Optical element, window material, fitting, solar shading device, and building

一种光学体、建筑物的技术,应用在光学体,窗材料,日射遮蔽装置及建筑物,隔断构件领域,能够解决温度上升、草坪生长等问题,达到抑制膜厚不均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] 7. Seventh Embodiment (Example of Applying an Optical Film to a Partition Member)

no. 1 Embodiment approach >

[0063] [Structure of Optical Film]

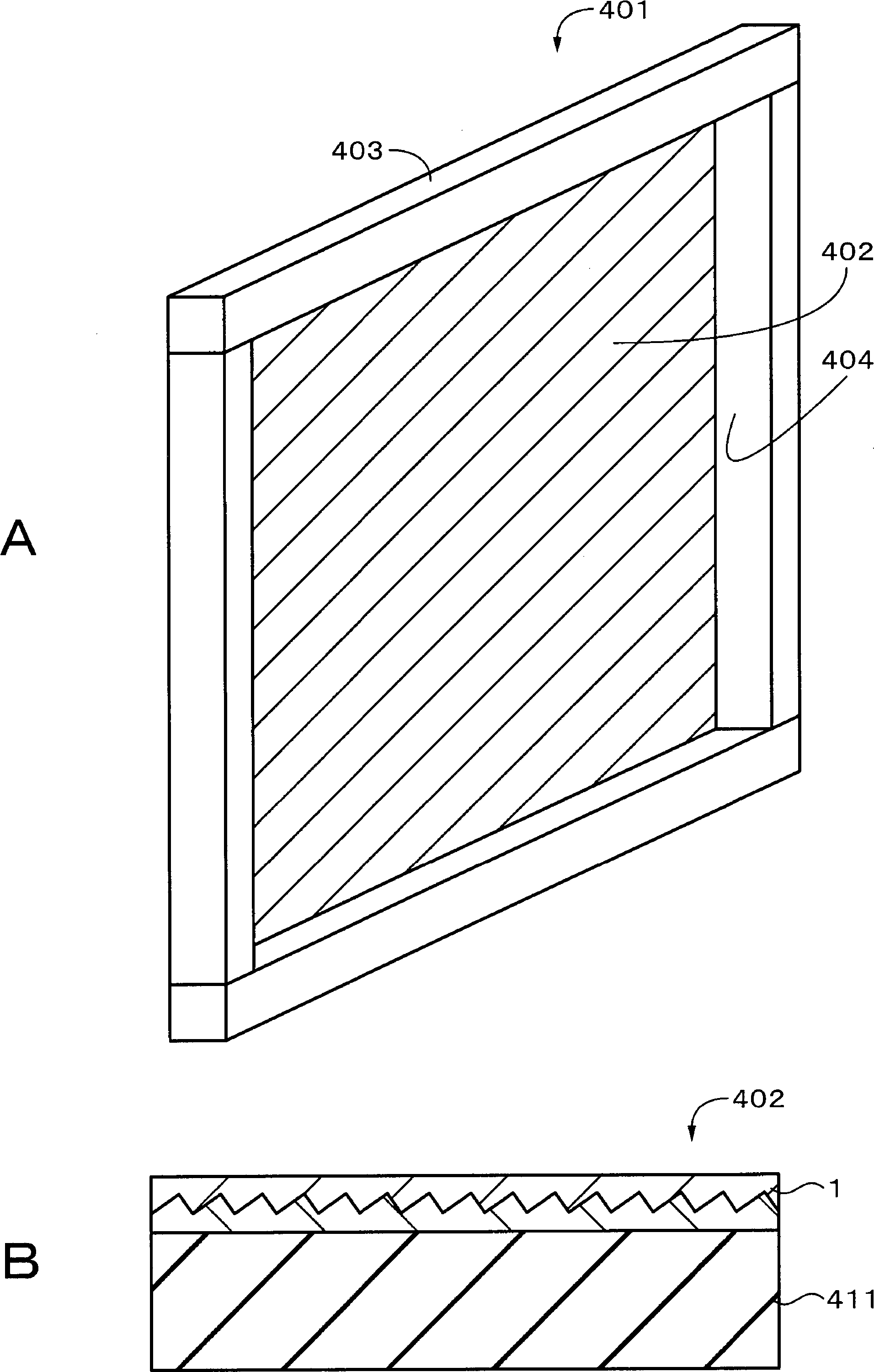

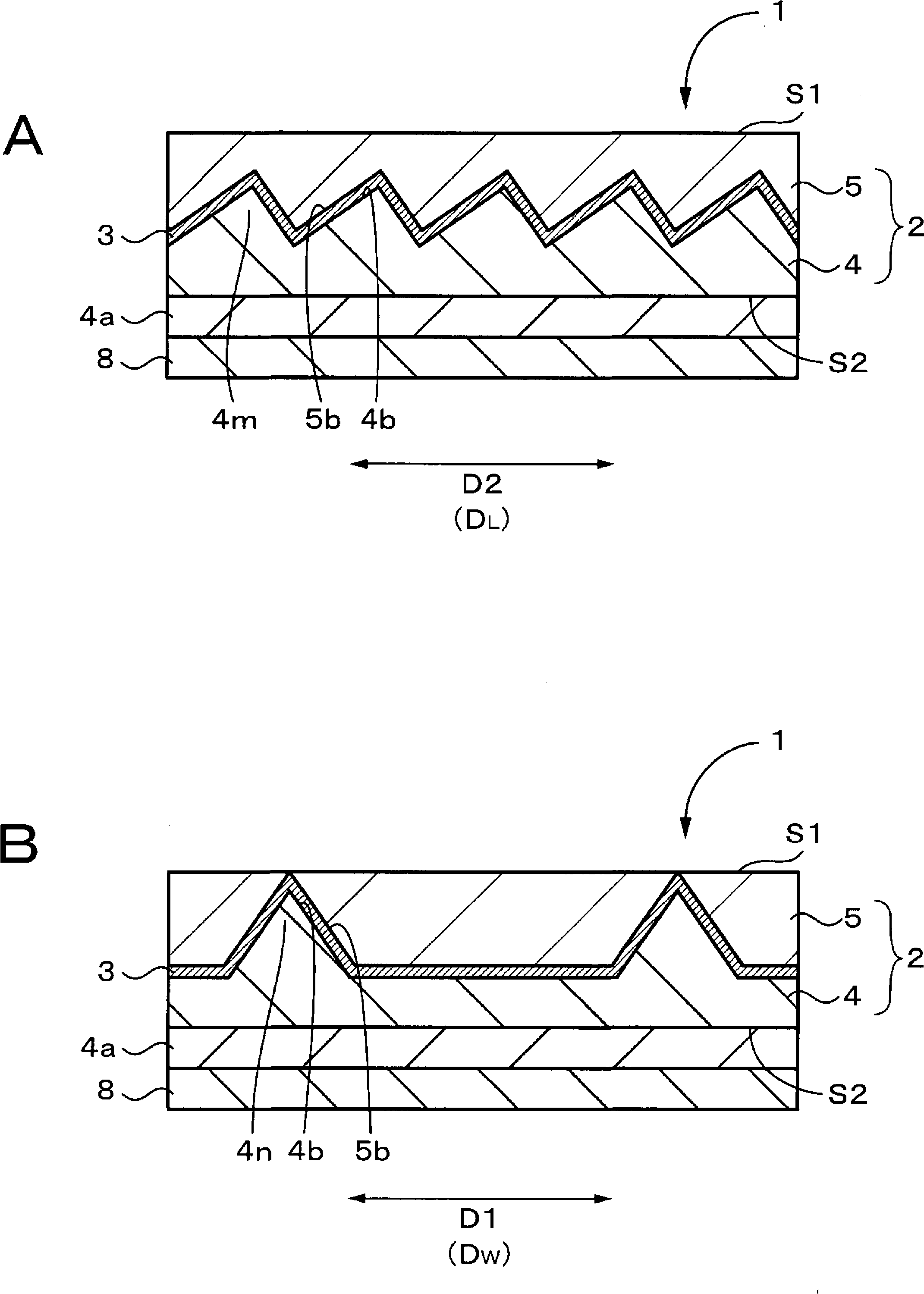

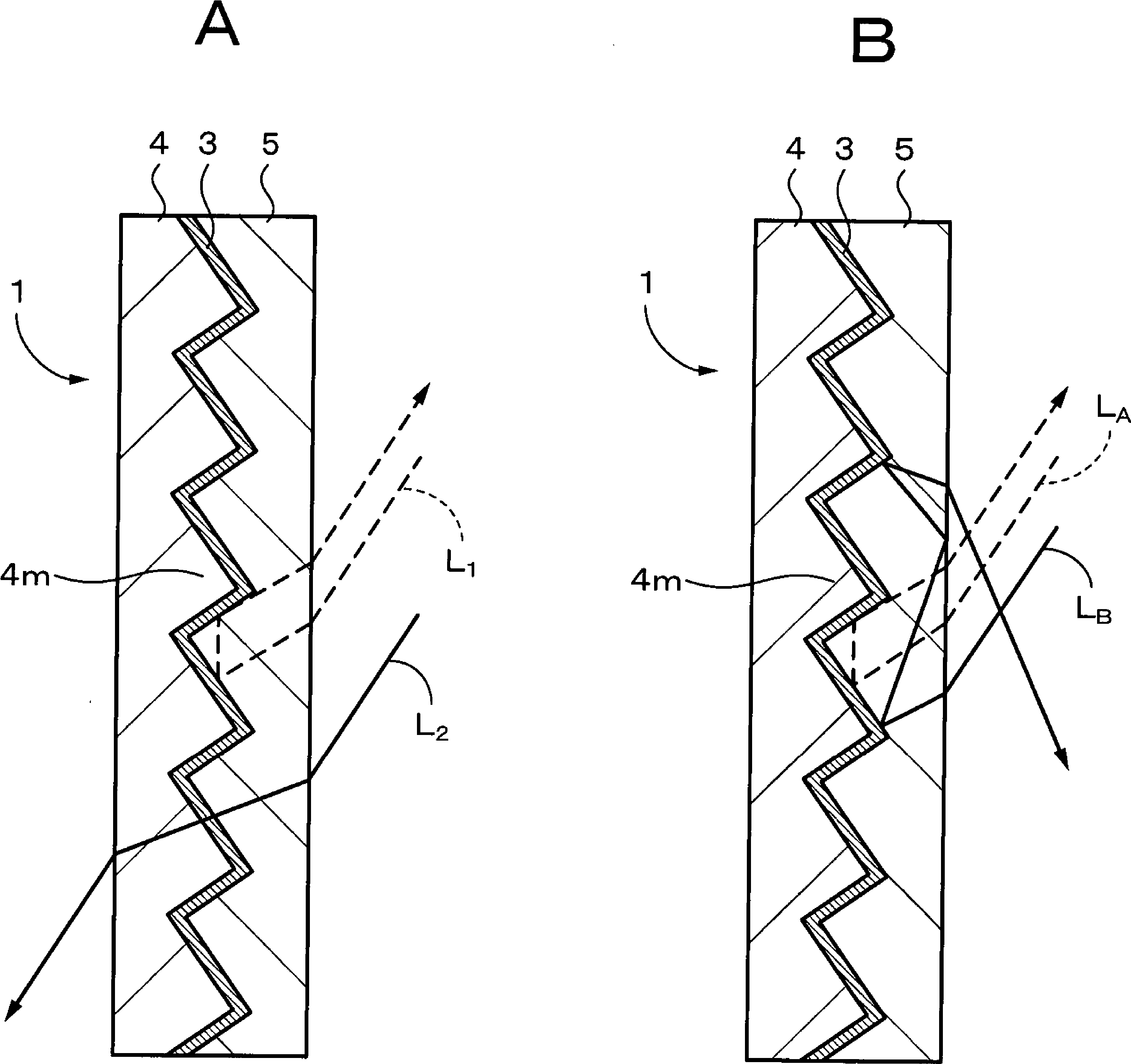

[0064] figure 1 A is a cross-sectional view showing an example of the configuration of the optical film according to the first embodiment. figure 1 B is a cross-sectional view illustrating an example in which the optical film according to the first embodiment is adhered to an attachment object. The optical film 1 as an optical body is an optical film