Itaconate/isoprene copolymer type biology base elastomer tread rubber and preparation method thereof

A technology of isoprene and itaconate, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of high energy consumption, pollution and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

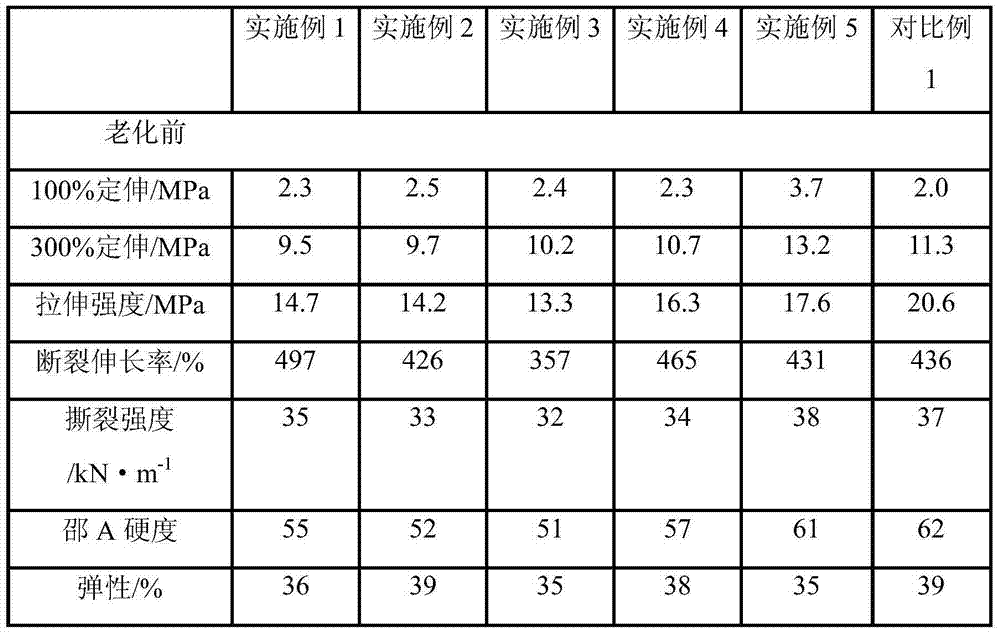

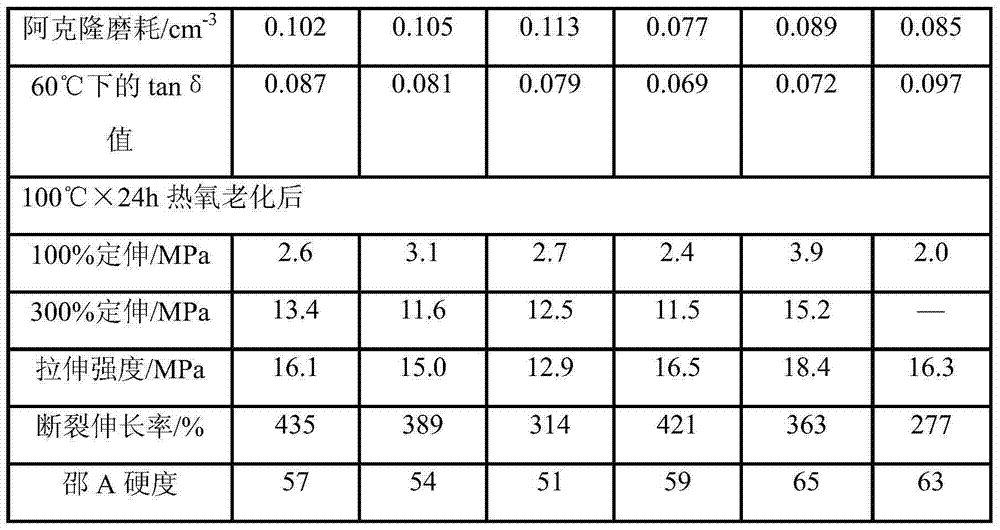

Examples

Embodiment 1

[0042] Dipropyl itaconate monomer was synthesized from itaconic acid and propanol, and then dipropyl itaconate / isoprene copolymer was prepared by emulsion polymerization of dipropyl itaconate monomer and isoprene. Itacon Dipropyl Ester / Isoprene Copolymer Bio-based Engineering Elastomer 100, Zinc Oxide 5, Stearic Acid 1, Antiaging Agent (4020) 1, Antiaging Agent (RD) 1, Silica (VN3) 60, Silane Coupling agent (Si69) 7, carbon black (N330) 5, sulfur 1.5, accelerator (CZ) 1, accelerator (NS) 1, paraffin wax 1.

[0043] Put the dipropyl itaconate / isoprene copolymer bio-based engineering elastomer on the open mixer for 3 minutes, add zinc oxide, stearic acid, and anti-aging agent and mix for 2 minutes, add white carbon black, silane coupling The agent was mixed for 7 minutes. Put one stage of masterbatch into the internal mixer for heat treatment for 8 minutes, the heat treatment temperature is 140°C, the rotor speed is 80r / min, take it out, and usually leave it for 2 hours to obta...

Embodiment 2

[0045] Dibutyl itaconate monomer was synthesized from itaconic acid and butanol, and then dibutyl itaconate / isoprene copolymer was prepared by emulsion polymerization of dibutyl itaconate monomer and isoprene. Itaconic dibutyl ester / isoprene copolymer bio-based engineering elastomer 100, zinc oxide 5, stearic acid 1, antioxidant (4020) 1, antioxidant (RD) 1, white carbon black (VN3) 60, silane Coupling agent (Si69) 7, carbon black (N330) 5, sulfur 1.5, accelerator (CZ) 1, accelerator (NS) 1, paraffin wax 1.

[0046] Put the dibutyl itaconate / isoprene copolymer bio-based engineering elastomer on the open mixer for 3 minutes, add zinc oxide, stearic acid, and anti-aging agent and mix for 2 minutes, add white carbon black, silane coupling The agent was mixed for 7 minutes. Put one stage of masterbatch into the internal mixer for heat treatment for 8 minutes, the heat treatment temperature is 140°C, the rotor speed is 80r / min, take it out, and usually leave it for 2 hours to obta...

Embodiment 3

[0048] Dioctyl itaconate monomer was synthesized from itaconic acid and octanol, and then dioctyl itaconate / isoprene copolymer was prepared by emulsion polymerization of dioctyl itaconate monomer and isoprene. Itaconate / isoprene copolymer bio-based engineering elastomer 100, zinc oxide 5, stearic acid 1, antioxidant (4020) 1, antioxidant (RD) 1, white carbon black (VN3) 60, silane Coupling agent (Si69) 7, carbon black (N330) 5, sulfur 1.5, accelerator (CZ) 1, accelerator (NS) 1, paraffin wax 1.

[0049] Put the dioctyl itaconate / isoprene copolymer bio-based engineering elastomer into the open mixer for 3 minutes, add zinc oxide, stearic acid, and anti-aging agent and mix for 2 minutes, add white carbon black, silane coupling The agent was mixed for 7 minutes. Put one stage of masterbatch into the internal mixer for heat treatment for 8 minutes, the heat treatment temperature is 140°C, the rotor speed is 80r / min, take it out, and usually leave it for 2 hours to obtain the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com