traverses the apparatus, the inclination of the apparatus, and terminate sterilization processing when an unsafe condition is detected. The apparatus may be used in-line with other food processing equipment for the real-time sterilization of food. The controller may also communicate with food processing components upstream of the apparatus for controlling the flow of food to the surface sterilizer

Owner:C & S EQUIP COMPANY

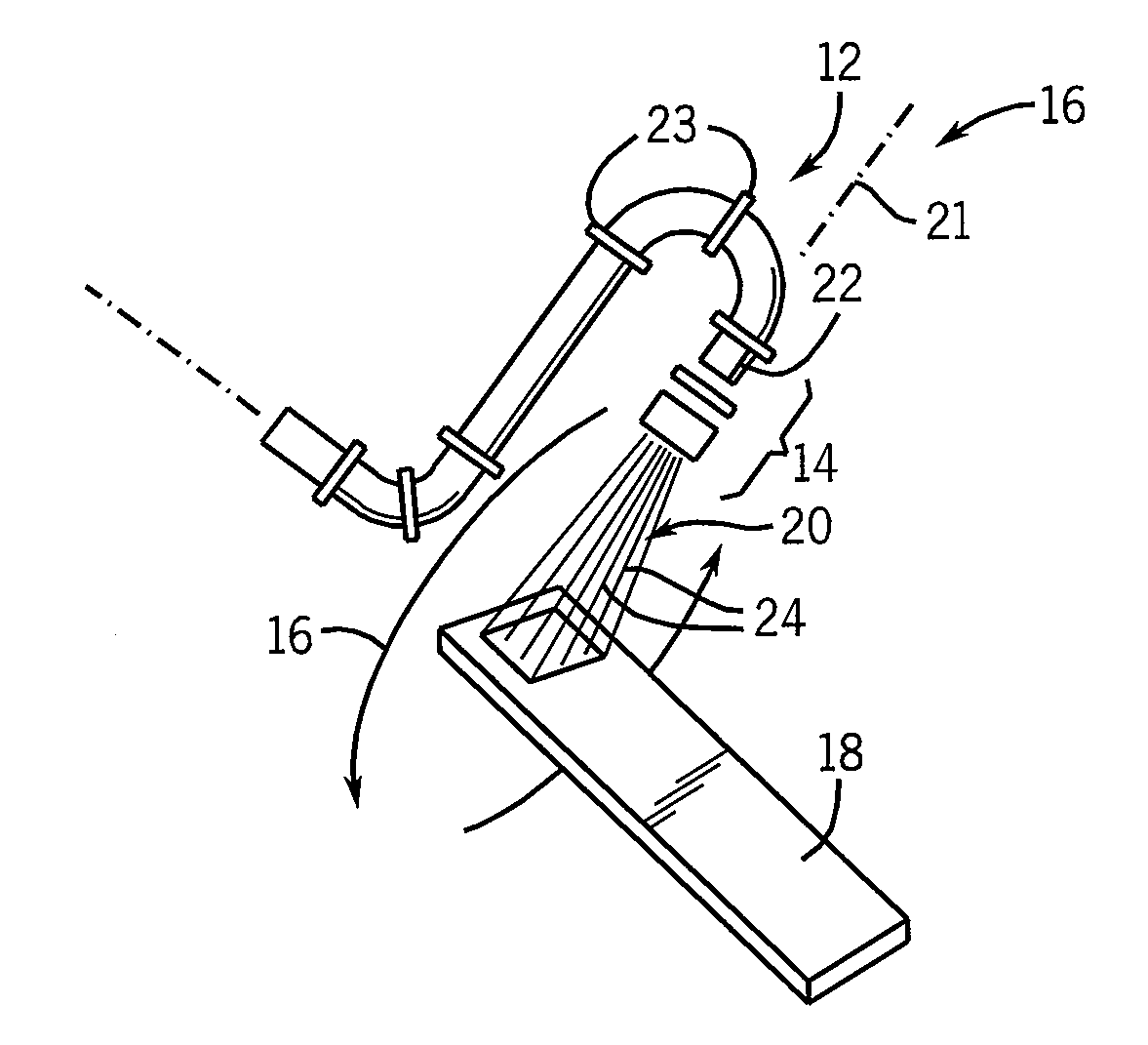

Automobile Scanning System

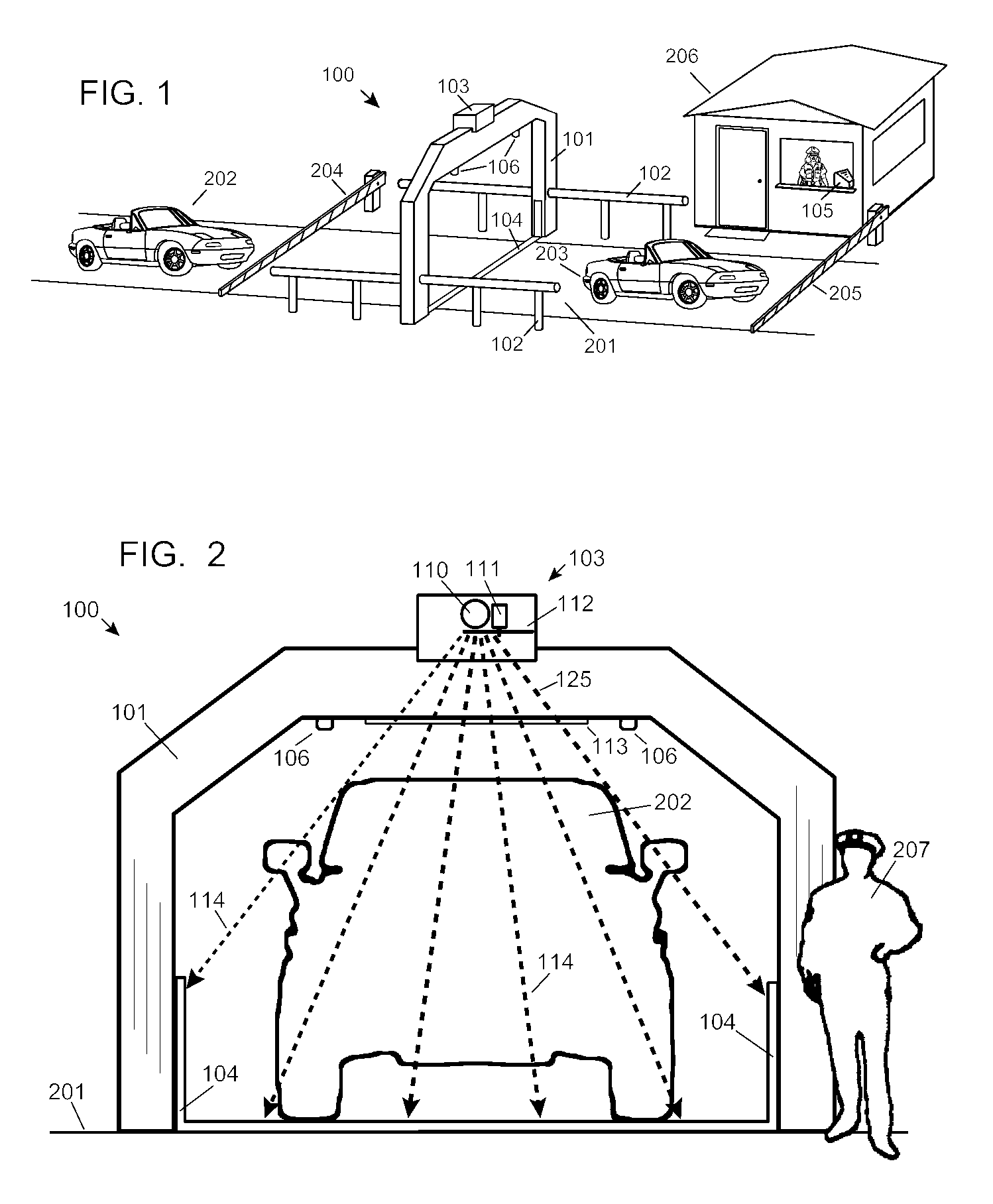

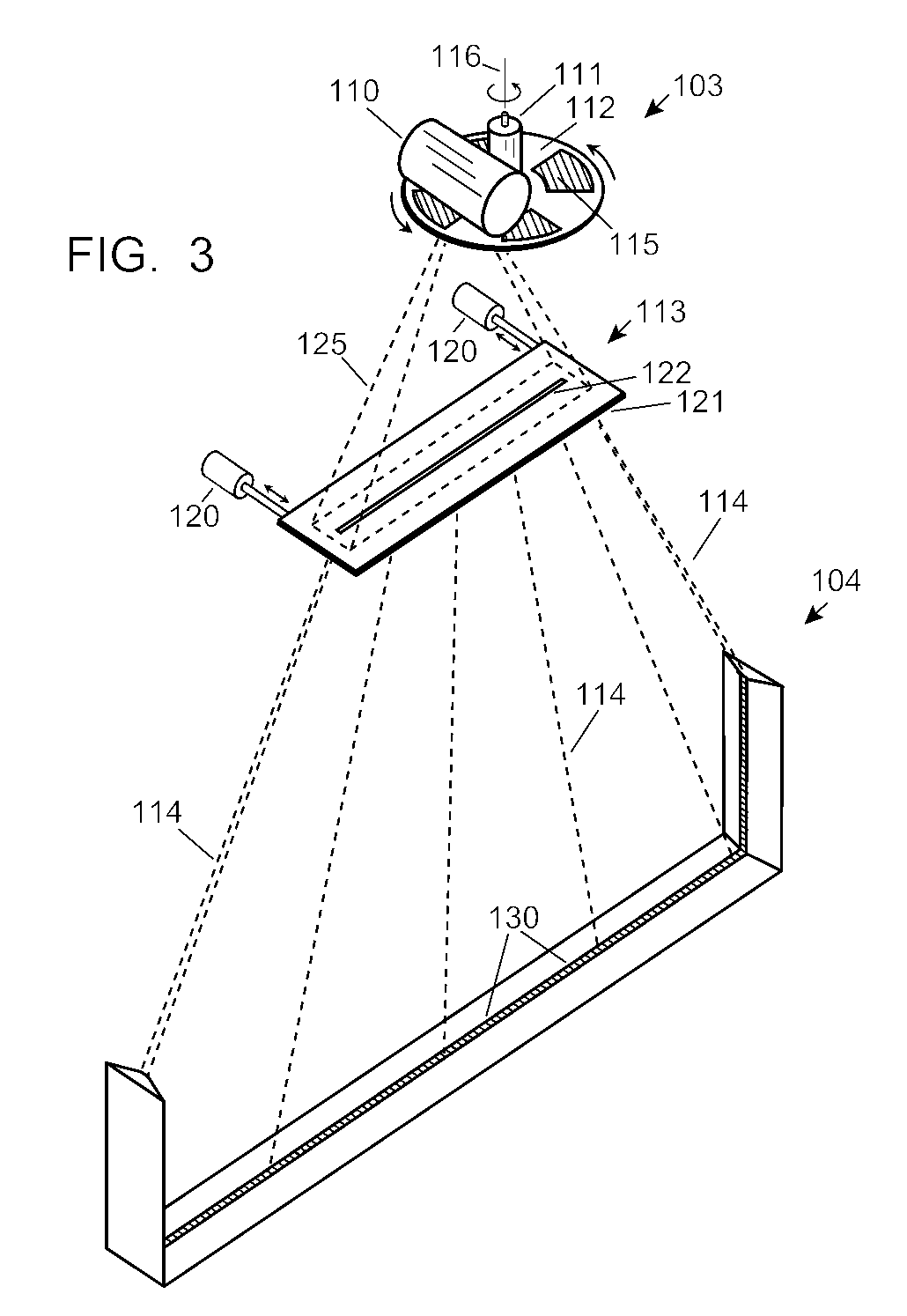

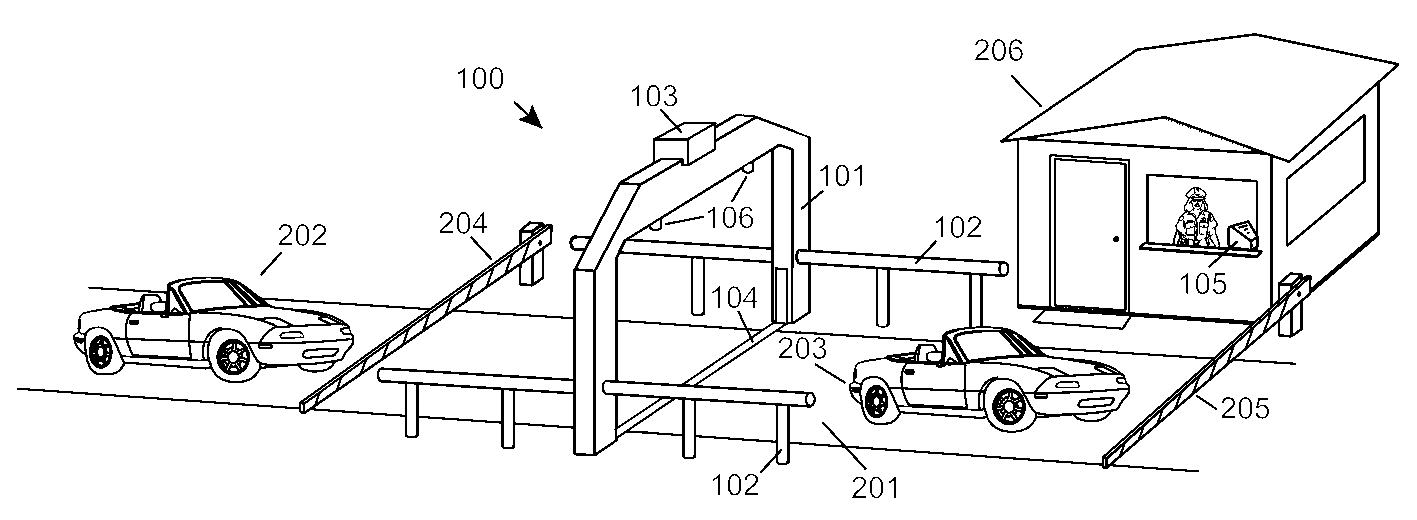

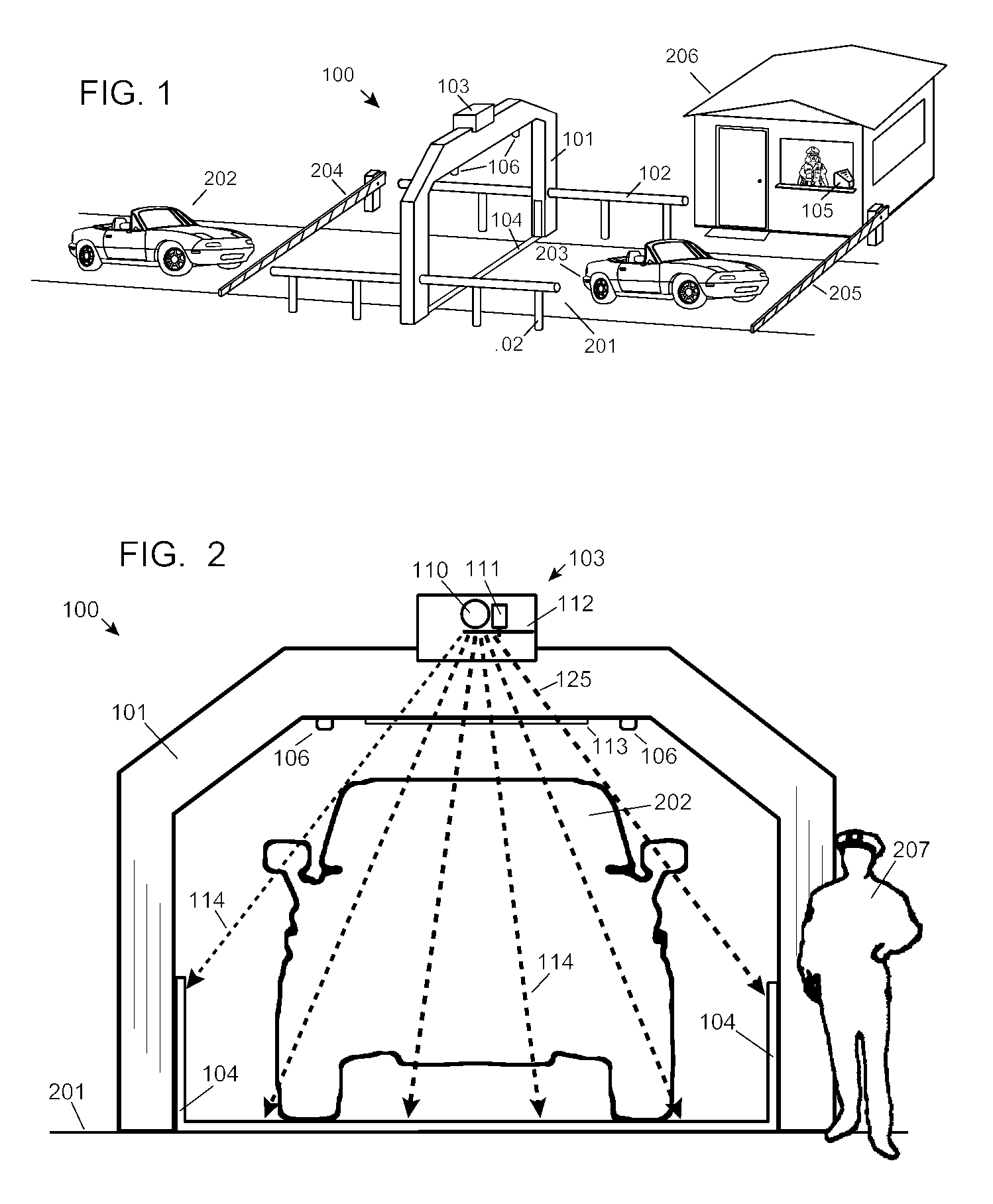

ActiveUS20090086907A1Easy to checkUniform radiation exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

Automobile scanning system

ActiveUS7742568B2Easy to checkUniform exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

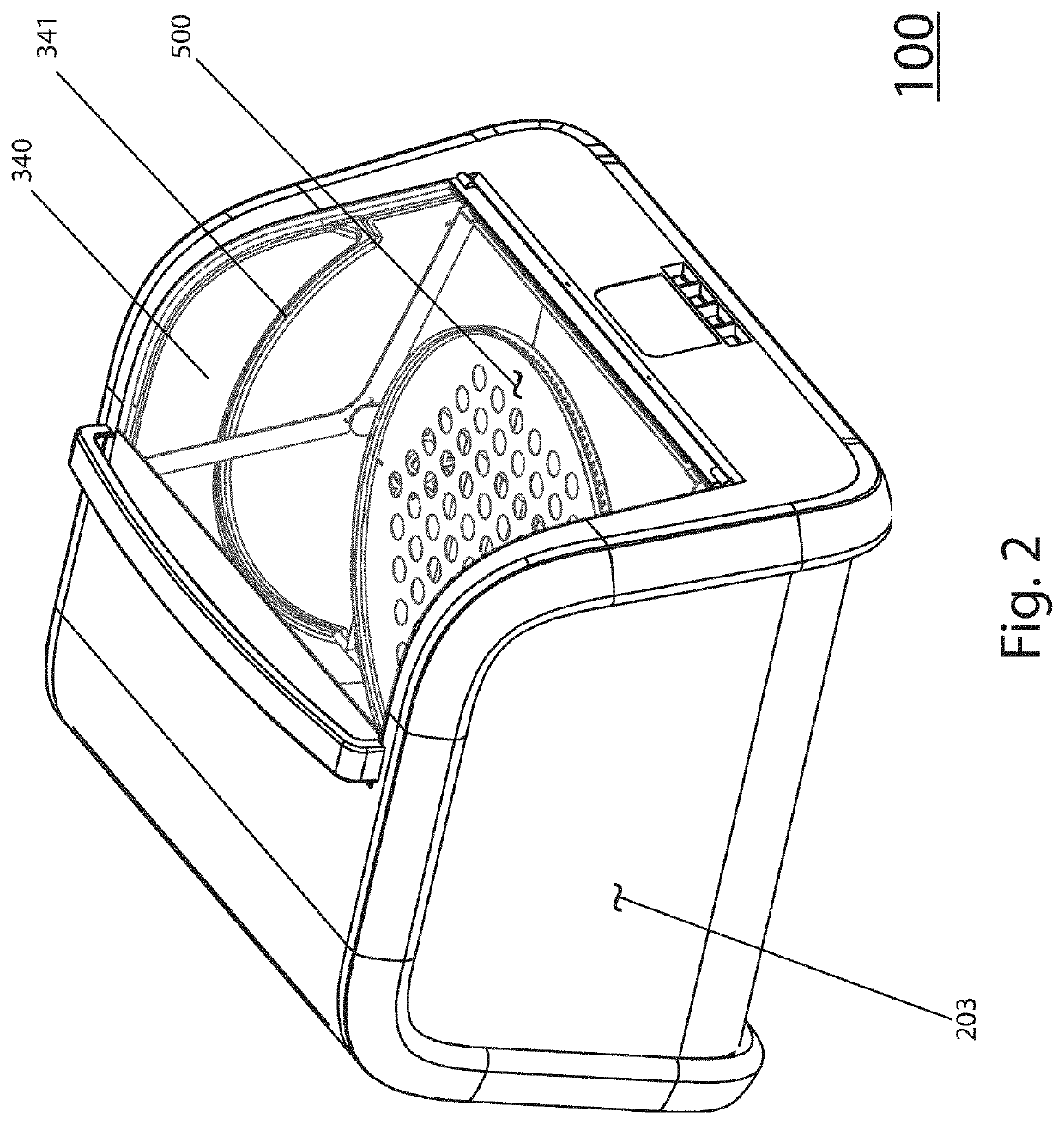

Counter top cooking appliance

ActiveUS20160309956A1Optimal performanceUniform exposureDomestic stoves or rangesStoves/ranges shelves or racksDriver/operatorCooker

A counter top electric appliance optimally performs a variety of cooking modes with both radiant and convective heat sources as well as control means for controlling the timing and intensity of the heat sources. A driver turns food about either a horizontal or a vertical axis of rotation suitable for the specific food and recipe. A hinged door supports the food to be cooked so that in one location the food is caused to be turned by the drive means and in another location the food is loaded into or removed the appliance, external of the cooking compartment, to be easily handled by the operator.

