Extrusion-grade highly filled polypropylene composite material and preparation method thereof

A composite material and extrusion-grade technology, applied in the field of materials, can solve problems such as composite modified polypropylene performance defects, unsatisfactory melt strength, etc., and achieve excellent bending resistance, good dimensional stability, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

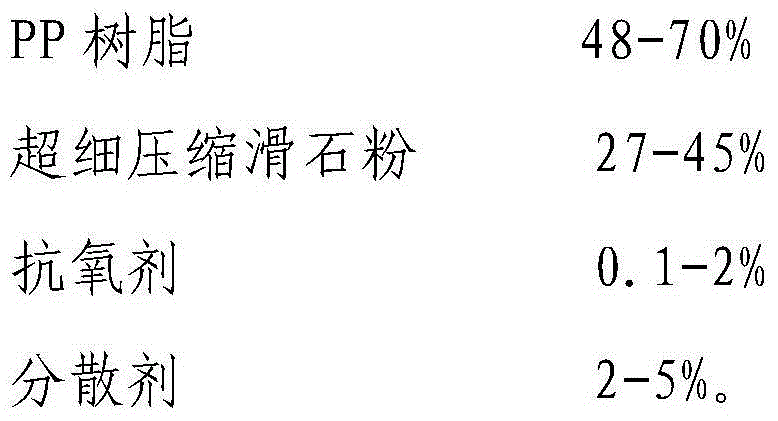

[0016] This embodiment prepares extrusion-grade high-fill PP composite material according to the following methods and ratios:

[0017] (1) 70KG Beijing Yanshan Petrochemical Polypropylene, 30KG 3000-4000 mesh ultra-fine compressed talc powder, 1010200g antioxidant, 168200g antioxidant, 3KG 50% silicone masterbatch, mixed for 5min at 150rpm in the mixer, A homogeneous blend is obtained.

[0018] (2) Put the blended material from the previous step into the twin-screw extruder from the main feeding port for extrusion processing. The temperature of each zone of the extruder is set to 190°C in the first zone, 200°C in the second zone, 210°C in the third zone, and 210°C in the fourth zone. 220°C, extrusion die 220°C, screw speed 350rpm. After cooling in a water tank, air-cooled and blow-dried, pelletized to obtain extrusion-grade high-filling PP composite materials.

[0019] Table 1 shows the properties of the above-prepared materials after injection molding and conditioning for ...

Embodiment 2

[0024] This embodiment prepares extrusion-grade high-fill PP composite material according to the following methods and ratios:

[0025] (1) 55KG Beijing Yanshan Petrochemical Polypropylene, 45KG 3000-4000 mesh ultra-fine compressed talc powder, 1010250g antioxidant, 168250g antioxidant, 4KG 50% silicone masterbatch, mixed 7min at 150rpm in the mixer, A homogeneous blend is obtained.

[0026] (2) Put the blended material from the previous step into the twin-screw extruder from the main feeding port for extrusion processing. The temperature of each zone of the extruder is set to 200°C in the first zone, 210°C in the second zone, 220°C in the third zone, and 220°C in the fourth zone. 220°C, extrusion die 225°C, screw speed 350rpm. After cooling in a water tank, air-cooled and blow-dried, pelletized to obtain extrusion-grade high-filling PP composite materials.

[0027] Table 2 shows the properties of the above-prepared materials after injection molding and conditioning for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com