Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "No pitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

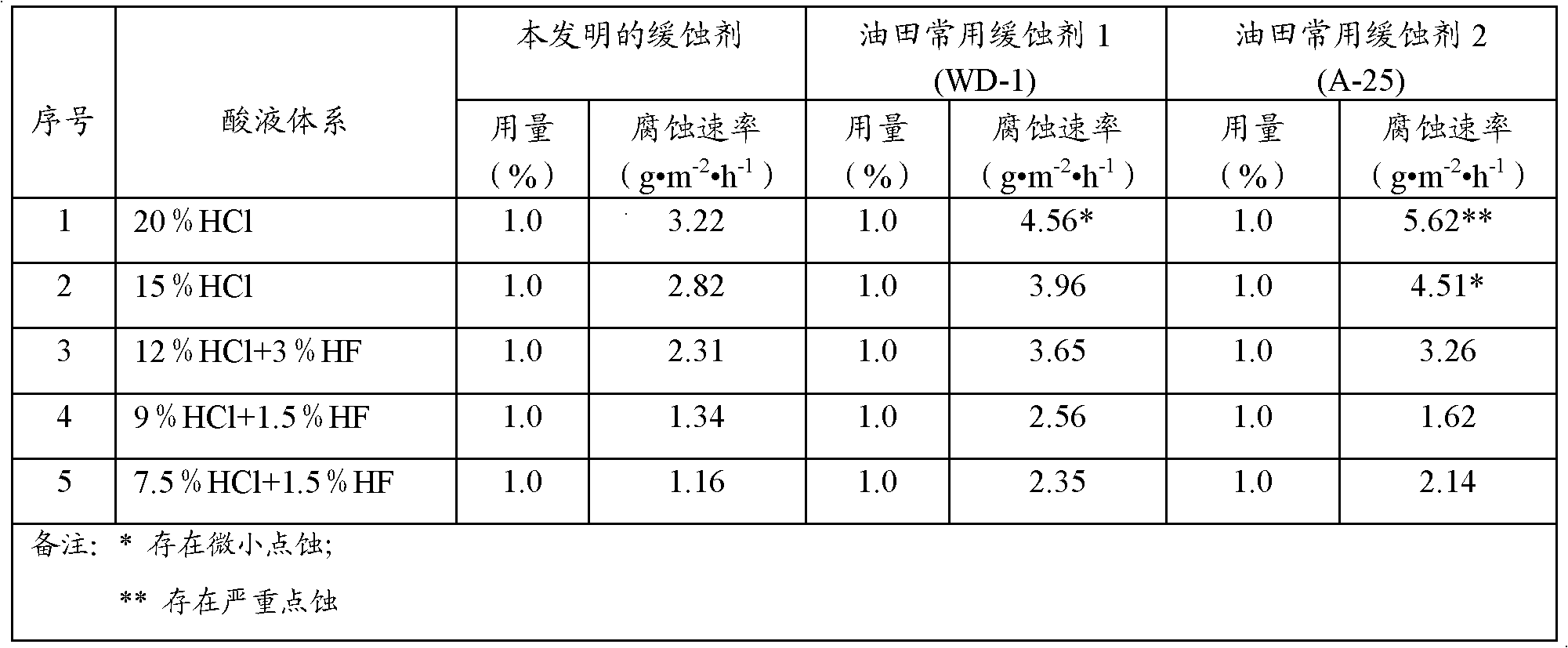

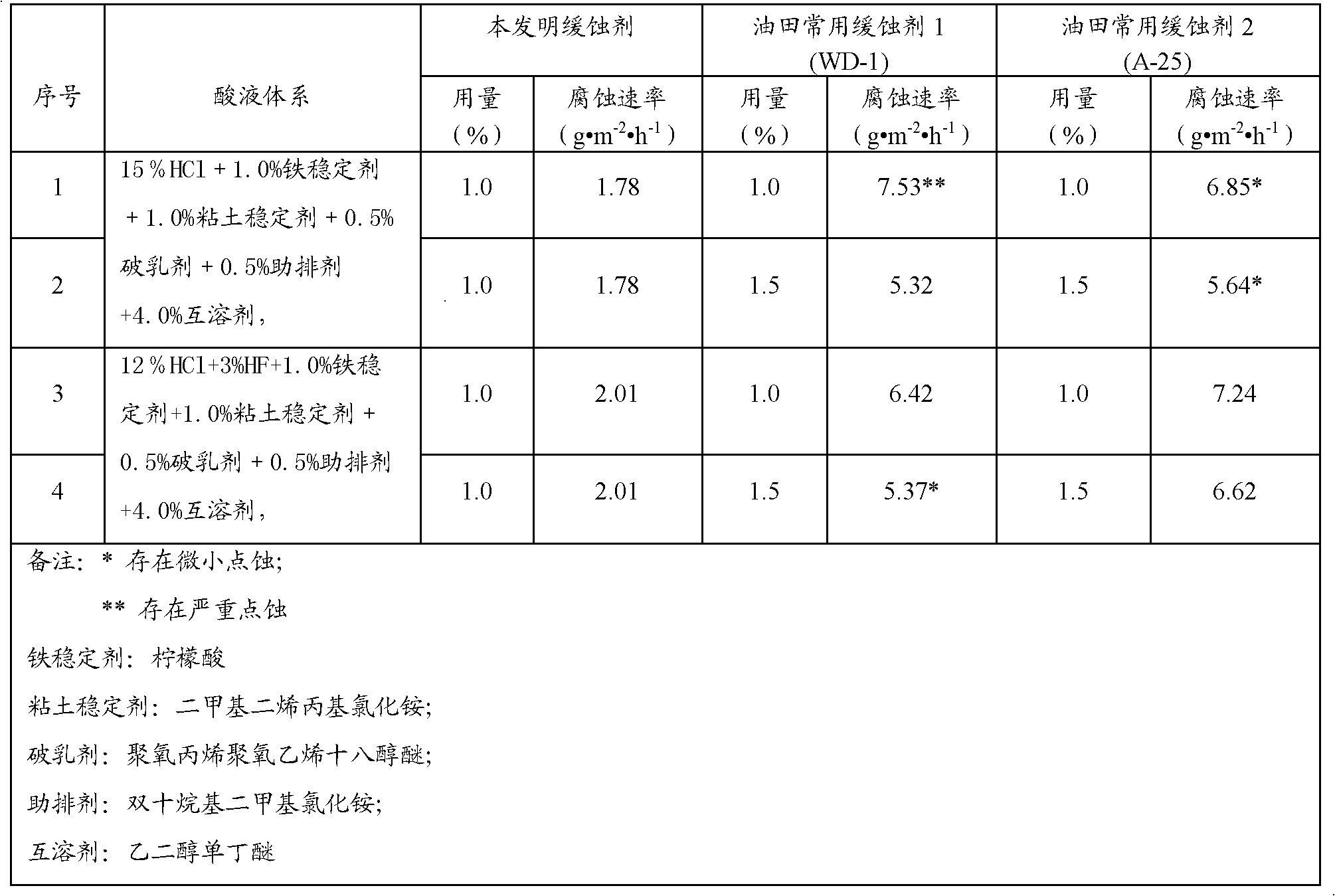

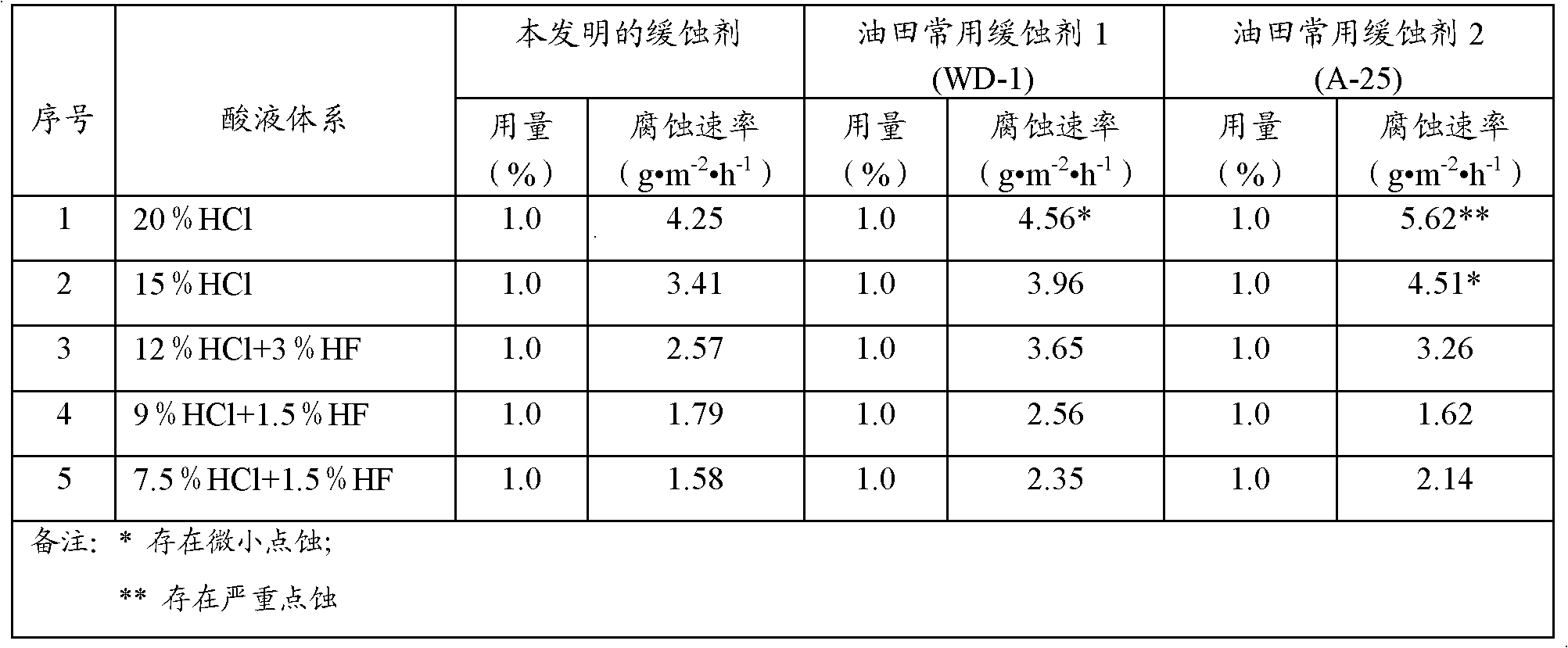

Low-temperature acidification corrosion inhibitor and preparation method thereof

The invention relates to a low-temperature acidification corrosion inhibitor which is composed of 10-50 parts by weight of alkynol, 10-50 parts by weight of quaternary ammonium salt and 5-10 parts by weight of heterocyclic compound, wherein the alkynol is selected from butyn alcohol, hexynol, popargyl alcohol, 1,4-butyne glycol, dormison, methyl butynol, butyne glycol, and 4-trimethylsilyl isocyanate-3-butyn alcohol; the quaternary ammonium is selected from dimethyl benzyl ammonium chloride, rosin modified oleic acid group imidazoline quaternary ammonium salt, quaternary ammonium tribenzal-imidazoline, (4-vinyl)-quinoline benzyl quinoline chloride quaternary ammonium salt, (4-vinyl)-quinoline benzyl pyridine chloride quaternary ammonium salt, epoxypropane group quinoline chloride, epoxypropane group pyridine chloride, allyl quinoline chloride and allyl pyridine chloride; the heterocyclic compound is selected from bromination hexadecy pyridine, cetylpyridine chloride, chlorinated dodecyl pyridine and bromination myristyl lycine pyridine. The invention also relates to a preparation method of the low-temperature acidification corrosion inhibitor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