Owner:GLUCKSMAN DOV Z

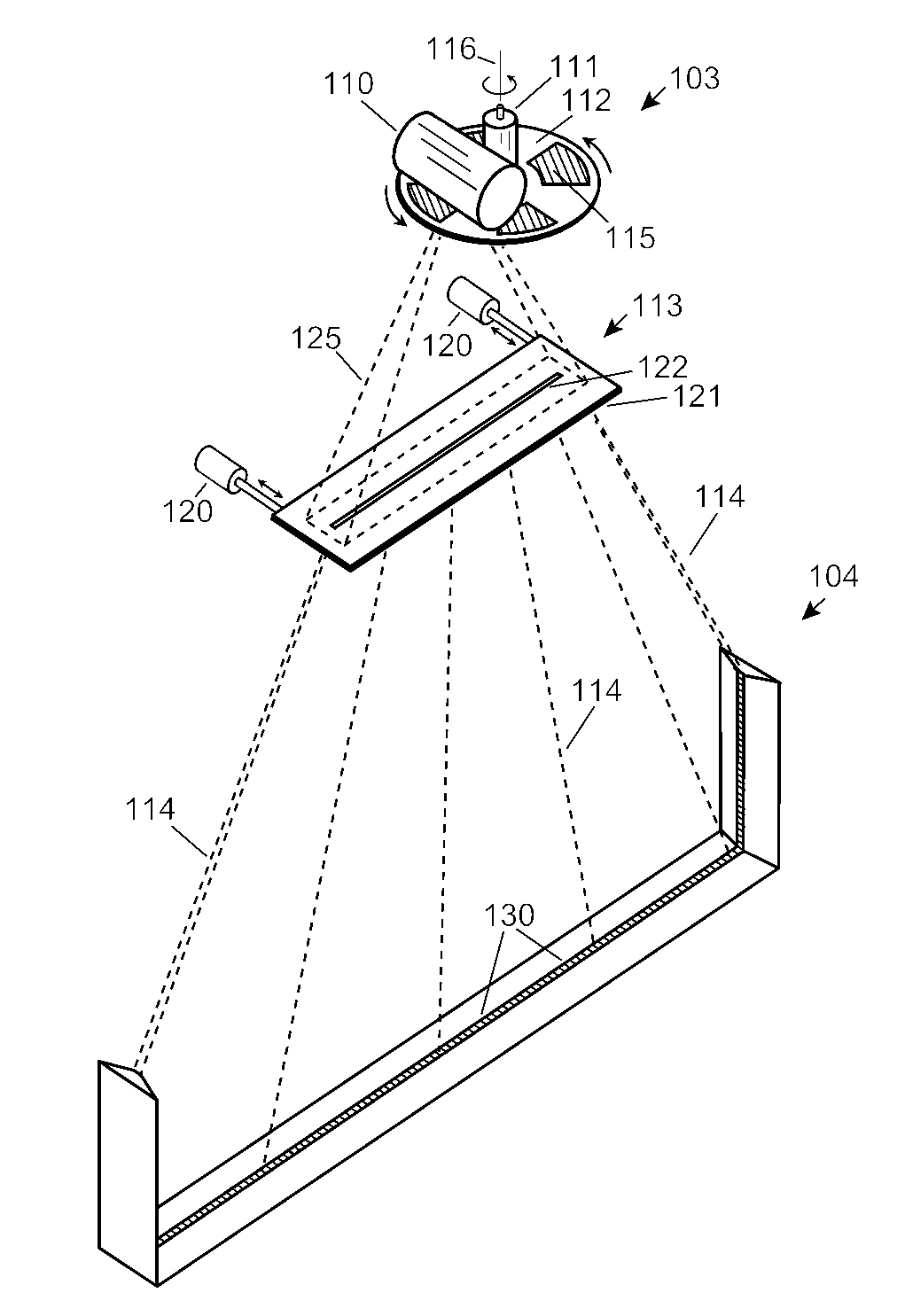

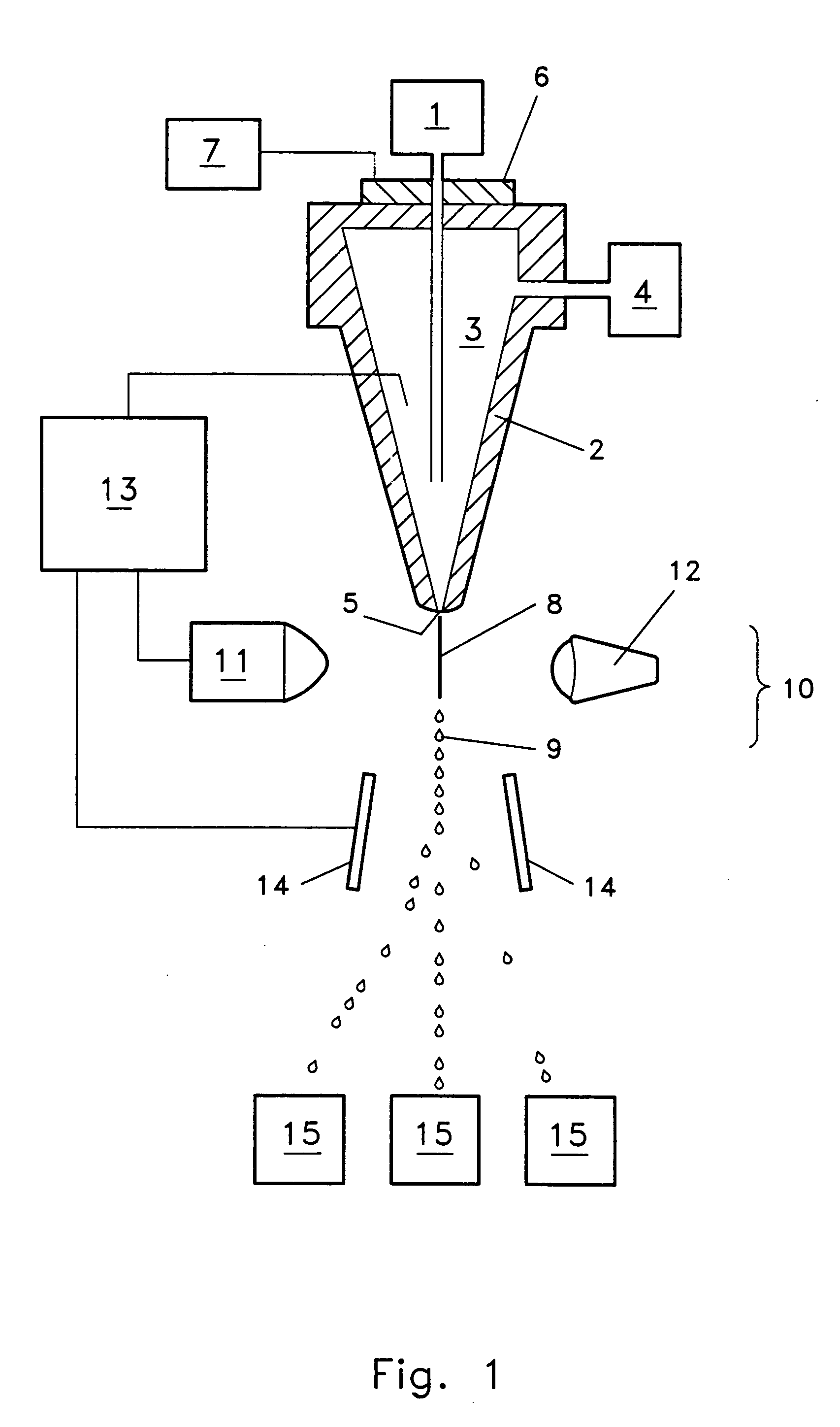

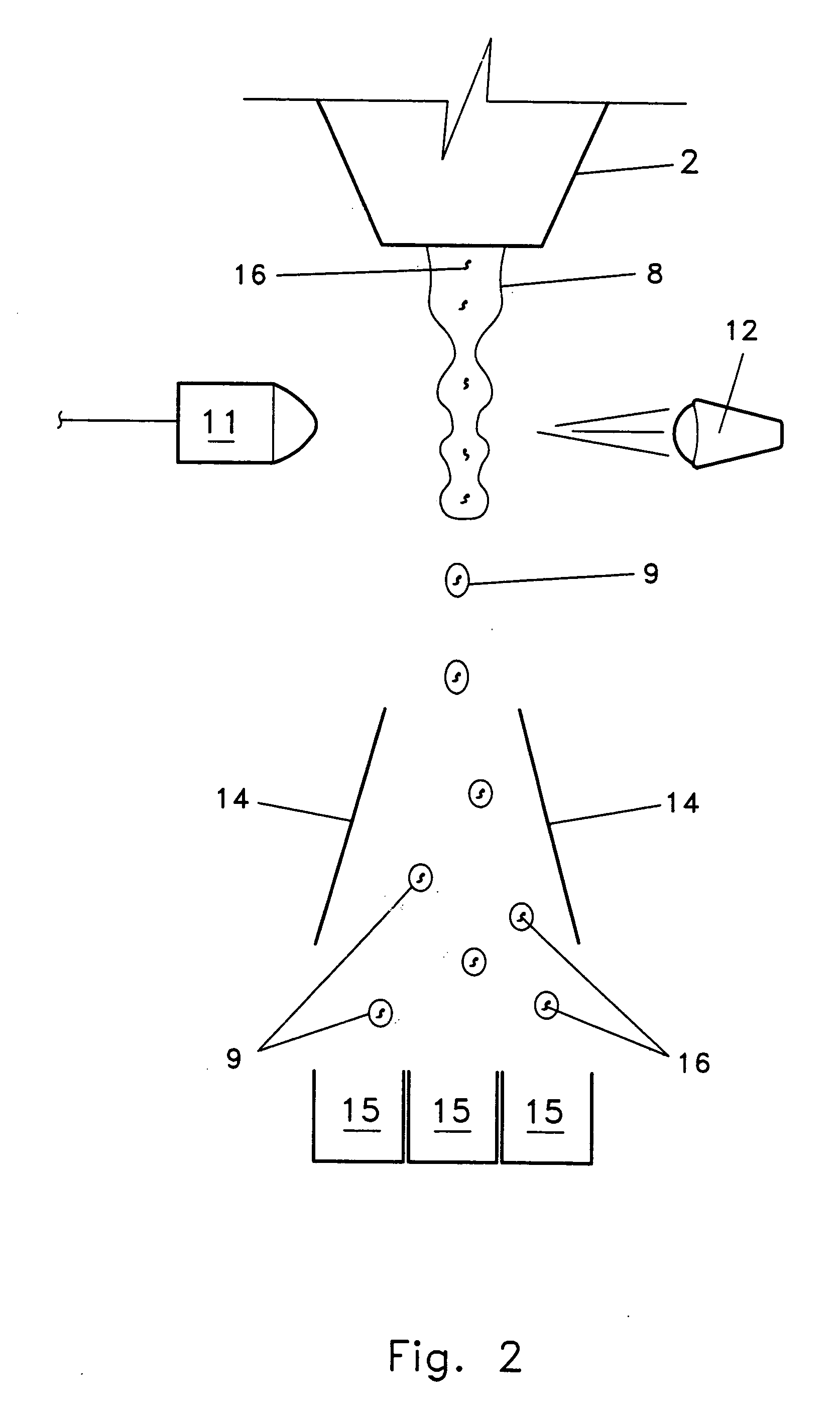

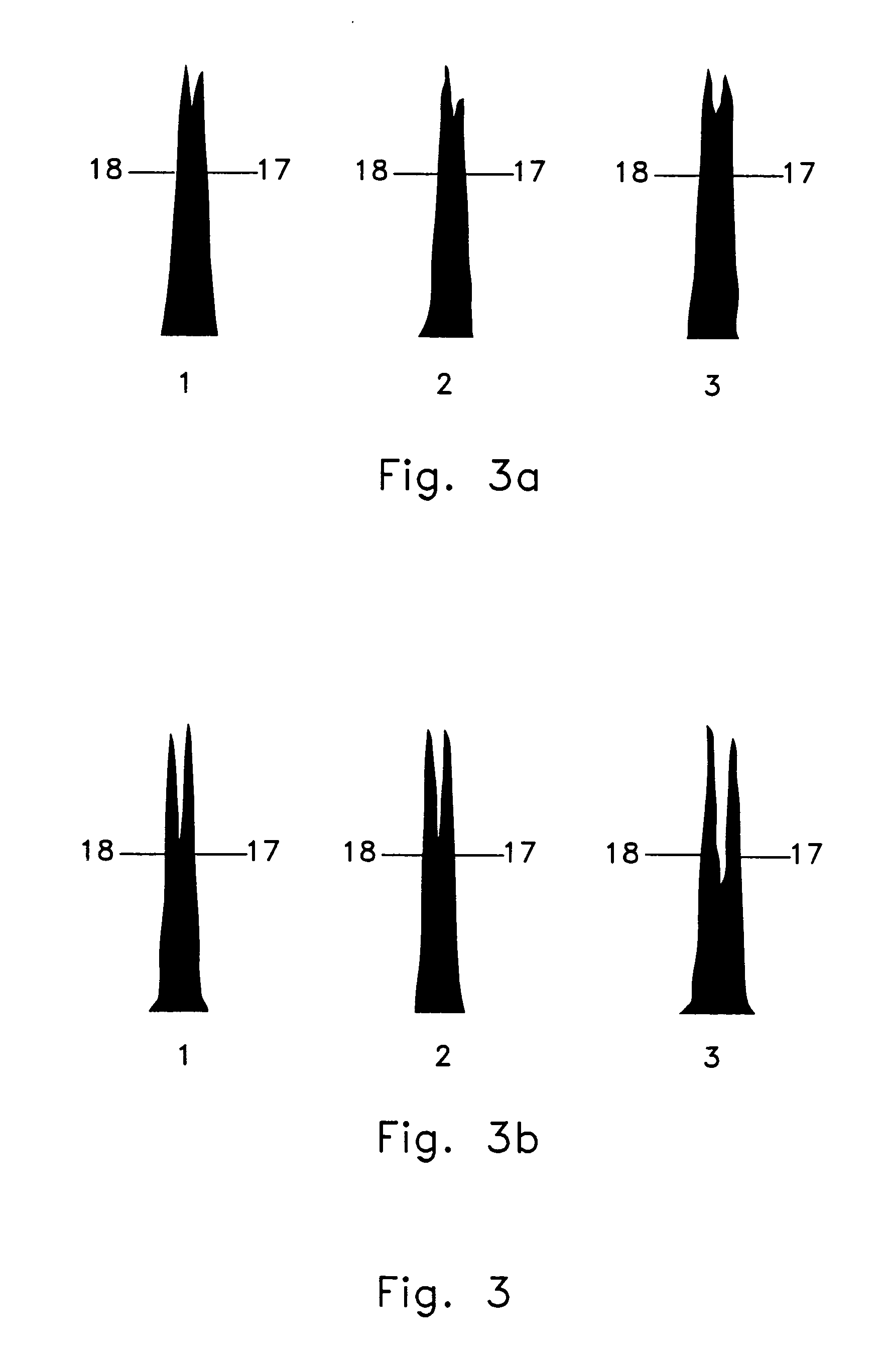

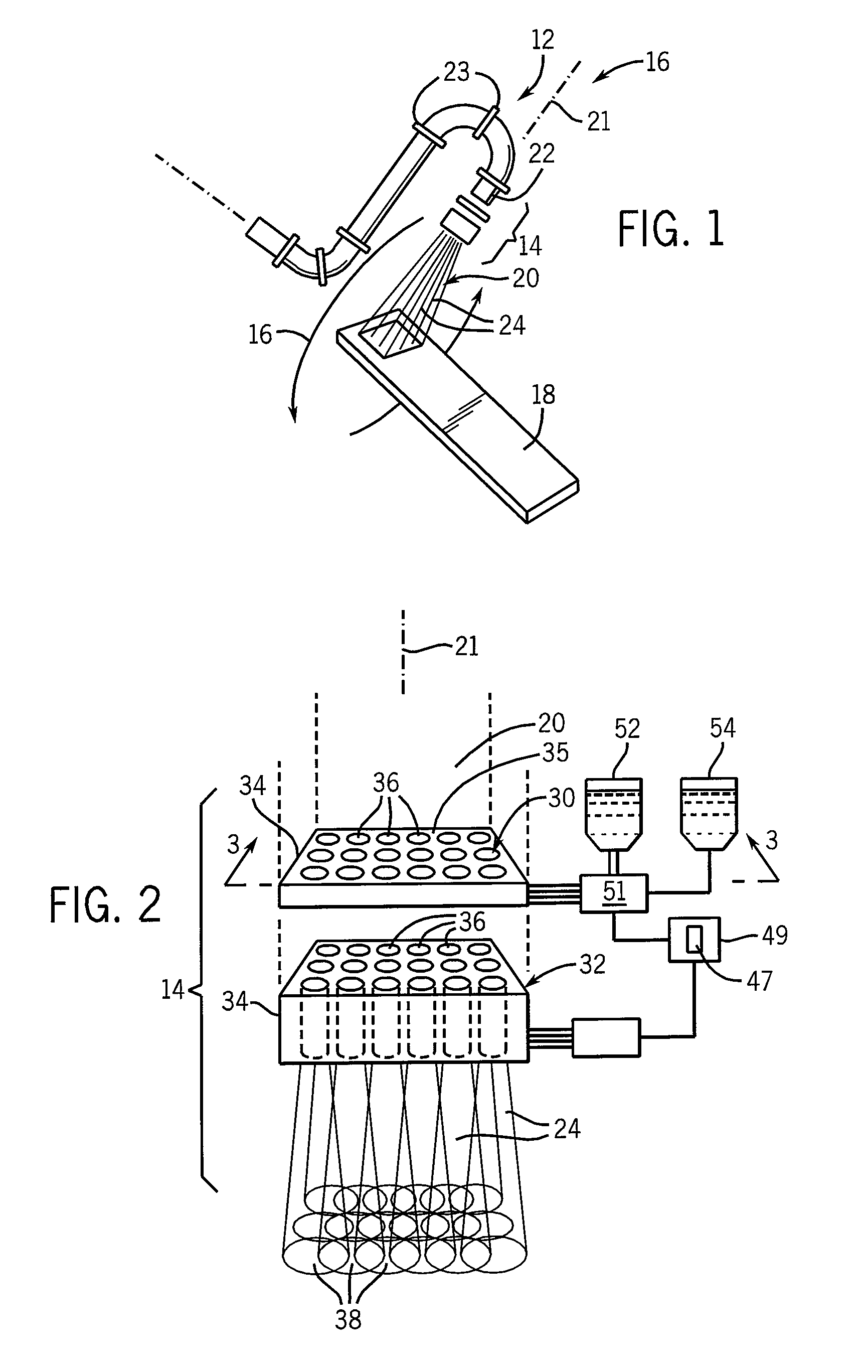

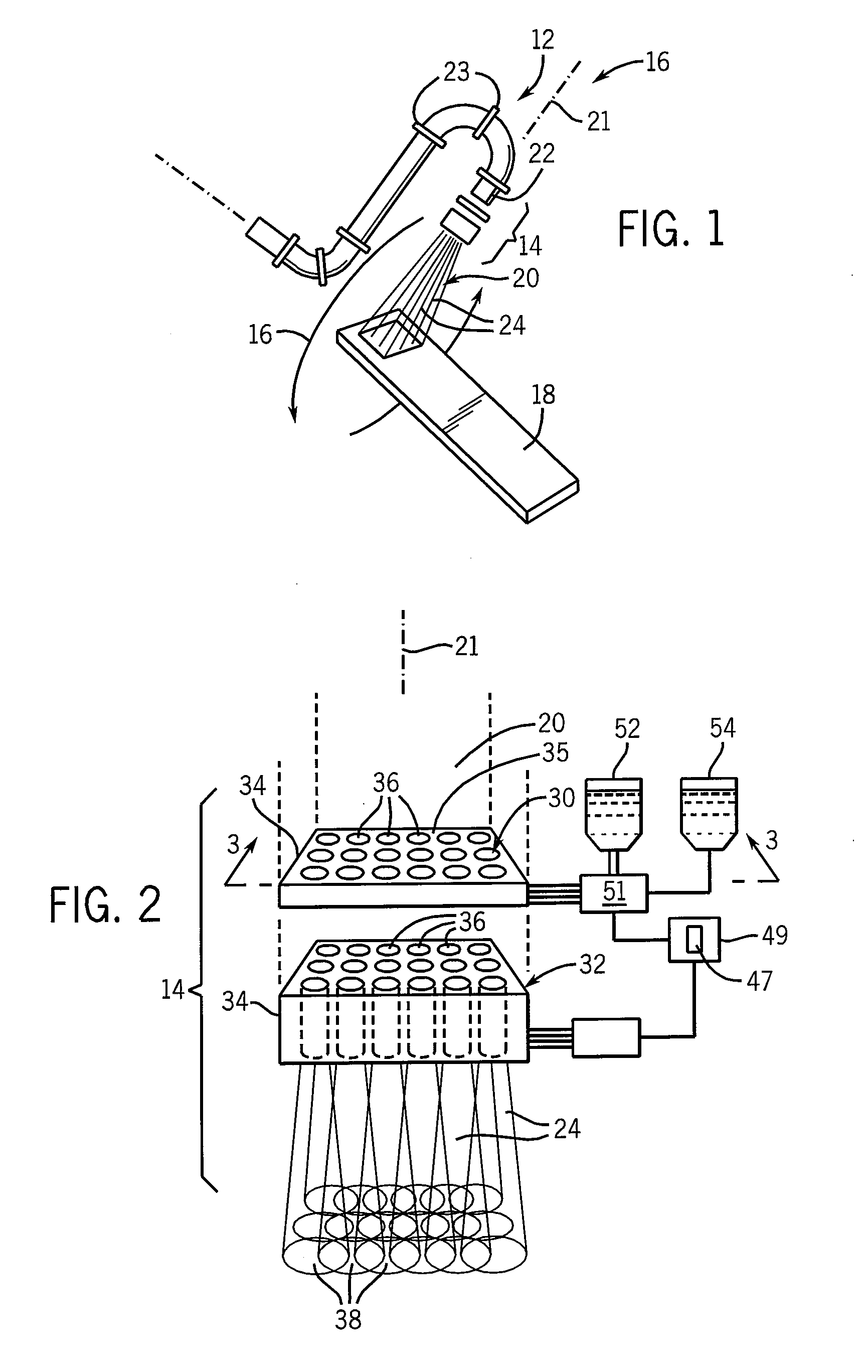

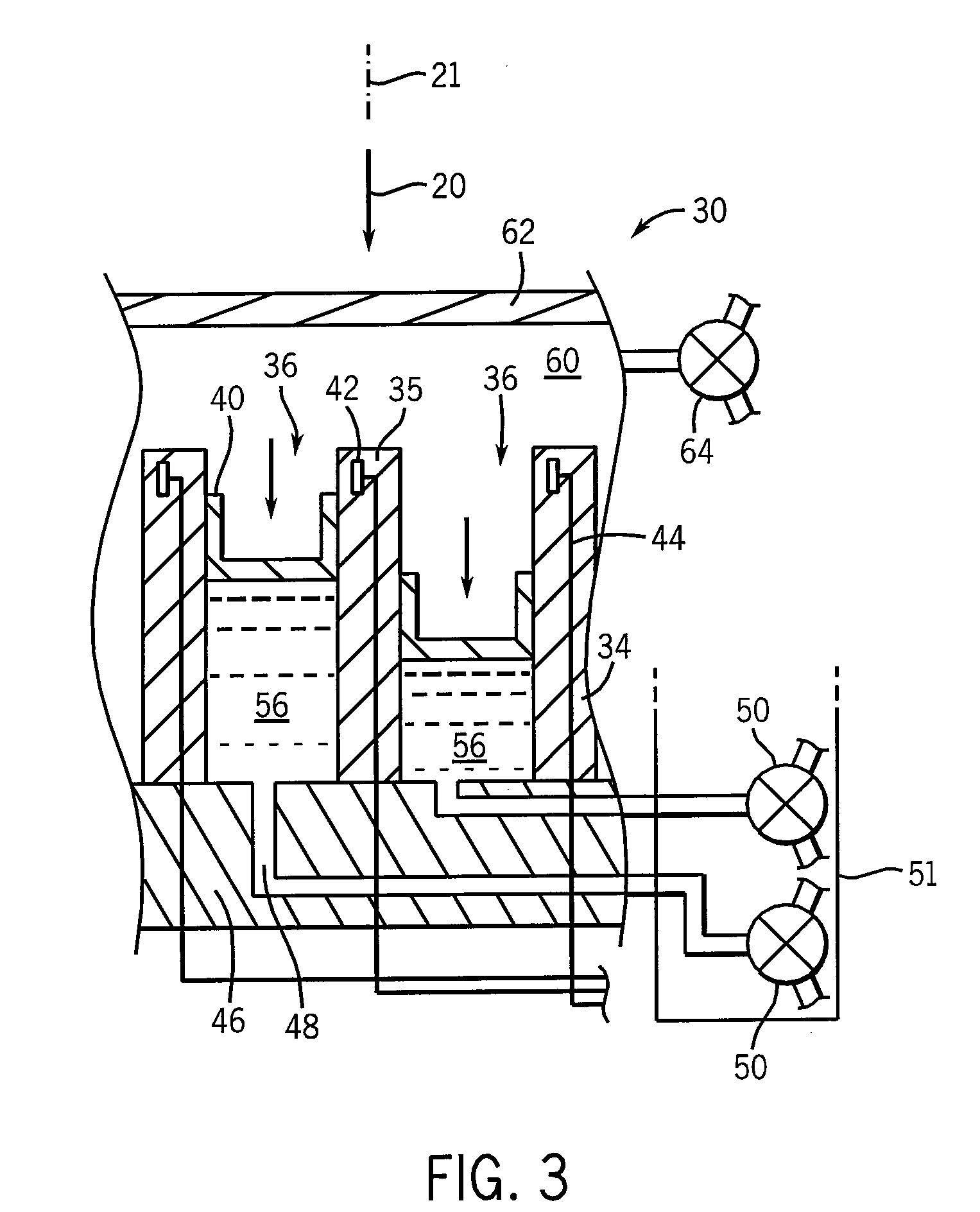

High purity x-chromosome bearing and y-chromosome bearing populations of spermatozoa

InactiveUS20040053243A1Improve apparent resolutionMinimizes coincidenceAnimal reproductionMaterial analysis by optical meansPhysiologyLight beam

Isolated non-naturally occurring populations of spermatozoa (15) having high purity and technologies to differentiate spermatozoa (28) based on characteristics such as mass, volume, orientation, or emitted light including methods of analysis and apparatus such as beam shaping optics (30) and detectors (32).

