Side pressure resistant submarine optical fiber cable core

A submarine optical cable, anti-lateral pressure technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of reducing the water tightness of optical fiber units, compressing optical fibers, etc., and achieve the effect of improving tensile and lateral pressure resistance and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

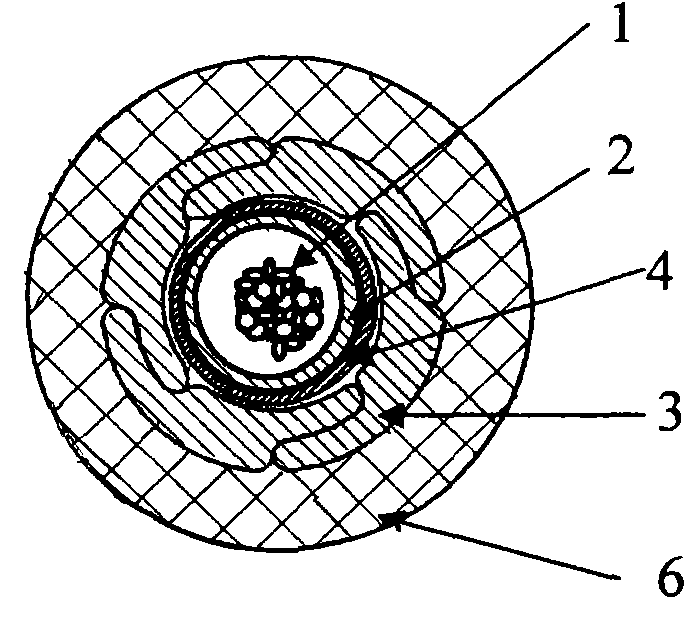

[0010] Embodiment 1, a kind of anti-lateral pressure submarine cable core, see figure 1 , the optical fiber unit protection tube (2) containing the optical fiber (1) and water-blocking fiber paste is longitudinally wrapped with a layer of copper tape (4) for detecting DC resistance, and an anti-corrosion resistance composed of 4 stainless steel special-shaped wires is twisted on the outside. The housing (3) is side-pressed, and a high-density polyethylene insulating sheath layer (6) is extruded on the outermost side. This cable core is mainly used for anti-side pressure non-repeater amplifier submarine optical cable that does not require power feeding but requires detection of insulation resistance.

Embodiment 2

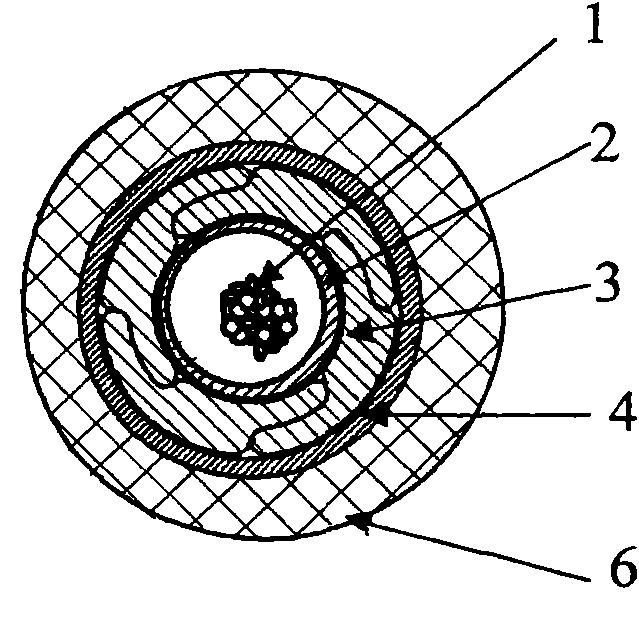

[0011] Embodiment 2, a kind of anti-lateral pressure submarine cable core, see figure 2 , is to directly twist 4 stainless steel special-shaped wires outside the optical fiber unit (1, 2) to form a lateral pressure-resistant shell (3), and cover the feed copper pipe (4) and high-density polyethylene on the outside in turn from the inside to the outside The insulating sheath layer (6), all gaps are filled with water-blocking materials. The cable core is used for side-pressure-resistant submarine cables with relay amplifiers that need to be fed.

Embodiment 3

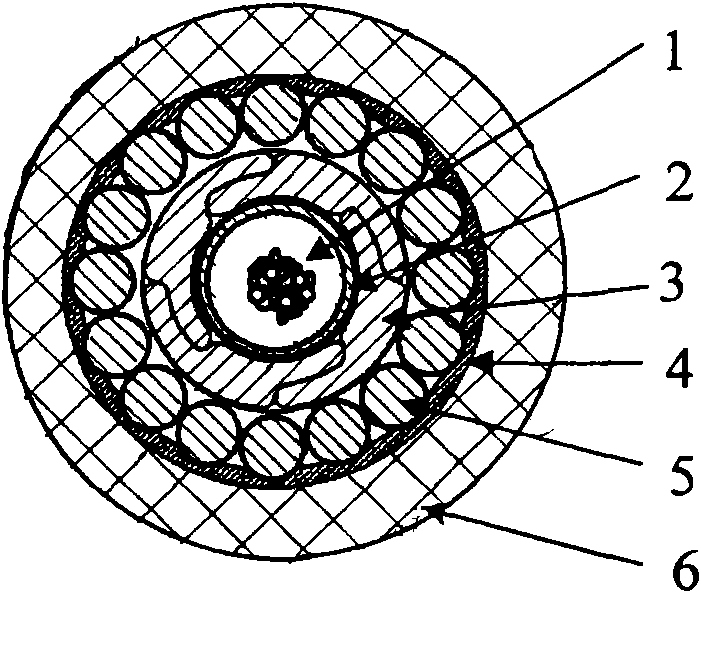

[0012] Embodiment 3, a kind of anti-lateral pressure submarine cable core, see image 3 , which is an anti-lateral pressure shell (3) composed of 4 stainless steel special-shaped wires twisted outside the optical fiber unit (1, 2), and the outer side is covered with inner armored galvanized steel wire (5) and longitudinally wrapped in turn from the inside to the outside. Feed copper pipe (4) and extruded high-density polyethylene insulating sheath (6). The cable core is mainly used to enhance the tensile strength. Relay amplifiers are required for power feeding, which can be directly laid on submarine optical cables in deep sea .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com