Method for improving percent of pass of liquid crystal box

A liquid crystal screen and pass rate technology, which is applied in the field of liquid crystal screen manufacturing, can solve the problems of zero pass rate and lower pass rate, and achieve the effect of reducing cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method to improve the qualified rate of LCD screen is:

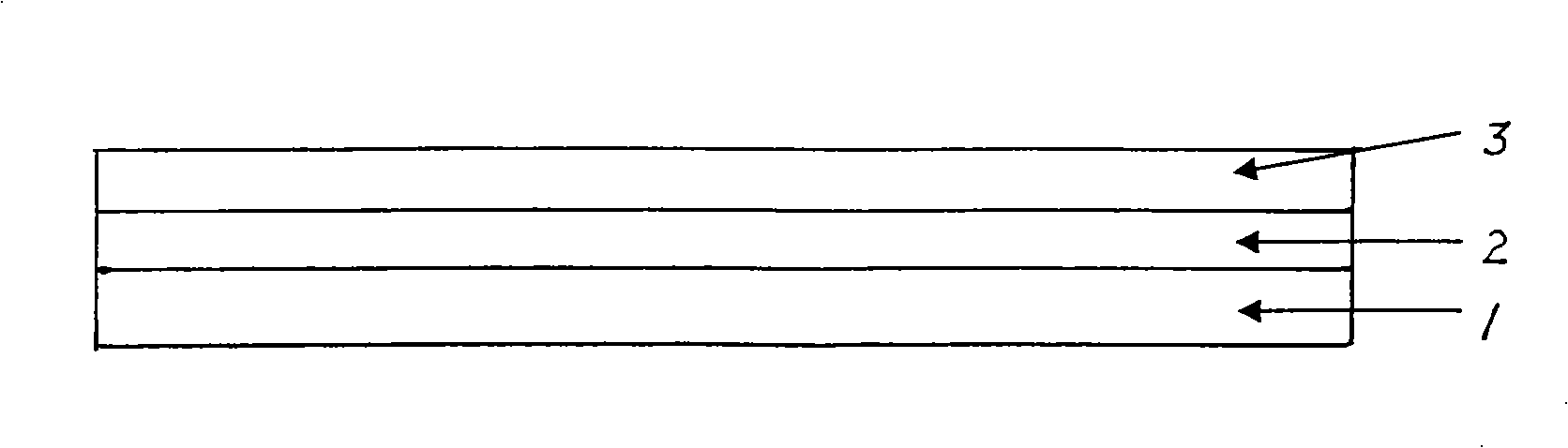

[0031] The first step is to selectively etch the ITO film on the ITO glass 1 by using a substrate cleaning agent, a photoresist printing machine, and an exposure machine. According to the needs of the product, the useful ones are retained and the useless ones are etched away;

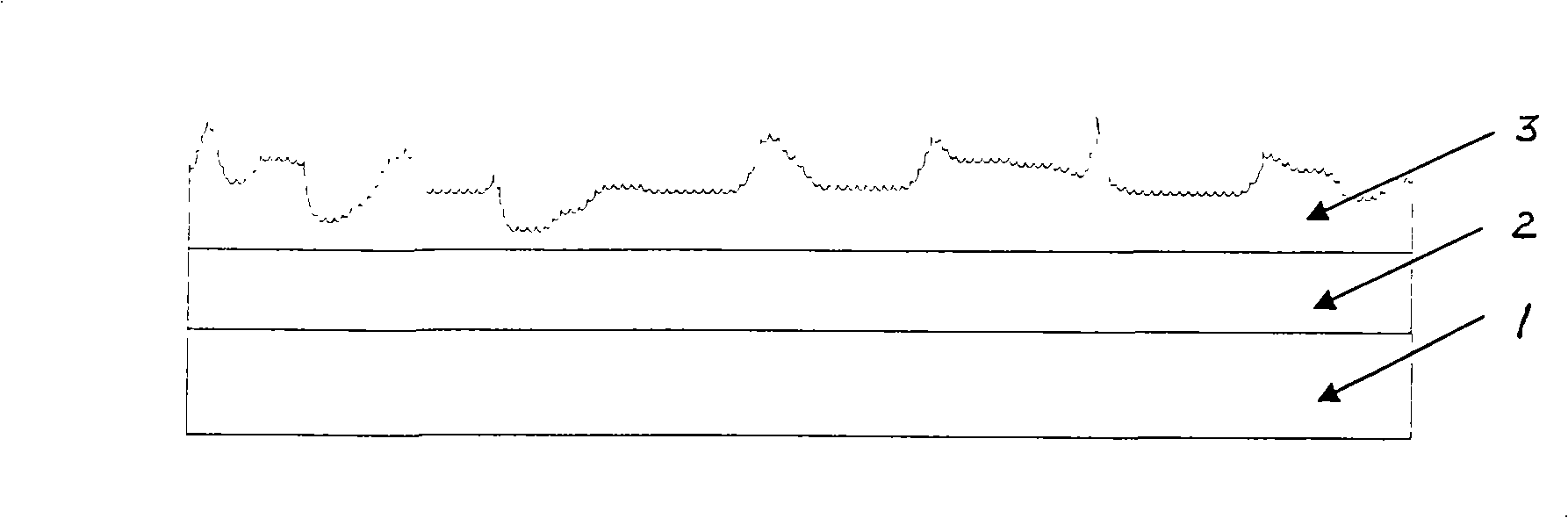

[0032] The second step: use a printing machine to coat a layer of inorganic thin film TOP layer 2 on the surface of the etched ITO glass 1;