having so-called retroreflection performance. like figure 1 As shown in A, this optical film 1 includes an optical layer 2 having a concavo-convex interface inside, and a wavelength selective reflection layer 3 provided on the interface of the optical layer 2 . The optical layer 2 includes a first optical layer 4 having a concave-convex first surface, and a second optical layer 5 having a concave-convex second surface. The interface inside the optical layer is formed by the concavo-convex first surface and the second surface arranged to face each other. Specifically, the optical film 1 inc...

no. 2 Embodiment approach >

[0208] Figure 20 It is a plan view which shows an example of the shape of the uneven|corrugated surface of the 1st optical layer of the optical film which concerns on 2nd Embodiment. In the second embodiment, two directions obliquely intersecting in the concave-convex surface of the first optical layer 4 are referred to as a first direction D1 and a second direction D2. When the first optical layer 4 has a rectangular shape having two sets of sides facing each other, it is preferable that the first direction D1 is the extending direction of one set of the two sets of sides. The first optical layer 4 has a short-side direction D W and the long side direction D L In the case of a strip shape or a rectangular shape, it is preferable that the first direction D1 is the short side direction D of the first optical layer 4 W .

[0209] The optical film related to the second embodiment is as follows Figure 20 As shown, the first embodiment differs from the first embodiment in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com