Lightweight acoustical system

a technology of acoustic systems and acoustic barriers, applied in the field of acoustic systems, can solve the problems of rusting floor pans, moldy and odor formation in the underpads, etc., and achieve the effect of improving the acoustic barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

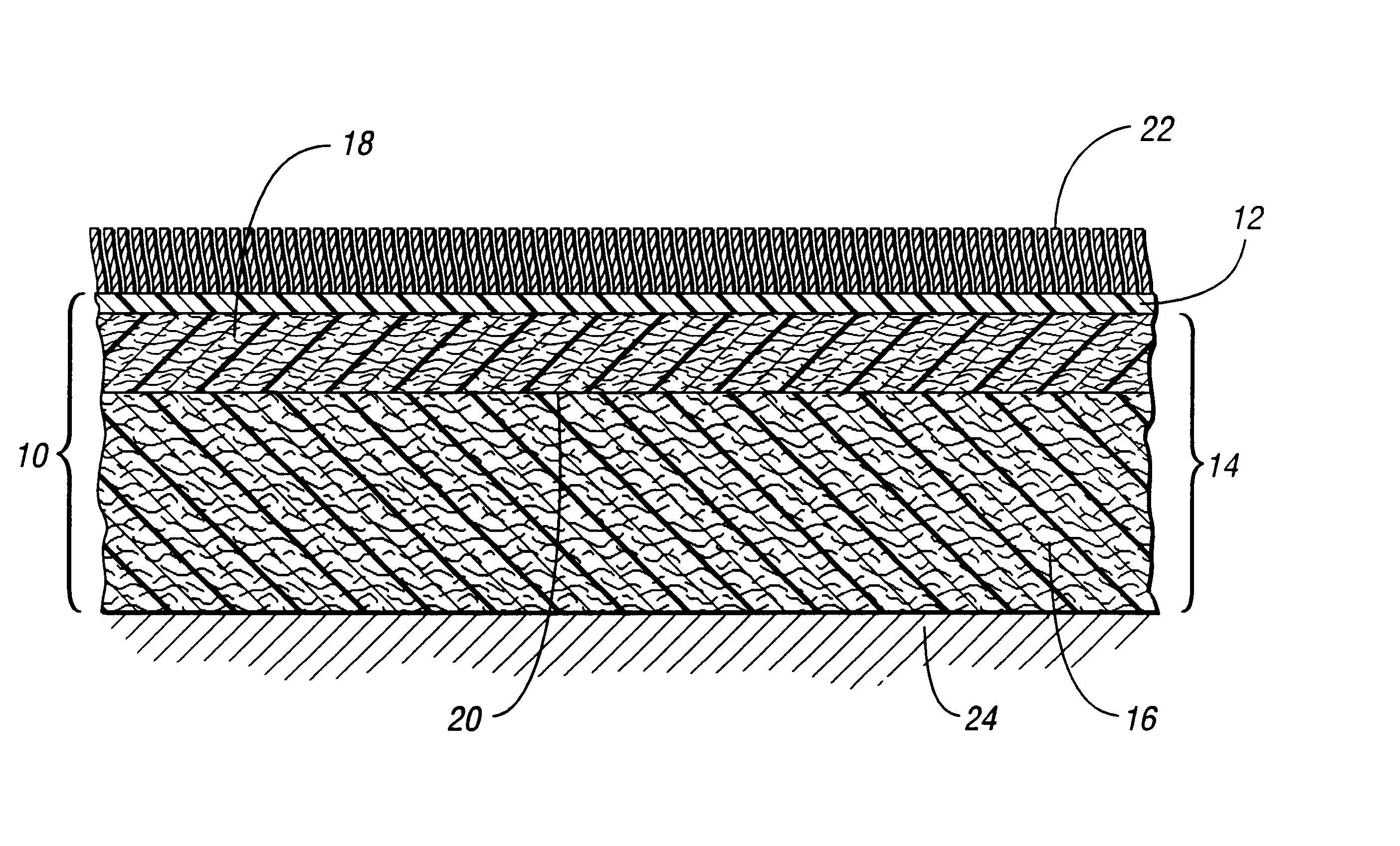

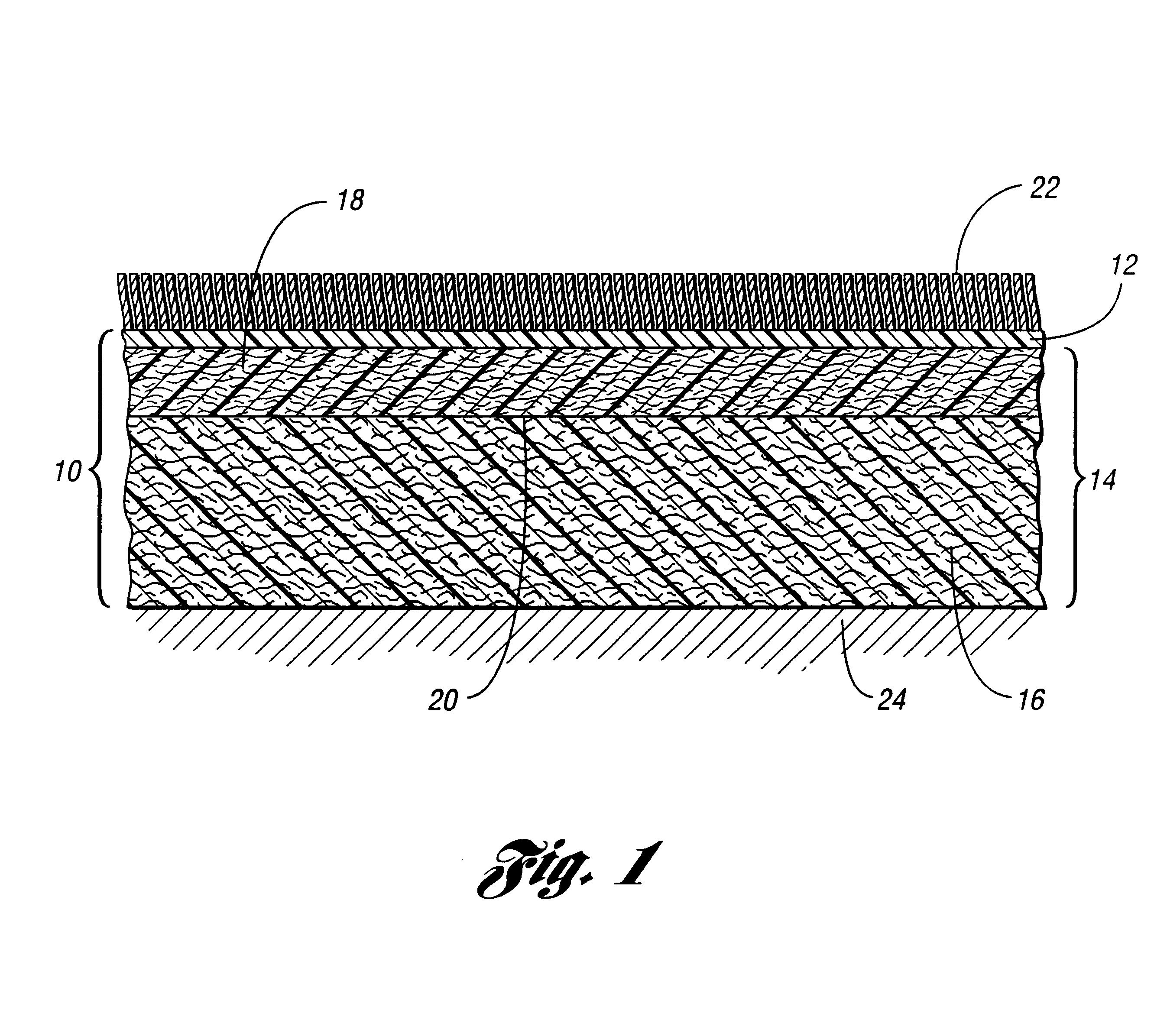

[0007]With reference to the drawing, the preferred embodiments of the present invention will be described. FIG. 1 shows a system 10 for inhibiting noise in a motor vehicle. The system 10 comprises a water-impermeable, relatively lightweight layer 12 and an underlayment 14.

[0008]The underlayment 14 is situated next to the impermeable layer 12, and includes a first or lofty fibrous layer 16 and a second or compressed fibrous layer 18. In a preferred embodiment, both of the layers 16 and 18 contain recycled, non-woven fibers which have been fluffed and combed to create a non-directional matrix or batt. Both layers 16 and 18 preferably have a surface density between about 500 grams per square meter and about 1400 grams per square meter.

[0009]A semi-permeable layer 20, comprising a fusible plastic film or cellulose filter scrim with a heat-settable adhesive, is preferably positioned between the layers 16 and 18 to provide additional airflow resistance and to help bond the layers together...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com