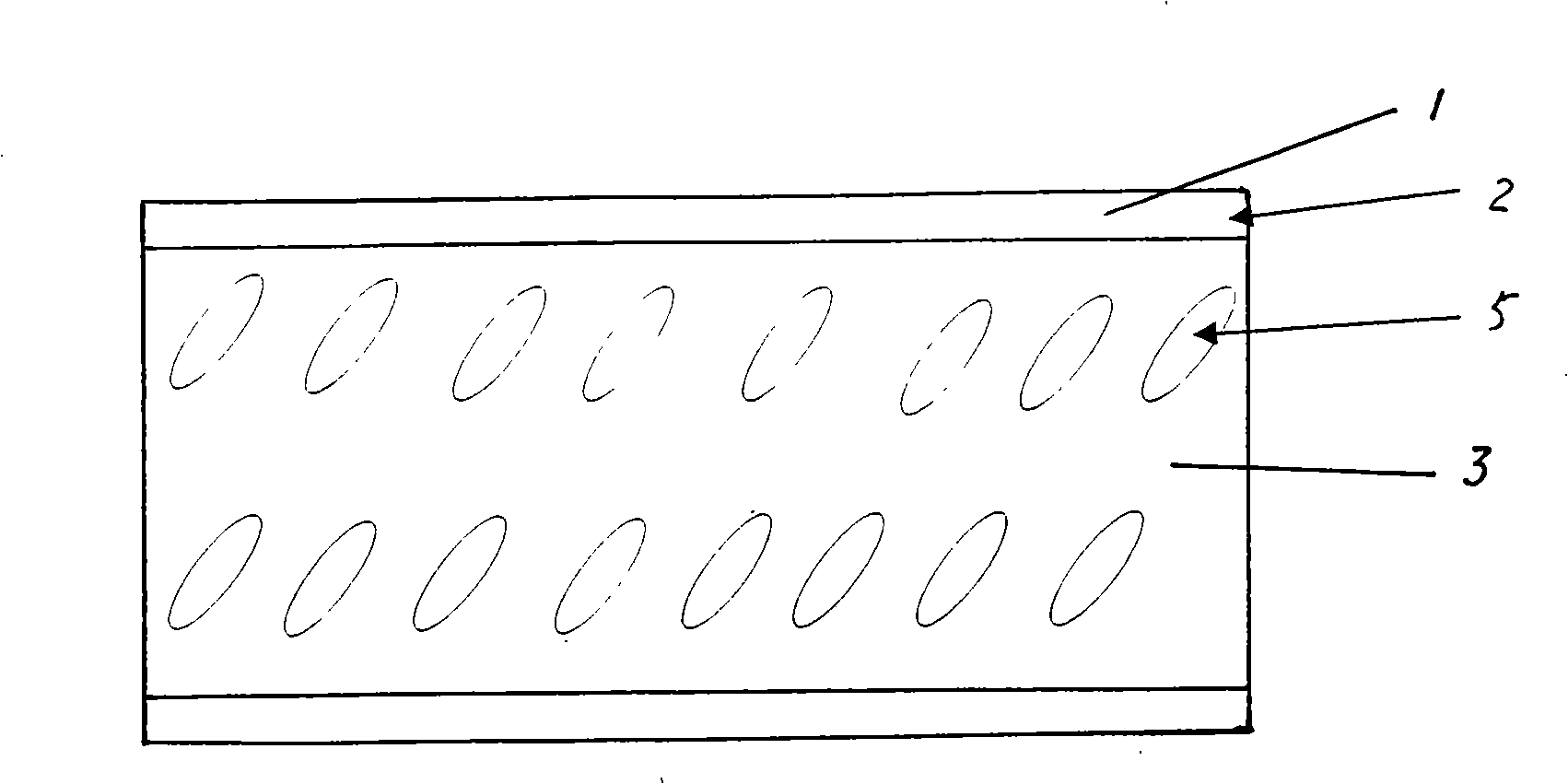

[0033] The third step: use a printing machine and a friction machine to coat a layer of film PI layer 3 that can produce grooves through friction on the surface of the TOP layer 2. If the machine is shut down, print 4-6 sheets of plain glass 4 before printing, such as Figure 5 shown;

[0034] Step 4: Use the laminating machine to paste two large pieces of glass into a large pair of glass;

[0035] Step 5: Use a cutting machine and a splitter to cut and split a large pair of glass into a strip scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com