Micro-perforated panel sound absorbing body with rough surface modified micro-pores

A technology of micro-perforated panels and rough surfaces, applied to floors, building components, sound insulation, etc., can solve problems such as poor sound absorption effect and inconvenient adjustment of audio absorption bands, and achieve excellent sound absorption effect, simple structure, and good sound energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

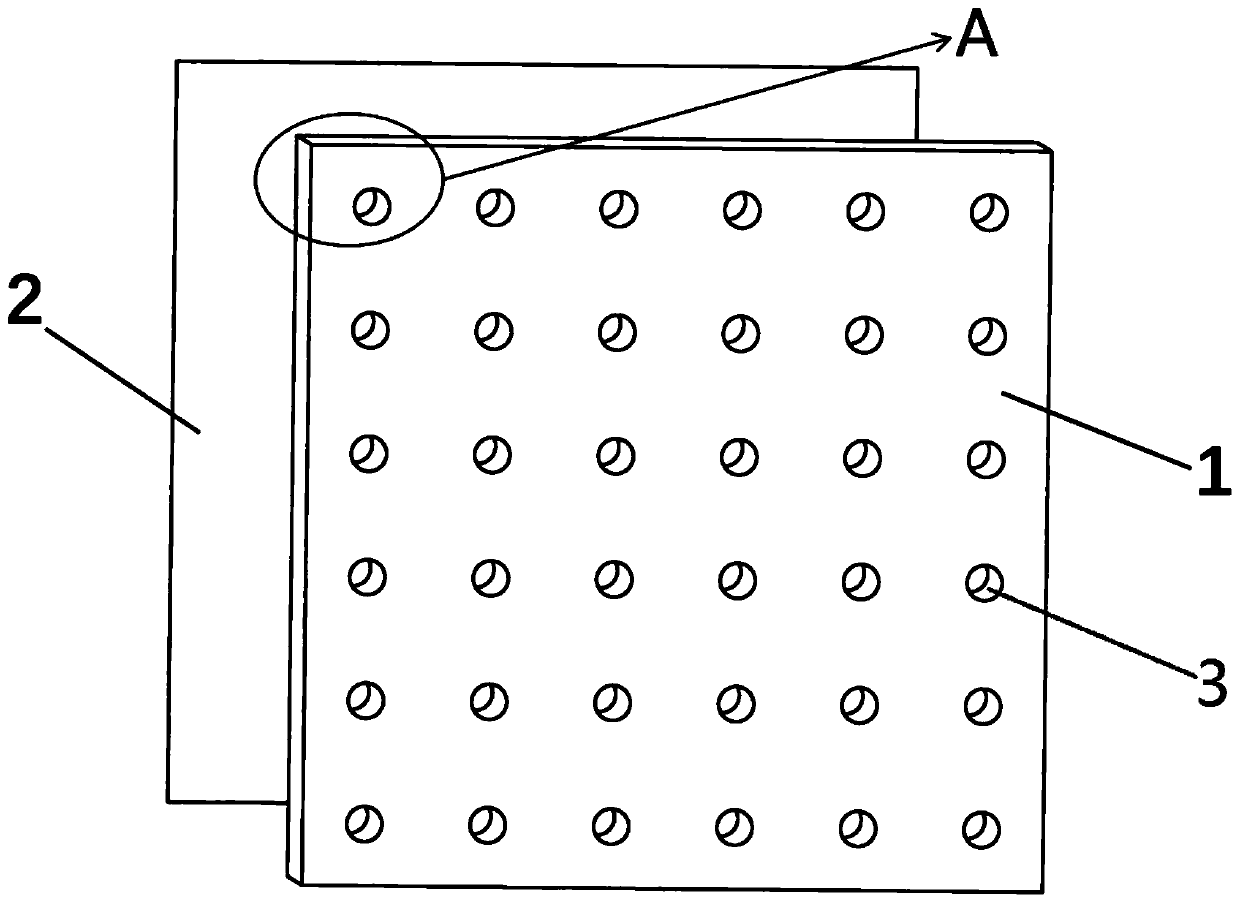

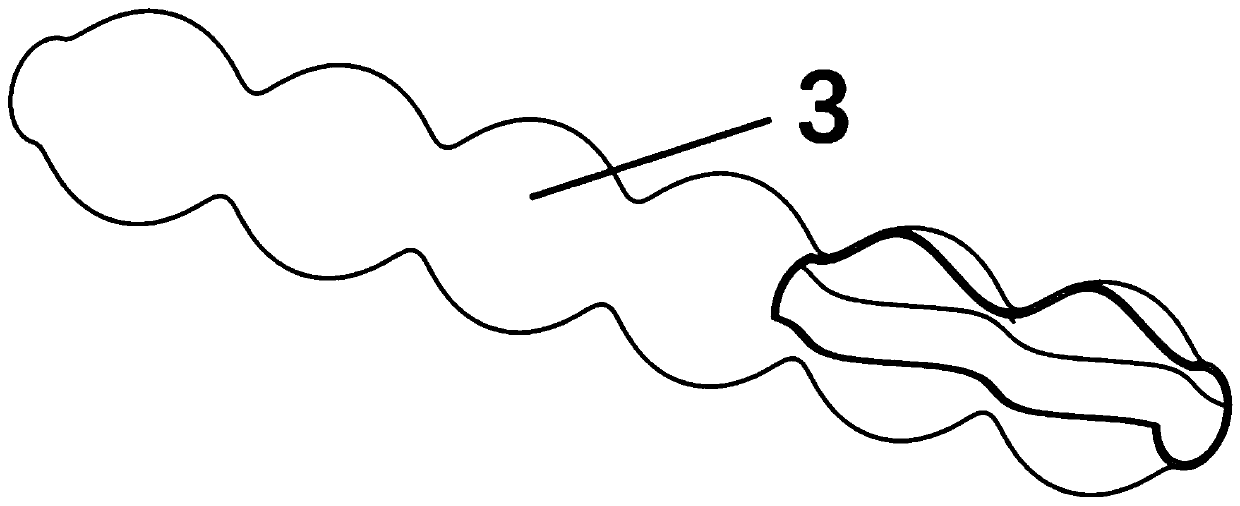

[0053] see figure 1 and figure 2, the sound absorber includes a perforated panel 1 and a rigid backing 2 . For the convenience of observing the variation of hole shape in this embodiment, figure 2 In the figure, the sound-absorbing hole 3 opened on the perforated panel 1 is enlarged, and the shape of the rough hole is observed.

