Thermally shrinkable polyolefin film, molded article using the film, thermally shrinkable label, and container

A technology for polyolefins and polyolefin resins, applied in the field of polyolefin heat shrinkable films, can solve the problem of not being able to obtain low temperature shrinkage characteristics, and achieve the effects of excellent heat shrinkage characteristics, excellent shrinkage processability and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

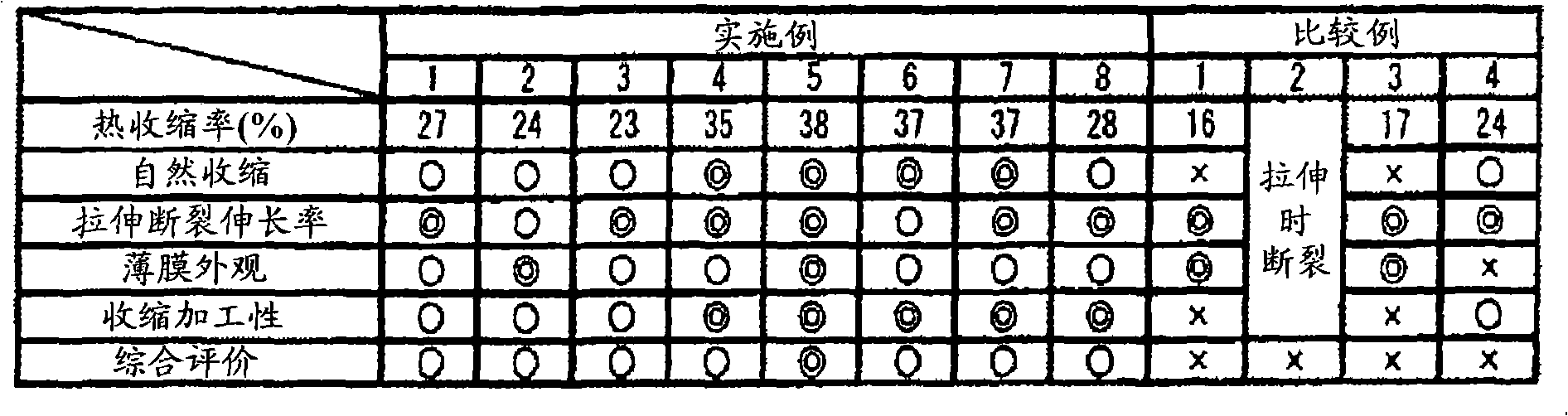

Embodiment 1

[0160] As shown in Table 1, 5 parts by mass of ethylene-methacrylic acid-glycidyl methacrylate copolymer (manufactured by Sumitomo Chemical Co., Ltd., trade name "Bondfirst 7M", Hereinafter abbreviated as "C-1") to obtain a resin composition, put the resin composition into a twin-screw extruder manufactured by Toshiba Machine Co., Ltd., melt and mix it at a set temperature of 200°C, and form a single-layer T Extruded from a die, wound up with a cast roll (Cayast Roll) at 50° C., cooled and solidified to obtain an unstretched sheet with a width of 300 mm and a thickness of 200 μm, the mixed resin composition comprises: 25% by mass of atactic polymer Propylene resin (manufactured by Japan Polyethylene Co., Ltd., trade name "WintecWFX4T", MFR7.0g / 10 minutes, hereinafter referred to as "A-1"), 40% by mass of polyethylene resin (manufactured by Ube Industries, Ltd., trade name "UMERIT 0540F", MFR4.0g / 10 minutes, hereinafter referred to as "A-2"), 15% by mass hydrogenated petroleum ...

Embodiment 2

[0163] As shown in Table 1, 10 parts by mass of ethylene-methacrylic acid copolymerization (manufactured by Mitsui DuPont Polymer Chemicals Co., Ltd., trade name "Elvaloy 1126AC", MFR0.6g / 10 minutes, hereinafter abbreviated as "C-2"), except that heat shrinkability was obtained in the same manner as in Example 1. film. Table 2 shows the evaluation results of the obtained film.

Embodiment 3

[0165] As shown in Table 1, the composition is A-1: 20% by mass, A-2: 20% by mass, ethylene-vinyl acetate copolymer (manufactured by Mitsui DuPont Polymer Chemicals Co., Ltd., trade name "Evaflex EV560") relative to 100 parts by mass. ", ethylene content rate 86% by mass, MFR3.5g / 10min, hereinafter referred to as "A-4"): 35% by mass, B-1: 25% by mass of mixed resin, adding 30 parts by mass of ethylene-vinyl acetate copolymer (manufactured by Mitsui DuPont Polymer Chemicals Co., Ltd., trade name "EvaflexEV45LX", ethylene content rate 55% by mass, MFR 2.5g / 10 minutes, hereinafter referred to as "C-3"), except that, the same as Example 1 A heat-shrinkable film was obtained in the same manner. Table 2 shows the evaluation results of the obtained film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com