Damping of planetary gears with flex-pins for wind turbines

A technology of gears and planetary carriers, applied in the field of damping of flexible pins, can solve the problems of impracticality and frequency reduction, and achieve the effects of reducing dynamic load, reducing weight and cost, and reducing the reliability of miniaturized machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

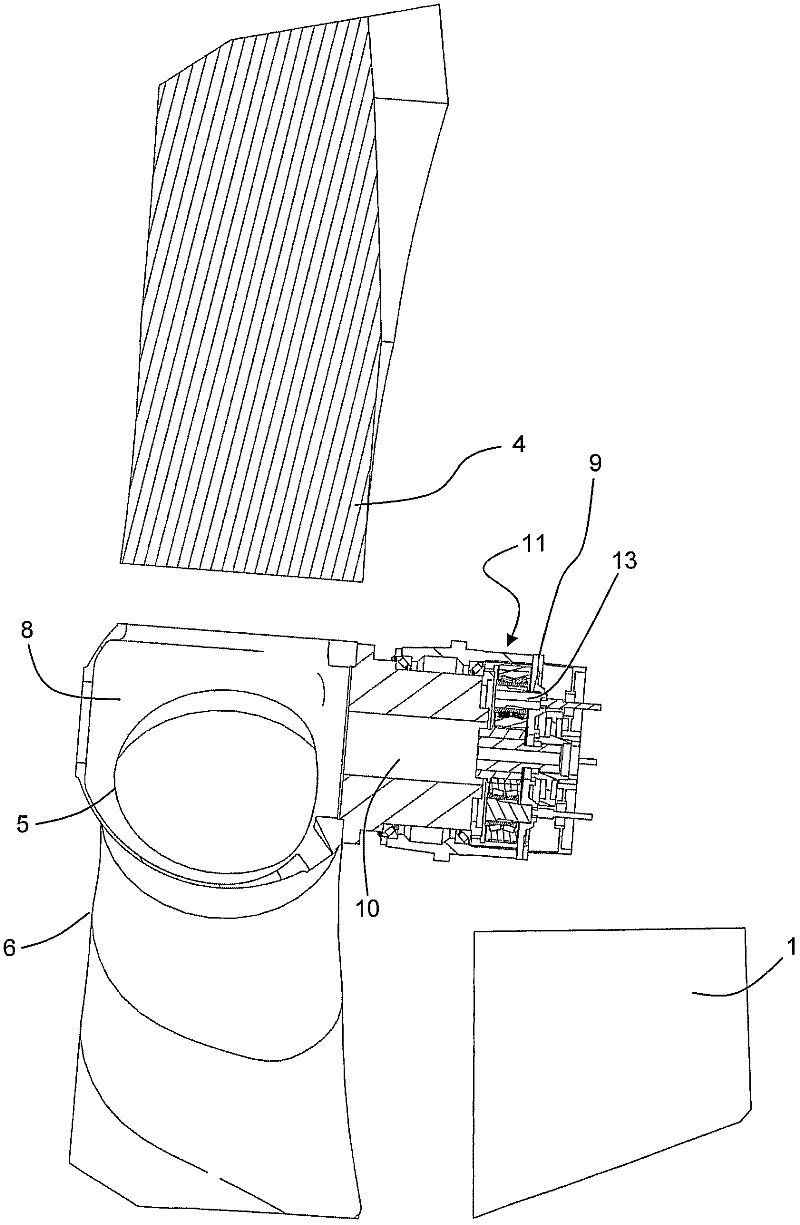

[0035] Wind turbines are rotating machines that convert wind energy into electricity. The rotor blades are connected to a gear train or gearbox that changes the slow rotation of the blades to a faster rotation more suitable for driving a generator. The gearbox uses an epicyclic transmission (planetary transmission) to gradually accelerate the rotation of the rotor blades to drive several generators. figure 1 The basic components of the system are shown in .

