Waterproof dirt-resistant shoe sole, waterproof dirt-resistant shoe and production method of waterproof dirt-resistant shoe sole

A dirt-resistant and waterproof membrane technology is used in shoes and their production, and in the field of waterproof and dirt-resistant soles. efficiency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of waterproof sole that embodiment 1 prior art provides

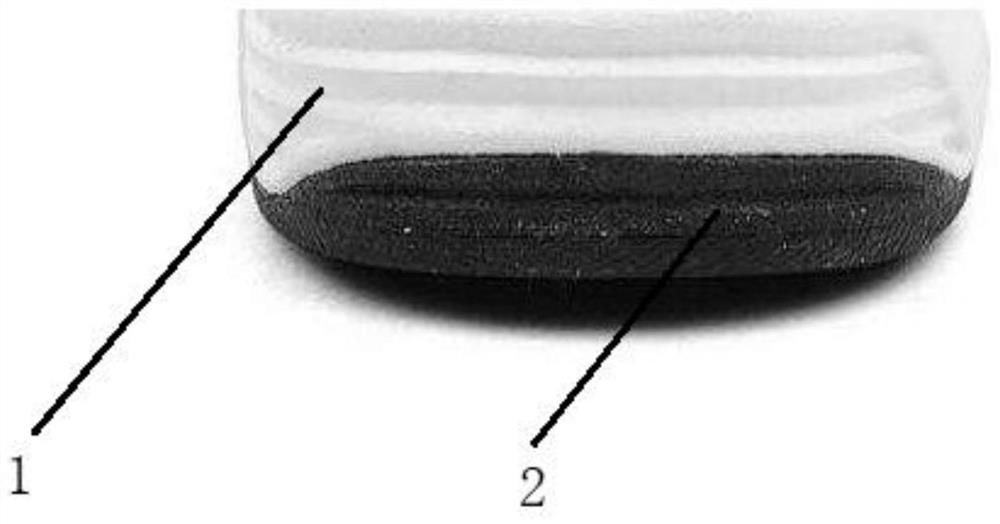

[0043] see figure 1 , what this figure shows is a kind of waterproof sole in the prior art. This waterproof sole is made of two parts, is respectively the PU midsole 1 and the rubber outsole 2 that are fully covered by the TPU film from top to bottom. When being made into shoes, it is necessary to cold-bond the upper and the PU midsole fully covered by the TPU film of the waterproof sole with an adhesive.

[0044] Though the shoe sole that this method makes has certain waterproof effect, sole can only show double-deck, double grain and double color effect. In addition, the method of cold bonding and fixing with adhesive is also prone to glue opening during wearing.

Embodiment 2

[0045] Another kind of waterproof sole preliminary product that embodiment 2 prior art provides

[0046] see figure 2 , what this figure shows is the schematic diagram of another kind of waterproof sole preliminary product in the prior art. This waterproof sole is made of two parts, is foamed PU midsole 11 and TPU outsole 12 respectively from top to bottom. Due to the adoption of the integral molding injection molding process to manufacture shoes, the periphery of the foamed PU midsole has more burrs formed by the foamed PU that overflows to the side. Later, when trimming the burr, skilled workers need to master the coordination between the trimming machine and the arc of the hand movement. The operation requires high technical proficiency, and the finished product after trimming has a wide cutting surface, and the aesthetics of the shoes is not high. In addition, this shoe is identical with embodiment 1, can only present the sole of double-layer, double-grain and double-co...

Embodiment 3

[0047] Embodiment 3 A kind of waterproof and dirt-resistant sole, shoes and production method thereof

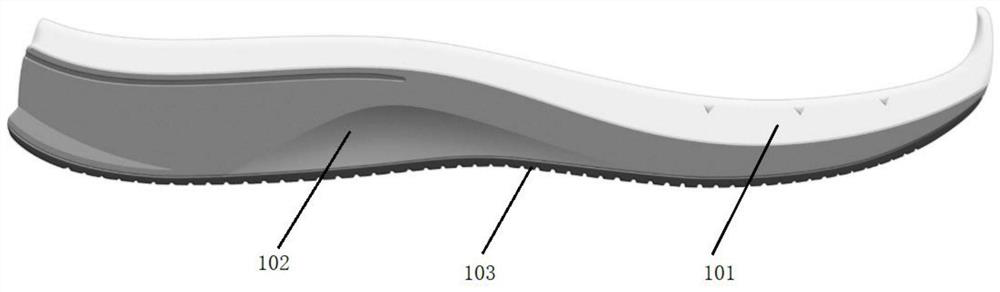

[0048] see image 3 , what this figure shows is the schematic diagram of a kind of waterproof and dirt-resistant shoe sole described in the specific embodiment of the present invention. The waterproof and dirt-resistant sole is composed of three layers, the upper part is a foamed PU layer 101, the middle part is coated with a foamed PU layer 102 by a TPU waterproof membrane, and the bottom TPU waterproof membrane is coated with a large bottom layer 103. Specifically, the waterproof and dirt-resistant sole includes a large bottom, a waterproof film layer (made of TPU), and a midsole (made of foamed PU). The lower half of the bottom forms a TPU waterproof membrane and covers the foamed PU layer 102. The lower half is the area of the midsole close to the outsole, and the waterproof membrane layer is TPU. The waterproof film layer is close to the outsole, and fills the hollo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com