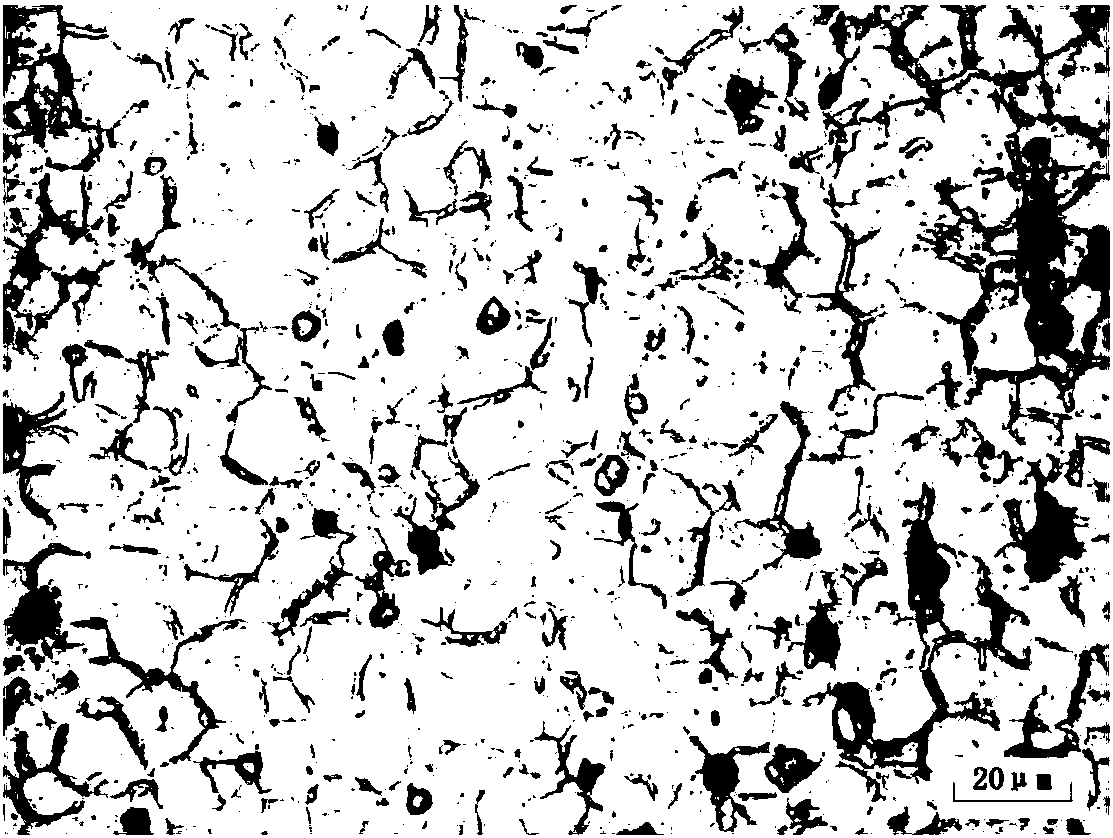

Anticorrosive and antiwear cast cobalt-base alloy

The present invention relates to Co-base alloy, especially, an anticorrosive and antiwear cast Co-base alloy. The alloy consists of C 1.0-2.5 wt%, Cr 20-35 wt%, W 5-20 wt%, Mo 1-6 wt%, Nb 1-8 wt%, Cu0.5-2.0 wt%, Si 0.5-3.0 wt%, Ni 2-15 wt% and Co 35-65 wt%. It has excellent anticorrosive performance and average hardness of about 48 HRC, and may be used in making cutter of water flow type chemical fiber cutting machine. Substituting partial Co with Ni can reduce the cost of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Vacuum aluminizing method of surface of neodymium-iron-boron permanent magnet

ActiveCN101736304AGood directionHigh hardnessVacuum evaporation coatingSputtering coatingIonizationHigh energy

The invention relates to a vacuum aluminizing method of the surface of a neodymium-iron-boron permanent magnet. The method sequentially comprises the following steps of: (1) polishing and cleaning the surface of the neodymium-iron-boron permanent magnet by adopting a wet method; (2) putting the neodymium-iron-boron permanent magnet on a rotating workpiece fame in a film plating chamber to ensure that the temperature of the neodymium-iron-boron permanent magnet is kept between 250 DEG C and 300 DEG C; (3) starting a vacuum pump on the film plating chamber and adjusting the vacuum degree of the film plating chamber to be 1-9*10<-3>Pa; (4) meanwhile, starting multi-arc cathode evaporators at both sides of the film plating chamber, a plane magnetic sputtering target and the rotating workpiece frame to carry out magnetic control multi-arc sputtering for 2-7 hours; (5) maintaining the film plating chamber to be cooled for 30-60 minutes under vacuum, aerating, opening the chamber, taking out the aluminized neodymium-iron-boron permanent magnet and carrying out passivation with a non-chrome passivation solution. High energy ions generated by magnetron sputtering strike low-energy ions generated by the multi-arc method so as to promote the low-energy ions to generate more ionization, wherein the speeds and the trends of the high-energy ions and the low-energy ions are uniform, thus the efficiency is improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL

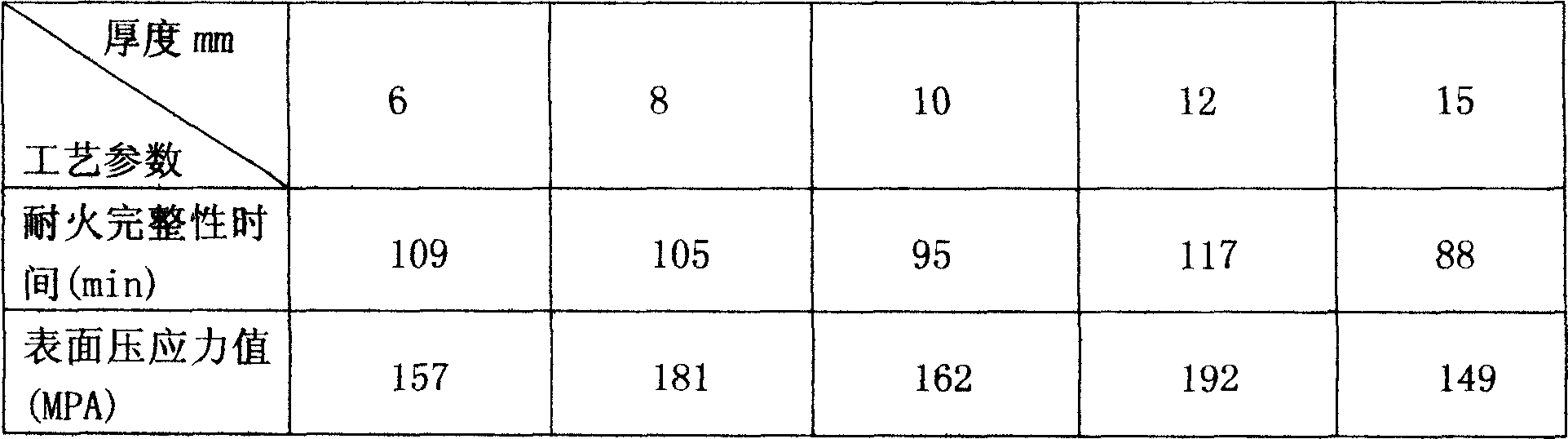

Method for producing fire-resisting glass and dedicated production equipment

ActiveCN101092286AAccelerates the ion exchange reaction processWon't peel off easilyGlass tempering apparatusGratingHeat resistance

This invention discloses method and specific apparatus for producing fireproof glass. The apparatus comprises: an upper stage plate, a furnace, a cooling wind grating and a lower stage plate. A baffle is set between the heating furnace and the cooling wind grating. The method comprises: (1) spray-coating a cesium / potassium salt solution onto glass at normal temperature; (2) naturally wind-drying the spray-coated glass at normal temperature, placing in a 680-725 deg.C tempering furnace, rapidly heating, cooling, circulating the glass between the heating furnace and the cooling wind grating by a roll so that the heating and cooling temperature is uniform, and unloading to obtain fireproof glass. The cesium / potassium salt solution comprises: cesium salt 0.8-1.2%, potassium salt 38-41%, acetone 40-45%, formic acid 8-13%, and Swiss-78 6-8%. The fireproof glass has such advantages as high heat resistance, low specific gravity, high light permeability, no yellowing, and no air bubbles.