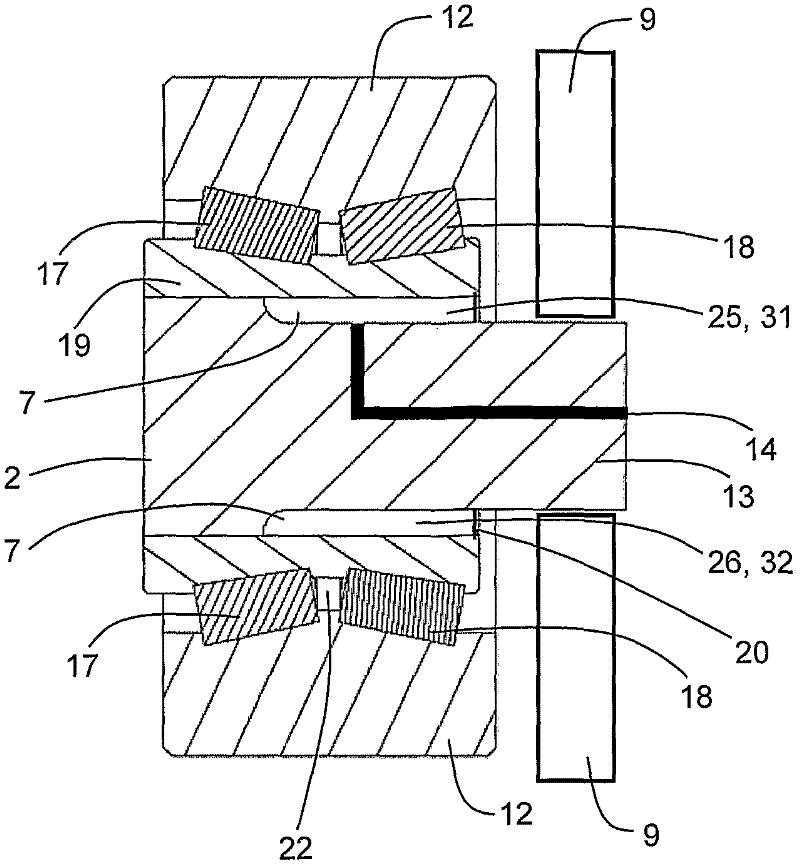

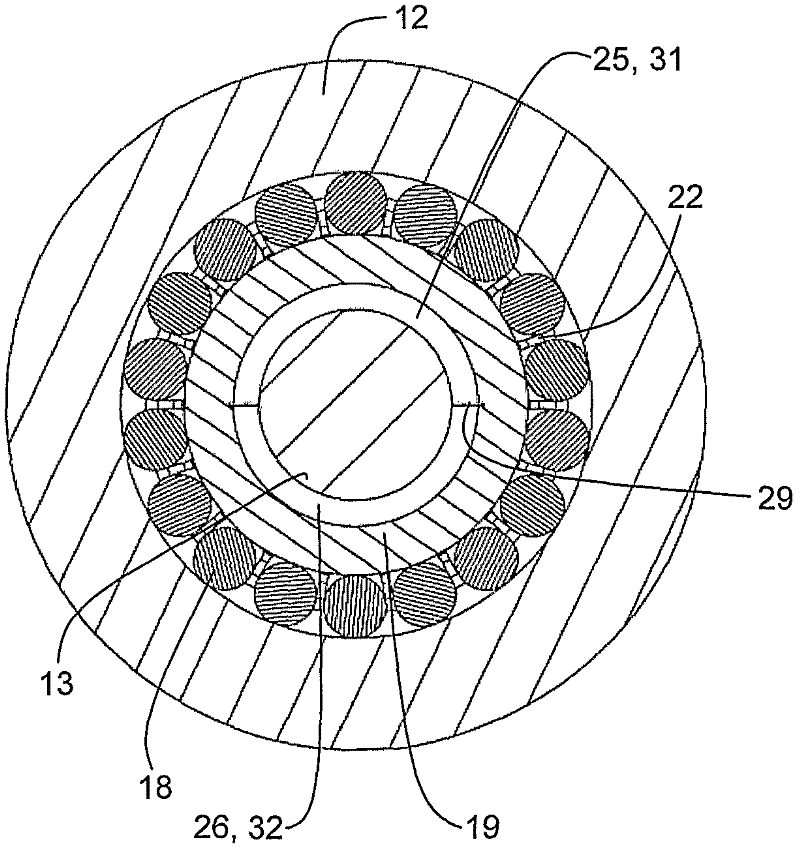

[0036] At once figure 1 as well as Figure 2A and 2BAs far as the wind turbine is concerned, the wind turbine is mounted on top of the tower 1. The aerodynamic rotor blades 4 , 5 , 6 rotate a rotor hub 8 which rotates a main shaft 10 . The main shaft 10 drives a gear train drive train 11 comprising epicyclic gear units. The epicyclic gear unit comprises a planet carrier 9 provided with a plurality of elastic or flexible pins 13 mounted to and supported by the planet carrier 9 at one end. A tubular sleeve 19 is moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com