High hardness butadiene-acrylonitrile rubber and preparation method thereof

A technology of nitrile rubber and high hardness, applied in the field of high hardness nitrile rubber and its preparation, can solve the problems of difficult to guarantee the processing size, the repairing layer is heated and softened, etc. The effect of oil resistance and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

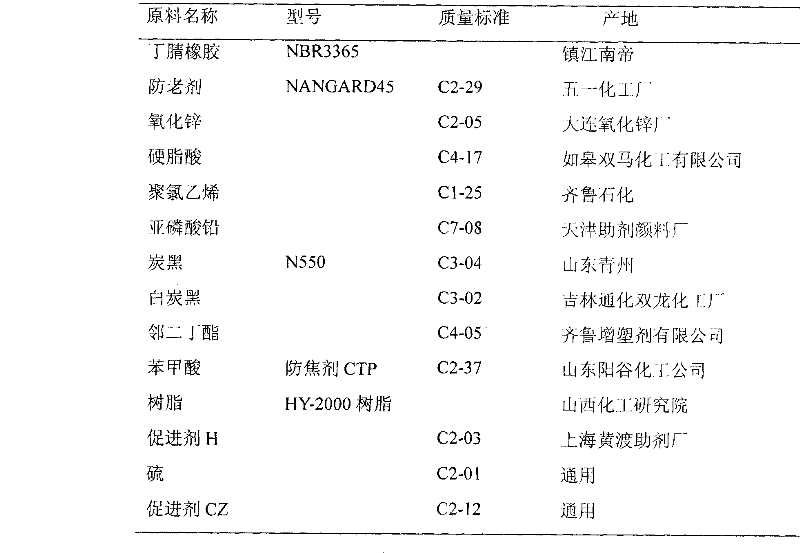

[0018] The formula of masterbatch of the present invention is as follows:

[0019] Raw material name

Actual formula (unit: gram)

weighing tool

NBR3365

Antiager D

30000±100

600±5

platform scale

pallet scale

PVC

Lead phosphite

N550 carbon black

Silica

o-dibutyl ester

Anti-scorch agent CTP

1500±5

300±5

9000±100

300±5

9000±100

10500±100

3000±5

150±5

pallet scale

pallet scale

platform scale

pallet scale

platform scale

platform scale

platform scale

pallet scale

[0021] The masterbatch mixing process is as follows (using K4 internal mixer):

[0022] serial number

Adding order

Speed (rev / min)

time (minutes)

Glue temperature(℃)

1

2

3

4

5

Add raw rubber, polyvinyl chloride and small ingredients ...

Embodiment 2

[0031] Take the raw materials according to the following weight ratio:

[0032] 80kg of nitrile rubber, 1kg of antioxidant, 2kg of zinc oxide, 0.5kg of stearic acid, 20kg of polyvinyl chloride, 0.5kg of lead phosphite, 20kg of carbon black, 25kg of white carbon black, 6kg of o-dibutyl ester, 0.2kg of benzoic acid, Resin 40kg, Accelerator H3kg, Accelerator CZ0.5kg, Sulfur 1kg.

[0033] (1) Mixing of masterbatch: mixing nitrile rubber and polyvinyl chloride with an internal mixer, first wrapping nitrile rubber sheets on rolls, and then adding zinc oxide, after mixing, in a roller temperature of 30 ℃ Under conditions, add polyvinyl chloride, refining for 10 minutes, then add carbon black, white carbon black, o-dibutyl ester, anti-aging agent, stearic acid, lead phosphite, benzoic acid, in the mixing room temperature of 100 ℃ Refining for 1 hour under the same conditions, plasticizing at a constant temperature for 2 hours at 155°C, and then discharging at 150°C to make a masterba...

Embodiment 3

[0036] Take the raw materials according to the following weight ratio:

[0037] 120kg of nitrile rubber, 4kg of antioxidant, 7kg of zinc oxide, 2kg of stearic acid, 40kg of polyvinyl chloride, 2kg of lead phosphite, 40kg of carbon black, 50kg of white carbon black, 12kg of o-dibutyl ester, 1kg of benzoic acid, 60kg of resin, Accelerator H8kg, accelerator CZ3kg, sulfur 4kg.

[0038] (1) Mixing of masterbatch rubber: mixing nitrile rubber and polyvinyl chloride with an internal mixer, first wrapping the nitrile rubber sheet on a roll, and then adding zinc oxide, after mixing, in a roller temperature of 50 ℃ Under conditions, add polyvinyl chloride, refine for 30 minutes, then add carbon black, white carbon black, o-dibutyl ester, anti-aging agent, stearic acid, lead phosphite, benzoic acid, in the mixing room temperature of 110 ℃ Refining for 3 hours under the same conditions, plasticizing at a constant temperature for 4 hours at 170°C, and then discharging at 170°C to make a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com