Owner:XY

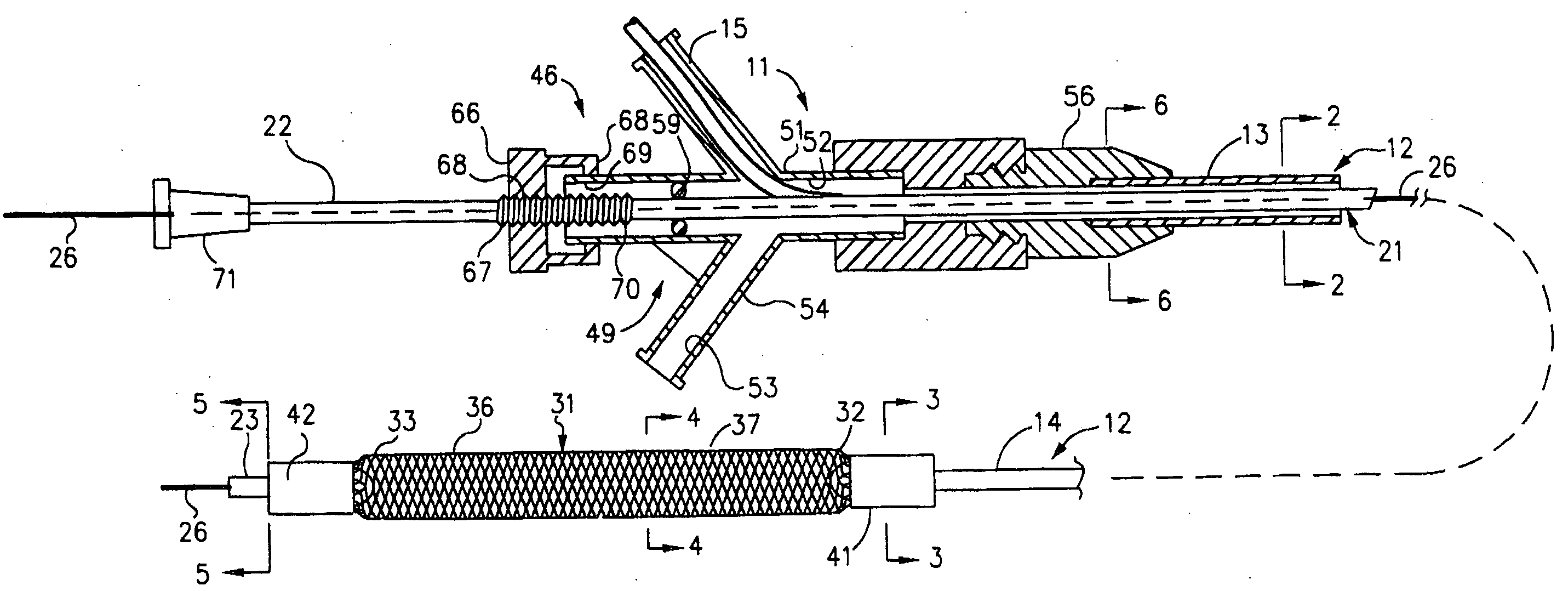

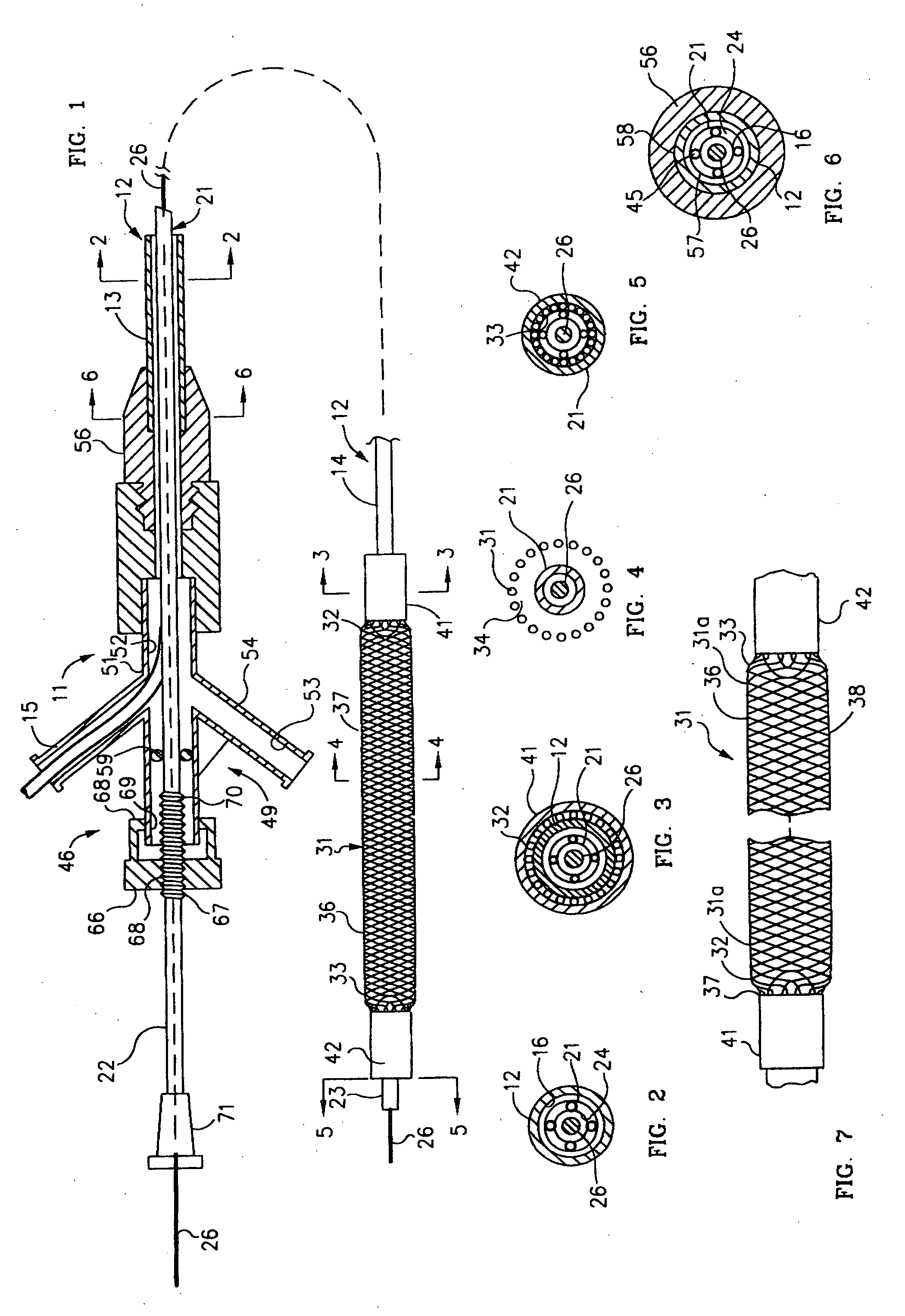

Mechanical apparatus and method for dilating and delivering a therapeutic agent to a site of treatment

InactiveUS20050043680A1Uniform exposureMinimal dangerElectrotherapyBalloon catheterPresent methodBiomedical engineering

A mechanical dilatation and medicament delivery device for enlarging a flow passage of a vessel by dilating and delivering a charged paclitaxel analogue therapeutic agent or medicament to an obstruction in the vessel. The present invention comprises a substantially cylindrically shaped expansion member and includes a means engaged to the expansion member for altering the distance between the proximal end and the distal end of the expansion member thereby transforming the expansion member between a diametrically contracted configuration to diametrically expanded configuration. A charged paclitaxel analogue therapeutic agent or medicament is coated on either the expansion member, or combined / incorporated into a substrate coated on the expansion member. The present method comprises the steps of advancing the coated expansion member to the obstruction in a vessel and applying opposed forces on said expansion member in an axial direction to move the expansion member to an expanded configuration wherein the expansion member dilates the obstruction and the expansion member either passively or actively delivers a charged paclitaxel analogue therapeutic agent or medicament to the obstruction.

Owner:BOSTON SCI SCIMED INC

Image registration and multi-resolution fusion-based panoramic image splicing method

InactiveCN108416732AReduce invalid areaUniform exposureImage enhancementImage analysisEqualizationMulti resolution

The invention discloses an image registration and multi-resolution fusion-based panoramic image splicing method. An adaptive threshold of sequence images is subjected to binary processing and image contour information is extracted by utilizing a pixel neighborhood relationship; a similar region of an image contour structure is quickly estimated through a similarity measurement method for Hu momentinvariant features; and SIFT feature point extraction is performed in a similar region part of two original images. Moreover, feature point initial matching is performed by using a bidirectional K-nearest classification algorithm; mismatched points are screened by an RANSAC algorithm; and an affine transformation matrix among the images is estimated. In addition, in an image fusion aspect, brightness equalization and local color mapping processing is adopted. Then, through an improved Laplacian pyramid multi-resolution fusion algorithm, spliced images are fused to realize seamless splicing. According to the method, the image splicing time is shortened, the image splicing efficiency is improved, the similar region can be quickly located, the mismatch in splicing is effectively improved, and the image registration precision is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