Owner:新福兴玻璃工业集团有限公司

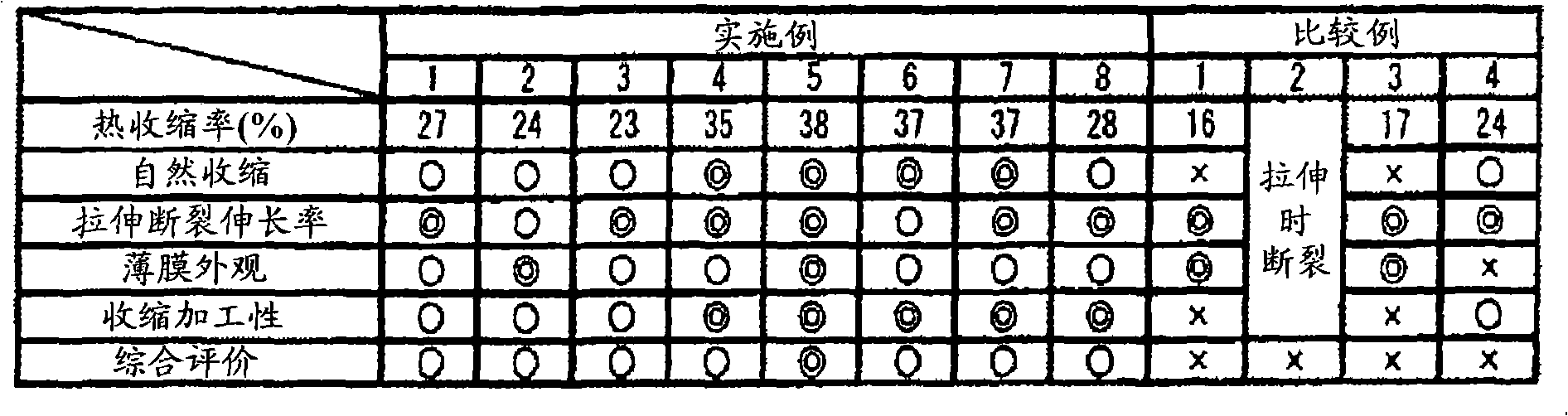

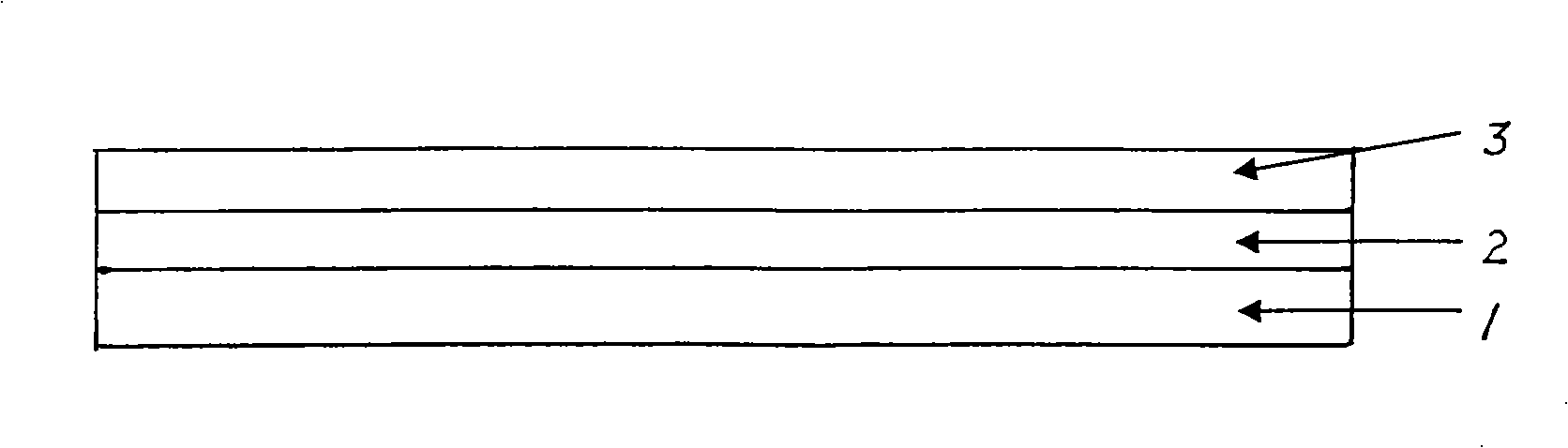

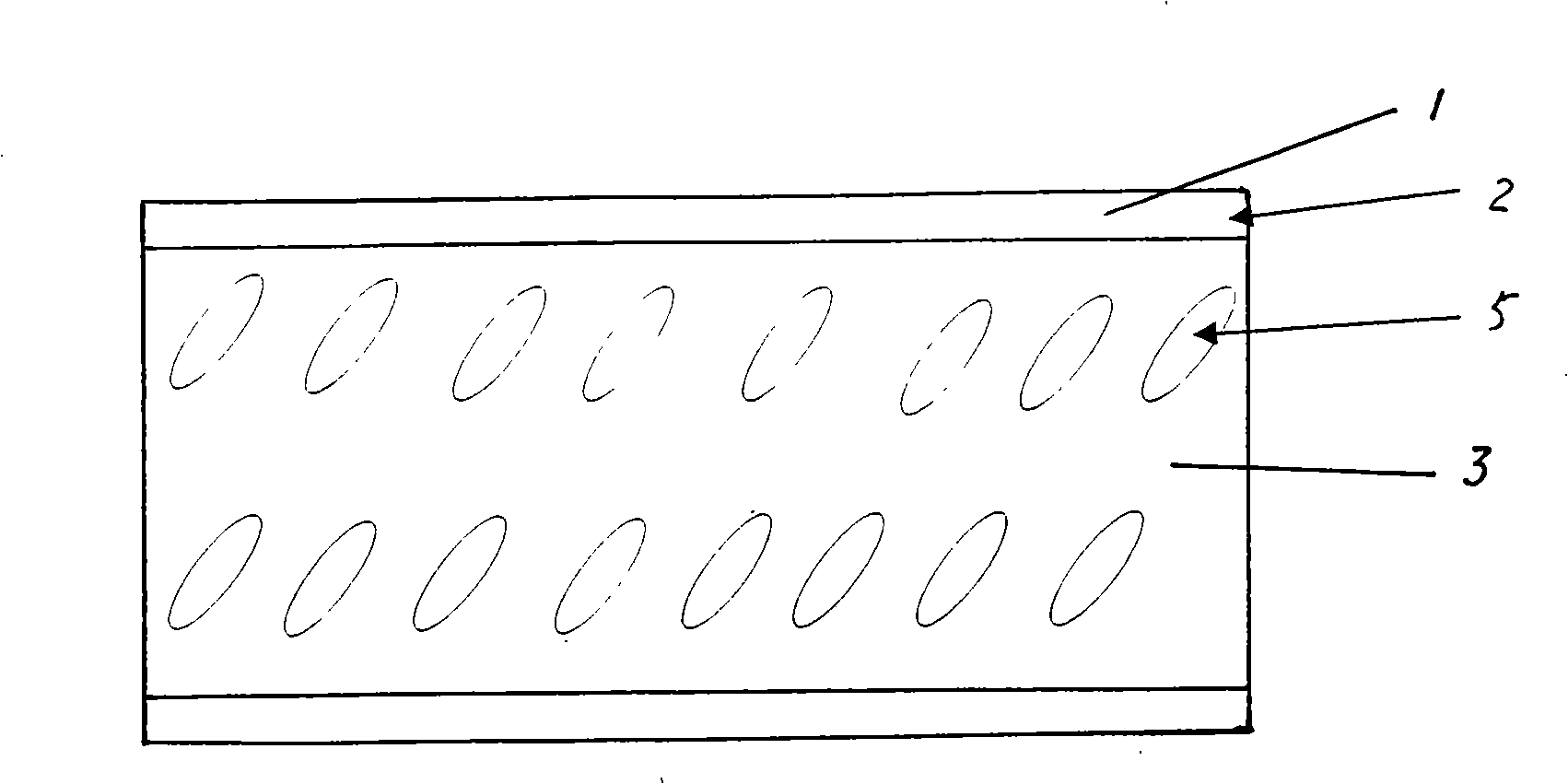

Thermally shrinkable polyolefin film, molded article using the film, thermally shrinkable label, and container

ActiveCN101316708AImprove featuresEasy to processStampsSynthetic resin layered productsPolyolefinPolyresin

Disclosed is a thermally shrinkable polyolefin film which comprises a mixed resin mainly composed of a polyolefin resin (A), a polylactic acid resin (B) and a resin (C) capable of improving the compatibility between the resin (A) and the resin (B) or has at least one layer comprising the mixed resin, wherein the ratio of the resin (A) to the resin (B) ((A) / (B)) is 99 / 1 to 70 / 30 by mass. The film has a thermal shrinkage ratio in at least one direction of 20% or higher as determined after immersing the film in hot water of 80 DEG C for 10 seconds, has a natural shrinkage ratio of less than 10% as determined after storing the film for 7 days under environment of 40 DEG C and 50% RH, is excellent in thermal shrinking properties and shrinkage finishing, and is reduced in natural shrinking. Also disclosed is a thermally shrinkable polyolefin label. Further disclosed is a container having the label thereon.

Owner:MITSUBISHI CHEM CORP

Ion liquid polishing solution for electrochemically polishing magnesium alloy and preparation method thereof

The invention discloses an ion liquid polishing solution for electrochemically polishing magnesium alloy, which is prepared from the following raw materials in percentage by mass: 88-96% of depth eutectic ion liquid and 4-12% of additives. The polishing solution can be used for well polishing and leveling the magnesium alloy to achieve an effect of high brightness; besides, the magnesium alloy is environmental-friendly, naturally degradable and pollution-free.

