Abrasion resistant fabric

A wear-resistant fabric and fabric technology, applied in the field of textile fabrics, can solve the problems of high price and poor weather resistance, and achieve the effects of low cost, improved tensile strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

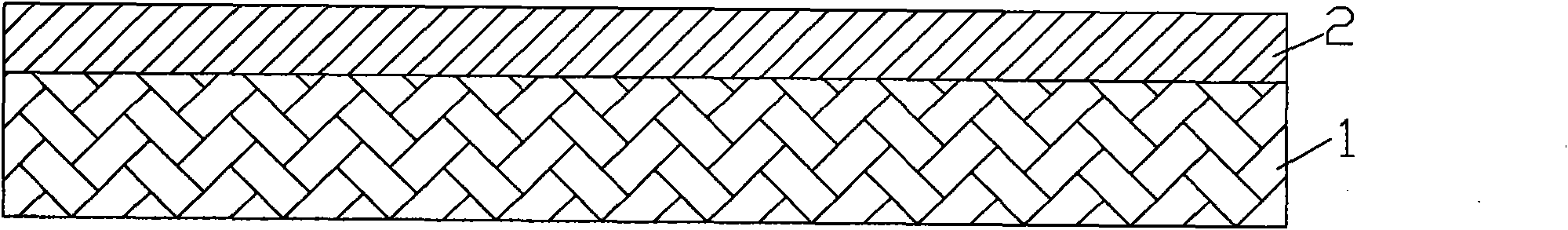

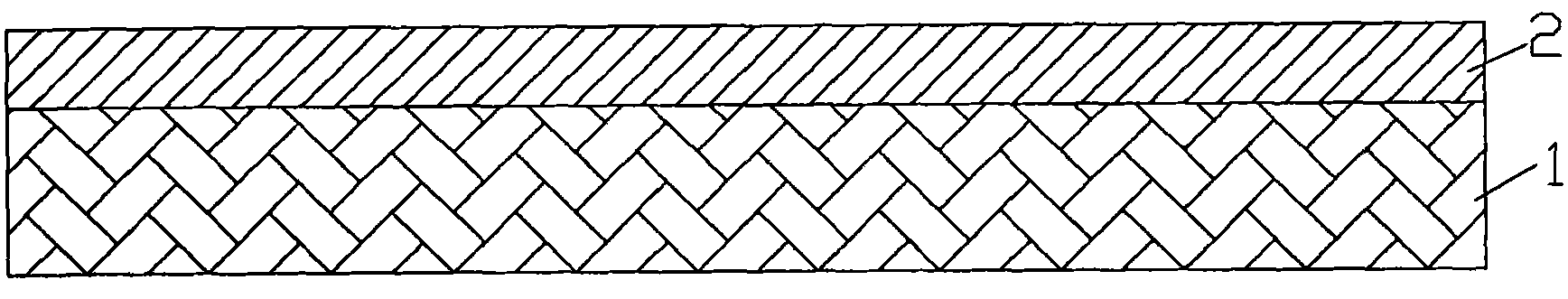

[0013] The present invention will now be described in further detail with reference to the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0014] like figure 1 As shown, a wear-resistant fabric includes a base fabric 1 interwoven with warp yarns and weft yarns. The base fabric 1 is blended with sea-island fibers and polyester fibers. The sea-island fibers have high coverage, soft hand feel, and good permeability. Moisture and breathability, while polyester fabric has good wrinkle resistance and shape retention, high strength, heat resistance, corrosion resistance, moth resistance and good light resistance, the sea island fiber accounts for 25-35% of the total weight of the fabric, The polyester fiber accounts for 65-75% of the total weight of the fabric.

[0015] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com