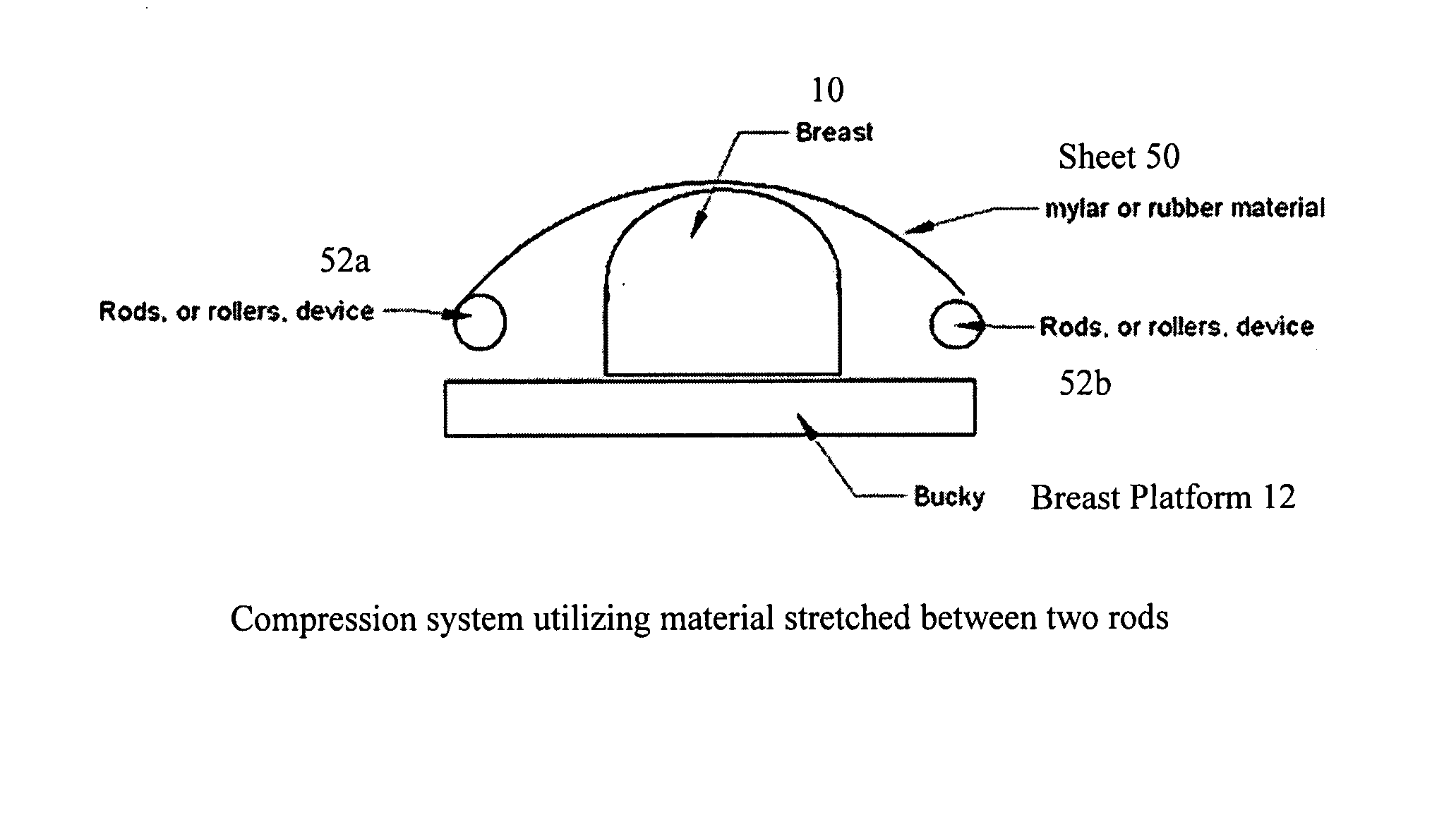

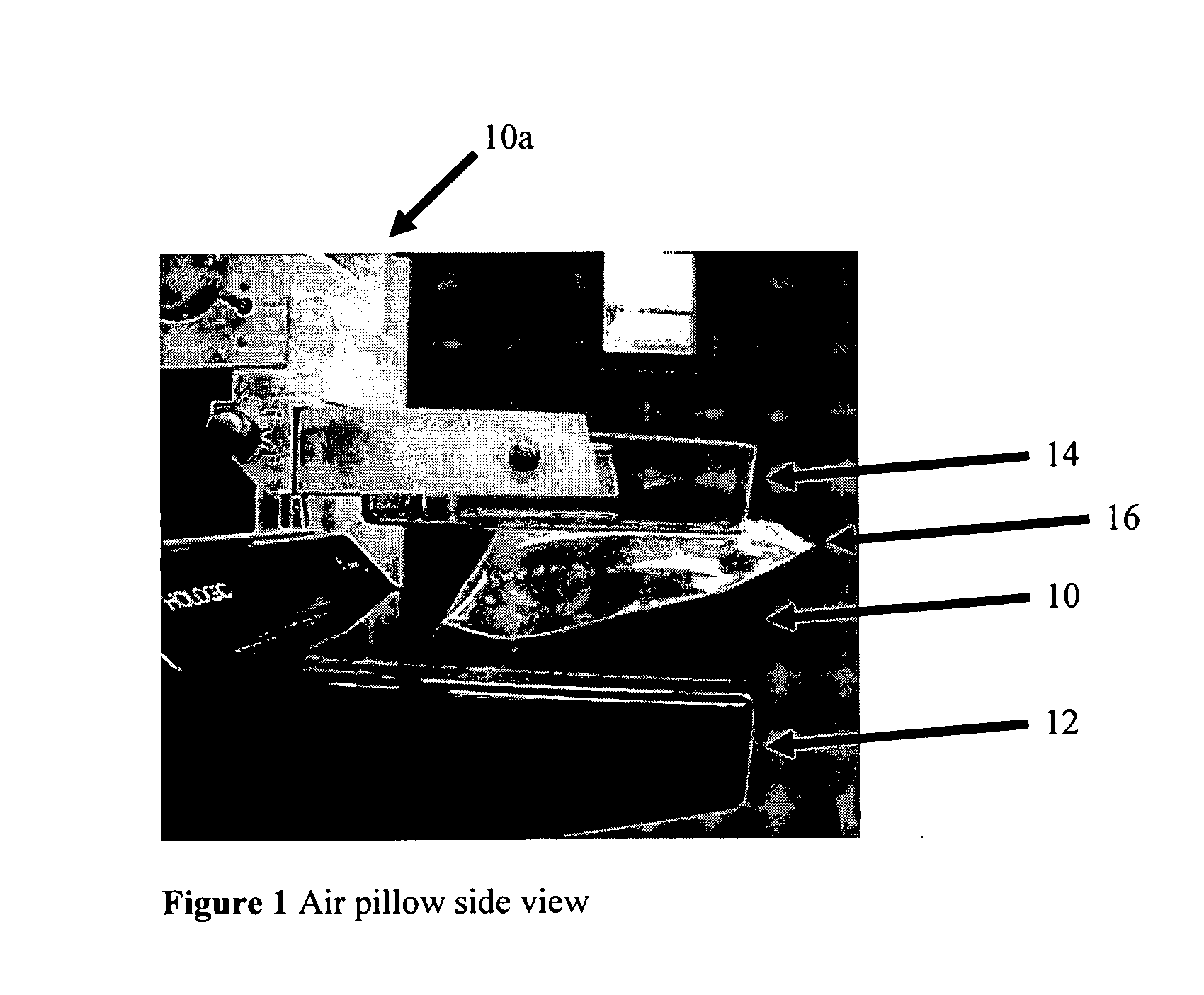

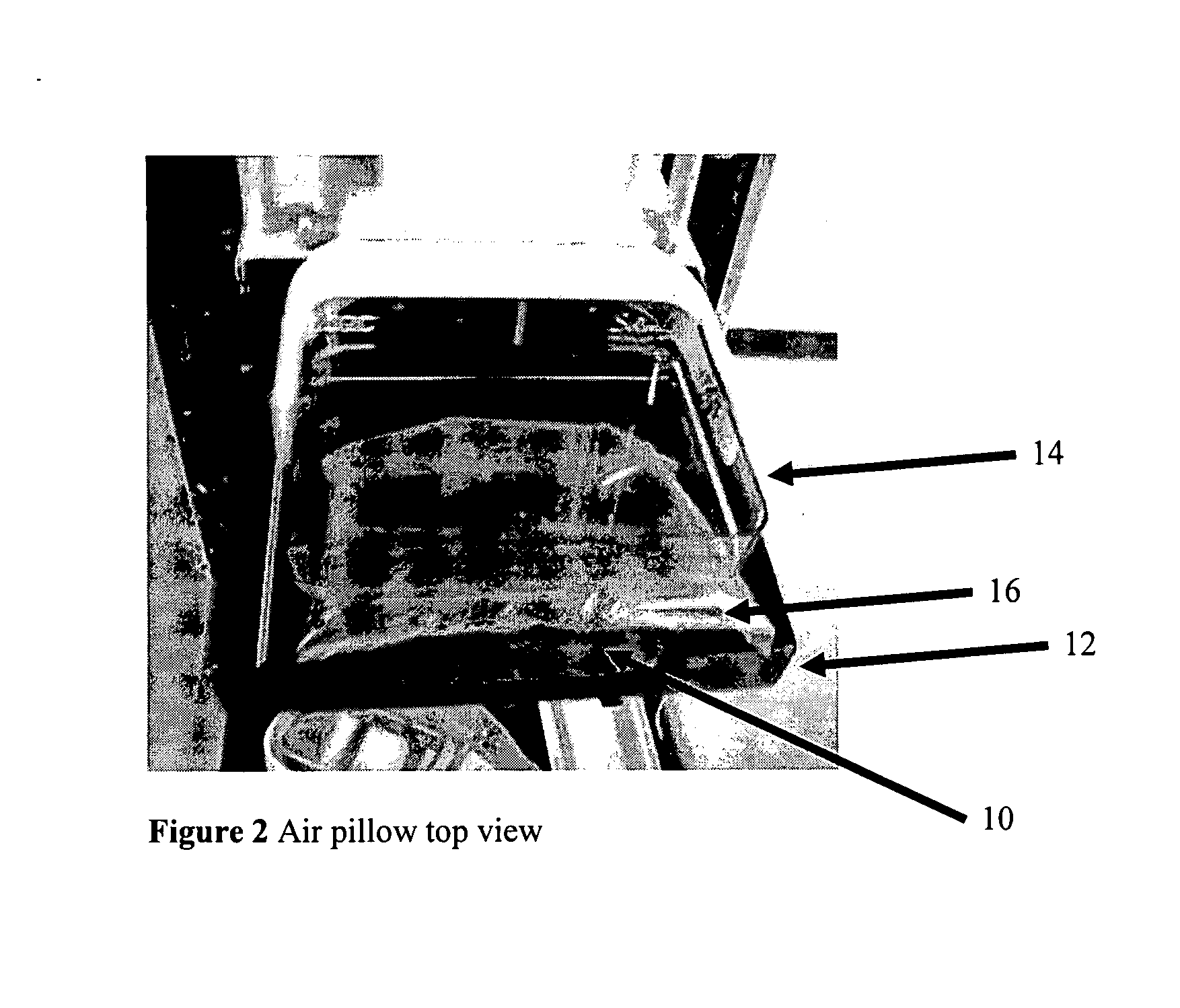

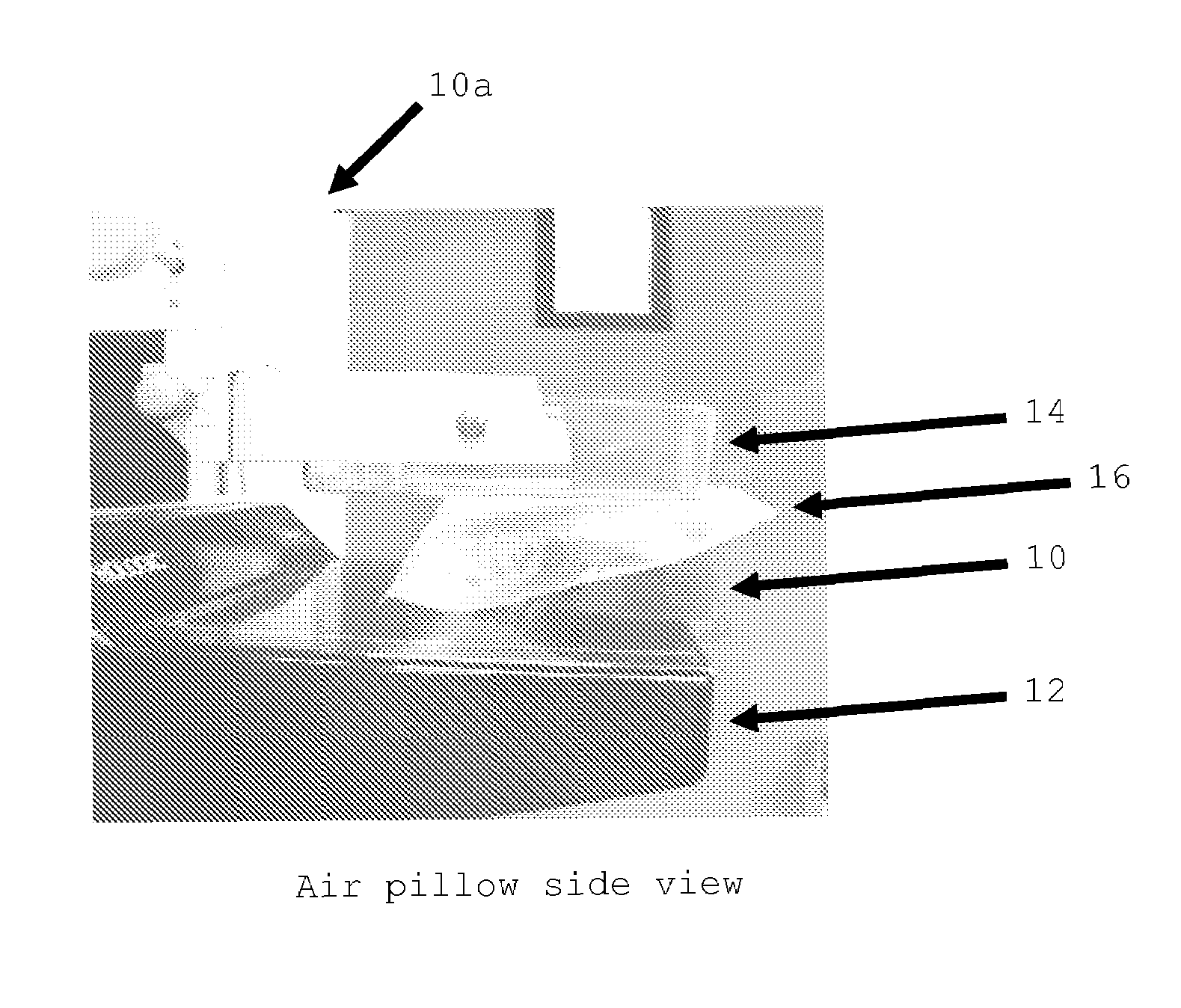

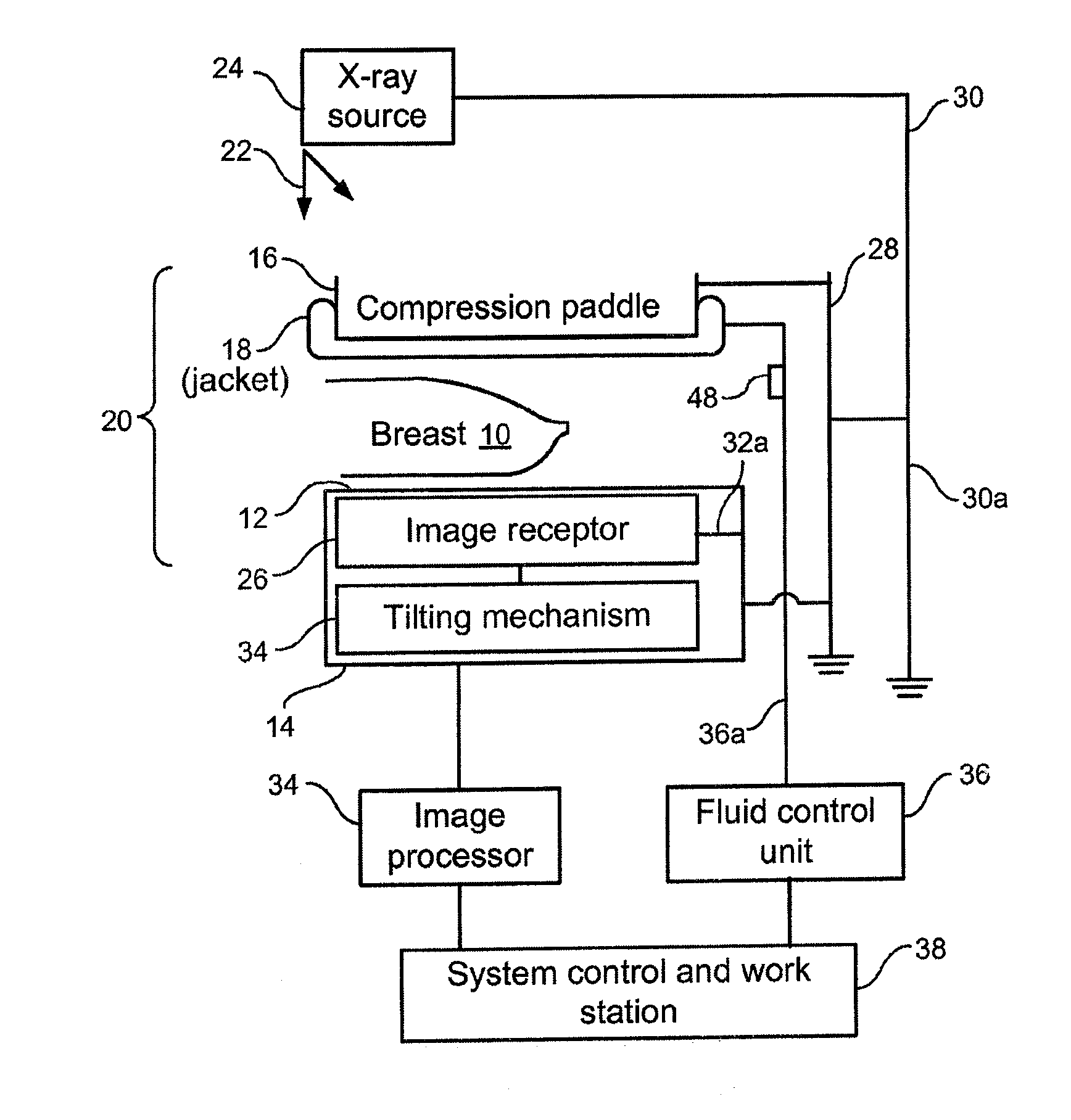

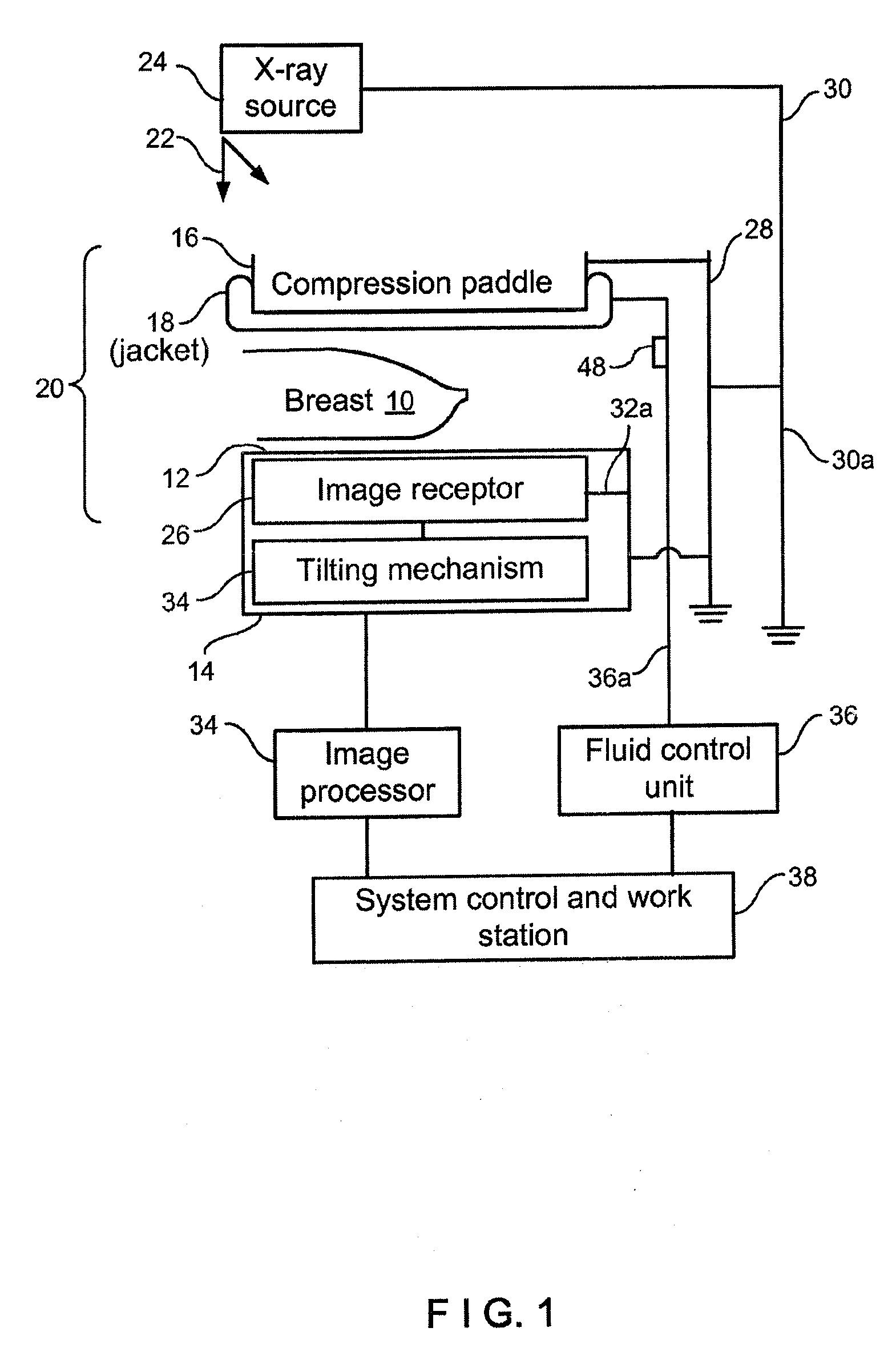

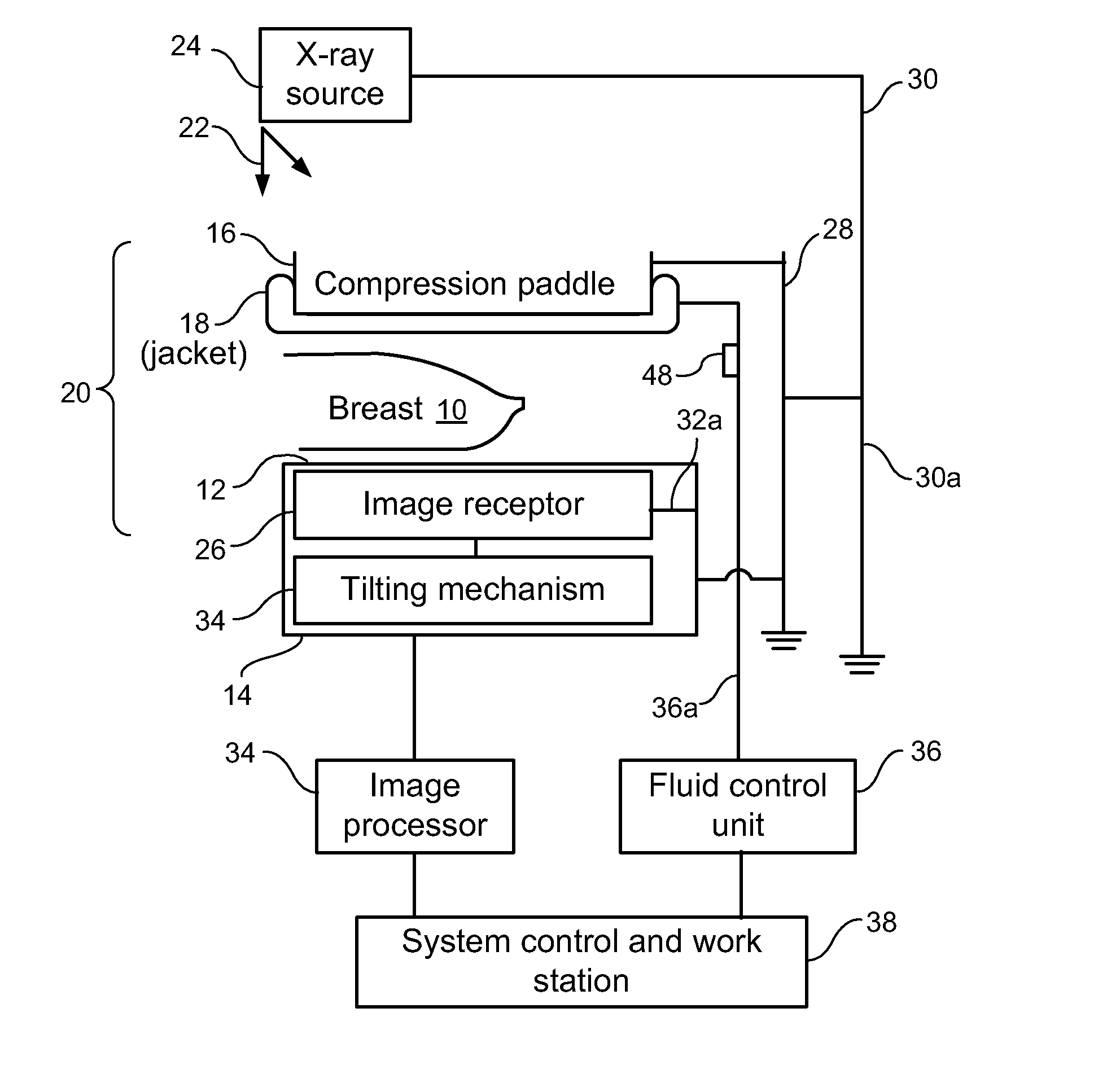

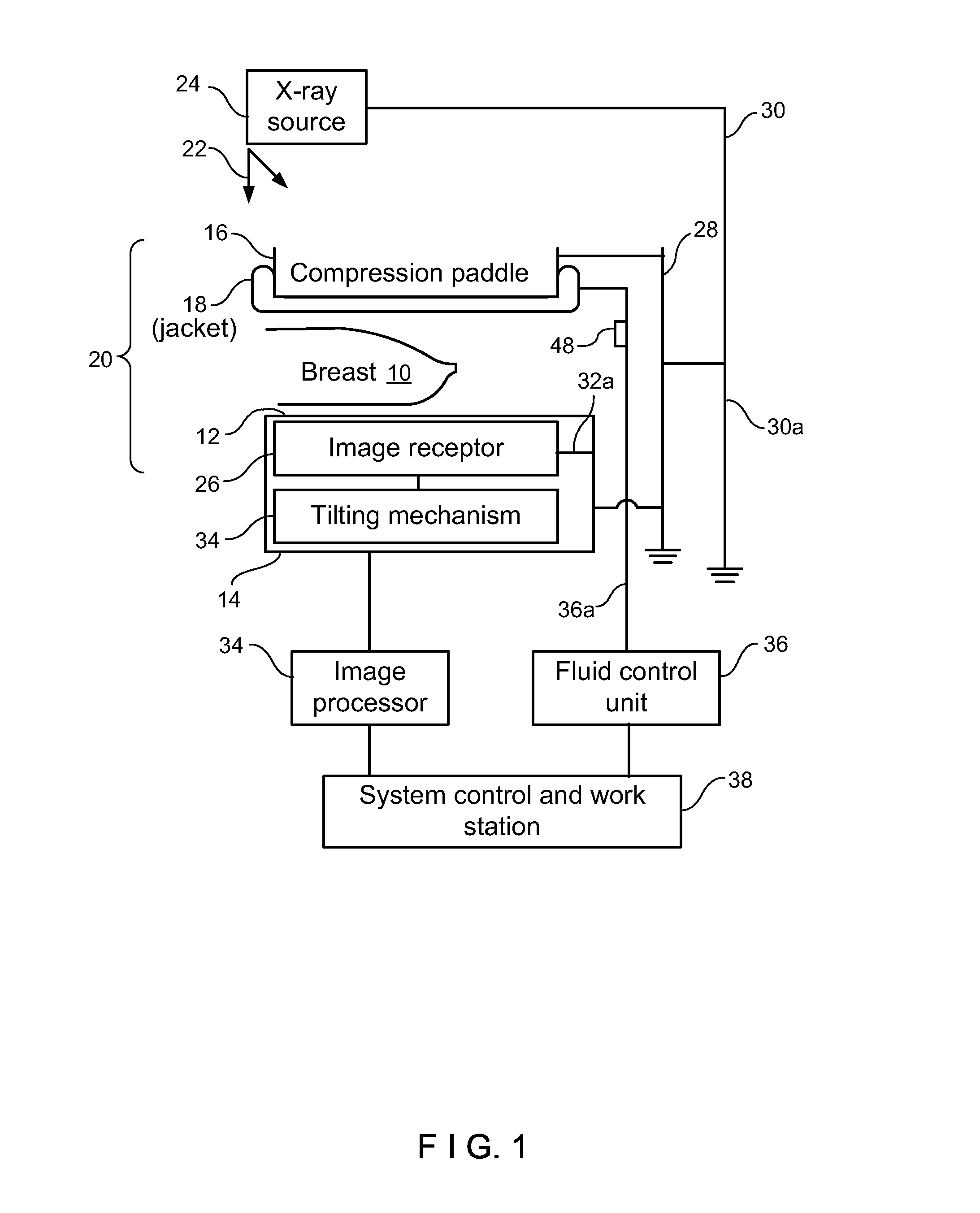

Breast compression for digital mammography, tomosynthesis and other modalities

ActiveUS20070280412A1Spread out the breast tissuesReduce radiation exposureTomosynthesisPatient positioning for diagnosticsTomosynthesisDigital mammography

A breast x-ray imaging method and system that is particularly suited for tomosynthesis imaging but also is useful for conventional mammography. A fluid containing pillow or bag is placed between the breast and a paddle that compresses the breast against a breast platform covering an imaging device, to enhance patient comfort and provide other benefits. Alternatives include a flexible sheet compressing the breast, and a compressible foam, preferably contoured to accommodate a patient's breast.

Owner:HOLOGIC INC

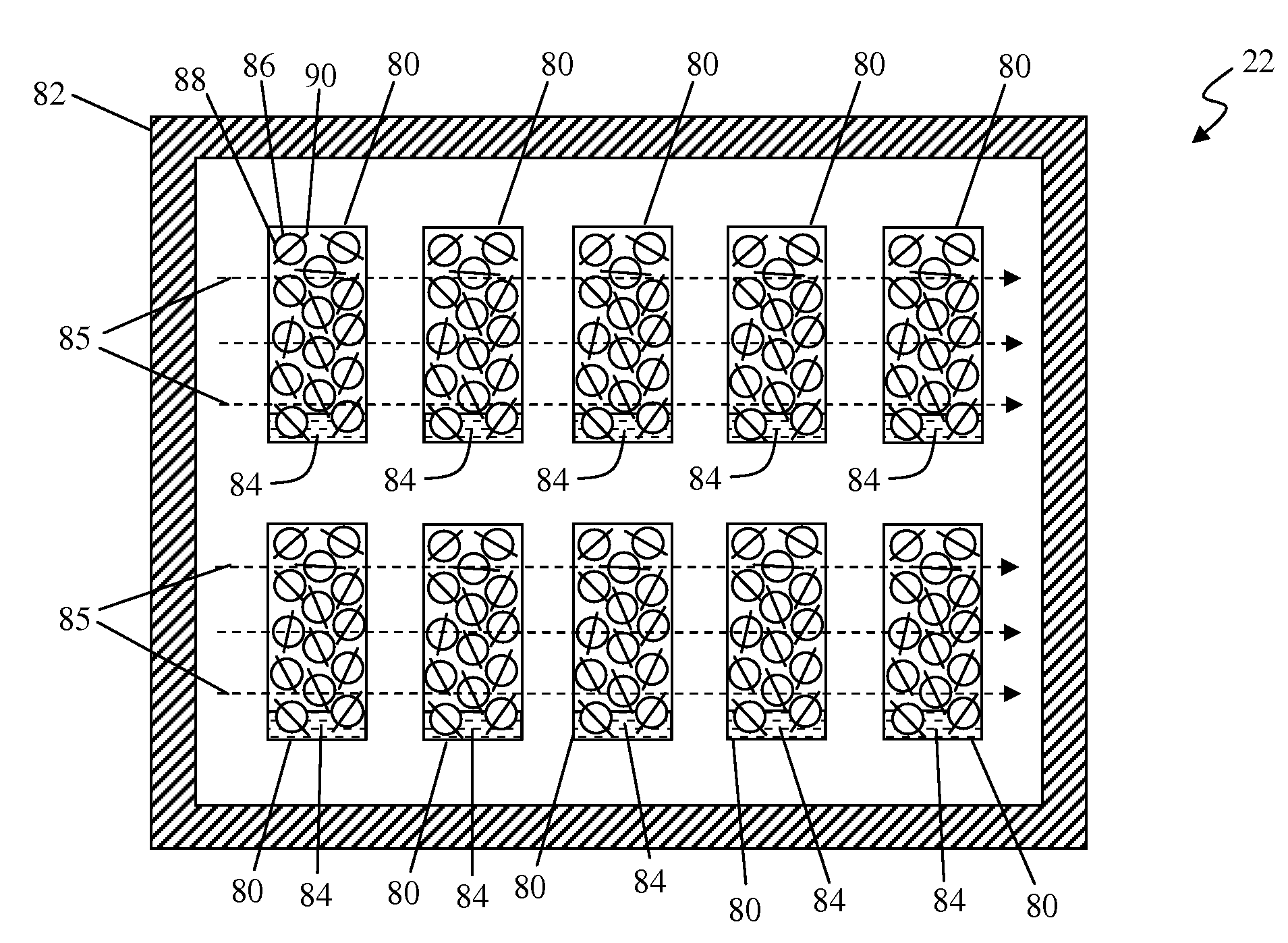

Areal modulator for intensity modulated radiation therapy

ActiveUS8129701B2Small sizeSpeed up treatmentElectrode and associated part arrangementsMaterial analysis by optical meansLight beamIntensity-modulated radiation therapy

A modulator for radiation therapy provides modulation of an area beam to decrease treatment time. Separate channels passing modulated “beamlets” are possible by spacing the channels such that spreading of the beams and multiple angles of treatment eliminate cold spots. The space between the channels allows well-defined channel walls and space for modulator mechanisms.

