Superfine fiber polyurethane synthesis leather and preparation method thereof

A superfine fiber, polyurethane technology, applied in fiber processing, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of strong rigidity, poor rigidity, and uneven leather.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

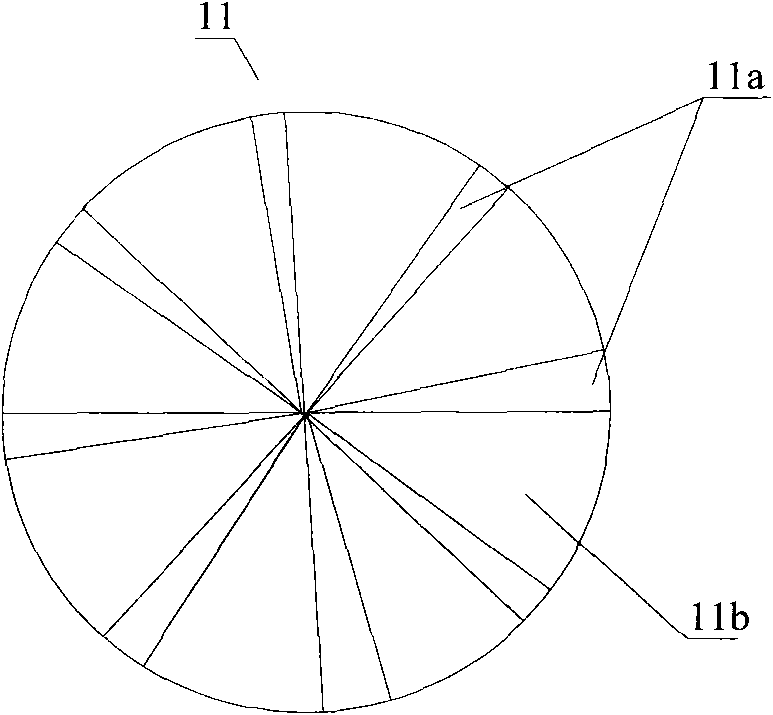

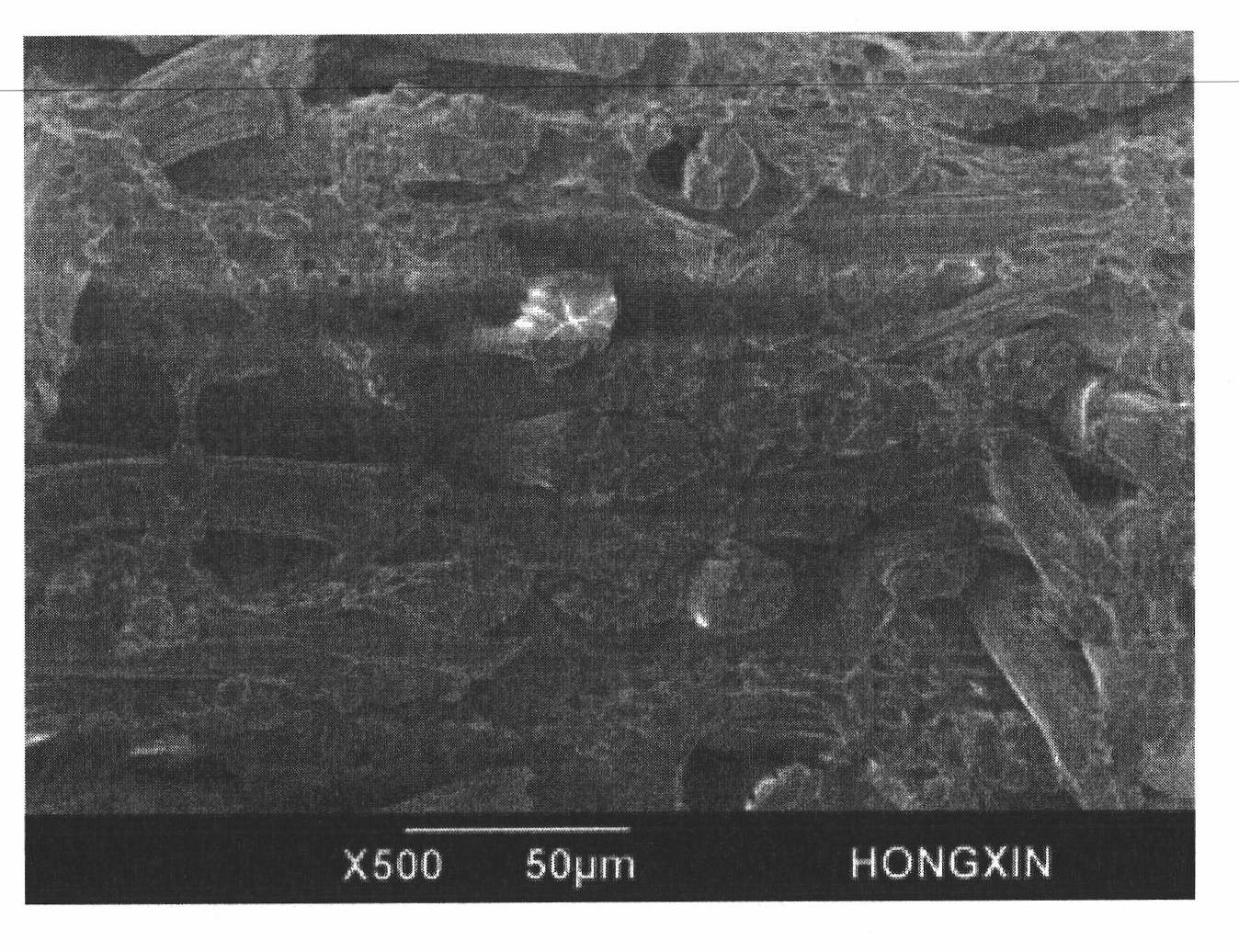

[0053] 1. Preparation of composite fibers

[0054] Take 25 parts of polyethylene terephthalate slices and put them into a polyester spinning screw extruder to melt and knead at 280 °C; take 75 parts of polycaprolactam chips into a polyamide spinning screw extruder to melt at 280 °C kneading. The mixed products of two screw extruders were subjected to figure 2 The 8-split spinneret shown is extruded, and the following examples all use this spinneret extrusion molding to obtain 8-split as-spun fibers, and the as-spun fibers are filled between the fiber skeleton and the fiber skeleton. The lobes between the fibers are composed of polyethylene terephthalate and the lobes are polycaprolactam;

[0055] The as-spun fibers were drawn sequentially by 1.8 times and 1.7 times, oiled with 4wt% silicone oil, and heat-set at 70°C to obtain composite fibers, which were then cut into 50mm composite short fibers.

