Beam specimen casting die, and method for testing mechanical performances of beam specimen

A technology for pouring molds and test pieces, which is applied in the field of concrete mechanical performance testing, can solve the problems of increasing production and processing costs, time-consuming and labor-intensive wooden molds, waste of wood resources, etc., and achieves quality assurance, simple production and assembly, and increased rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

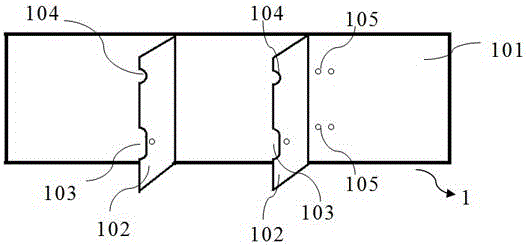

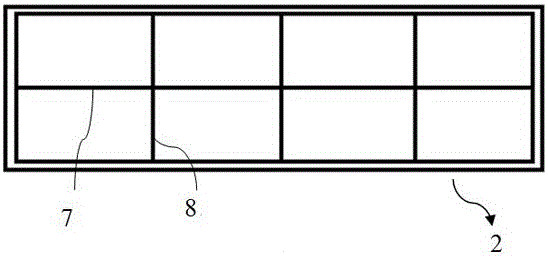

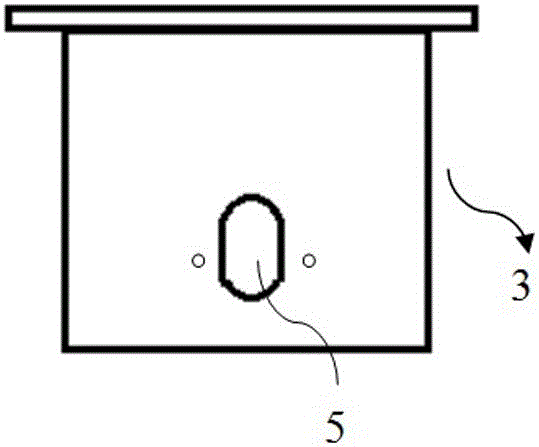

[0035] Such as Figure 1-Figure 7 As shown, the pouring mold for the beam-type test piece in this embodiment includes a bottom plate 2, two side plates 1 and two adjustment plates 3, the two side plates 1 are arranged in parallel on both sides of the bottom plate 2, and the adjustment plates 3 are arranged in parallel on the two sides. between plates 1. The side plate 1 includes a panel 101 and two connecting plates 102 vertically connected to the panel 101. The lower end of the connecting plate 102 has a first through hole 103, and the upper end of the connecting plate has a second through hole 104. The connecting plates 102 of the two side plates 1 are connected to each other. In relative contact, a cavity 6 is formed, and two pouring cavities 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com