Process for preparing cladding layer on surface of copper base body by utilizing high-speed laser cladding technology

A technology of laser cladding and cladding layer, applied in the direction of metal material coating process, coating, etc., can solve the problems of big difference in performance, large spot reflectivity, unable to form molten pool, etc., and achieve the effect of good metallurgical combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment relates to the process of preparing a cladding layer on the surface of a copper substrate by using high-speed laser cladding technology.

[0047] A cladding layer prepared on the surface of a copper substrate by using high-speed laser cladding technology, the cladding alloy material includes the following raw material components in mass percentage: Ni: 15% to 20%; Cr: 5% to 10% ;Fe: 15%-28%; C: 6-9%; Co: 9-20%; B: 2-4%; Si: 3.0-5.0%; P: 2%; W: 3%-4%; Wherein, the particle size of the cladding alloy material is 200-800 mesh.

[0048] The raw material formula of alloy material in each embodiment is as shown in the table below:

[0049] Example 1.1 Example 1.2 Example 1.3 Ni 12g 16.44g 20g Cr 5.2g 8g 10g Fe 16.8g 23g 28g C 5.4g 7.4g 9g co 12g 16.5g 19.96g B 2g 3g 4g Si 3g 4g 5g P 1.2g 1.66g 2.04g W 2.4g 3g 4g

[0050] The alloy material of each embodiment in the above t...

Embodiment 2

[0088] This embodiment relates to the detection of the performance of the cladding layer prepared in the first embodiment.

[0089] The cladding alloy materials in the proportions of Examples 1.1-1.3 were prepared under the process of the present invention to obtain samples.

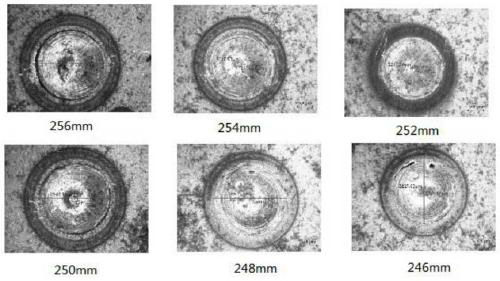

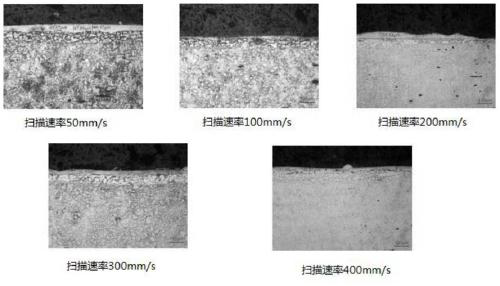

[0090] (1) Detection of phase properties

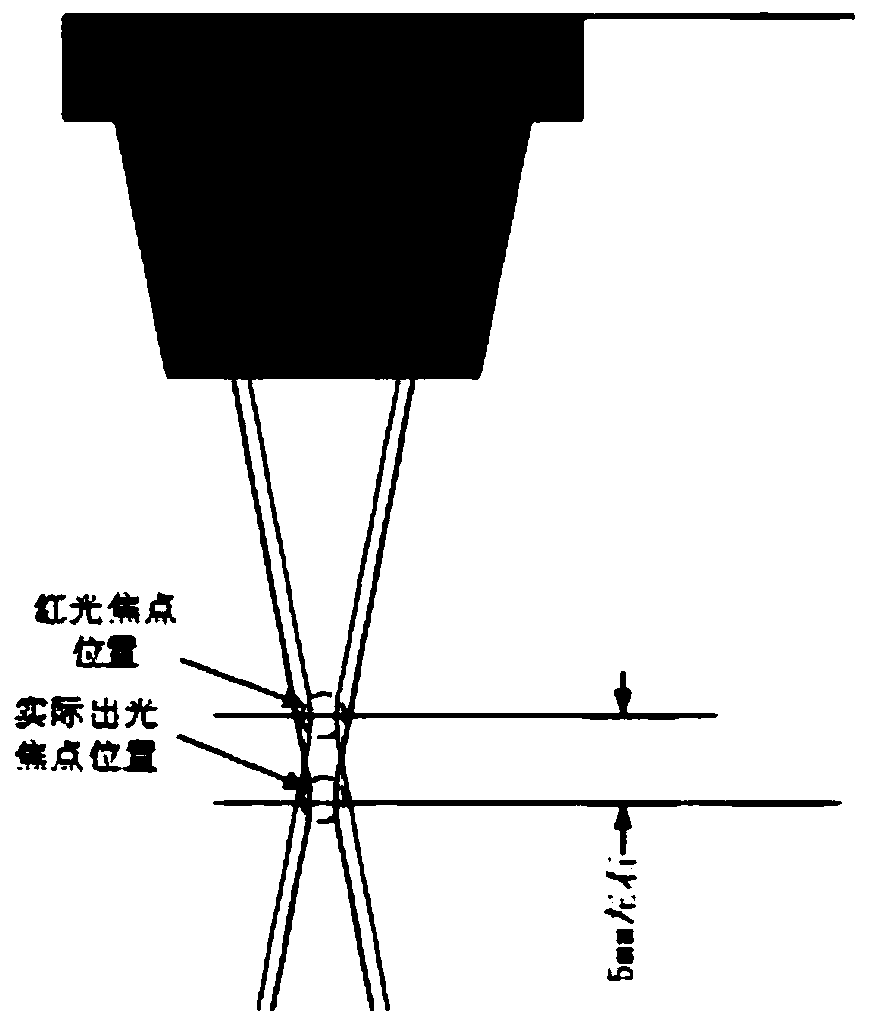

[0091] A number of samples were randomly selected from the prepared samples, and the image analysis of the high-speed laser cladding layer of each sample was carried out by using the DX-2700X camera diffractometer, and the following results were obtained: Figure 8 Metallographic diagram of cladding layer cross-section shown in (a); Figure 8(a) It can be seen that the upper part is the cladding layer, and the lower part is the mold copper plate, and the cladding layer and the crystallizer copper plate have a clear interface. At the interface, the substrate and the cladding layer are metallurgically bonded. The thickness of the cladding layer is about 0.4mm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com