Low-phosphorus corrosion inhibitor for sea water desalinization first-level reverse osmosis producing water

A corrosion inhibitor and reverse osmosis technology, which is applied in the fields of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, and can solve problems such as threats to the safety of water distribution pipe networks, corrosion, and pipeline scaling , to achieve the effect of simple wastewater treatment process, alleviating corrosion and increasing pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

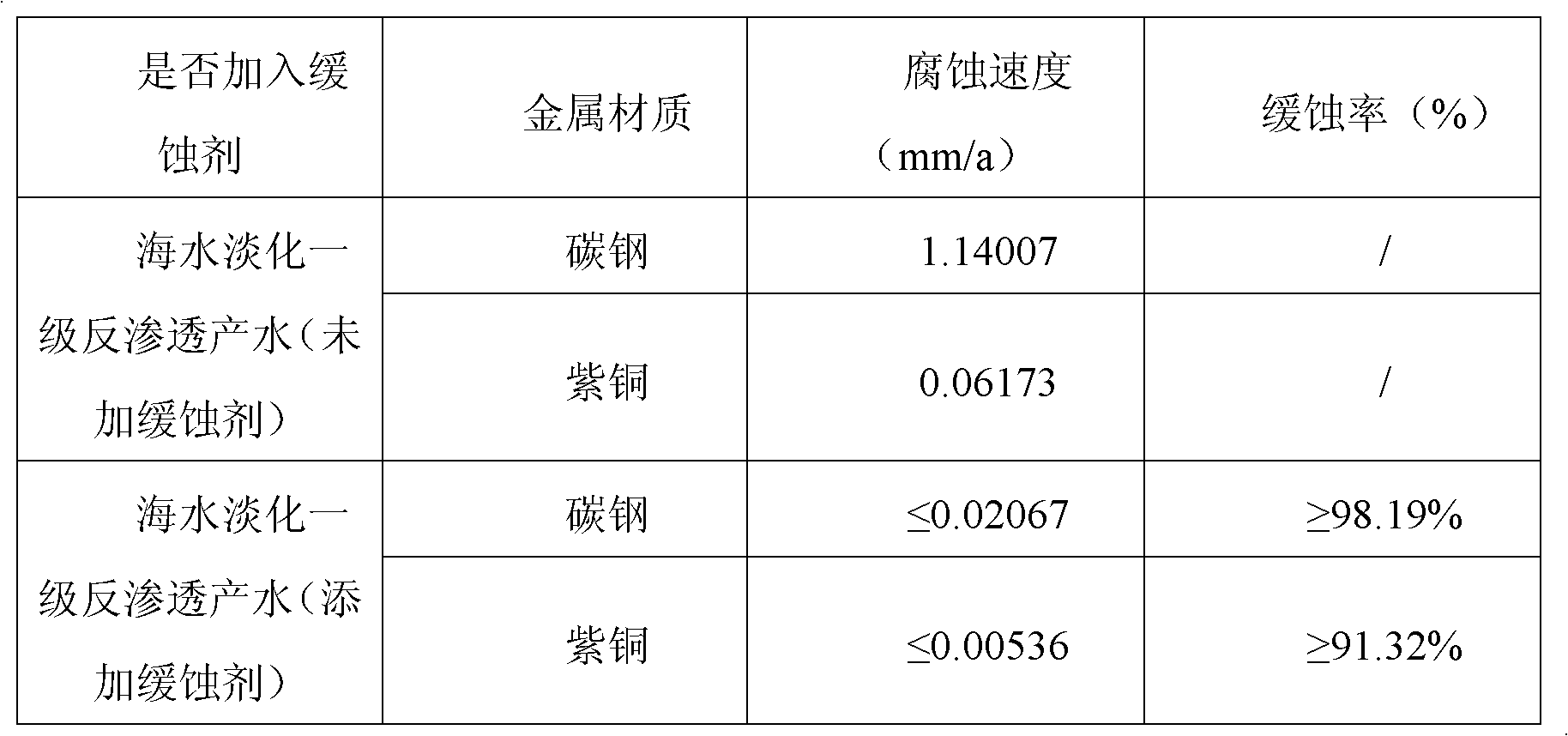

Embodiment 1

[0020] This embodiment relates to a metal corrosion inhibitor in seawater desalination primary reverse osmosis product water, and the proportion of the corrosion inhibitor is as follows: sodium silicate (based on SiO 2 Total) 3mg / L, sodium hexametaphosphate 10mg / L, zinc sulfate (as Zn 2+ Total) 3mg / L, benzotriazole 3mg / L, sodium hydroxide 80mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of carbon steel and copper test pieces after 96 hours. The results are shown in Table 2.

Embodiment 2

[0022] This embodiment relates to a metal corrosion inhibitor in seawater desalination primary reverse osmosis product water, and the proportion of the corrosion inhibitor is as follows: sodium silicate (based on SiO 2 Total) 10mg / L, sodium hexametaphosphate 10mg / L, zinc sulfate (as Zn 2+ Total) 3mg / L, benzotriazole 3mg / L, sodium hydroxide 80mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of carbon steel and copper test pieces after 96 hours. The results are shown in Table 2.

Embodiment 3

[0024] This embodiment relates to a metal corrosion inhibitor in seawater desalination primary reverse osmosis product water, and the proportion of the corrosion inhibitor is as follows: sodium silicate (based on SiO 2 Total) 6mg / L, sodium hexametaphosphate 5mg / L, zinc sulfate (as Zn 2+ Total) 3mg / L, benzotriazole 3mg / L, sodium hydroxide 80mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of carbon steel and copper test pieces after 96 hours. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com