Owner:AL SADAH JIHAD H +3

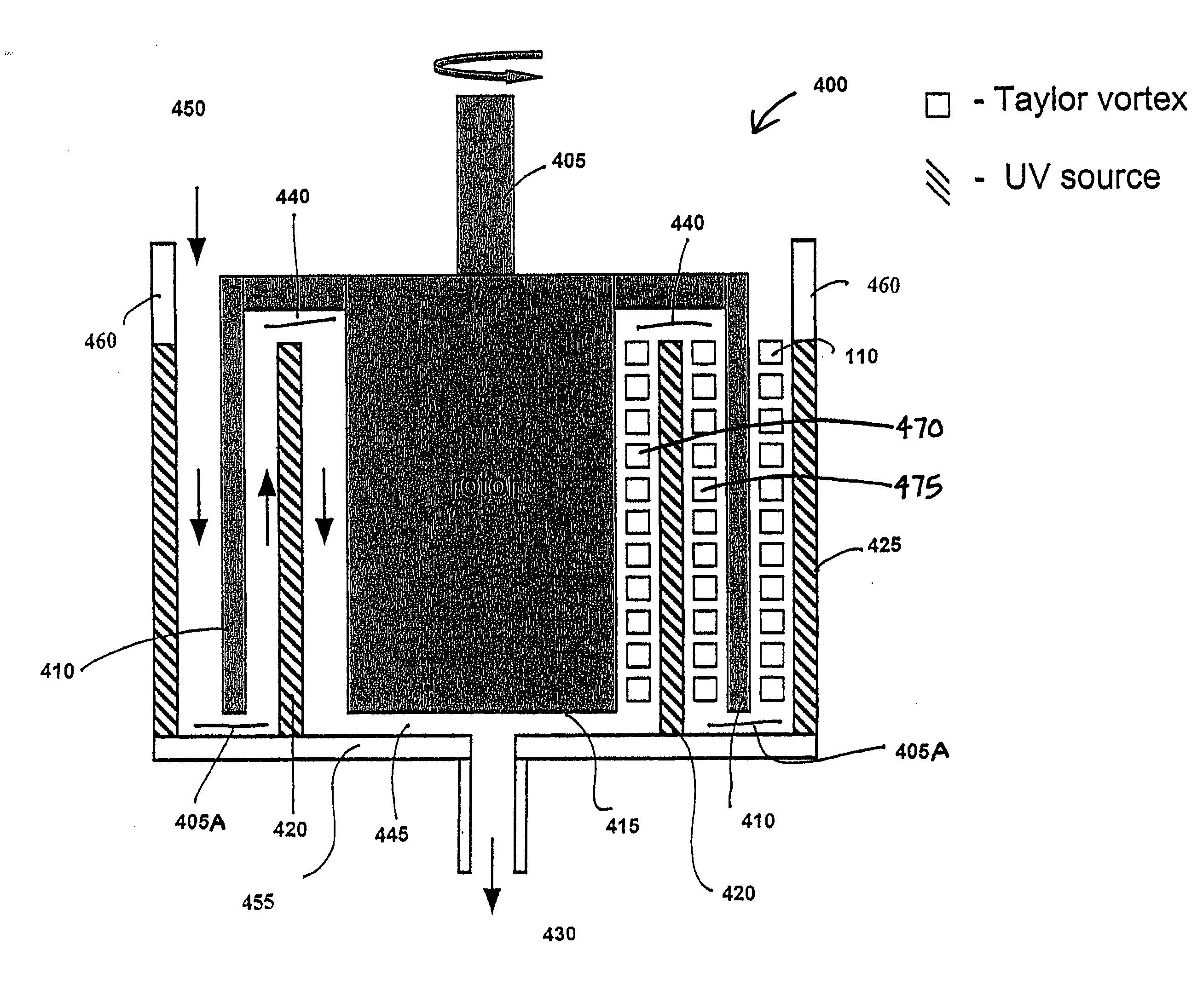

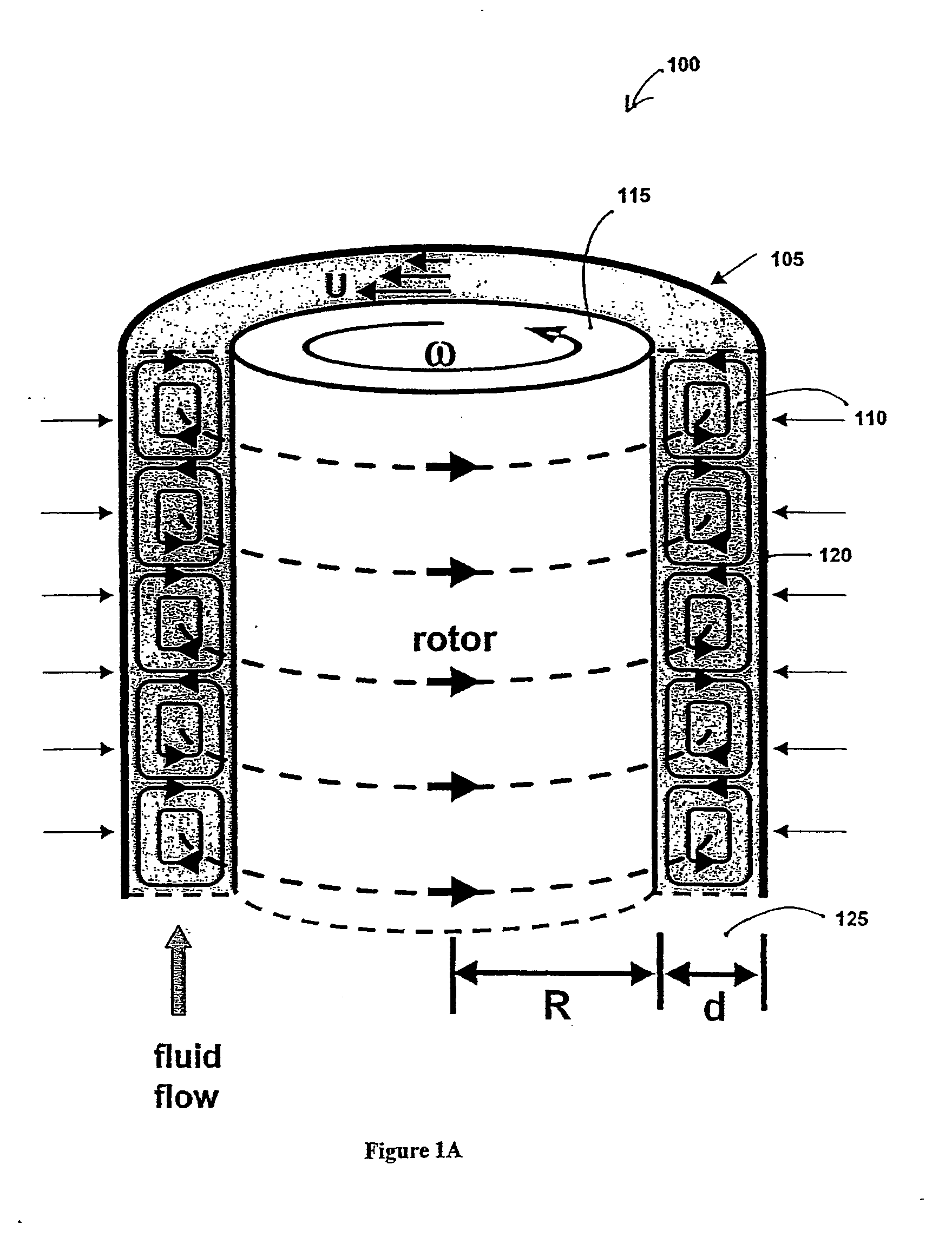

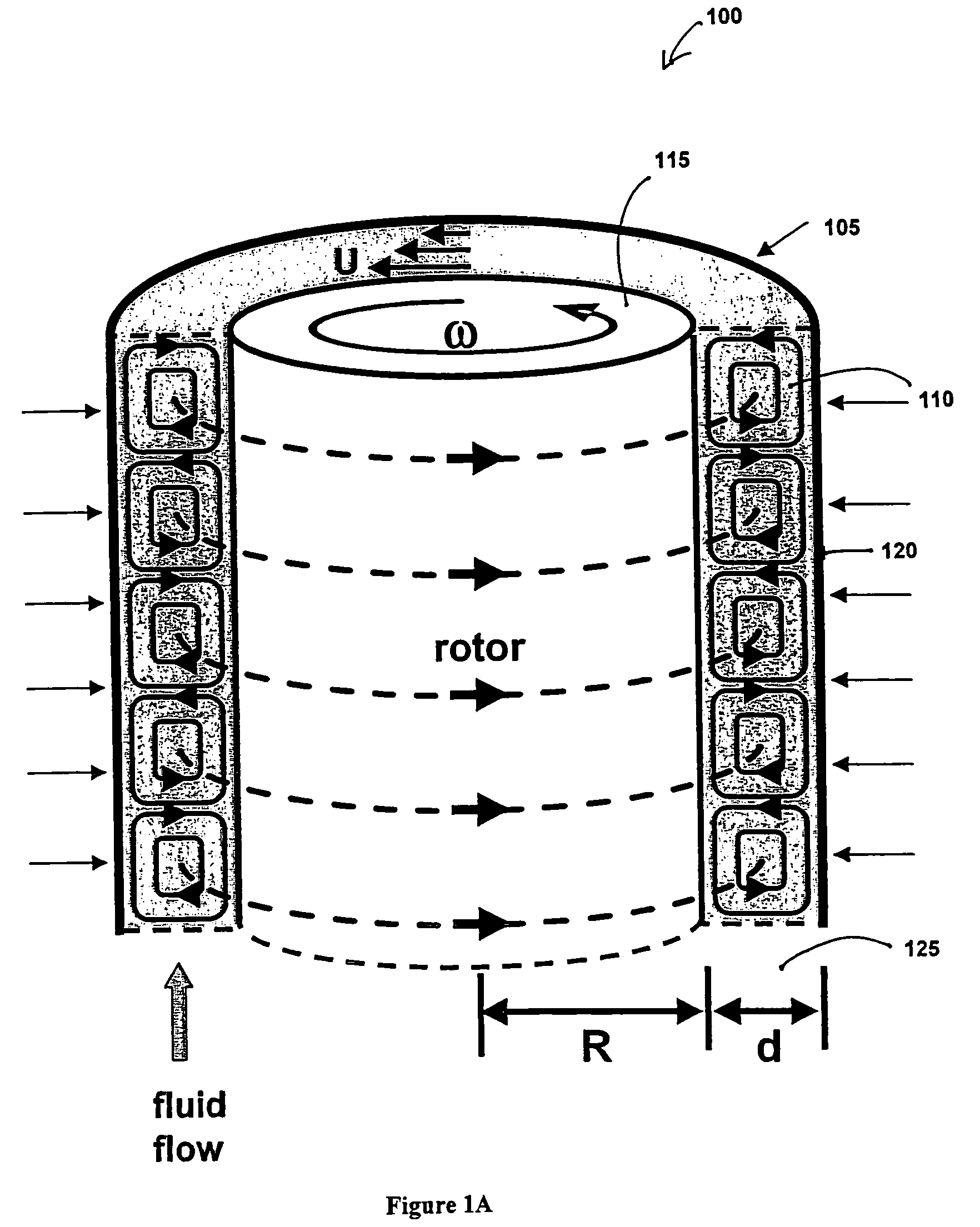

Systems and Methods for Disinfection

ActiveUS20090081340A1Uniform radiation exposureUniform exposureMilk preparationMilk preservationRadiation exposureStator

Methods and systems for establishing Taylor-Couette flow in a fluid are provided. Aspects of the disclosed methods and systems incorporate laminar Taylor-Couette flow in combination with a source of radiation to provide more uniform radiation exposure to the fluid and its components. Common problems of non-uniform radiation levels and concentration boundary layer effects in UV reactors are largely eliminated using the methods and devices provided herein. In an exemplary embodiment, the reactor of the present disclosure has a hollow outer cylinder or stator and a rotor positioned therein and smooth walls for both the outer wall of its rotor and the inner wall of the outer cylinder or stator in which the rotor is positioned, the space between which forming the annular fluid gap.

Owner:GEORGIA TECH RES CORP

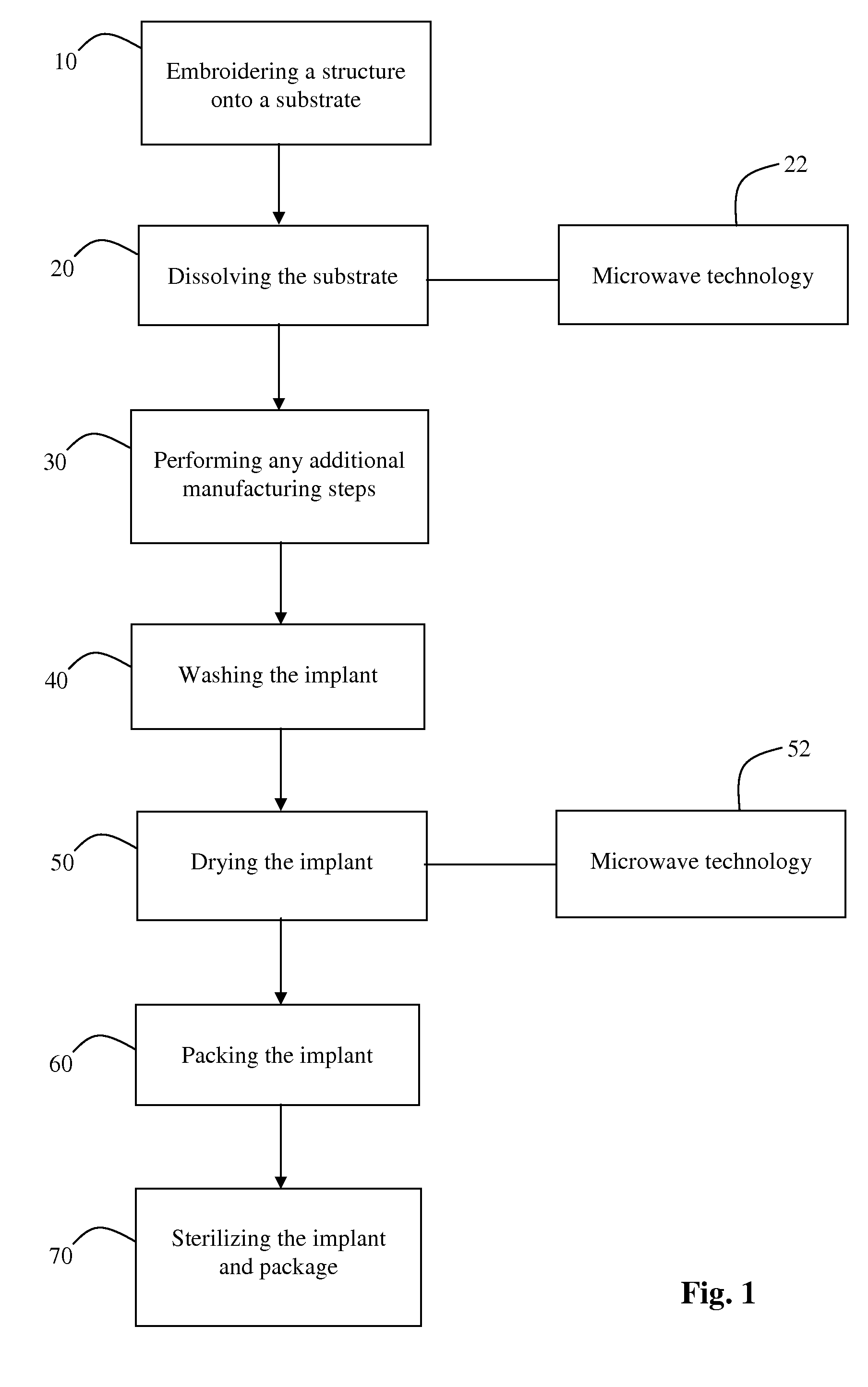

Method of manufacturing embroidered surgical implants

InactiveUS7713463B1Shorten the timeQuality improvementDielectric heatingProsthesisSurgical implantMicrowave technology

A method for applying microwave techniques to embroidered surgical implants including using microwave technology in the process of acetate removal and using microwave technology in the process of drying implants.

Owner:NUVASIVE

Breast compression for digital mammography, tomosynthesis and other modalities

ActiveUS7489761B2Spread out the breast tissuesReduce radiation exposureTomosynthesisPatient positioning for diagnosticsTomosynthesisDigital mammography

A breast x-ray imaging method and system that is particularly suited for tomosynthesis imaging but also is useful for conventional mammography. A fluid containing pillow or bag is placed between the breast and a paddle that compresses the breast against a breast platform covering an imaging device, to enhance patient comfort and provide other benefits. Alternatives include a flexible sheet compressing the breast, and a compressible foam, preferably contoured to accommodate a patient's breast.

