Bearing lubricated with a medium

A sliding bearing and bearing technology, applied in sliding contact bearings, bearings, bearings in rotating motion, etc., can solve the problems of sacrificial anode consumption and weakening of bearing rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

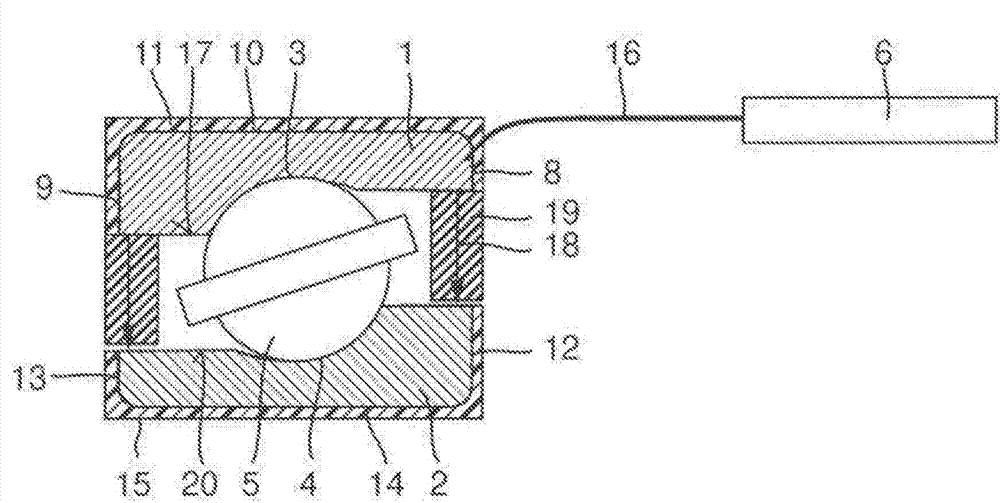

[0020] figure 1 Shown is a bearing designed as a rolling bearing, which comprises a first bearing ring 1 designed as an outer ring and a second bearing ring 2 designed as an inner ring, wherein each of the two bearing rings 1 , 2 is provided with a The rolling elements 5 of the rolling bearing are configured as bearing raceways 3, 4 of rolling raceways.

[0021] The bearing is designed as a medium-lubricated bearing, that is to say, the bearing is passed through by a liquid surrounding medium, which lubricates the bearing raceways 3, 4, the surrounding medium, in particular water, is corrosive, in particular based on chloride ions The surrounding medium can attack the material of the bearing rings 1 , 2 , ie the rolling bearing steel, in a pitting manner, and dissolve it point by point, especially in the vicinity of the bearing raceways 3 , 4 .

[0022] Furthermore, the bearing comprises a sacrificial anode 6 which is assigned to the first bearing ring 1 , ie is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com