Coating device

A coating device and nozzle technology, which can be applied to devices for coating liquid on surfaces, coatings, and photolithographic process coating equipment, etc. The effect of preventing the resonance state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

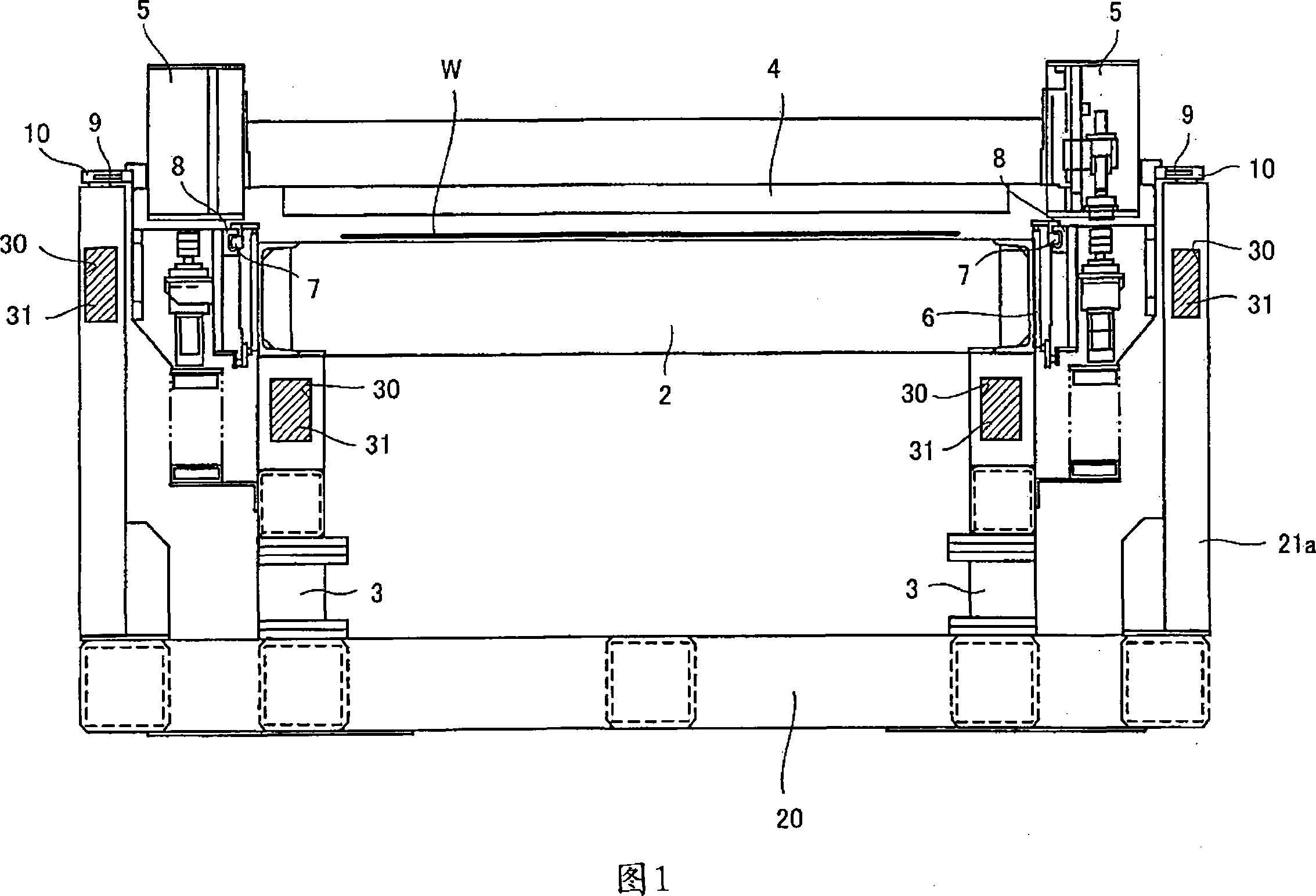

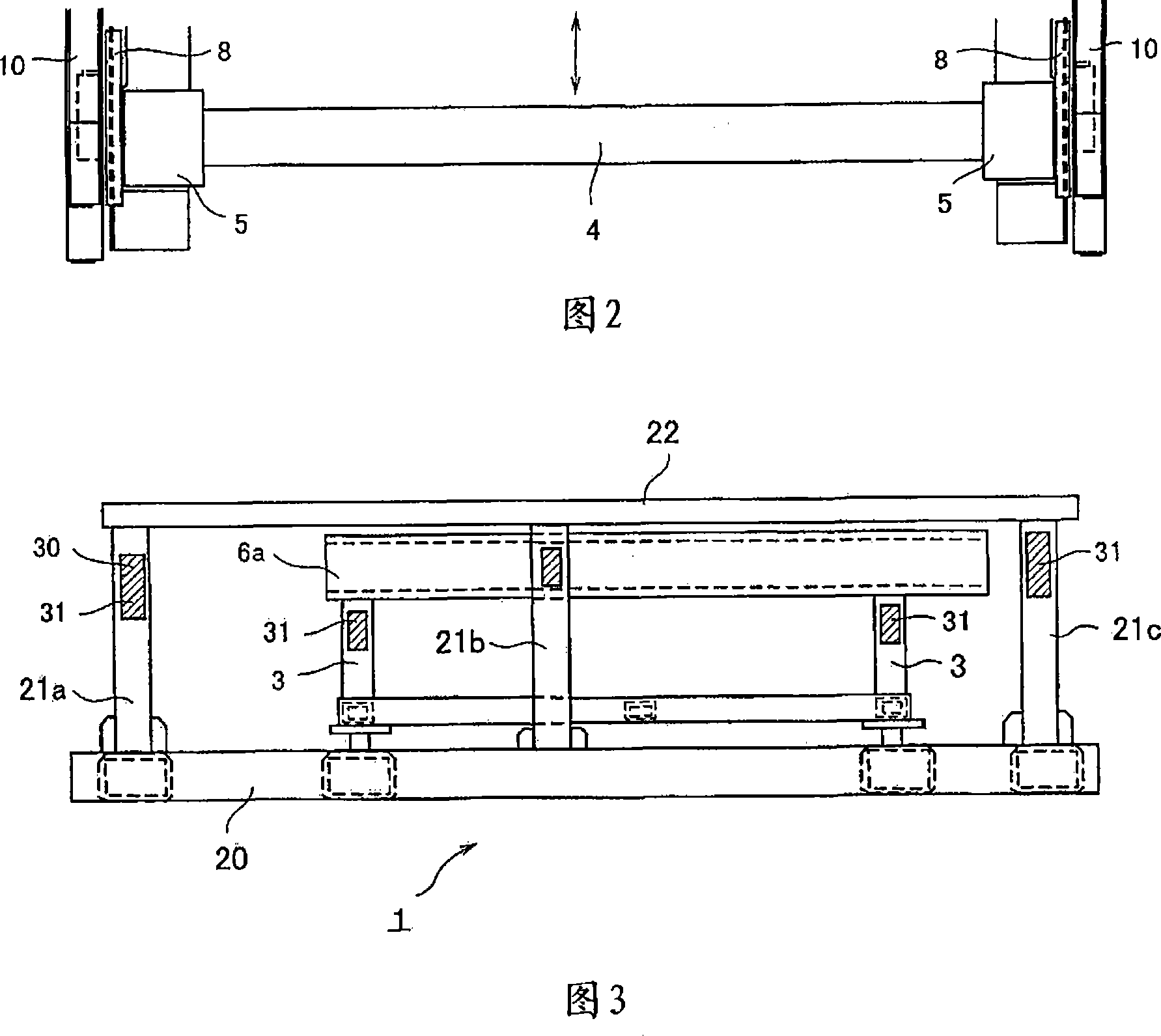

[0015] The present invention will be described in detail below with reference to the accompanying drawings. 1 to 3 show an example of a coating device of the present invention. FIG. 1 is a front view seen from the moving direction of the slit nozzle, FIG. 2 is a plan view showing the main part of FIG. 1 , and FIG. 3 is a side view showing the arrangement structure of the base frame.

[0016] The coating apparatus of the present invention has a base 1 composed of a plurality of hollow frames extending horizontally and vertically, and supports a stage 2 and a nozzle moving mechanism (moving body) by these hollow frames.

[0017] The stage 2 on which the substrate W to be processed is placed is fixed on the susceptor 1 via the pedestal 3 . A slit nozzle 4 is disposed above the stage 2. The slit nozzle 4 has a slit opening extending in the left-right direction of FIG. 1 . vertical direction) to apply the coating liquid onto the substrate W.

[0018] Both ends of the slit nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com