Owner:合肥金盟工贸有限公司

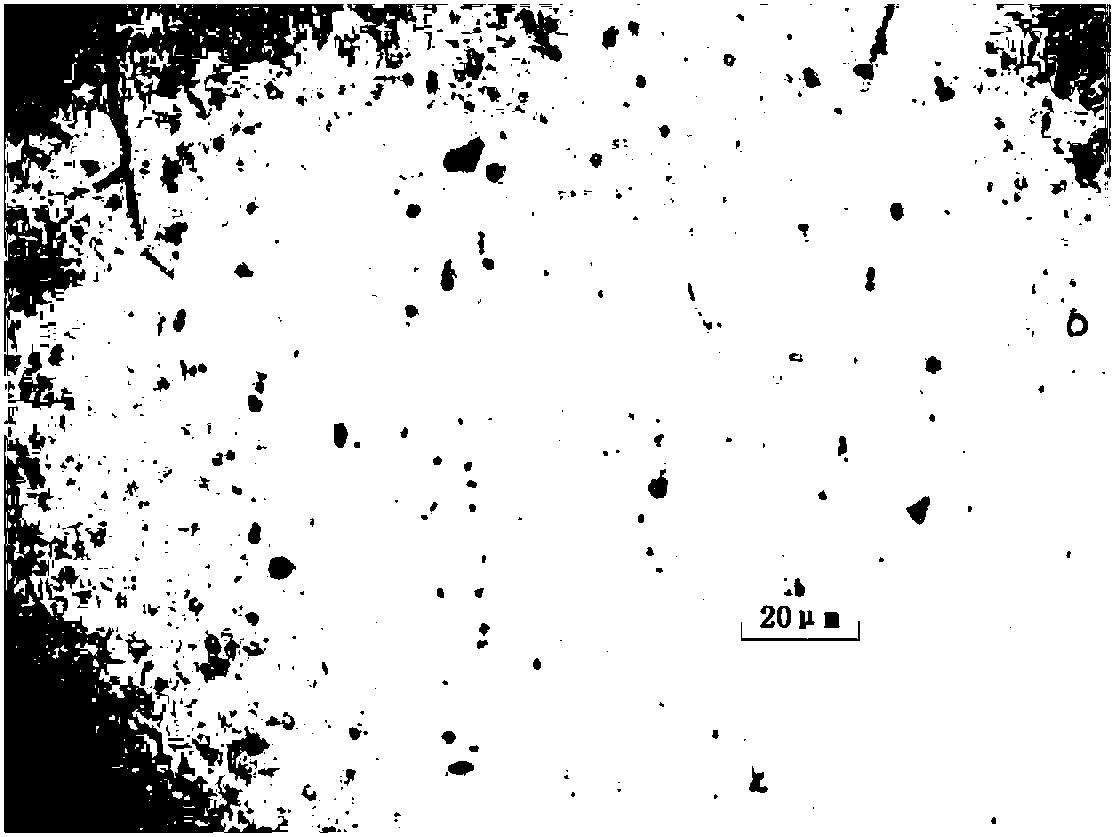

Early transition metal high-entropy alloy for biomedicine application

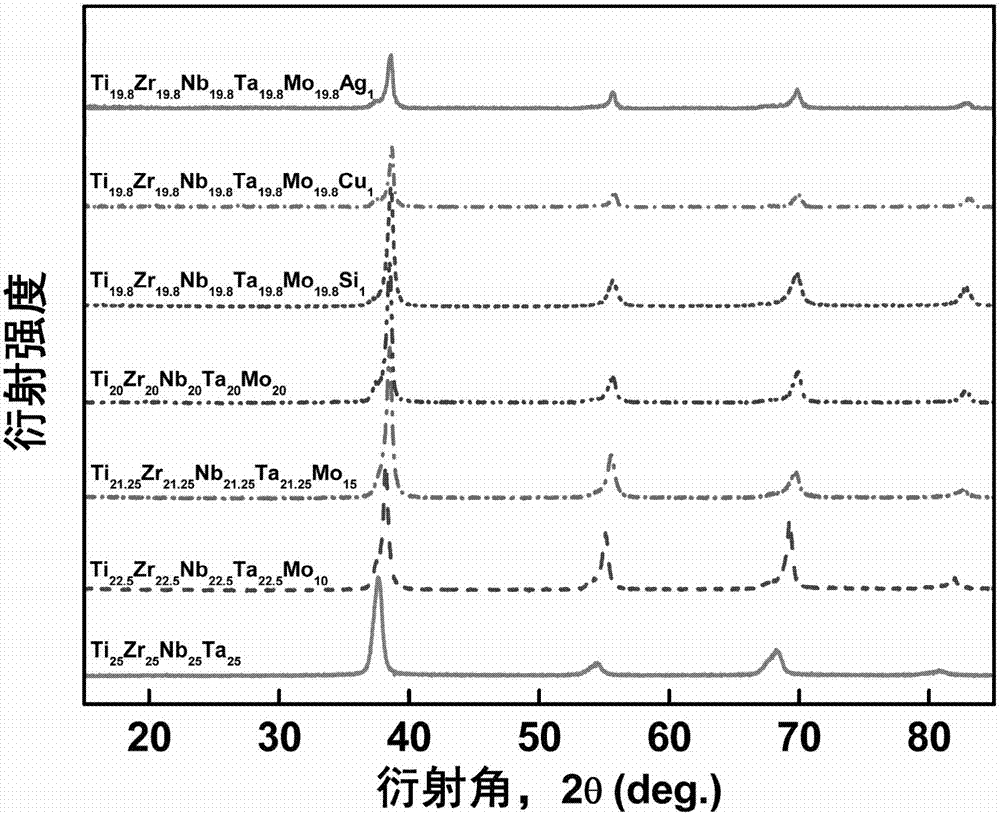

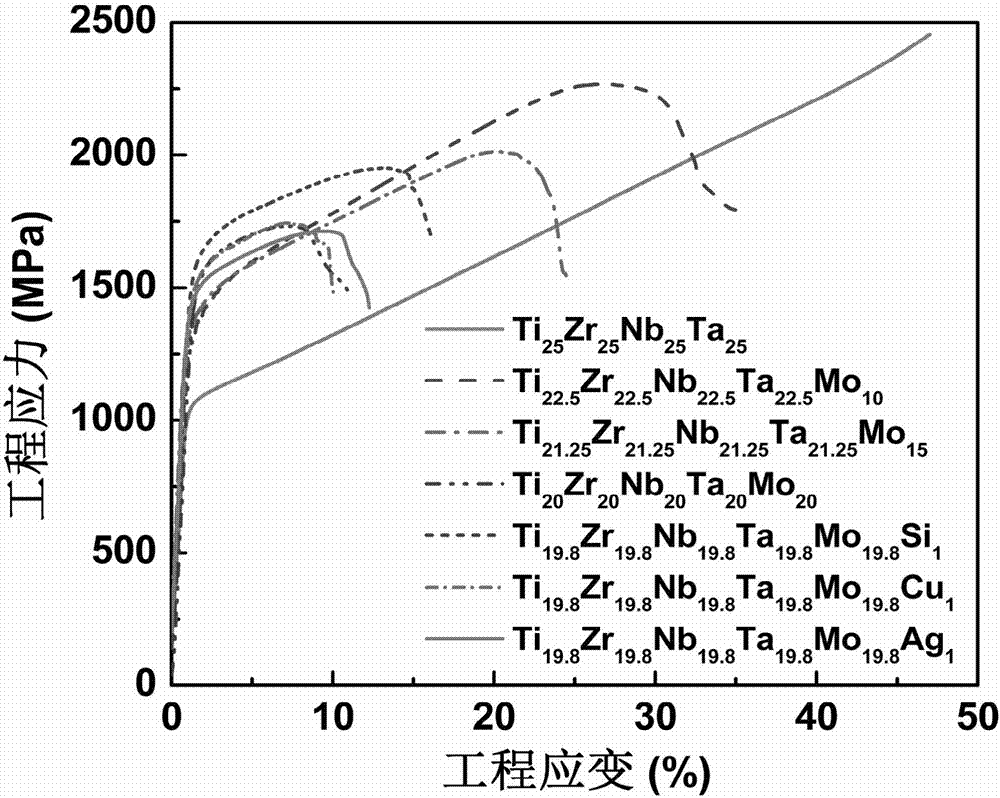

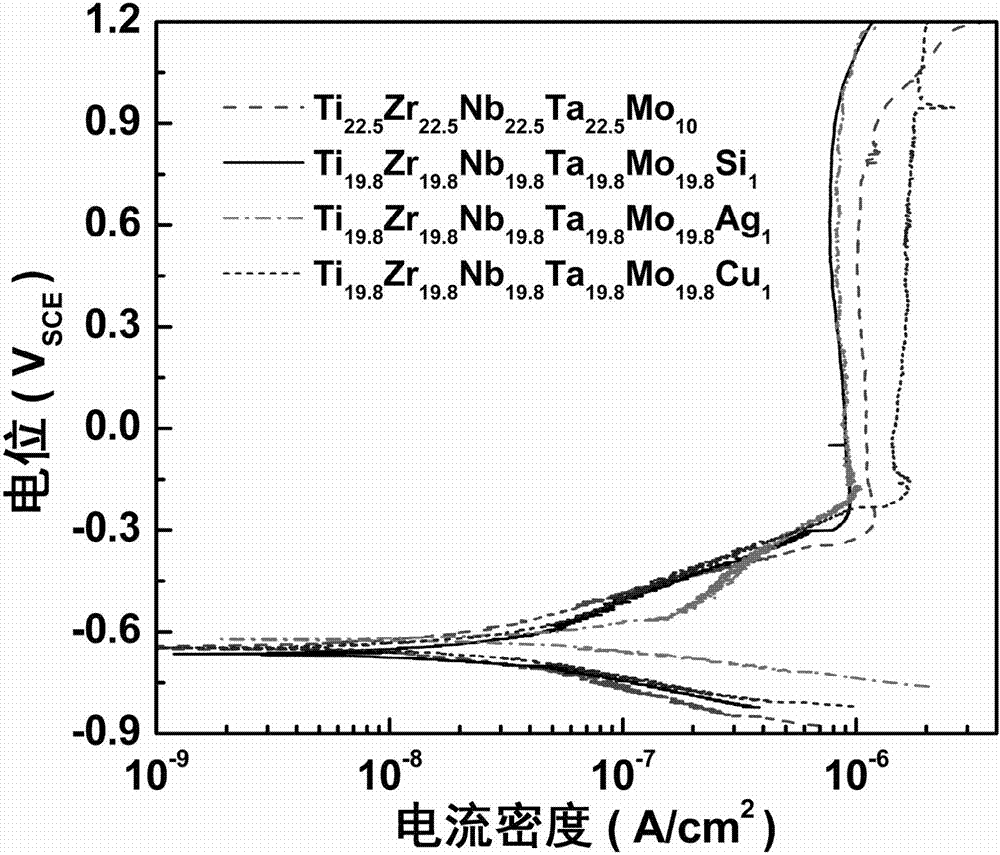

InactiveCN107488803AGood corrosion resistance behaviorNo pittingHigh entropy alloysBiocompatibility Testing

The invention provides a multi-component high-entropy alloy prepared from the components of early transition metal elements such as titanium, zirconium, tantalum and molybdenum. The multi-component high-entropy alloy is characterized in that the alloy comprises the components of the early transition metal elements of Ti, Zr, Nb and Ta, the component chemical formula of the alloy is TiaZrbNbcTad, wherein a, b, c and d show the atom content percentage, a is 20-30, b is 20-30, c is 20-30, d is 20-30, and the sum of a, b, c and d is 100; and the appropriate quantity of elements of Mo, Si, Cu and Ag can be further added in the alloy. The high-entropy alloy has the characteristics of body-centered cubic crystal structure, high strength, high hardness, corrosion resistance, good biocompatibility and the like, and is suitable for being used as a biomedicine application material for hard tissue repairing and replacing.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

PVC stabilizing agent and preparation method thereof

The invention discloses a PVC stabilizing agent, which comprises 50 to 75 weight parts of organic weak-acidic rare-earth salt and 25 to 50 weight parts of zeolite reactor. The organic weak-acidic rare-earth salt is prepared by reacting 1 mole part of organic weak acid with 1 to 5 mole parts of natural rare-earth compound under an alkaline conduction, wherein the organic weak acid is one or more than two of phenylformic acid, oleic acid, stearic acid and stearic acid; and the rare-earth compound is one or more than two of the natural compounds of lanthanum, cerium, neodymium and europium. The zeolite reactor is that zeolites absorbing maleic anhydrides are arranged in a channel and a cage. The PVC stabilizing agent of the invention has the advantages of small dosage, self-lubrication, yellowing resistance, no pock and the like; and the PVC material prepared by the stabilizing agent of the invention has good thermal stability and plasticity.

Owner:GUANGZHOU UNIVERSITY

Polyvinyl chloride pipe resistant to heat, oil, acid and alkali and method for preparing same

InactiveCN102952355AHigh temperature resistantImprove thermal stabilityRigid pipesPlasticizerPolyvinyl chloride

The invention provides a polyvinyl chloride (PVC) pipe resistant to heat, oil, acid and alkali and a method for preparing the same. The polyvinyl chloride pipe resistant to heat, oil, acid and alkali is composed of 100 parts of PVC, 30-75 parts of plasticizer, 20-40 parts of fire retardant, 5.5-10 parts of thermal stabilizer, 20-40 parts of modifier and 0.5-1 part of lubricant by weight. The pipe is resistant to low temperature and high temperature, high in shock resistance, good in rigidity, high in pressure resistance and resistant to corrosion, and has the characteristics of excellent acid resistance, alkali resistance, oil resistance, chemical corrosion resistance, good electrodynamic corrosion resistance, long service life, low production cost and the like; and therefore, the pipe is certainly to be used widely and may take the place of the existing material gradually.

Owner:JIANGSU CHENDIAN SOLAR PHOTOELECTRIC TECH

Polishing treatment method for solar grade monocrystal silicon bar

InactiveCN101498055AIncrease profitImprove yieldEdge grinding machinesAfter-treatment detailsHydrofluoric acidMaterials science

The invention relates to a polishing treatment method of a solar-grade single crystal silicon rod. The method comprises the following the steps: soaking the solar-grade single crystal silicon rod into acid liquor with lower concentration of hydrofluoric acid, removing a damaged layer and eliminating the stress of the solar-grade single crystal silicon rod; and then mechanically sanding and polishing the surface of the solar-grade single crystal silicon rod by polishing equipment. Due to low requirements for the concentration and the purity of the acid, the invention can use waste acid liquor for production to improve the utilization rate and decrease the cost; moreover, the erosion time does not need to be accurately controlled, and a corrosion pit phenomenon can not occur so that the rate of finished products is improved.

Owner:郜勇军

Environment-friendly sapphire film deplating solution and using method thereof

InactiveCN105002564AImprove permeabilityStrong complexing abilityAfter-treatment detailsSapphire waferAqueous solution

The invention provides an environment-friendly sapphire film deplating solution and a using method thereof. The deplating solution is a water solution containing alkali compounds, inorganic auxiliary agents and water stabilizer. Compared with the prior art, the environment-friendly sapphire film deplating solution and the using method have the advantages that the inorganic auxiliary agents have high permeability and complexing effect on a film, the deplating ability of a product is made to be higher and more thorough, and a very good deplating effect can be achieved just by conducting soaking or spray contact; deplating is even, the size of a sapphire wafer is not affected, and point corrosion cannot be caused on a workpiece; the depalting time is short, machining time is saved, the depalting solution is easy to process after being used, and no influences are caused to the environment.