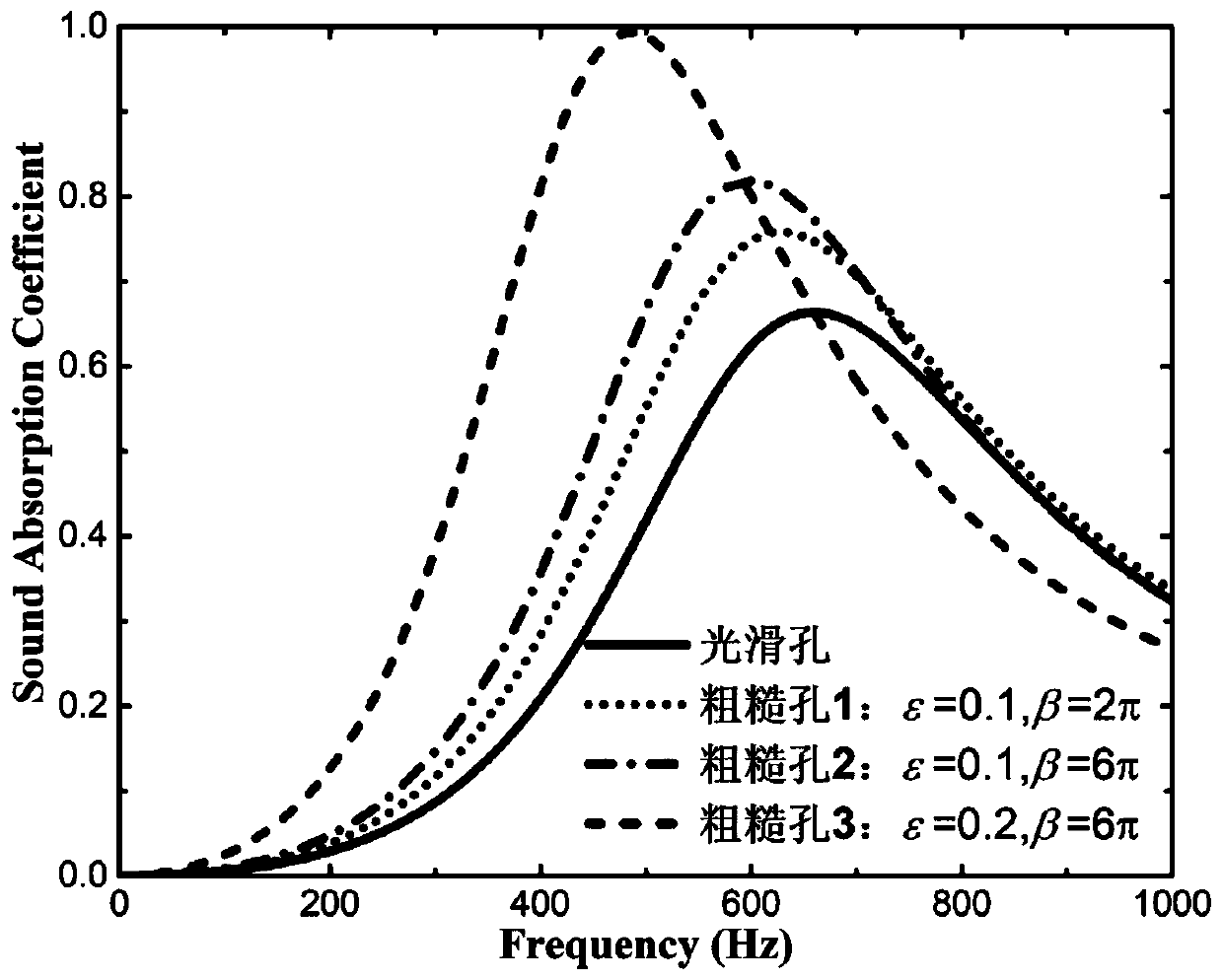

[0054] The thickness of the perforated panel 1 is 6 mm and the cavity thickness is 50 mm. The perforated panel 1 is evenly opened with a reference aperture r 0 The sound-absorbing hole is 0.5mm, so that the noise can enter the composite structure, so as to achieve the purpose of sound absorption. The sound-absorbing holes 3 are arranged in a square, the hole spacing is 3.545mm, and the perforation rate is 6.25%. The range of roughness factor ε is [0,0.2], and the range of β is [0,6π]. The cavity between the perforated panel 1 and the rigid backing 2 is filled or not filled with porous sound-absorbing material.

[0055] In this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com