Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

A glass fiber, ablation-resistant technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as human body or facility injury, and achieve good heat resistance, low thermal conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

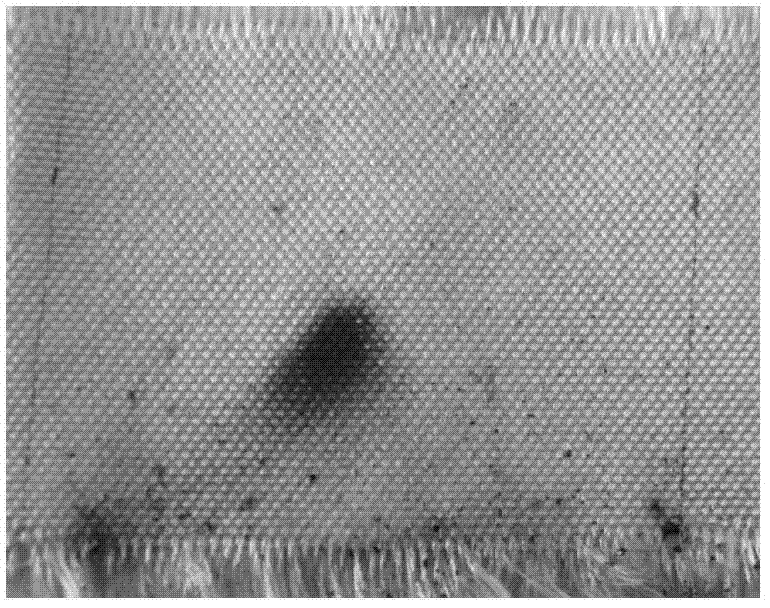

Image

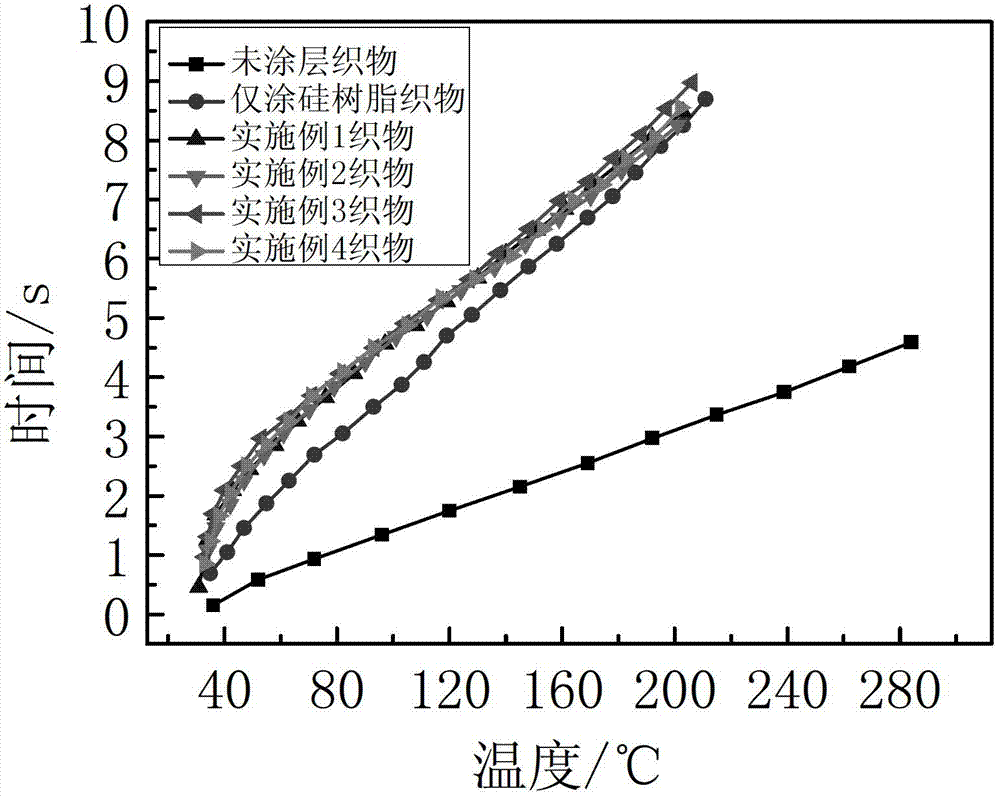

Examples

Embodiment 1

[0030] 1. Glass fiber fabric pretreatment: Use absolute ethanol to wipe the surface of the glass fiber fabric; in order to ensure that the fabric is more firmly bonded to the coating and no air bubbles are generated during the drying process, pre-soak benzyl silicone resin solution, soak The rolling method is one dipping and one rolling, the liquid rolling rate is 50%, and then baked at 100°C for 10 minutes.

[0031] The benzyl silicone resin solution solute is benzyl silicone resin, the solvent is xylene and toluene, and the mass ratio of solvent and solute is 1:1.

[0032] 2. Coating and drying of glass fiber fabric: Scrape-coat the composite silicone resin coating liquid on the pretreated glass fiber fabric, adopt double-sided coating method, the coating thickness on both sides of the fabric is the same, and the coating The thickness is controlled at 60 μm.

[0033] After coating the front side of the fabric, pre-bake at 80°C for 15 minutes, and then dry at 100°C for 30 minu...

Embodiment 2

[0039] 1. Glass fiber fabric pretreatment: Use absolute ethanol to wipe the surface of the glass fiber fabric; in order to ensure that the fabric is more firmly bonded to the coating and no air bubbles are generated during the drying process, pre-soak benzyl silicone resin solution, soak The rolling method is one dipping and one rolling, the liquid rolling rate is 50%, and then baked at 100°C for 15 minutes.

[0040] 2. Coating and drying of glass fiber fabric: Scrape-coat the composite silicone resin coating liquid on the pretreated glass fiber fabric, adopt double-sided coating method, the coating thickness on both sides of the fabric is the same, and the coating The thickness is controlled at 50 μm.

[0041] After coating the front side of the fabric, pre-bake at 80°C for 15 minutes, and then dry at 100°C for 30 minutes; then coat the reverse side of the fabric, and the drying process is as follows: The fabric coated on both sides was further baked at 200° C. for 40 minute...

Embodiment 3

[0045] 1. Glass fiber fabric pretreatment: Use absolute ethanol to wipe the surface of the glass fiber fabric; in order to ensure that the fabric is more firmly bonded to the coating and no air bubbles are generated during the drying process, pre-soak benzyl silicone resin solution, soak The rolling method is one dipping and one rolling, the liquid rolling rate is 50%, and then baked at 100°C for 15 minutes.

[0046] Coating and drying of glass fiber fabric: Scrape-coat the composite organic resin coating solution on the pretreated glass fiber fabric, adopt double-sided coating method, the coating thickness on both sides of the fabric is the same, and the coating thickness is controlled at 80 μm.

[0047] After coating the front side of the fabric, pre-bake at 80°C for 15 minutes, and then dry at 100°C for 30 minutes; then coat the reverse side of the fabric, and the drying process is as follows: The fabric coated on both sides was further baked at 210° C. for 30 minutes. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com