Owner:深圳市海风润滑技术有限公司

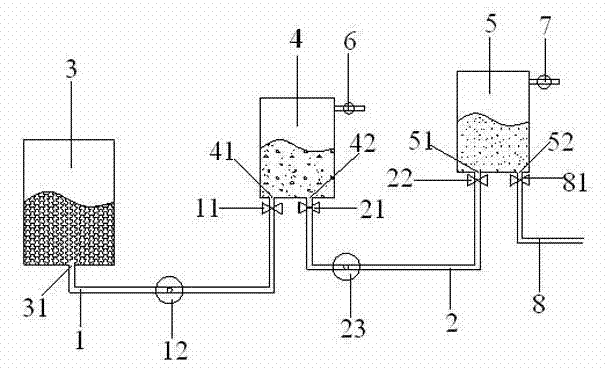

Preparation apparatus and method for lithium ion battery slurry

ActiveCN102824872AWell mixedReduce generationCell electrodesMixing methodsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

Aluminum alloy cyanide-free and nickel-free electroplating method and electroplating products thereof

ActiveCN101768768ANo pittingImprove bindingThin material handlingSuperimposed coating processCyanideCupronickel

The invention provides an aluminum alloy cyanide-free and nickel-free electroplating method, the method includes that matrix material is sequentially dipped with zinc, then is electroplated with non-cyanide alkaline copper, acid copper, white copper tin and is electroplated with trivalent chromium. The invention also provides the products which are prepared by using the method of the invention. The coating of the electroplating products which are obtained by using the electroplating method of the invention has no pockmark, the bonding force is high, the corrosion resistance of the coating is high, and the surface of plating article is level and attractive. The method of the invention uses the non-cyanide alkaline copper to precoat and prime, then performs the acid copper electroplating, meanwhile the non-cyanide white copper tin system replaces the common nickel plating process, thereby the nickel allergy of human body is decreased, at last the trivalent white chromium electroplating is implemented. The application range of the preparation method is wide, and is applicable to various aluminum alloy materials, the process is environmental friendly and has no pollution, and is nontoxic and harmless.

Owner:BYD CO LTD

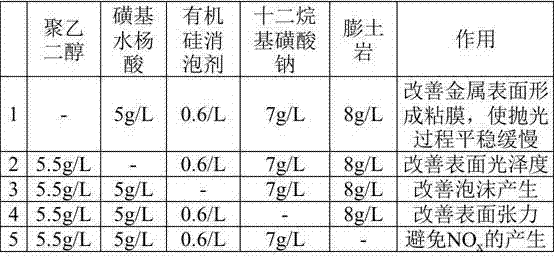

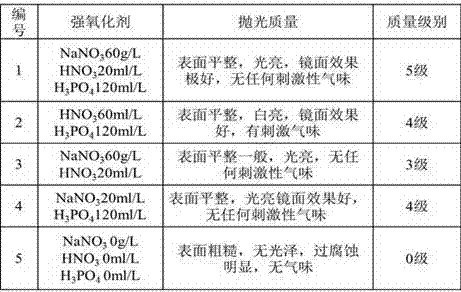

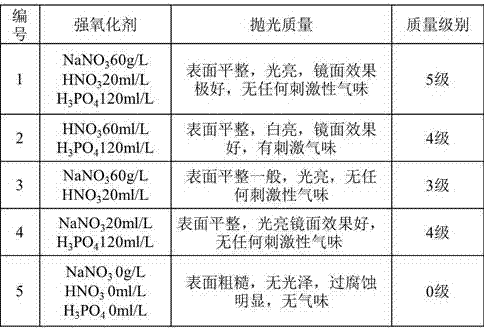

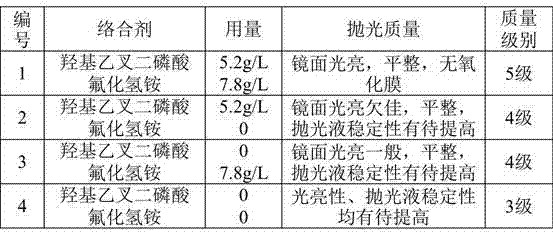

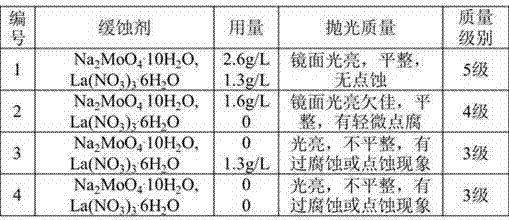

Environment-friendly stainless steel polishing solution and preparation method and polishing process thereof

The invention provides an environment-friendly stainless steel polishing solution and a preparation method and polishing process thereof. The environment-friendly stainless steel polishing solution comprises a strong oxidant, corrosive acid, a compound complexing agent, a corrosion inhibitor, a rare earth additive, a viscosity regulator, a brightening agent, a defoaming agent, a surfactant, a NOx remover and deionized water. The polishing solution is good in stability and long in service life, the polishing solution preparation and stainless steel treatment processes are simple, the surface of treated stainless steel is smooth, oxide films are avoided, point corrosion is avoided, the mirror plane is great, the polishing time is short, no irritant gas is generated in the using process, and the polishing solution can be used repeatedly and circularly.

Owner:无锡市恒利弘实业有限公司

Long-service-life multi-protection coolant

InactiveCN105419741AImprove cooling effectSolve the decline of corrosion inhibitionHeat-exchange elementsAdditive ingredientGlycerol

The invention discloses a long-service-life multi-protection coolant. The coolant is prepared from a propylene glycol and ethylene glycol blend, citric acid, simethicone, sodium silicate, starch, glycerol, tribasic polycarboxylic acid, a formic acid and acetic acid mixture, a succinic acid and dodecanedioic acid mixture, montmorillonite nano-particles, a lauric acid and palmitic acid mixture, nano-alumina and guar gum by weight. The coolant is good in cooling performance, the problems that due to gel polymerization of traditional silicate in a coolant, the corrosion inhibition of the coolant is reduced, and a pipeline is blocked are solved, and the problem that an existing engine coolant lacks the protection function for cast aluminum components of a cooling system is also solved; the ingredient composition of the coolant is improved, various comprehensive properties of the coolant are improved, soldering tin of the cooling system is greatly protected, pitting corrosion caused by the engine coolant to the engine cooling system is greatly reduced, and the protection performance of inhibiting cavitation corrosion is improved.

Owner:蚌埠市华科机电有限责任公司

Weather-resistant and flame-retardant PC/PBT alloy and preparation method thereof

The invention discloses a weather-resistant and flame-retardant PC / PBT alloy. The weather-resistant and flame-retardant PC / PBT alloy comprises raw materials of organosilicon modified polycarbonate, polybutylene terephthalate, compatibilizer, flame retardant, flame retardant auxiliary, anti-dripping agent, transesterification inhibitor, antioxidant, liquid lubricant, and UV absorber. According to the weather-resistant and flame-retardant PC / PBT alloy, an organic transesterification inhibitor having a good compatibility with a matrix is added to the alloy, so that the alloy material surface is smooth and free of pocking marks, and at the same time, the transesterification inhibitor used is organophosphorus which can play a synergistic effect with a brominated flame retardant, thereby reducing the using amount of the flame retardant.

Owner:DONGGUAN HONOUR E P

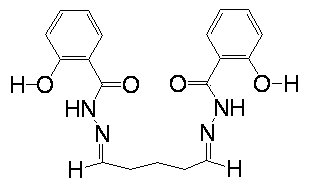

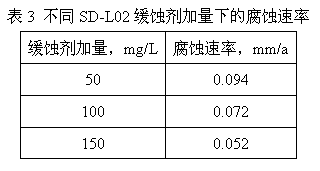

Gemini type bimolecular Sciff base waste water corrosion inhibitor and preparation method thereof

The invention relates to a Gemini type bimolecular Sciff base waste water corrosion inhibitor. The corrosion inhibitor is characterized by comprising the following components by weight percent: 10-20 percent of Sciff base, 6-9 percent of benzotriazol, 2-5 percent of thioglycollic acid, 1-3 percent of surface active agent and 63-81 percent of solvent. A method for preparing the Gemini type bimolecular Sciff base waste water corrosion inhibitor comprises the following steps: (1) a bimolecular Sciff base compound 1,5-bi(hydroxybenzhydrazide)-pentane is synthesized from the raw materials of salicylyl hydrazine and glutaric dialdehyde; and (2) the bimolecular Sciff base compound 1,5-bi(hydroxybenzhydrazide)-pentane prepared in the step (1) is compounded to obtain the corrosion inhibitor according to the weight percent: 10-20 percent of Sciff base compounds and 80-90 percent of compounds. The corrosion inhibitor can restrain the corrosion of waste water media, and guarantees the safe operation of water injection pipelines during production.

Owner:XI'AN PETROLEUM UNIVERSITY +1

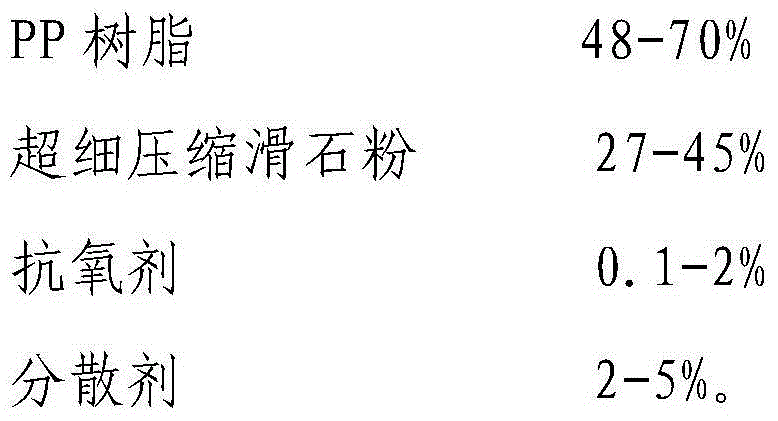

Extrusion-grade highly filled polypropylene composite material and preparation method thereof

InactiveCN104403199AExcellent bending resistanceGood dimensional stabilityPolypropylene compositesExtrusion

The invention relates to a composite material and a preparation method thereof, particularly relates to an extrusion-grade highly filled polypropylene composite material and a preparation method thereof, and belongs to the technical field of materials. The extrusion-grade highly filled polypropylene composite material comprises the following raw materials in percentage by weight: 48-70% of PP resin, 27-45% of superfine compressed talcum powder, 0.1-2% of an antioxidant and 2-5% of a dispersing agent. The extrusion-grade highly filled polypropylene composite material and the preparation method thereof have the benefit that the prepared material has excellent bending resistance and favorable size stability (relatively low shrinking percentage), is easy to process, smooth and free of pocking marks on the surfaces of extruded sections, and tidy in fracture surface, has a favorable caking property with rubber, has no foreign smell and accords with the requirement of ROHS environmental protection.