Owner:HOLOGIC INC

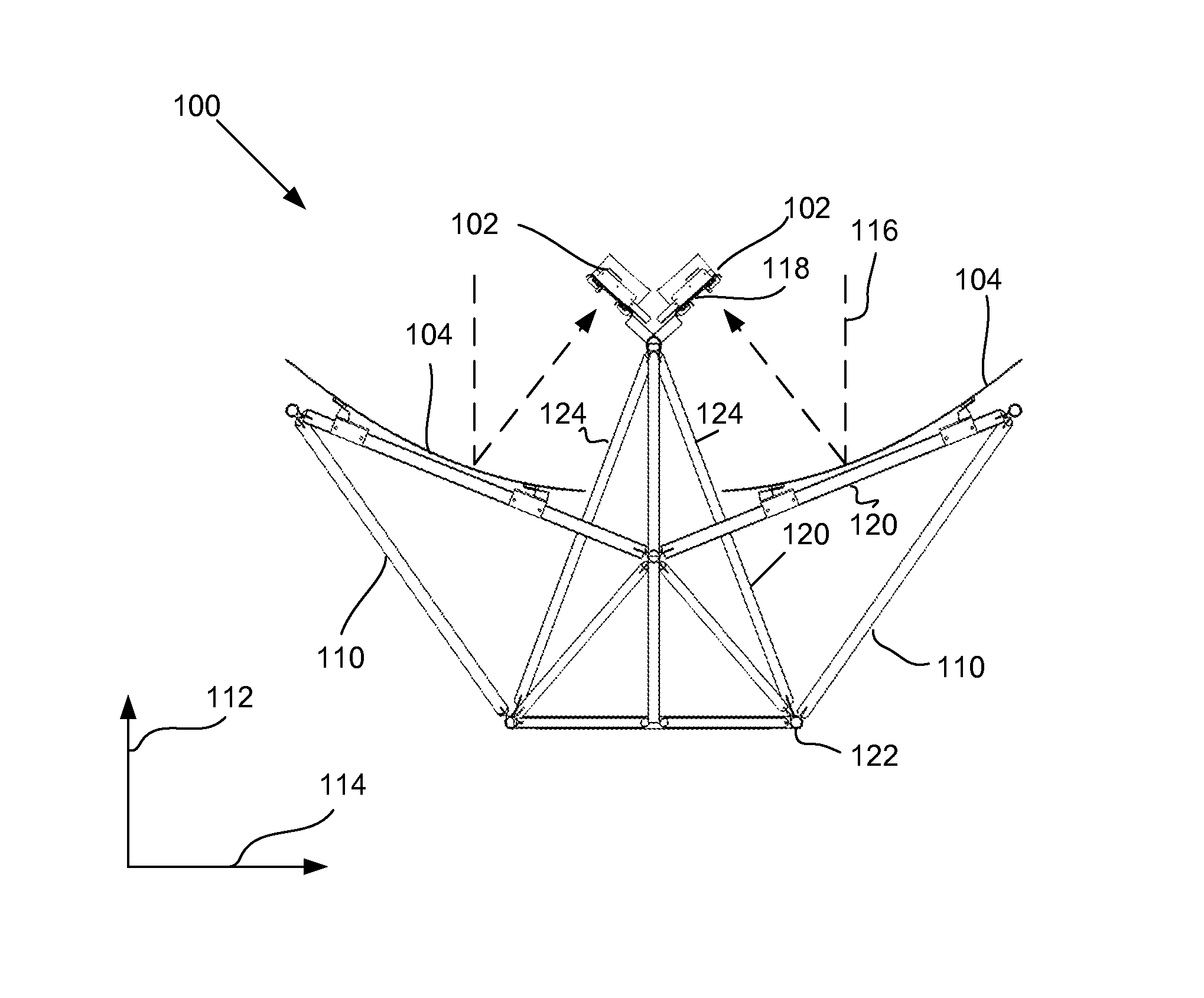

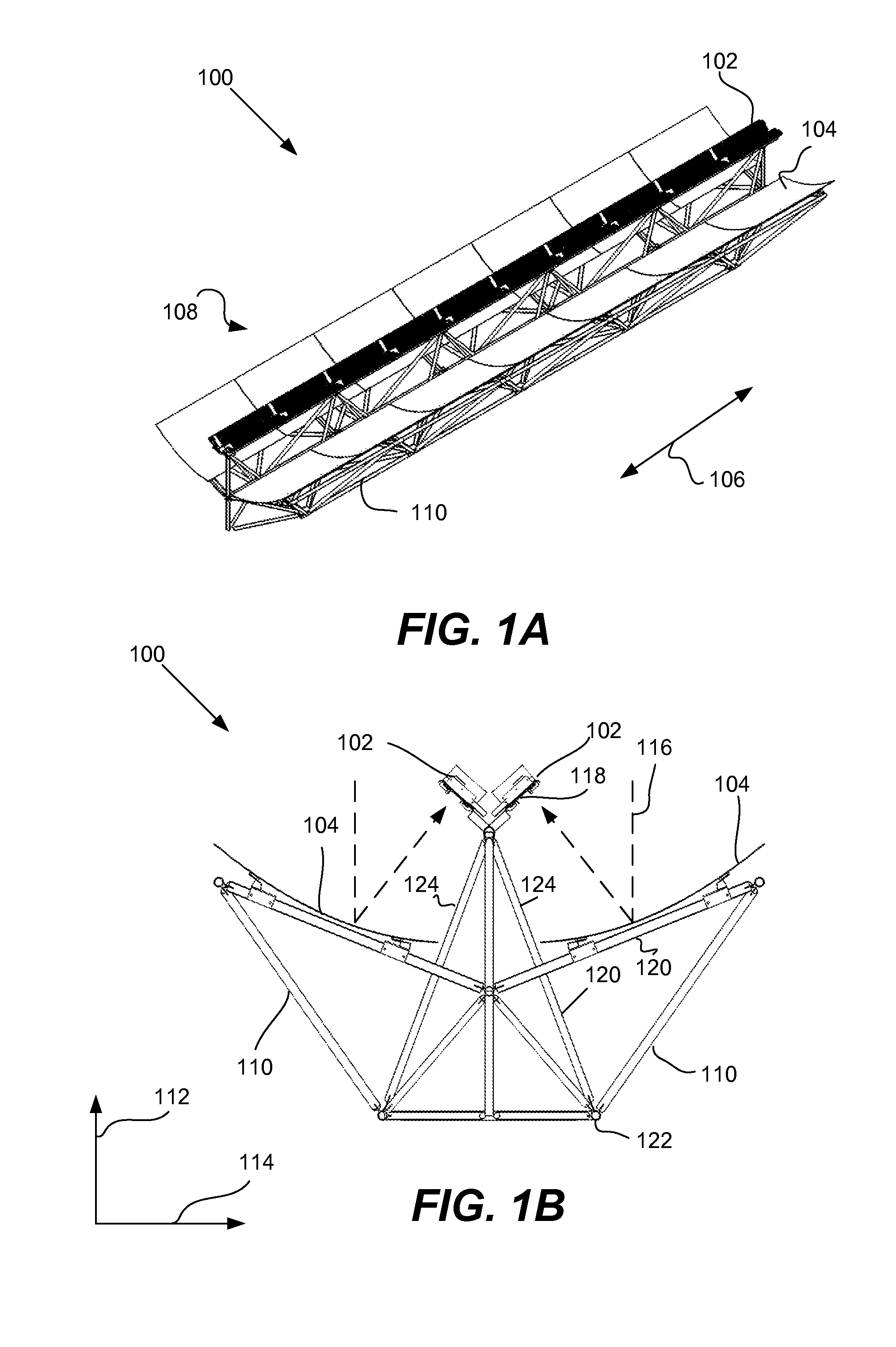

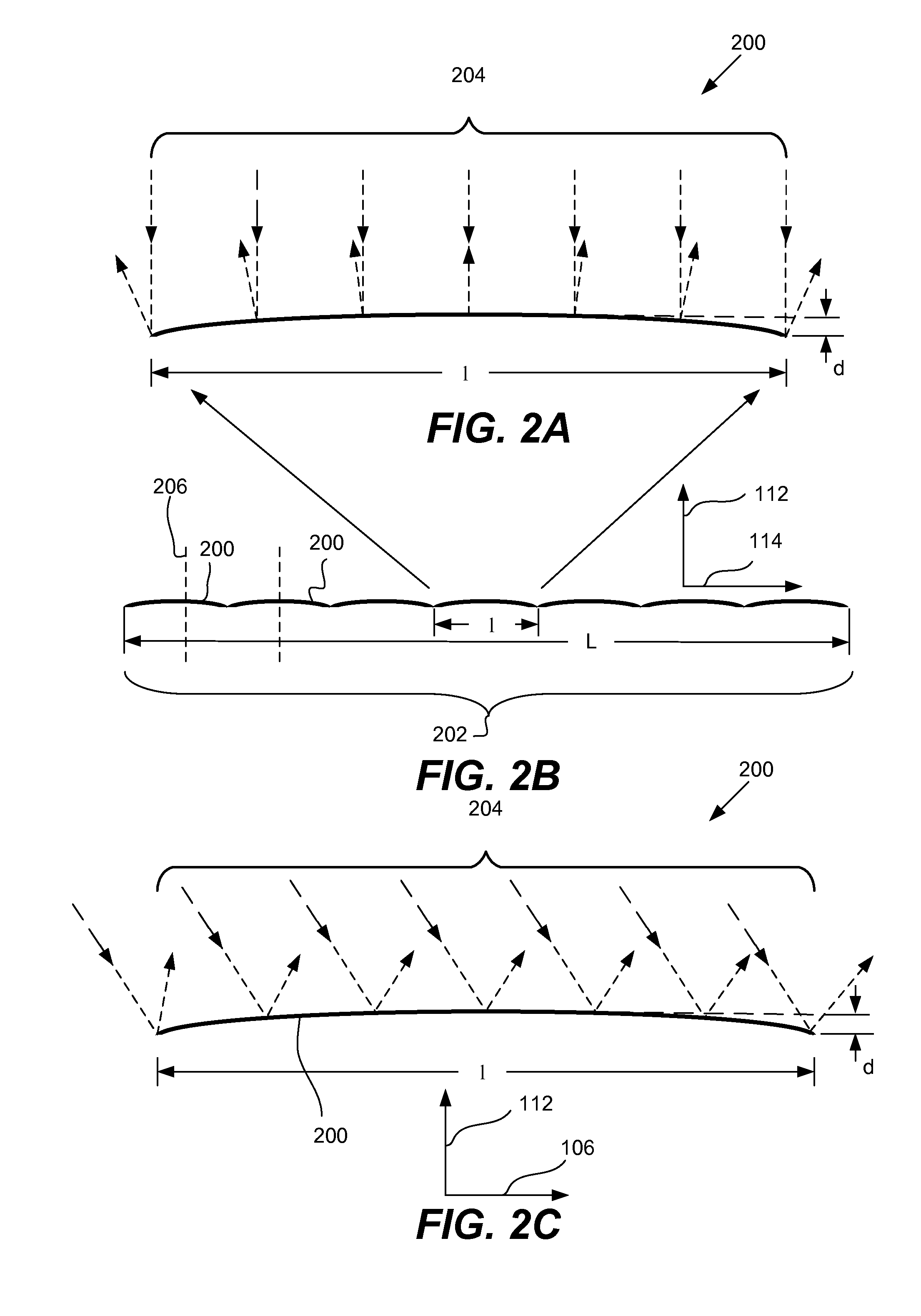

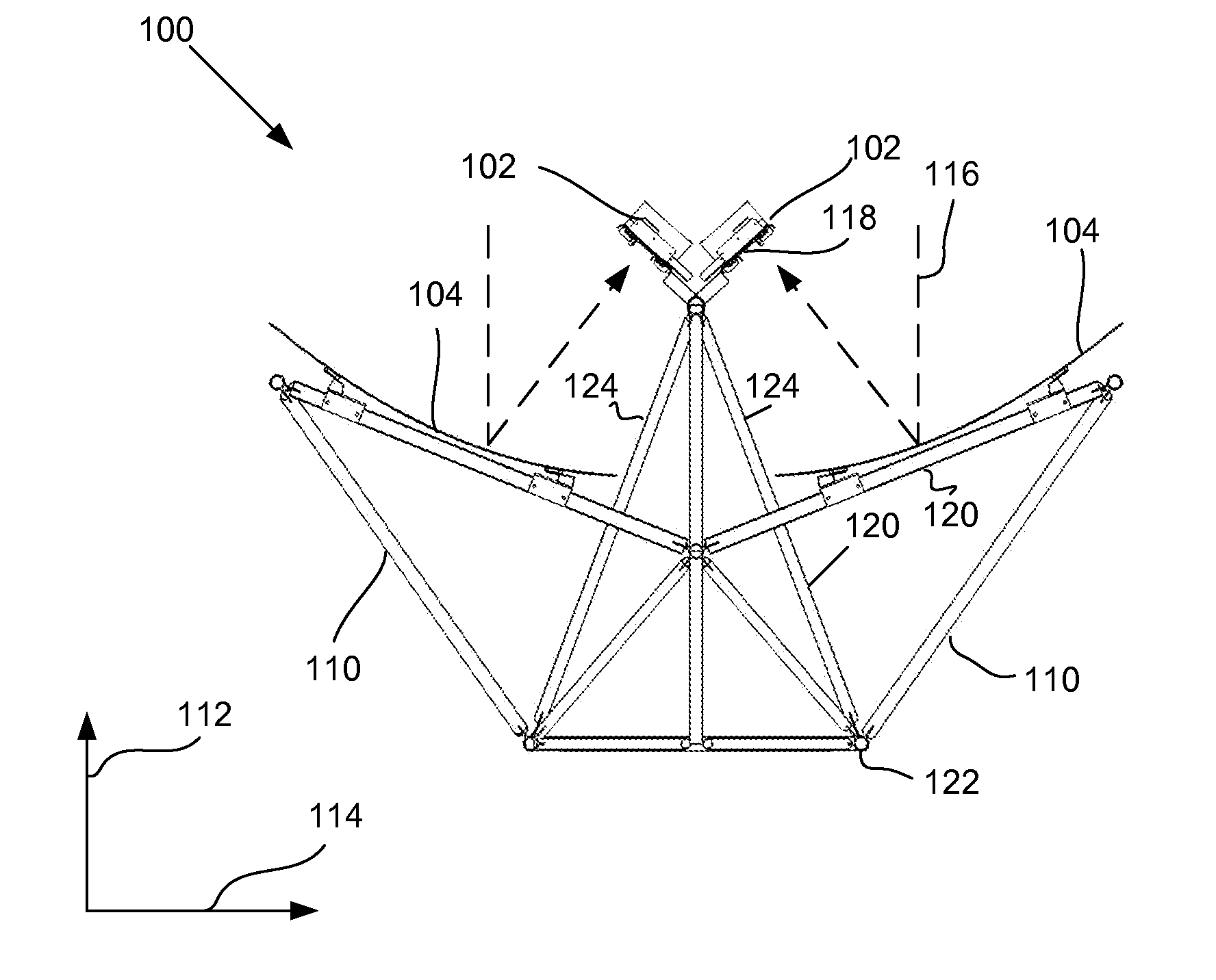

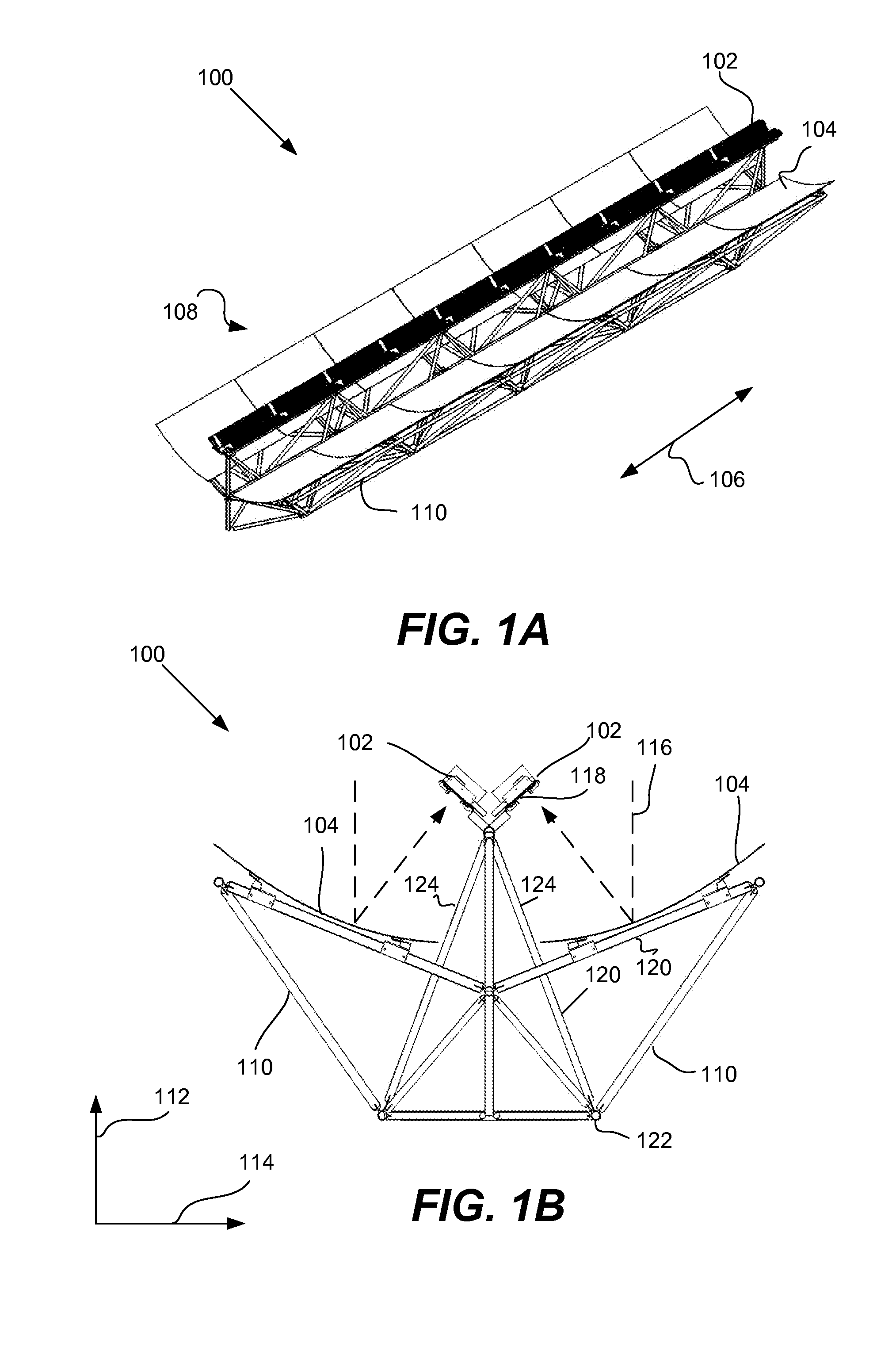

Solar collector with reflector having compound curvature

ActiveUS8039777B2Low efficiencyUniform exposureSolar heating energyPhotometry using reference valueCollection systemCollector device

The present invention relates to a solar energy collector suitable for use in a solar energy collection system. The solar energy collection system includes the collector, a stand that supports the collector and a tracking system that causes the collector to track movements of the sun along at least one axis. The collector includes one or more reflector panels, one or more solar receivers, and a support structure that physically supports the reflector panels and solar receivers. Some designs involve a reflector panel that has a compound curvature. That is, the reflector panel has a convex shape along one direction and a concave shape in another direction. In another aspect of the invention, the collector includes a space frame support structure.

Owner:SKYLINE SOLAR INC +1

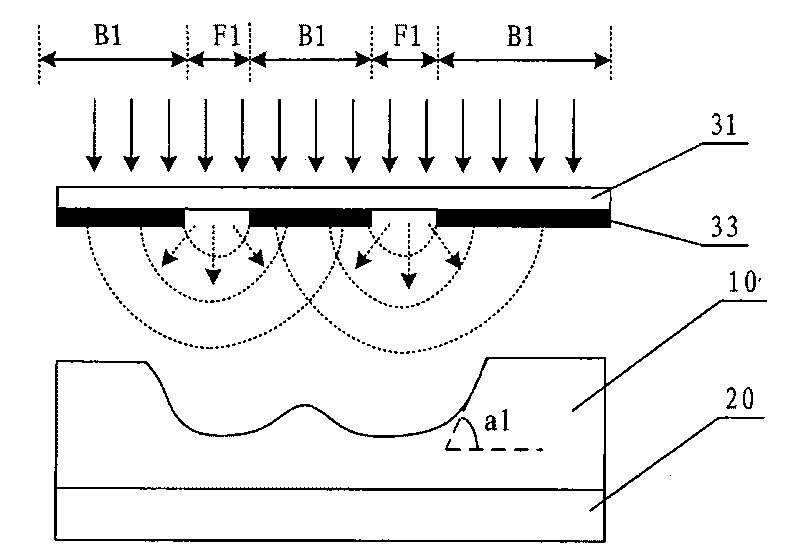

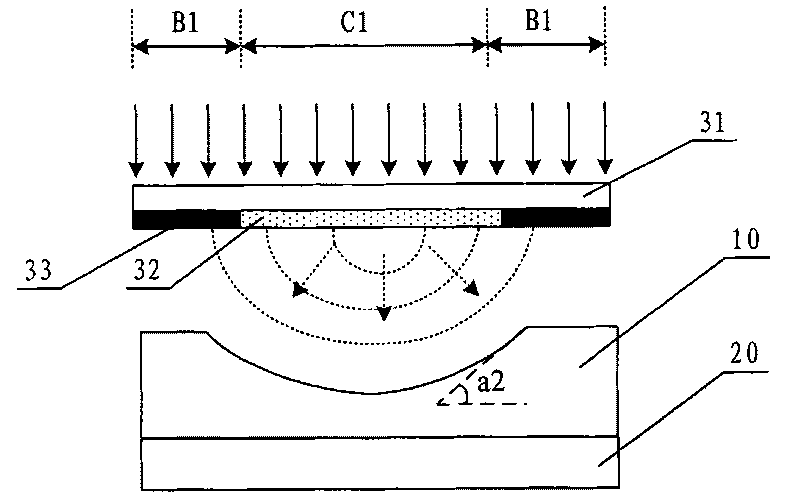

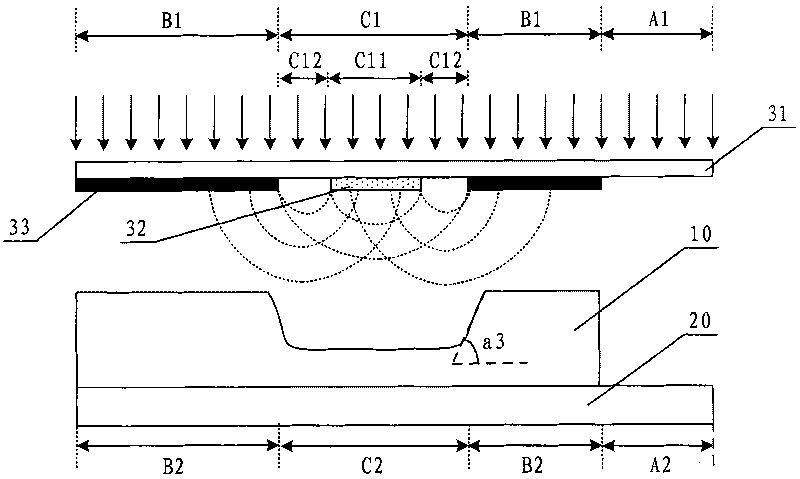

Mask plate and manufacture method thereof

ActiveCN101738846AImprove yield rateImprove electrical performanceSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringPhotoresist

The invention relates to a mask plate and a manufacture method thereof. The mask plate comprises a lightproof region, a fully transparent region and a partial transparent region; the partial transparent region is formed in a such way that a semi-transparent part and a transparent part are alternatively arranged. The invention is a new mask plate manufactured by combining a grey mask plate technique and halftone mask plate technique; the mask plate ensures that the exposure of photoresist at the lower part of the partial nonopaque region is uniform when in use, which is beneficial to forming the smooth surface of a partial maintaining region of the photoresist, thereby facilitating the TFT groove etch and improving the yield of array substrates, at the same time, the obliquity of the photoresist at the edge of the partial maintaining region of the photoresist is increased, thereby the technique can be accurately controlled in the process of forming the TFT groove.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

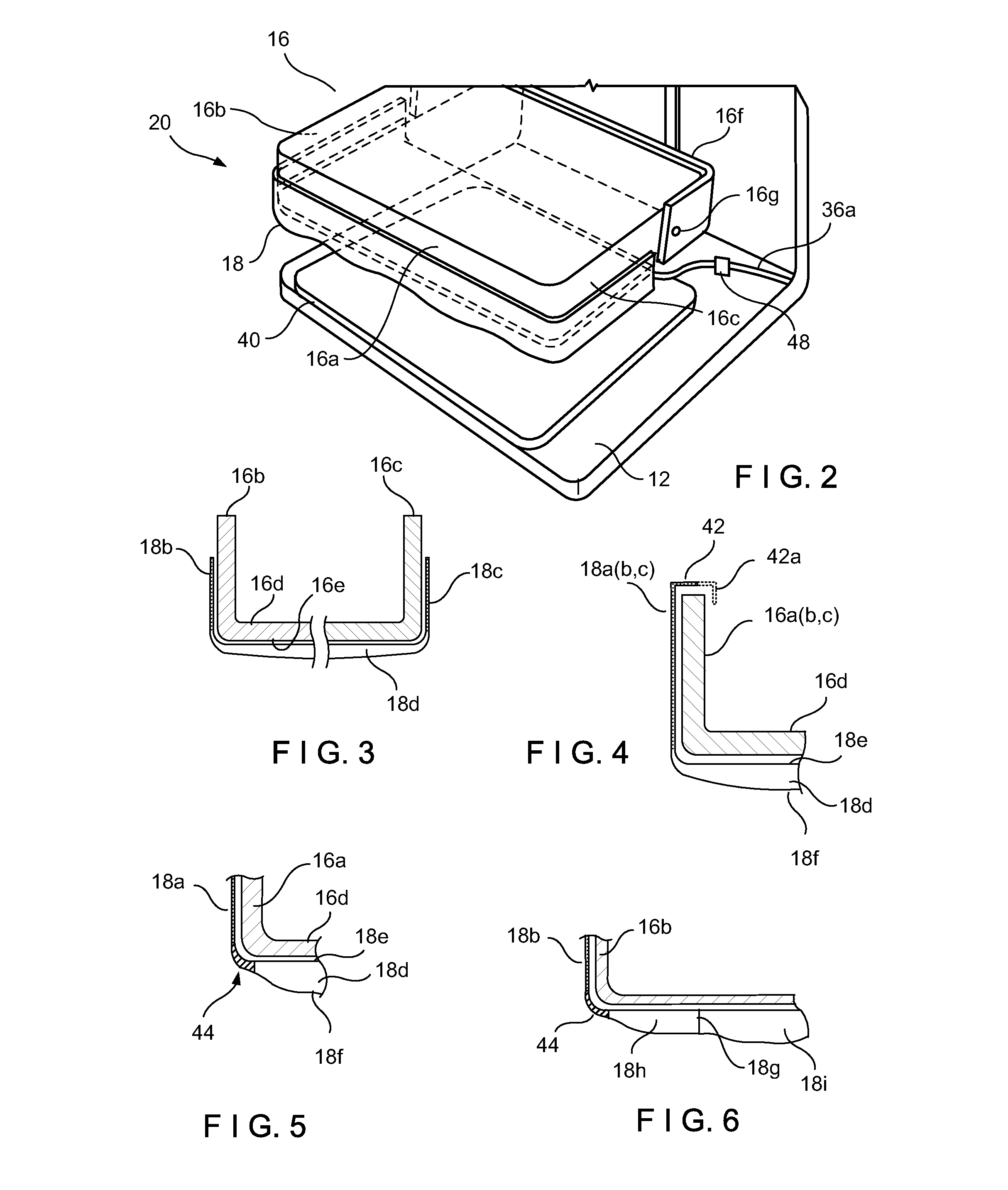

X-ray mammography and/or breast tomosynthesis using a compression paddle

ActiveUS20160081633A1Improve breast imagingImprove patient comfortTomosynthesisPatient positioning for diagnosticsMedicineX-ray

An x-ray breast imaging system comprising a compression paddle in which the compression paddle comprises a front wall and a bottom wall. The front wall is configured to be adjacent and face a chest wall of a patient during imaging and the bottom wall configured to be adjacent a length of a top of a compressed breast. The bottom wall extends away from the patient's chest wall, wherein the bottom wall comprises a first portion and a second portion such that the second portion is between the front wall and the first portion. The first portion is generally non- coplanar to the second portion, wherein the compression paddle is movable along a craniocaudal axis. The x-ray breast imaging system also comprises a non-rigid jacket releasably secured to the compression paddle, the non-rigid jacket positioned between the compression paddle and the patient.

