Coating drier with regulating air flow path function

A drying device and air flow path technology, applied in photoplate making process coating equipment, optics, instruments, etc., can solve the problems affecting production efficiency and uneven film thickness, avoiding uneven film thickness, improving quality, and improving airflow. effect of path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

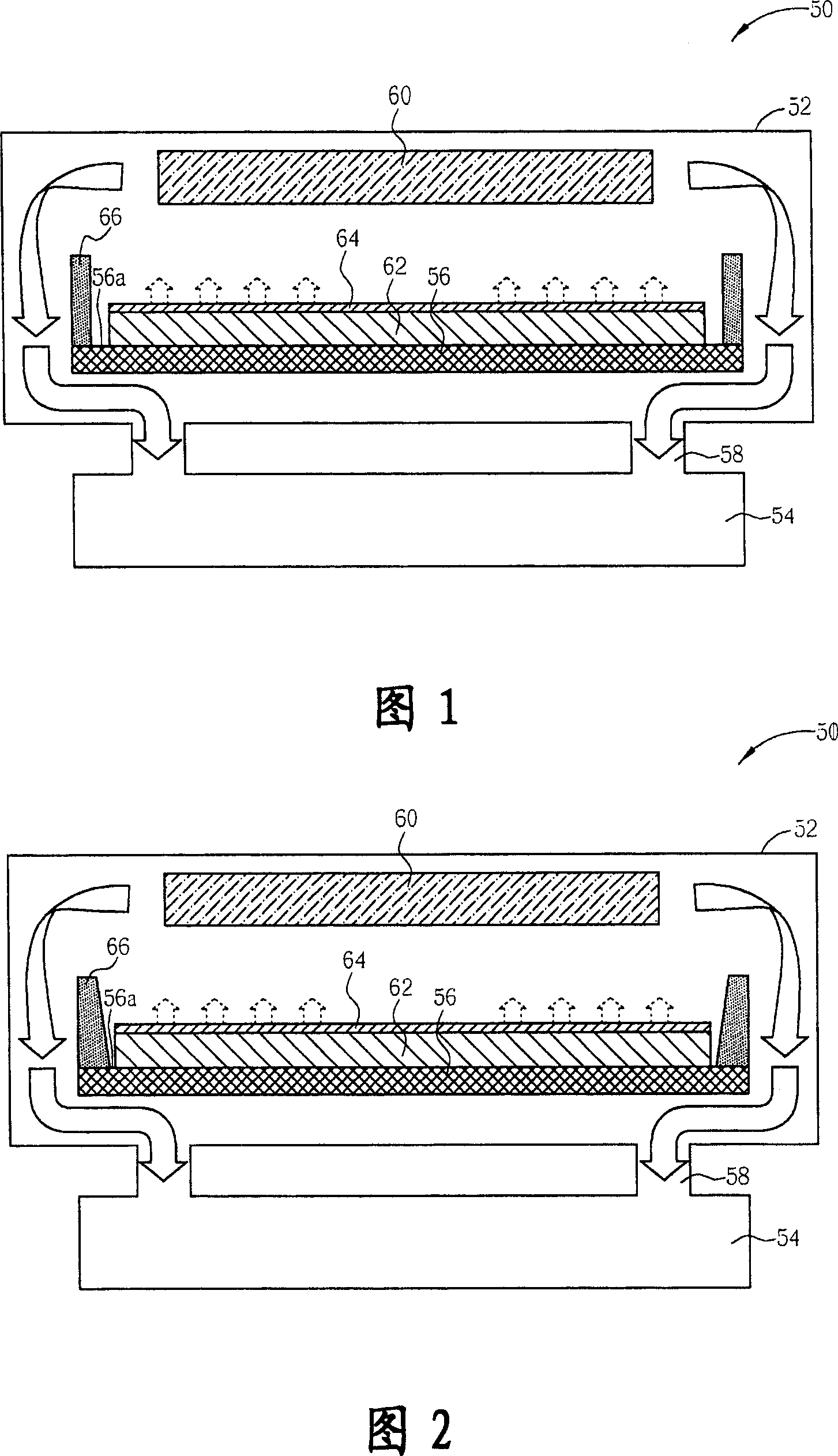

[0016] The following are detailed descriptions and accompanying drawings of the present invention. However, the accompanying drawings are only for reference and auxiliary description, and are not intended to limit the present invention.

[0017] Please refer to Fig. 1, Fig. 1 is a schematic diagram of a coating and drying device with the function of adjusting the airflow path of a preferred embodiment of the present invention, wherein the following embodiment is a slit type (slit) for making color filters ) coating device as an example to illustrate the characteristics of the present invention, but the application of the present invention is not limited thereto, but can be applied to other such as rotary coating device or vacuum drying device, or for making non-color filter Photoresist layers and other coating material layers, etc. As shown in FIG. 1 , the coating device 50 of this embodiment includes a reaction chamber 52 , a vacuum system (such as a vacuum pump) 54 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com