Owner:NANJING JULONG SCI&TECH CO LTD

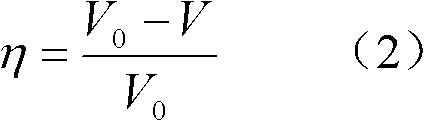

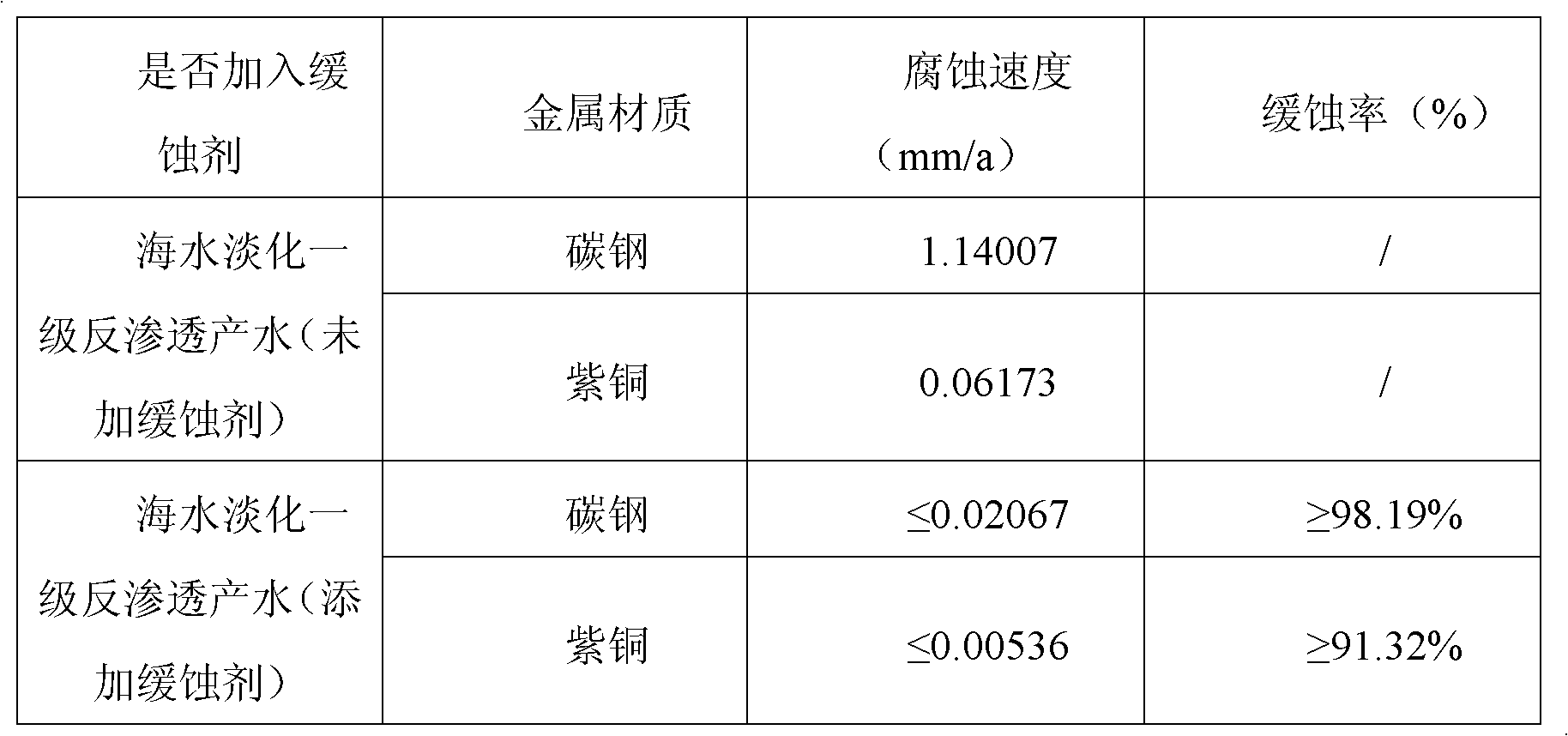

Low-phosphorus corrosion inhibitor for sea water desalinization first-level reverse osmosis producing water

InactiveCN102010076AReduce corrosionExtended service lifeScale removal and water softeningReverse osmosisSilicon dioxide

The invention relates to a low-phosphorus corrosion inhibitor for sea water desalinization first-level reverse osmosis producing water. One liter of low-phosphorus corrosion inhibitor is prepared from 3 to 10 milligrams of sodium silicate (based on silicon dioxide (SiO2)), 5 to 15 milligrams of sodium hexametaphosphate, 2 to 4 milligrams of zinc sulfate (based on zinc ion (Zn<2+>)), 2 to 4 milligrams of benzotriazole or methyl benzotriazole and 60 to 100 milligrams of sodium hydroxide. By the low-phosphorus corrosion inhibitor, the corrosion rates of the metal materials commonly used in a heat-engine plant, such as carbon steel, red copper and the like in the sea water desalinization first-level reverse osmosis producing water are reduced from 1.14007 mm / a to 0.02067 mm / a and from 0.06173 mm / a to 0.00536 mm / a respectively; the corrosion inhibition rates of the low-phosphorus corrosion inhibitor on the carbon steel and the red copper are over 98 percent and 91 percent respectively; the corrosive action of the first-level reverse osmosis producing water on the materials is greatly relieved; and the metal surface pitting is completely inhibited, so that the service life of each of pipelines and equipment is greatly prolonged and the low-phosphorus corrosion inhibitor has almost no harm to the environment and is simple in subsequent treatment.

Owner:WUHAN UNIV

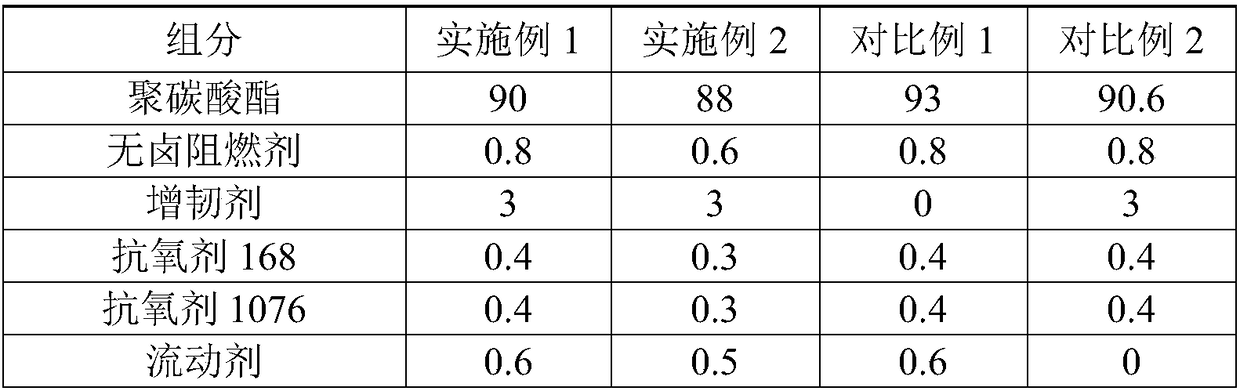

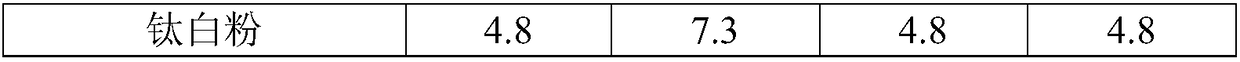

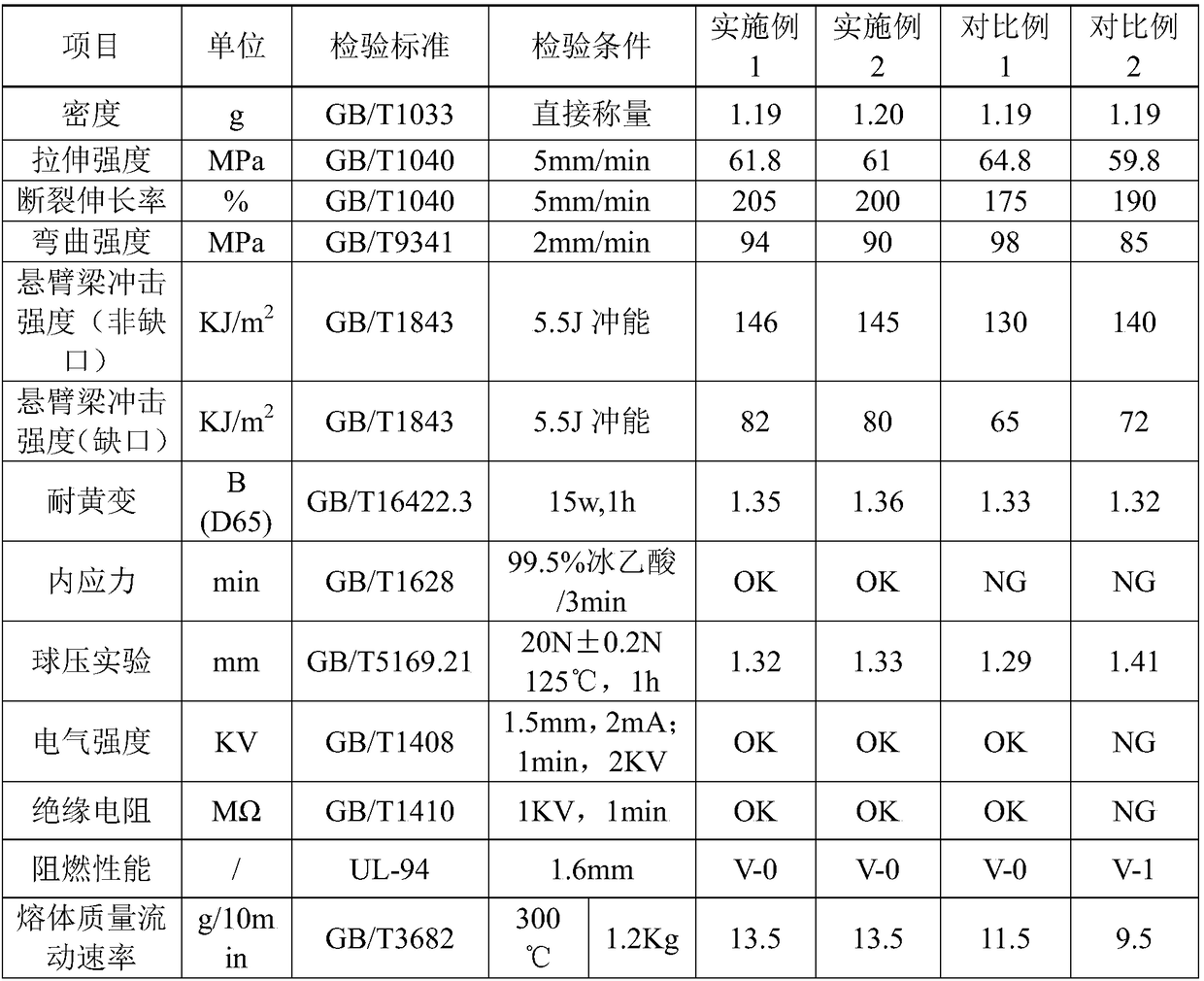

Halogen-free flame-retardant porcelain-white polycarbonate composite material with high glossiness

The invention discloses a halogen-free flame-retardant porcelain-white polycarbonate composite material with high glossiness. The composite material comprises following raw materials in parts by weight: 85 to 95 parts of polycarbonate, 0.4 to 1 part of halogen-free flame retardant, 1 to 5 parts of flexibilizer, 0.5 to 1 part of antioxidant, 0.2 to 0.6 part of flowing agent, and 2 to 8 parts of titanium dioxide. A flexibilizer is compounded with a halogen-free flame retardant with high fluidity and a flowing agent; the fluidity of the melt is good, the moulding efficiency and surface glossinessare high; the mechanical performance, flame retardant performance, and electrical properties are excellent; and the problems of cracking caused by stress and pits in the surface are solved effectively.

Owner:广东三易科技有限公司

Environment-friendly type stainless steel polishing liquid and preparation method and polishing technology thereof

The invention provides environment-friendly type stainless steel polishing liquid and a preparation method and a polishing technology thereof. The environment-friendly type stainless steel polishing liquid is prepared from a strong oxidant, corrosive acid, a compound complexing agent, a corrosion inhibitor, a rare earth additive, a viscosity adjuster, a polishing agent, a defoaming agent, a surfacant, an NOx removal agent and deionized water. The environment-friendly type stainless steel polishing liquid has the advantages that the stability is good, the service life is long, a technology of preparing the polishing liquid and treating stainless steel is simple, the surface of the treated stainless steel is flat, the forming of an oxide film and pitting corrosion are avoided, a mirror surface is excellent, the polishing time is shorter, the production of irritant gas in the use process is avoided, and the polishing liquid can be recycled for multiple times.