Owner:HOLOGIC INC

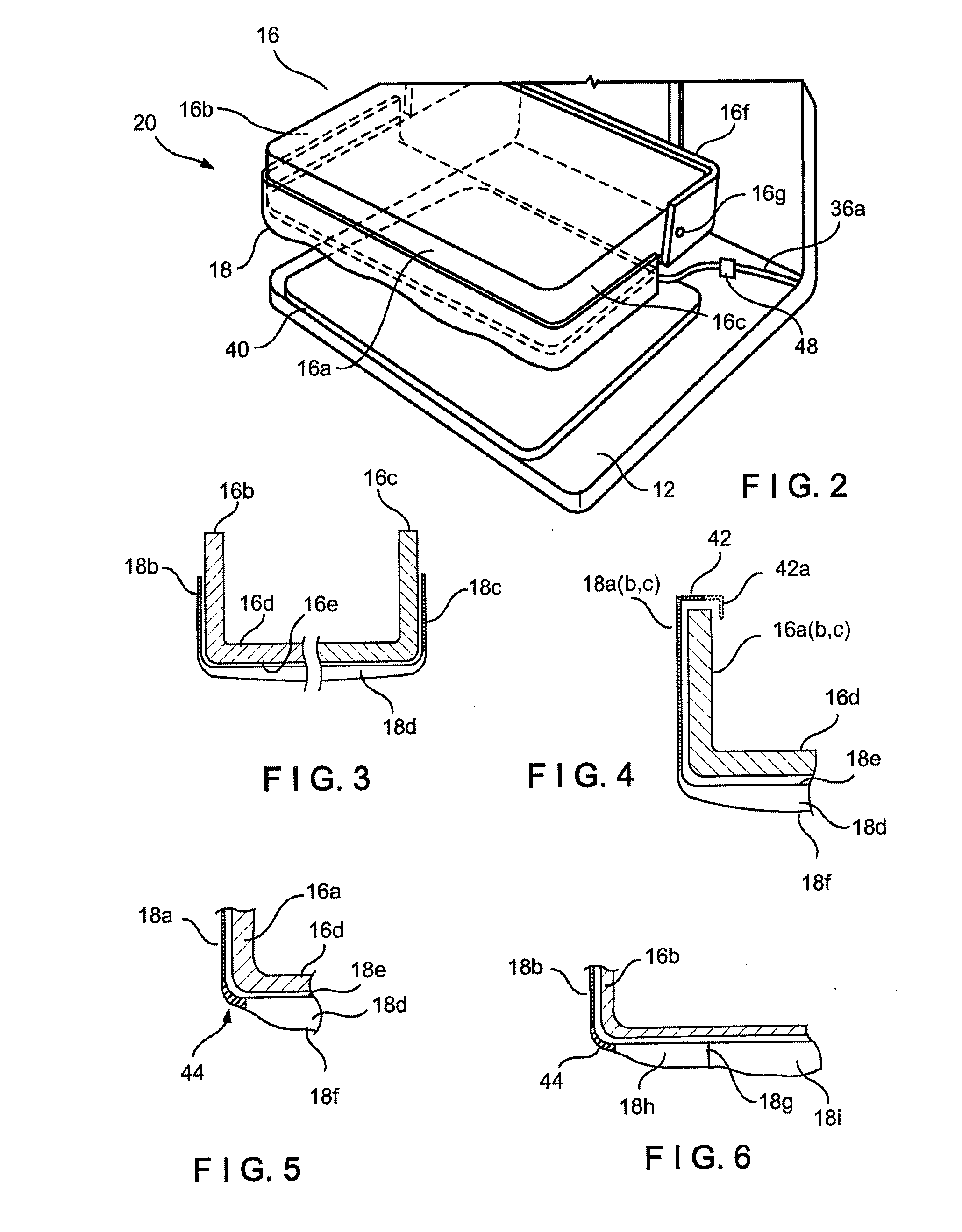

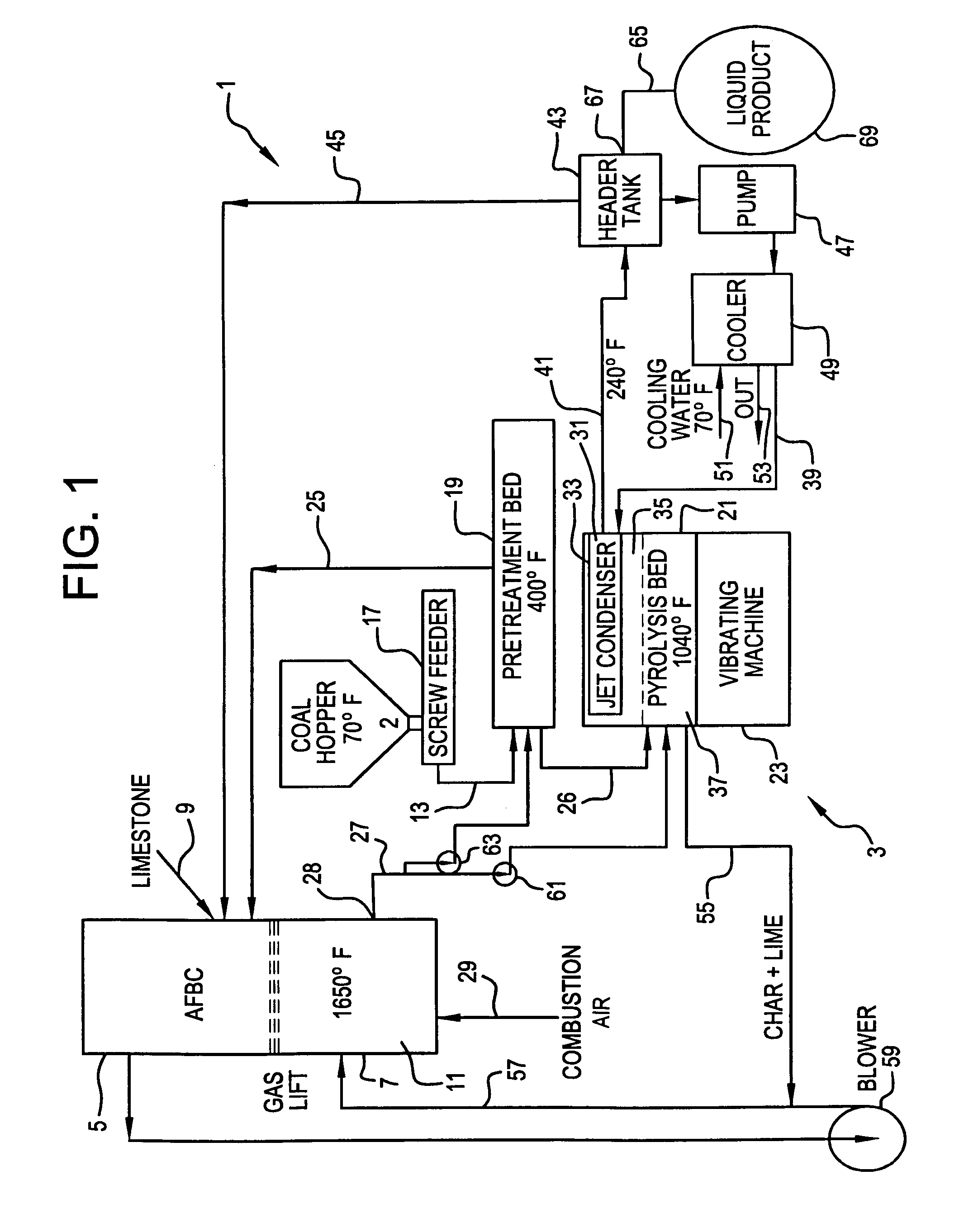

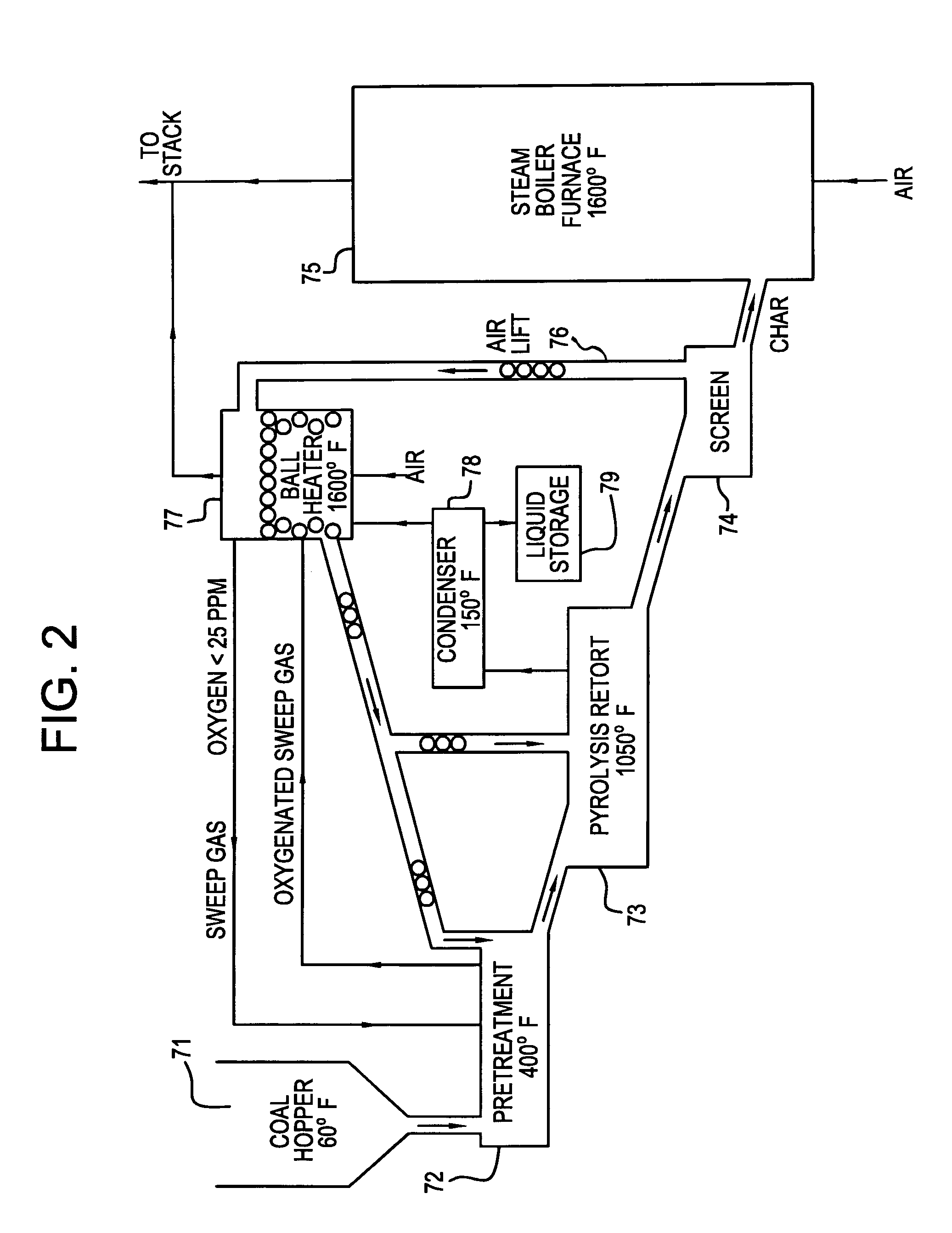

Pretreatment process to remove oxygen from coal en route to a coal pyolysis process as a means of improving the quality of the hydrocarbon liquid product

InactiveUS7008459B1Heat loss minimizationOxygen in-leakage can be kept extremely lowMechanical conveying coke ovensDirect heating destructive distillationLiquid productFlue gas

A process and apparatus for coal pyrolysis pretreatment. The apparatus is made up of a pretreatment vessel for holding a bed of coal particles, a preheater for heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and an oxygen remover for removing oxygen released from the heated coal particles. The apparatus can also have a flue gas source as an oxygen removal sweep gas to the bed of coal, a collector for collecting non-condensable combustible gases, and the preheater having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles. The process involves heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and preventing air from contacting the bed of coal particles in addition to collecting non-condensable combustible gases or the preheating step accomplished by having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles.

Owner:MACLEAN JOHN DR

Planarizing antireflective coating compositions

InactiveUS6855466B2Minimize CD variationIncrease depth of focusPhotosensitive materialsRadiation applicationsPlasticizerPolymer chemistry

The present invention provides new light absorbing compositions suitable for use as antireflective coating compositions (“ARCs”), including for deep UV applications. The antireflective compositions of the invention are particularly useful where a planarizing coating layer is required. ARCs of the invention contain a low molecular weight resin, a plasticizer compound and / or a low Tg resin. The invention also includes methods for applying forming planarizing ARC coating layers.

Owner:SHIPLEY CO LLC

Counter top cooking appliance

ActiveUS20200093329A1Uniform exposureImprove performanceDomestic stoves or rangesStoves/ranges shelves or racksDriver/operatorProcess engineering

A countertop electric appliance optimally performs a variety of cooking modes with both radiant and convective heat sources as well as control means for controlling the timing and intensity of the heat sources. A driver turns food about either a horizontal or a vertical axis of rotation suitable for the specific food and recipe. A hinged door supports the food to be cooked so that in one location the food is caused to be turned by the drive means and in another location the food is loaded into or removed from the appliance, external of the cooking compartment, to be easily handled by the operator.

Owner:GLUCKSMAN DOV Z

Solar collector

ActiveUS20110108090A1Low efficiencyUniform exposureSolar heating energyPhotometry using reference valueCollection systemCollector device

The present invention relates to a solar energy collector suitable for use in a solar energy collection system. The solar energy collection system includes the collector, a stand that supports the collector and a tracking system that causes the collector to track movements of the sun along at least one axis. The collector includes one or more reflector panels, one or more solar receivers, and a support structure that physically supports the reflector panels and solar receivers. Some designs involve a reflector panel that has a compound curvature. That is, the reflector panel has a convex shape along one direction and a concave shape in another direction. In another aspect of the invention, the collector includes a space frame support structure.

Owner:SKYLINE SOLAR INC +1

X-ray mammography and/or breast tomosynthesis using a compression paddle with an inflatable jacket enhancing imaging and improving patient comfort

ActiveUS20130129039A1Reduce radiation exposureUniform exposureTomosynthesisPatient positioning for diagnosticsTomosynthesisRadiology

A system and method using an inflatable jacket over the compression paddle of a mammography and / or tomosynthesis system to enhance imaging and improve patient comfort in x-ray breast imaging.

Owner:HOLOGIC INC

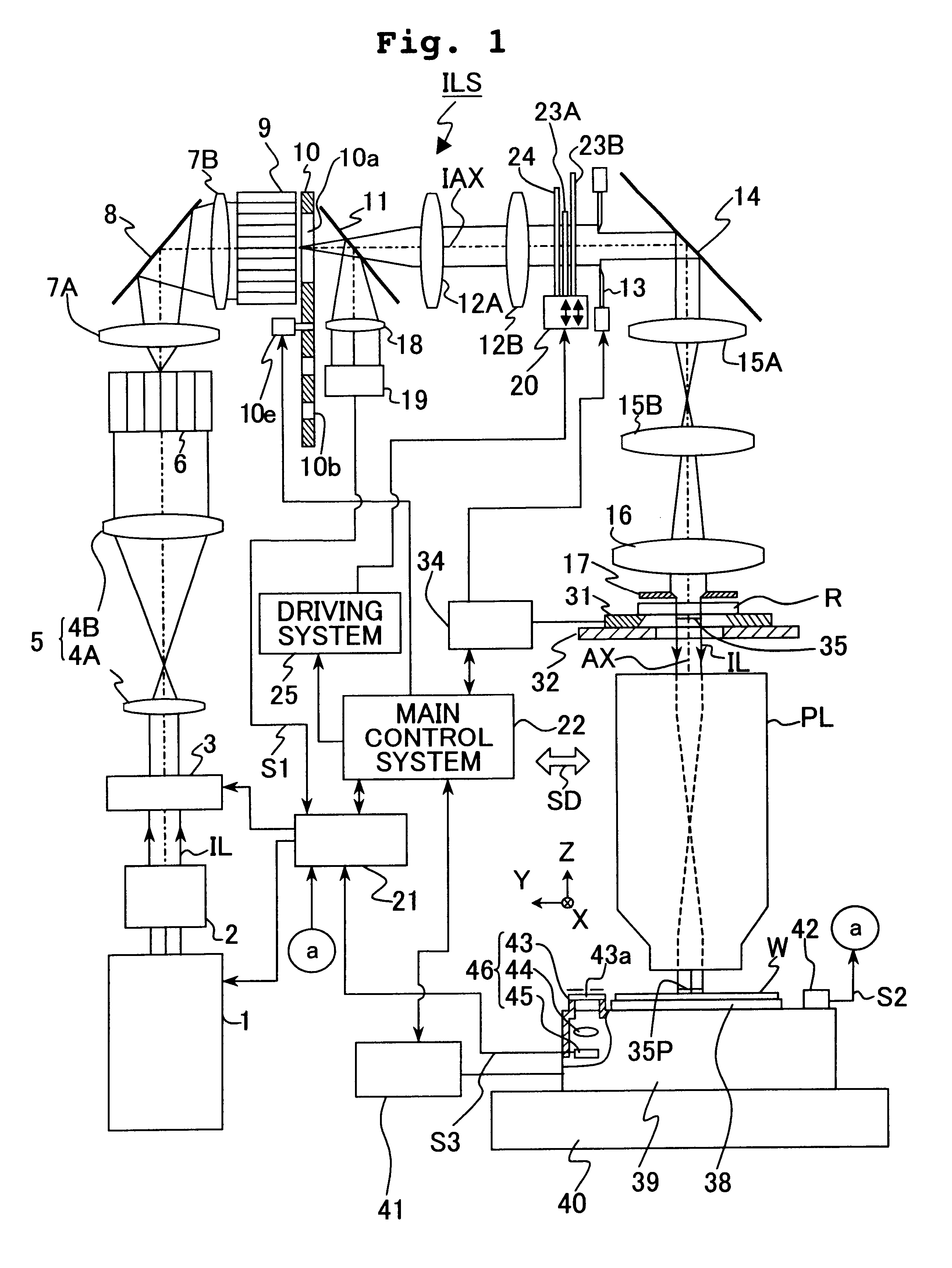

Exposure method and exposure apparatus

InactiveUS6704090B2Improve uniformityHighly accurately mass-produce devices having high degrees of integrationPhotomechanical exposure apparatusMicrolithography exposure apparatusIlluminanceLight beam

An exposure apparatus transfers an image of a pattern on a reticle onto a wafer W by synchronously scanning the reticle and the wafer with respect to a projection optical system in a state in which the reticle is illuminated with an exposure light beam from an exposure light source subjected to pulse light emission via a fly's eye lens, a movable blind, a main condenser lens system, and a fixed blind. First and second uneven illuminance-correcting plates, on which shielding line groups for correcting convex and concave uneven illuminance are depicted, are arranged at a position defocused from a conjugate plane with respect to a pattern plane of the reticle. A third correcting plate for roughly correcting uneven illuminance is arranged at a position further defocused therefrom. It is possible to enhance the uniformity of the totalized exposure amount on the wafer or the telecentricity when the exposure is performed in accordance with the scanning exposure system.

Owner:MITUTOYO CORP +1

Systems and methods for disinfection

InactiveUS7001571B2Uniform radiation exposureUniform exposureScattering properties measurementsWater distributersRadiation exposureDisinfection methods

Methods and systems for establishing Taylor-Couette flow in a fluid are provide. Aspects of the disclosed methods and systems incorporate Taylor-Couette flow in combination with a source of radiation to provide more uniform radiation exposure to the fluid and its components. Common problems of non-uniform radiation levels and concentration boundary layer effects in UV reactors are largely eliminated using the methods and devices provided herein.

Owner:GEORGIA TECH RES CORP

Method and device for providing service object information in page

ActiveCN105653545AEasy to findUniform exposureWebsite content managementResourcesWorld Wide WebBusiness object

The embodiment of the invention discloses a method and device for providing service object information in a page. The method includes the following steps: providing a page after a page access request is received, wherein the page includes at least one first zone and at least one second zone including a plurality of sub-zones, contents included in all zones in the page can be determined through the following manner of calculating operation information of a service object displayed in the sub-zones; determining information of a target service object according to a calculated result of the operation information of the service object; and adding the information of the target service object to the first zone, associating the information of the target service object in the first zone and position information of the sub-zones corresponding to the information of the target service object to jump to a position of one sub-zone corresponding to the target service object when the information of the target service object displayed in the first zone is operated. Through the method and the device, load balancing of a server can be achieved, and the utilization rate of resources can be improved.

Owner:ALIBABA GRP HLDG LTD

Systems and methods for disinfection

Methods and systems for establishing Taylor-Couette flow in a fluid are provided. Aspects of the disclosed methods and systems incorporate laminar Taylor-Couette flow in combination with a source of radiation to provide more uniform radiation exposure to the fluid and its components. Common problems of non-uniform radiation levels and concentration boundary layer effects in UV reactors are largely eliminated using the methods and devices provided herein. In an exemplary embodiment, the reactor of the present disclosure has a hollow outer cylinder or stator and a rotor positioned therein and smooth walls for both the outer wall of its rotor and the inner wall of the outer cylinder or stator in which the rotor is positioned, the space between which forming the annular fluid gap.

Owner:GEORGIA TECH RES CORP

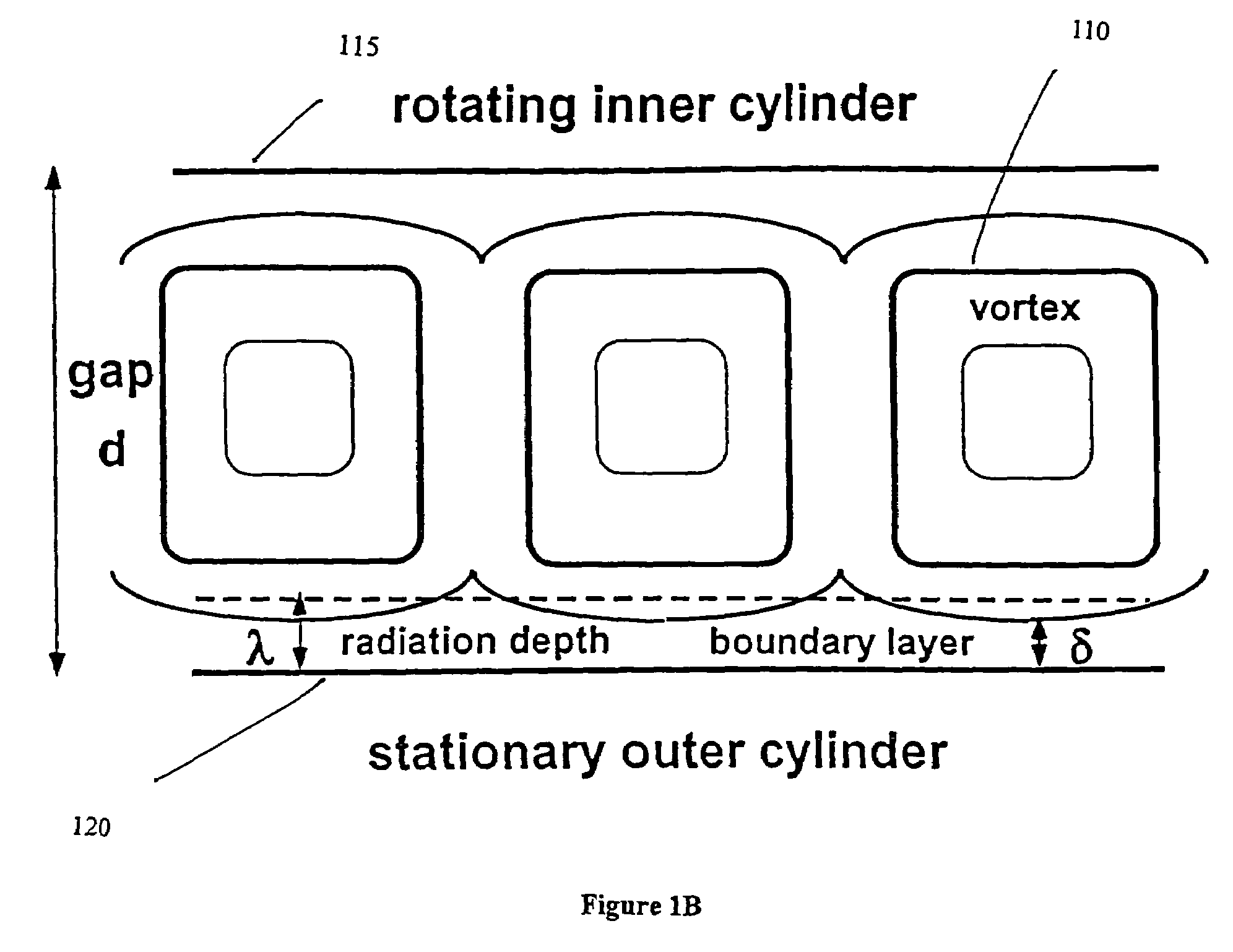

Methods for forming dense dielectric layer over porous dielectrics

InactiveUS20080242118A1Uniform exposureUniform thicknessSemiconductor/solid-state device manufacturingLow-k dielectricRadiation rays

Methods for forming a dense dielectric layer over the surface of an opening in a porous inter-layer dielectric having an ultra-low dielectric constant are disclosed. The disclosure provides methods for exposing the sidewall surface and the bottom surface of the opening to a plurality of substantially parallel ultra-violet (UV) radiation rays to form a dense dielectric layer having a substantially uniform thickness over both the sidewall surface and the bottom surface.

Owner:ALSEPHINA INNOVATIONS INC

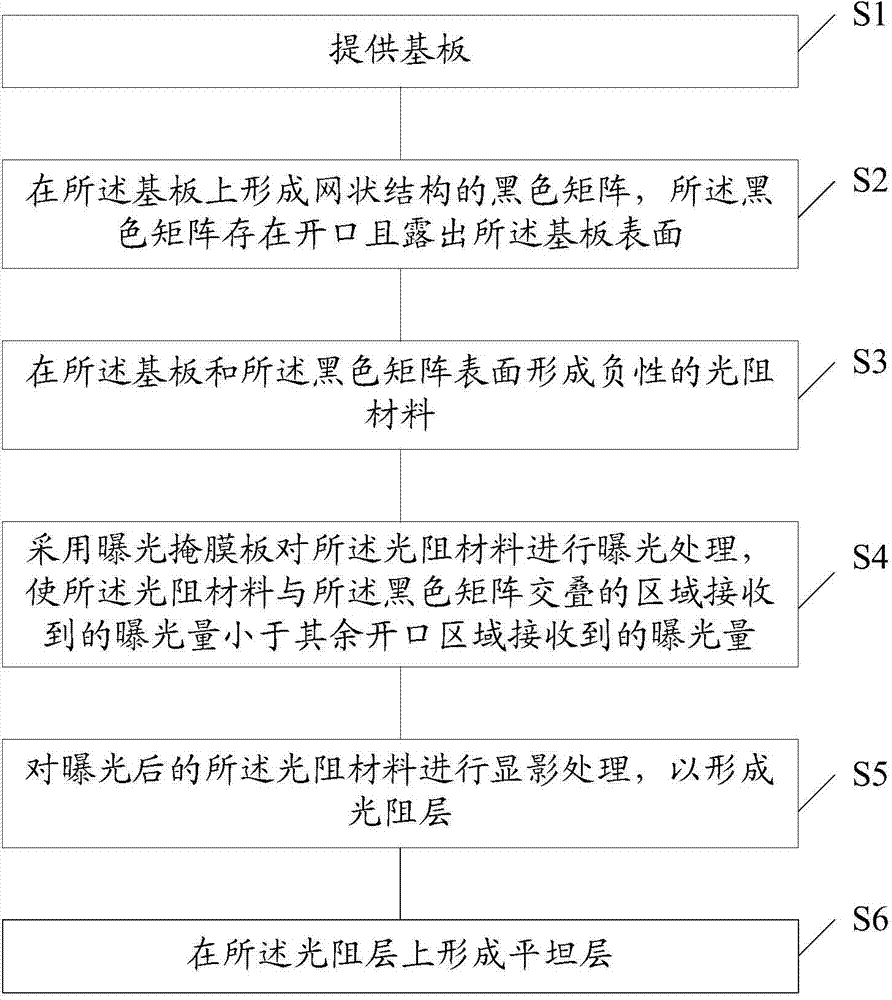

Light filter manufacturing method and exposure mask plate

InactiveCN104749674ALow costImprove the display effectOptical filtersPhotomechanical exposure apparatusLiquid-crystal displayEngineering

Provided are a light filter manufacturing method and an exposure mask plate. The light filter manufacturing method comprises the step of providing a substrate; forming a black matrix with a net structure on the substrate, wherein the black matrix is provided with an opening and exposed out of the surface of the substrate; forming a negative photoresist material on the surfaces of the substrate and the black matrix; adopting the exposure mask plate to conduct exposure treatment on the photoresist material and enabling the exposure amount received by a overlapped region of the photoresist material and the black matrix to be smaller than the exposure amount received by the residual open region; conducting developing treatment on the exposed photoresist material to form a light resistance layer. The exposure mask plate is used for the light filter manufacturing method. The exposure mask plate comprises a shading region and an exposure region, wherein multiple protrusion structures are arranged at the edge position in contact with the exposure region in the shading region. The horned portions of the light resistance layer can be decreased or eliminated, the phenomenon that poor liquid crystal deflection caused by too thick horns influences a light filer and the display performance of a liquid crystal display is prevented, and further the cost of light filter can be reduced.

Owner:INESA DISPLAY MATERIALS

Areal modulator for intensity modulated radiation therapy

ActiveUS20080260098A1Small sizeSpeed up treatmentElectrode and associated part arrangementsMaterial analysis by optical meansCold spotMedicine

A modulator for radiation therapy provides modulation of an area beam to decrease treatment time. Separate channels passing modulated “beamlets” are possible by spacing the channels such that spreading of the beams and multiple angles of treatment eliminate cold spots. The space between the channels allows well-defined channel walls and space for modulator mechanisms.