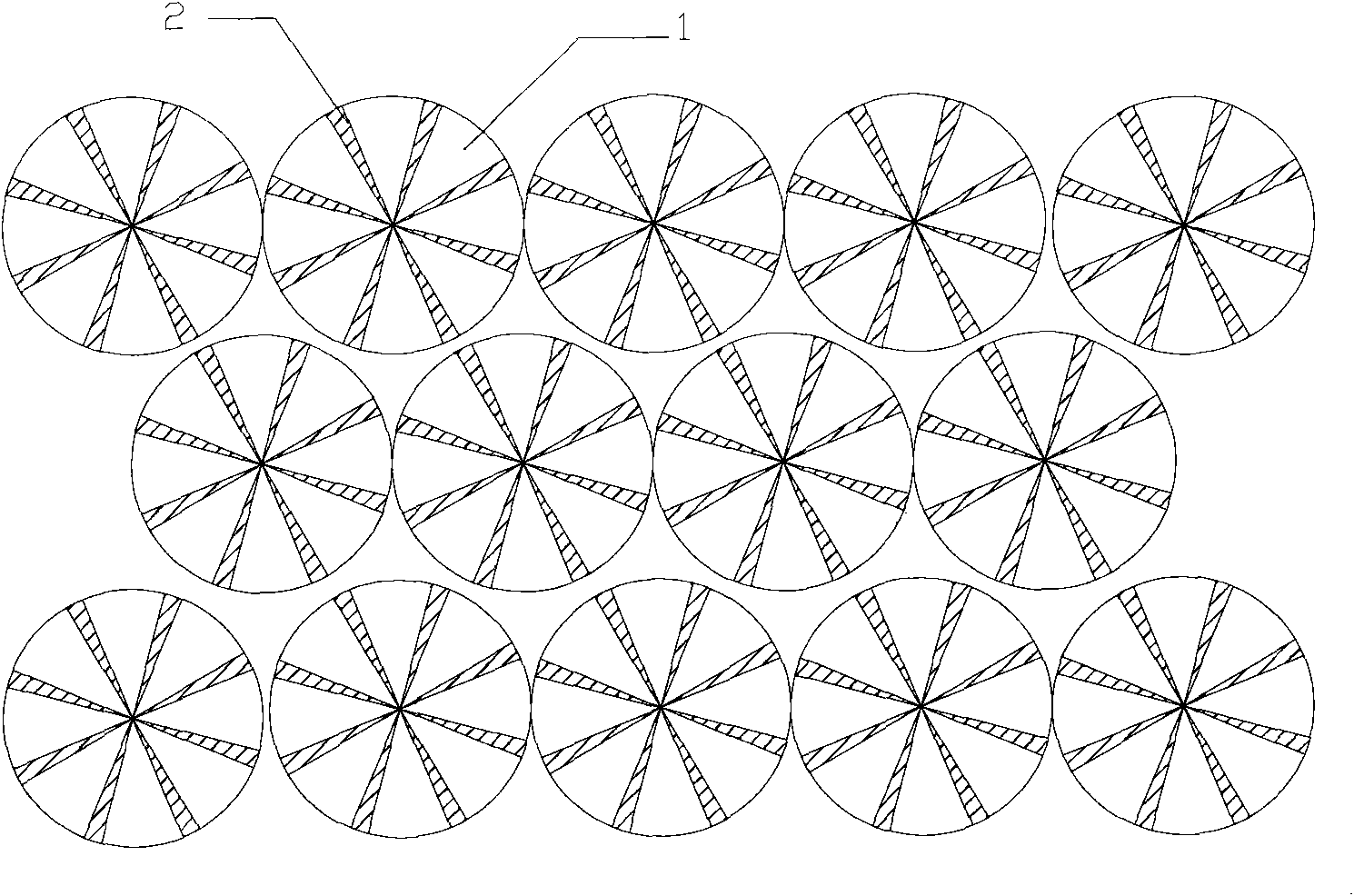

[0056] 2. Preparation of non-woven fabric:

[0057] Unpack the composite s...

Embodiment 2

[0066] 1. Preparation of composite fibers

[0067] In this example, when preparing composite fibers, the weight ratio of polyethylene terephthalate: polycaprolactam is 75:25; wherein, polyethylene terephthalate forms the split part, and polycaprolactam forms the skeleton part; other The spinning process was the same as in Example 1 to obtain composite fibers.

[0068] 2. Preparation of non-woven fabrics

[0069] Get described composite fiber unpacking, carding, acupuncture to make density 0.23g / cm 3 , Gram weight is 525g / cm 2 of non-woven fabrics.

[0070] 3. Impregnated non-woven fabric

[0071] The PVA dipping solution comprises by weight: 3% polyvinyl alcohol and the remainder water;

[0072] Polyurethane impregnation liquid comprises by weight: 20% polyurethane resin P-138 (Shandong Yutian chemical company provides), 2.8% ammonium lauryl sulfate and balance DMF for wet-process synthetic leather;

[0073] The coagulation liquid comprises by weight: 39% dimethylformami...

Embodiment 3

[0078] 1. Preparation of composite fibers

[0079] In this example, when preparing composite fibers, the weight ratio of polyethylene terephthalate: polycaprolactam is 70:30; wherein, polyethylene terephthalate forms the split part, and polycaprolactam forms the skeleton part; other The spinning process was the same as in Example 1 to obtain composite fibers.

[0080] 2. Preparation of non-woven fabrics

[0081] Get described composite fiber unpacking, carding, acupuncture to make density 0.24g / cm 3 , the weight is 536g / cm 2 of non-woven fabrics.

[0082] 3. Impregnated non-woven fabric

[0083] The PVA dipping liquid comprises by weight: 1.5% polyvinyl alcohol and the remainder water;

[0084]Polyurethane dipping solution comprises by weight: 15% polyurethane resin P-138 (provided by Shandong Yutian Chemical Co., Ltd.), 2.1% ammonium lauryl sulfate and remainder DMF for wet-process synthetic leather;

[0085] The coagulation liquid comprises by weight: 30% dimethylforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com