Owner:佛山市顺德区亚特祥展洗涤剂有限公司

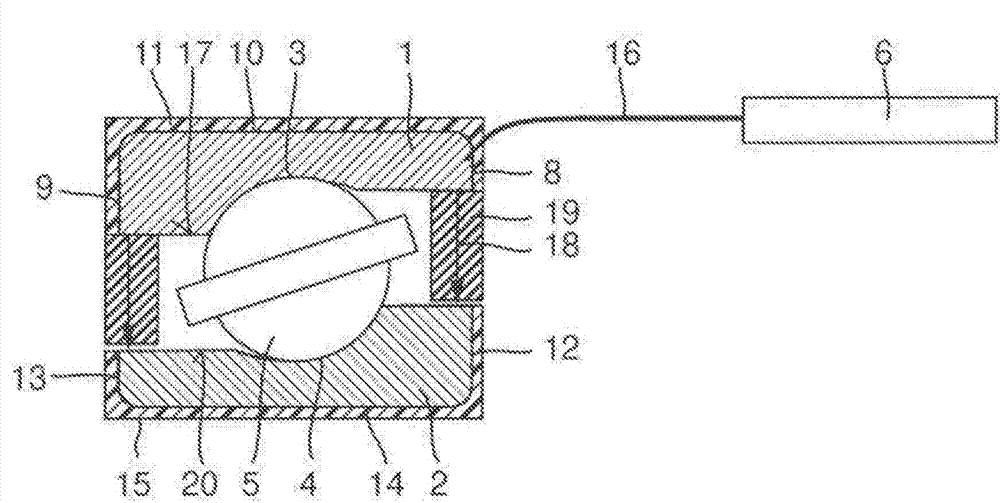

Bearing lubricated with a medium

InactiveCN104718386AEasy to replaceImprove protectionRolling contact bearingsShaftsEngineeringPlain bearing

The invention relates to a bearing lubricated with a medium, particularly a roller bearing or sliding bearing, comprising two bearing rings (1, 2) and a bearing path (3, 4) arranged on each of said bearing rings (1, 2), and a sacrificial anode (6) that is associated with at least one of the two bearing rings (1). The problem addressed by the invention is that of providing a bearing lubricated with a medium and comprising a sacrificial anode, the operational behaviour of said bearing being only slightly influenced by said sacrificial anode. According to the invention, this problem is solved in that the sacrificial anode (6) is arranged outside of the bearing interior (7) which is formed between said bearing rings (1, 2); and in that the sacrificial anode (6) is connected to the bearing interior (7) in an electrically-conductive manner.

Owner:SCHAEFFLER TECH AG & CO KG

6-series aluminum alloys and preparation method thereof

The invention relates to 6-series aluminum alloys. The 6-series aluminum alloys are composed of the following components in percentage by weight: 0.75-1.1% of magnesium, 0.01-0.02% of titanium, 0.06-0.13% of manganese, 0.5-0.7% of silicon, 0.55-0.7% of copper, 0.005-0.01% of strontium, 0.002-0.008% of pickaxe, not more than 0.13% of iron, not more than 0.01% of zinc, not more than of 0.01% of chromium and the balance of aluminum. The invention also relates to a preparation method of the 6-series aluminum alloys. The 6 series aluminum alloys have the advantages that alloy mechanical propertiesare obviously improved and glossiness is high after the alloys are subjected to highlight oxidation.

Owner:SICHUAN FURONG TECHNOLOGY CO LTD

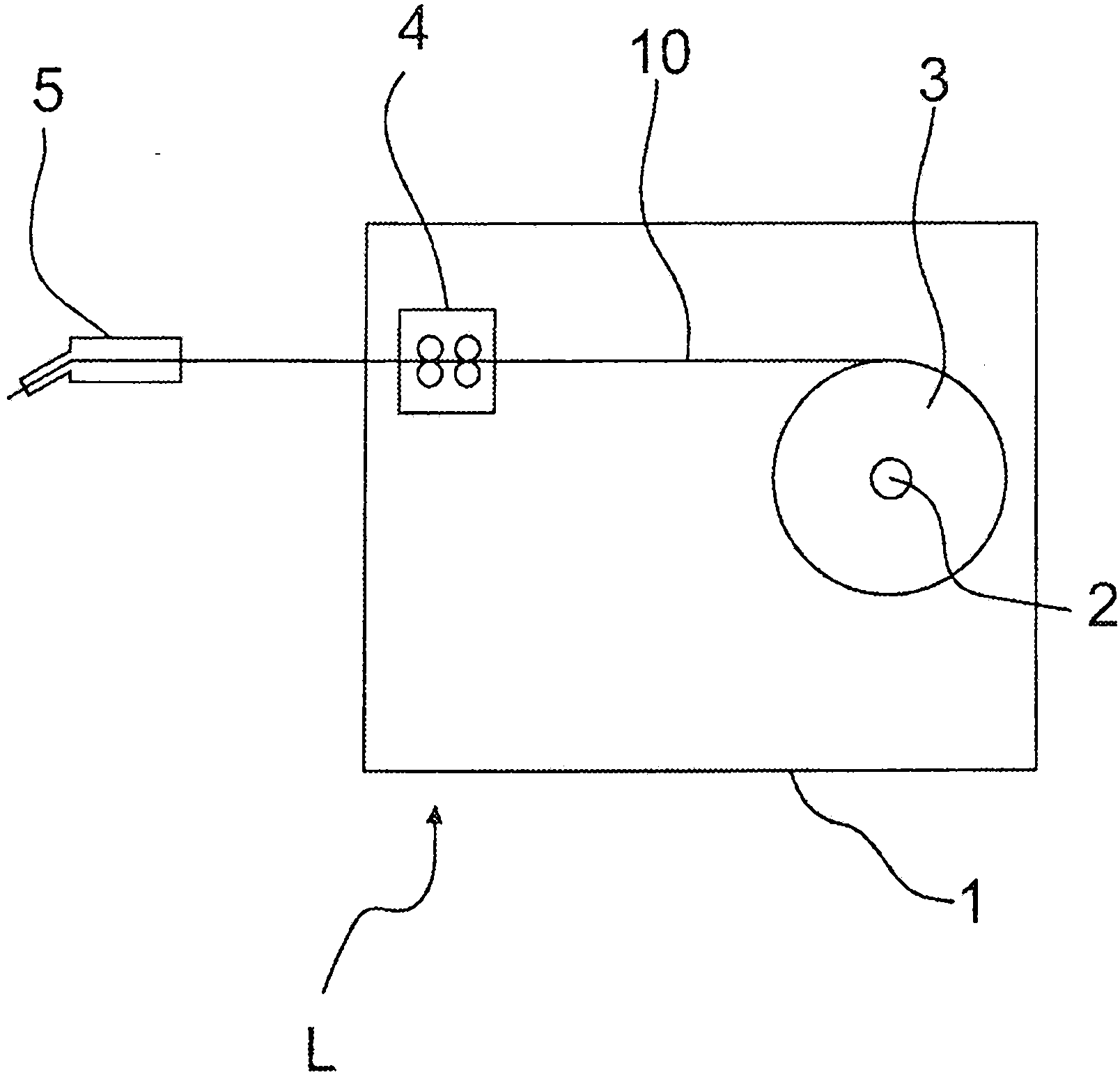

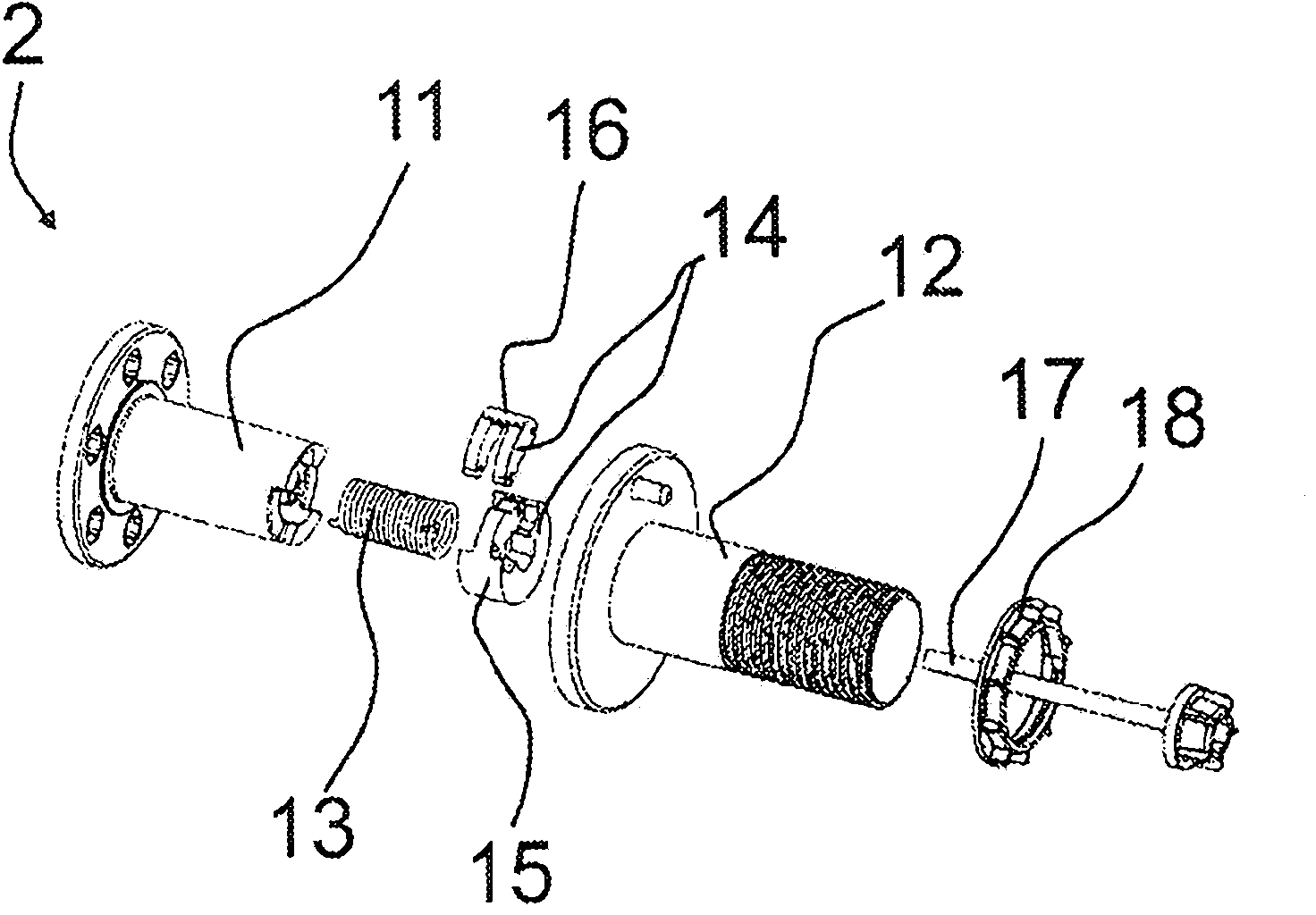

Arrangement in wire feeding device of welding machine and method for moving welding wire

The invention relates to an arrangement and a method in a wire feeding device (L) comprising a frame (1), a hub system (2) arranged on the frame (1) for winding a wire coil (3), and a wire feeding mechanism (4) for pulling a welding wire (10) from the wire coil (3) such that the wire coil (3) rotates in the unwinding direction and for feeding the welding wire (10) through the wire feeding mechanism (4) to a welding torch (5). In the method, in the wire feeding starting stage, the wire feeding mechanism (4) pulls the welding wire (10) into motion and, in the wire feeding stopping stage, the wire feeding mechanism (4) stops pulling the welding wire (10). The hub system (2) comprises means for storing energy, and the means for storing energy is adapted to store energy as the wire feeding mechanism (4) starts to pull the welding wire (10) from the wire coil (3) in the unwinding direction such that, when the wire feeding mechanism (4) stops pulling the welding wire (10), the stored energy is adapted to be released to pull the wire coil (3) in the winding direction, which is the opposite direction in relation to the unwinding direction.