Owner:AL SADAH JIHAD H +3

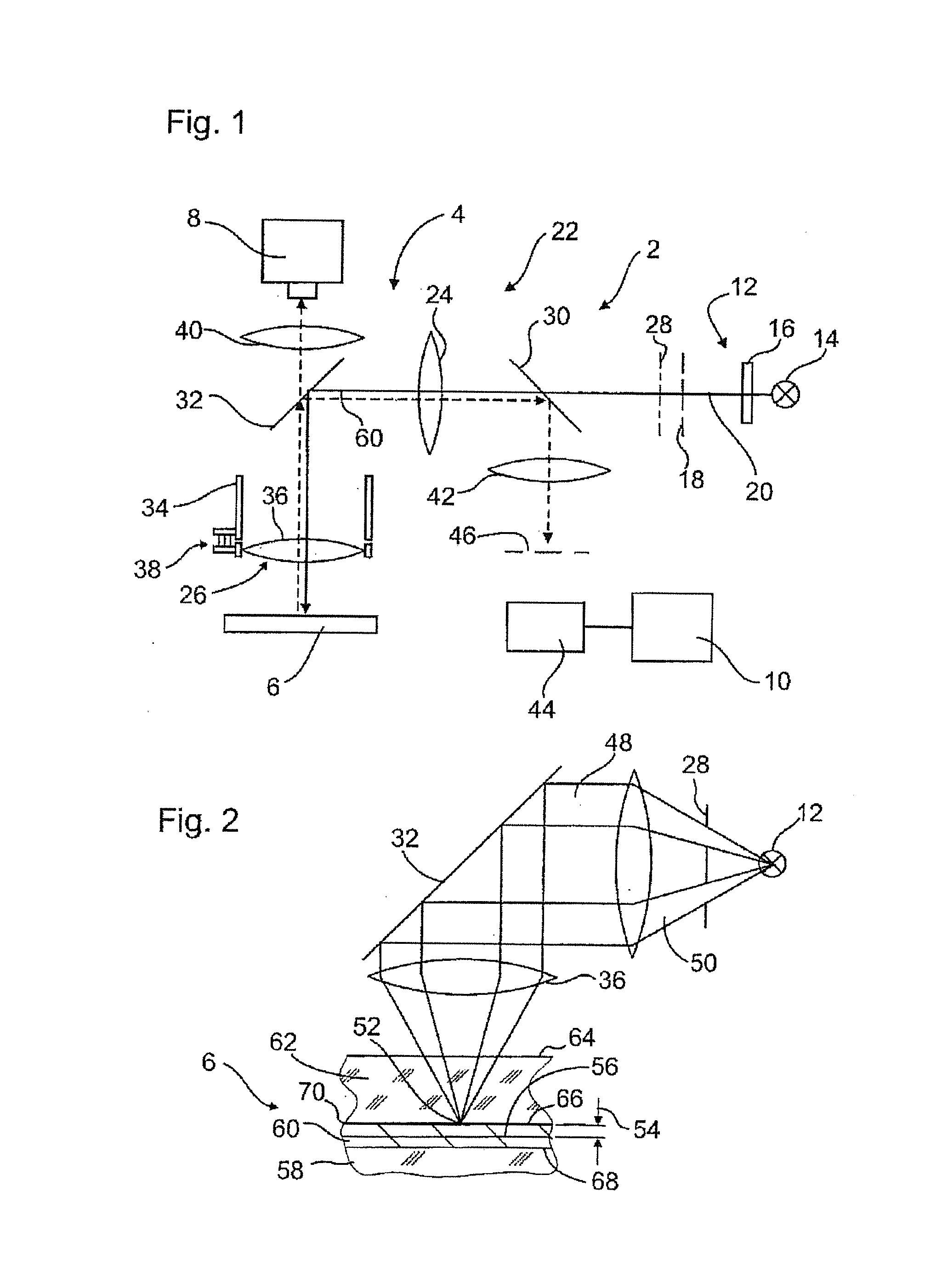

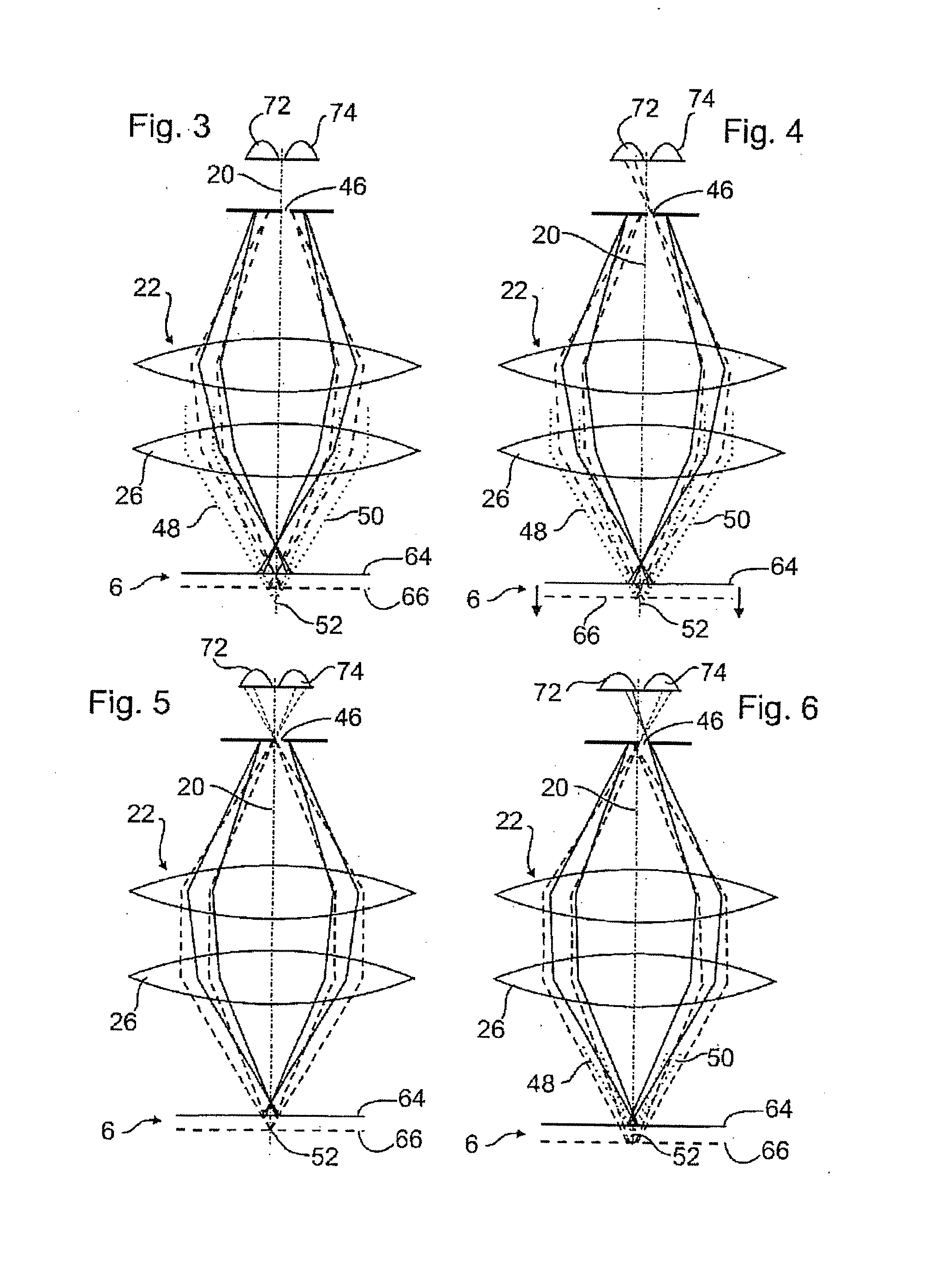

Autofocus method and autofocus device

The invention is based on an autofocus method in which light from a light source is focused at a measurement light focus in a sample and is reflected from there and the reflected light is guided through an optical system in two light paths onto at least two detector elements. In order to achieve fast and accurate automatic focusing on the sample, it is proposed that the measurement light focus is moved in layers of the sample which reflect light to different extents, and the detector elements are arranged in such a way that, in this case, profiles of a radiation property registered by the detector elements are different and a focus position is set in a manner dependent on the profiles.

Owner:SAKURA FINETEK U S A

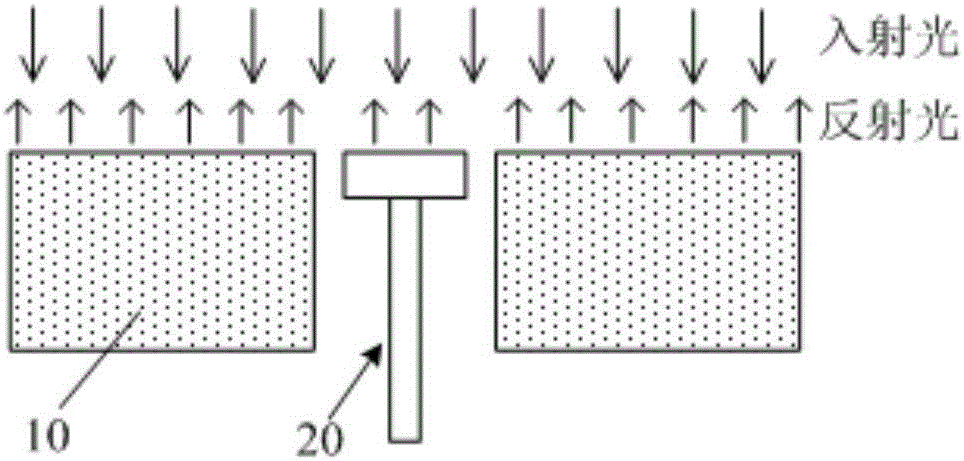

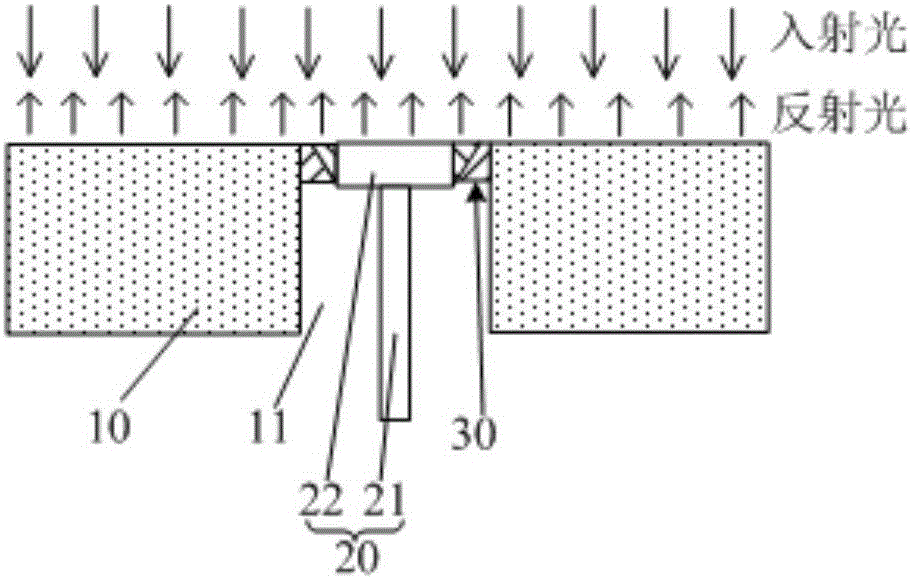

Carrying device and exposure equipment

ActiveCN106773553AUniform exposureQuality improvementSolid-state devicesPhotomechanical exposure apparatusLight reflectionEngineering

The invention provides a carrying device. The carrying device comprises a carrying table, wherein a lifting passage which penetrates through the carrying table is formed in the carrying table, a rising and falling structure is formed in the lifting passage, a gap exists between the rising and falling structure and the internal wall of the lifting passage, a light reflection compensating block is further arranged between the rising and falling structure and the internal wall of the lifting passage, and both the difference of light reflectivity of the top face of the light reflection compensating block and a load bearing face of the carrying table and the difference of light reflectivity of the top face of the light reflection compensating block and the top face of the rising and falling structure are not greater than preset threshold values. Correspondingly, the invention further provides exposure equipment. According to the carrying device and the exposure equipment, the degree of exposure of photoresists at different positions of a substrate can be more uniform.

Owner:CHONGQING BOE OPTOELECTRONICS +1

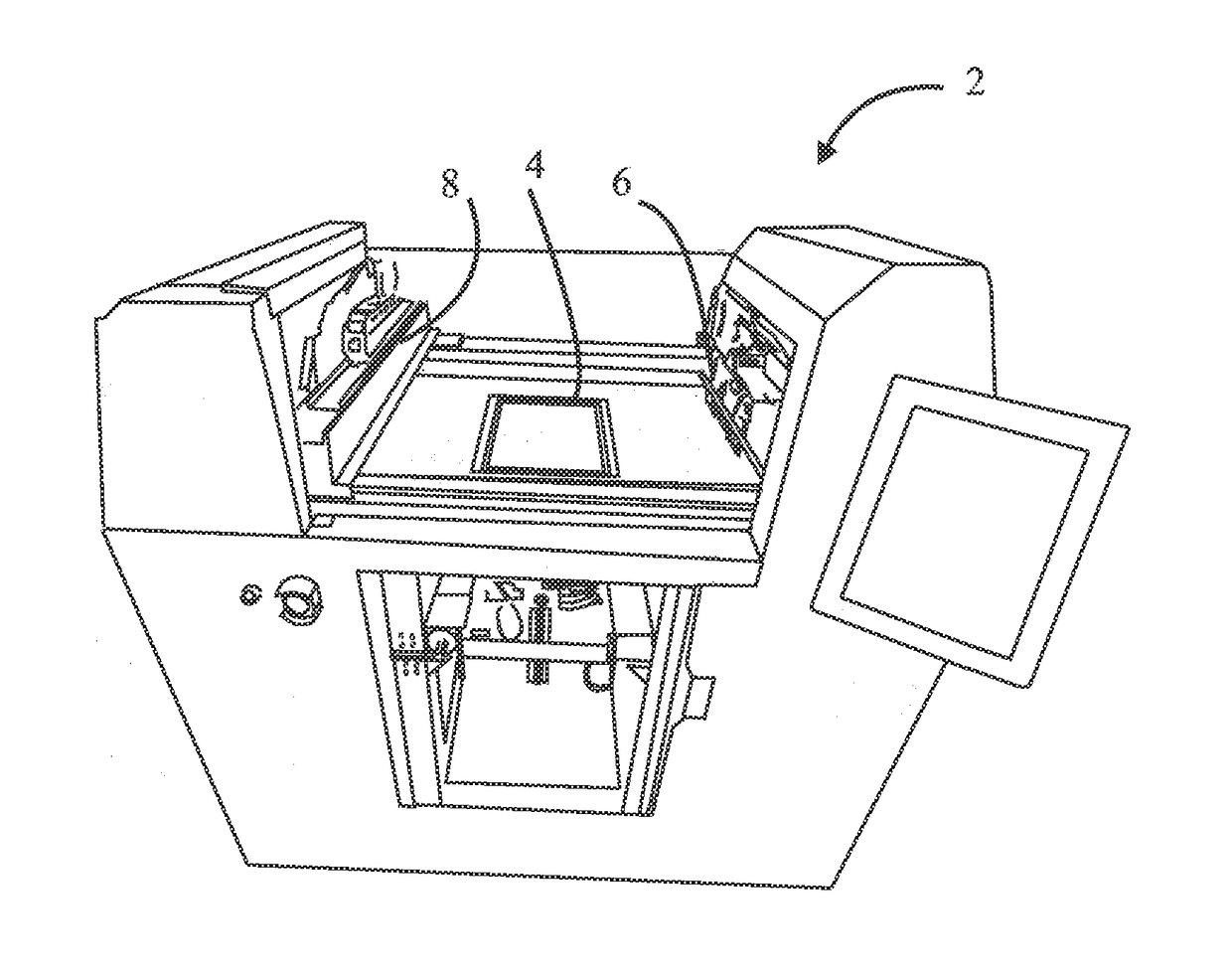

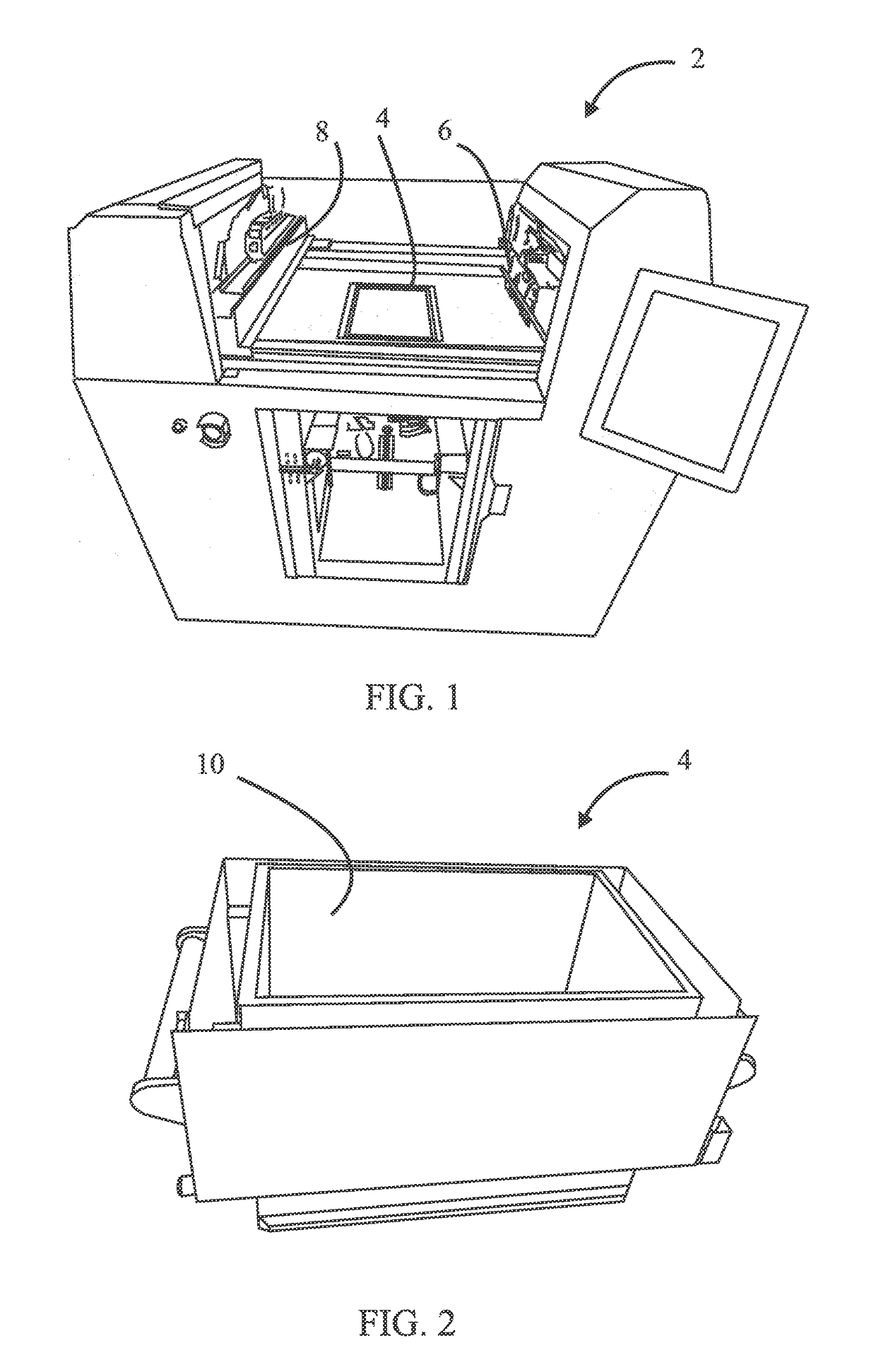

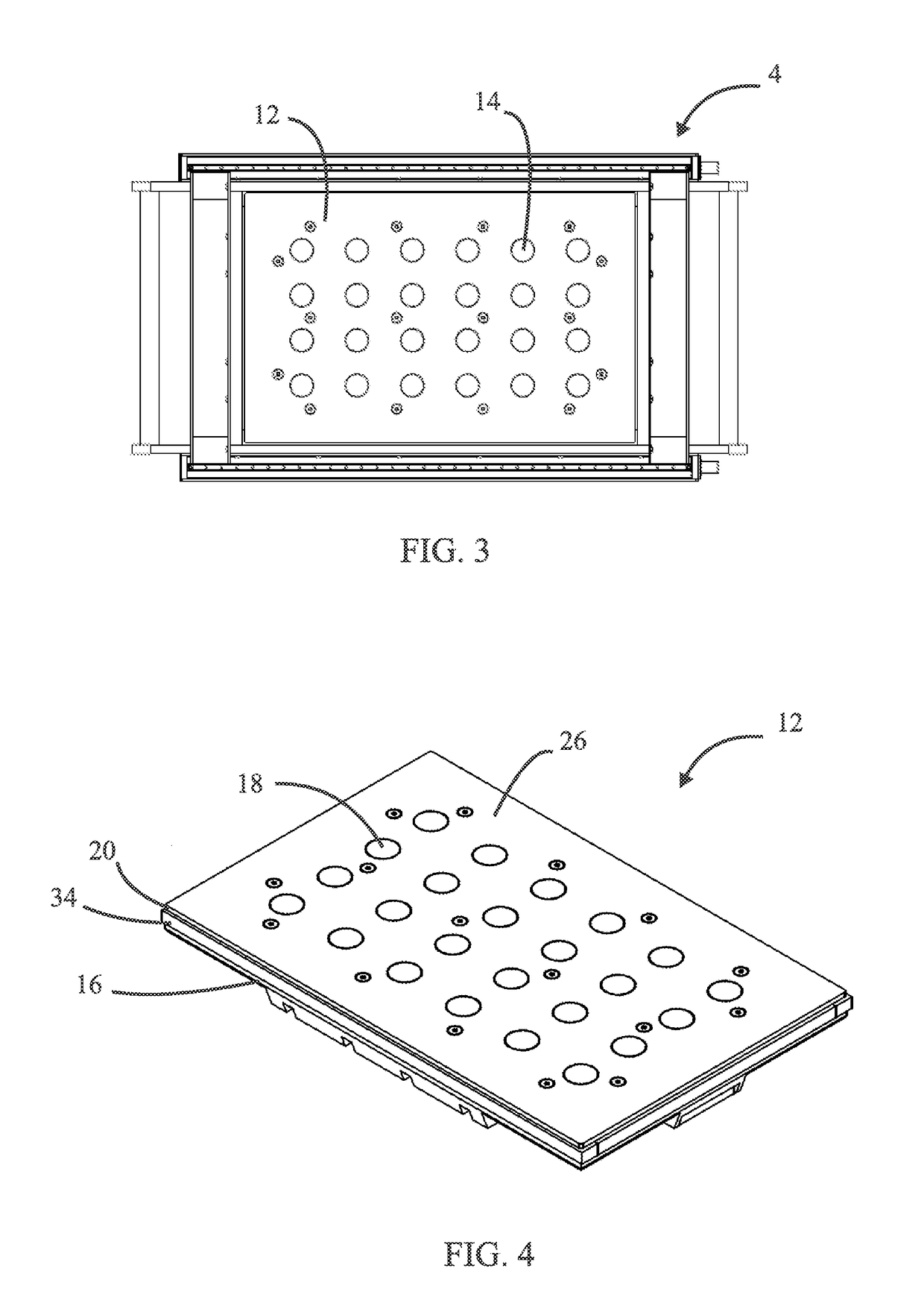

Methods and Apparatuses for Curing Three-Dimensional Printed Articles

InactiveUS20170203514A1Improve curingUniform exposureAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidAirflowEngineering

Methods and apparatuses are disclosed for faster curing of three-dimensionally inkjet printed articles (88) having a curable binder. After the printing of the article (88) is completed, a gas flow is driven in the powder bed (90) that surrounds the article (88). The build box (54) which contains the powder bed (90) may include one or more gas-permeable features (14) in contact with the powder bed (90). The gas-permeable feature (14) may be in the form a plurality of gas-permeable disks (18) which are flush with the supporting surface (26) of the build box floor (12) and which are in fluid communication with the channels (28) of the bottom surface (30) of the build box floor (12). Curing apparatuses (50) are disclosed which have a cavity (68) for receiving the build box (54) and a gas propulsion device (74a) for driving a gas flow in the build box (54). Methods also include driving gas flow in the powder bed (90) by way of wands (230) and paddles (240).

Owner:THE EX ONE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com