Owner:KEMPPI OY

Method for improving percent of pass of liquid crystal box

InactiveCN101315478AImprove yield rateLow costPhotomechanical apparatusNon-linear opticsEngineeringPrinting press

The invention relates to a method for increasing the qualification rate of LCD screens. The method is characterized in that the third step and the tenth step of the former technology are improved. In the third step of the technology, a printer and a rubbing machine are utilized to apply a film layer called a PI layer, which can generate a groove after being rubbed, on a TOP layer. In case of abnormal equipment shutdown during the application of the PI layer, 4 to 6 additional pieces of mother glass are printed to carry away superfluous physic liquid, so that the accumulation of the physic liquid can be avoided and the phenomenon of uneven film surface of the PI layer printed on the TOP layer can be prevented. In the tenth step, the method adopts a gradual cooling method to ensure liquid crystal molecules in the PI layer are arranged in time, so as to prevent pocking marks from appearing. The method has the advantages that major problems occurring during the production process can be solved by the most cost-effective and simple method, and the qualification rate of LCD screens can be greatly improved.

Owner:上海广电液晶显示器有限公司

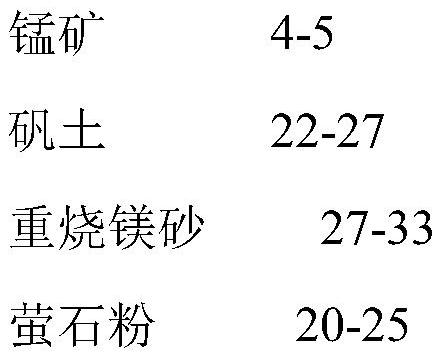

Fluorine alkaline sintered flux and preparation method and application thereof

InactiveCN111673316AImprove performanceEasy to prepareWelding/cutting media/materialsSoldering mediaPotassium silicateFerrosilicon

The invention discloses a fluorine alkaline sintered flux. The fluorine alkaline sintered flux is formed in the manner that the raw materials comprising, by weight, 4-5 parts of manganese ores, 22-27parts of alumina, 27-33 parts of dead-burned magnesia, 20-25 parts of fluorite powder, 1-2 parts of ferrosilicon and 5-10 parts of wollastonite are added to 21-27 parts of sodium potassium silicate and undergo sintering. The prepared fluorine alkaline sintered flux has excellent low-temperature impact resistance. The invention also provides a specific preparation method of the fluorine alkaline sintered flux and the application of the fluorine alkaline sintered flux to X70 pipeline steel welding. The fluorine alkaline sintered flux prepared through sintering can be completely applied to X70 pipeline steel.

Owner:济南市金材焊接材料有限公司

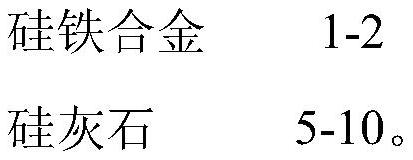

Method for electroplating copper and sliver on iron-nickel alloy frame

The present invention discloses a method for electroplating copper and sliver on an iron-nickel alloy frame. The method is characterized by comprising: 1, fixing an iron-nickel alloy frame; 2, carrying out cathode-anode combined degreasing; 3, carrying out acid washing; 4, carrying out cyanogen neutralization; 5, pre-plating copper; 6, plating copper; 7, pre-plating silver; 8, plating silver; 9, deplating sliver; 10, carrying out copper protection; and 11, drying, and taking the iron-nickel alloy frame from the bracket so as to complete the electroplating process. According to the present invention, the method has advantages of good electroplating effect and low cost.

Owner:TAIZHOU HUALONG ELECTRONICS

Vacuum aluminizing method of surface of neodymium-iron-boron permanent magnet

ActiveCN101736304BGood directionHigh hardnessVacuum evaporation coatingSputtering coatingHigh energyMetallurgy

The invention relates to a vacuum aluminizing method of the surface of a neodymium-iron-boron permanent magnet. The method sequentially comprises the following steps of: (1) polishing and cleaning the surface of the neodymium-iron-boron permanent magnet by adopting a wet method; (2) putting the neodymium-iron-boron permanent magnet on a rotating workpiece fame in a film plating chamber to ensure that the temperature of the neodymium-iron-boron permanent magnet is kept between 250 DEG C and 300 DEG C; (3) starting a vacuum pump on the film plating chamber and adjusting the vacuum degree of thefilm plating chamber to be 1-9*10<-3>Pa; (4) meanwhile, starting multi-arc cathode evaporators at both sides of the film plating chamber, a plane magnetic sputtering target and the rotating workpieceframe to carry out magnetic control multi-arc sputtering for 2-7 hours; (5) maintaining the film plating chamber to be cooled for 30-60 minutes under vacuum, aerating, opening the chamber, taking outthe aluminized neodymium-iron-boron permanent magnet and carrying out passivation with a non-chrome passivation solution. High energy ions generated by magnetron sputtering strike low-energy ions generated by the multi-arc method so as to promote the low-energy ions to generate more ionization, wherein the speeds and the trends of the high-energy ions and the low-energy ions are uniform, thus theefficiency is improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

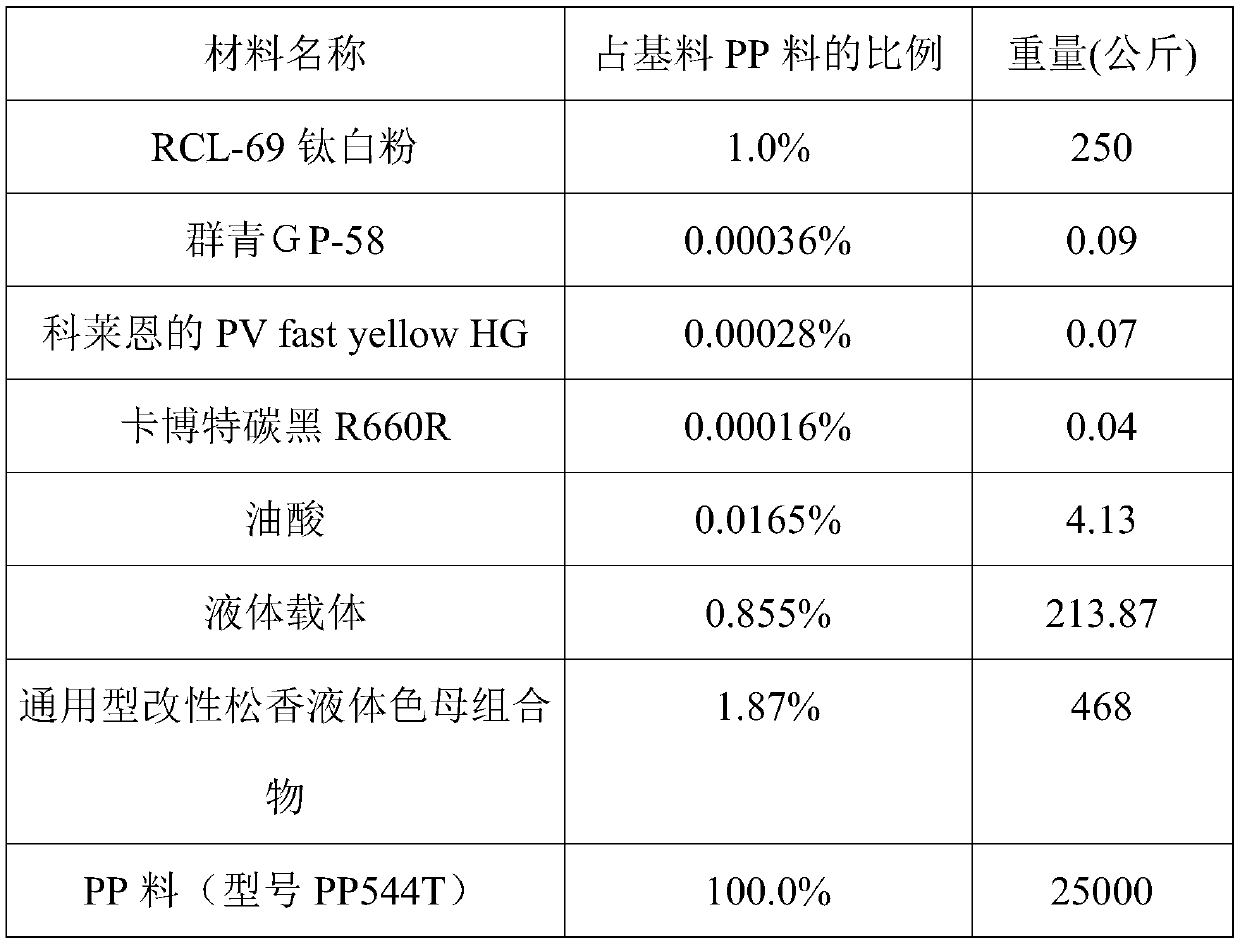

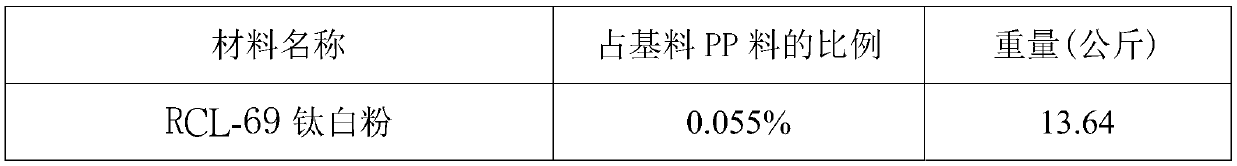

Universal modified rosin liquid color master batch composition, and preparation method and application thereof

PendingCN111040458ANot easy to slipThe mechanical properties are slightly affectedPlastic materialsFood packaging

The invention discloses a universal modified rosin liquid color master batch composition and a preparation method thereof, belonging to the technical field of plastic processing. The universal modified rosin liquid color master batch composition comprises the following components in percentages by mass: 30%-70% of a modified rosin thickening liquid carrier and 30%-70% of a plastic additive. According to the invention, in the storage period of the universal modified rosin liquid color master batch composition, a coloring agent and an additive do not float and sink and are not separated; the universal modified rosin liquid color master batch composition has good flowability in a guide pipe; in the processing process, the universal modified rosin liquid color master batch composition is not prone to causing screw slippage, and can maintain good stability at a high temperature; the influence of the universal modified rosin liquid color master batch composition on the mechanical property ofplastic is slight after the universal modified rosin liquid color master batch composition is added into the plastic; the universal modified rosin liquid color master batch composition is free of color powder points, color distribution non-uniformity, color spots and pocking marks; the universal modified rosin liquid color master batch composition is universal, is suitable for various different types of plastics, and can be used for manufacturing transparent and opaque plastic products; and the universal modified rosin liquid color master batch composition is non-toxic and harmless, and can be used for preparing food packaging plastic materials.

Owner:司徒志成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com