Method for producing fire-resisting glass and dedicated production equipment

A technology of fire-resistant glass and production methods, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve problems such as low thermal shock resistance, low fire-resistant integrity, and failure to meet the fire-resistant requirements of fire-resistant glass. Achieve the effect of alleviating the temperature difference and satisfying the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

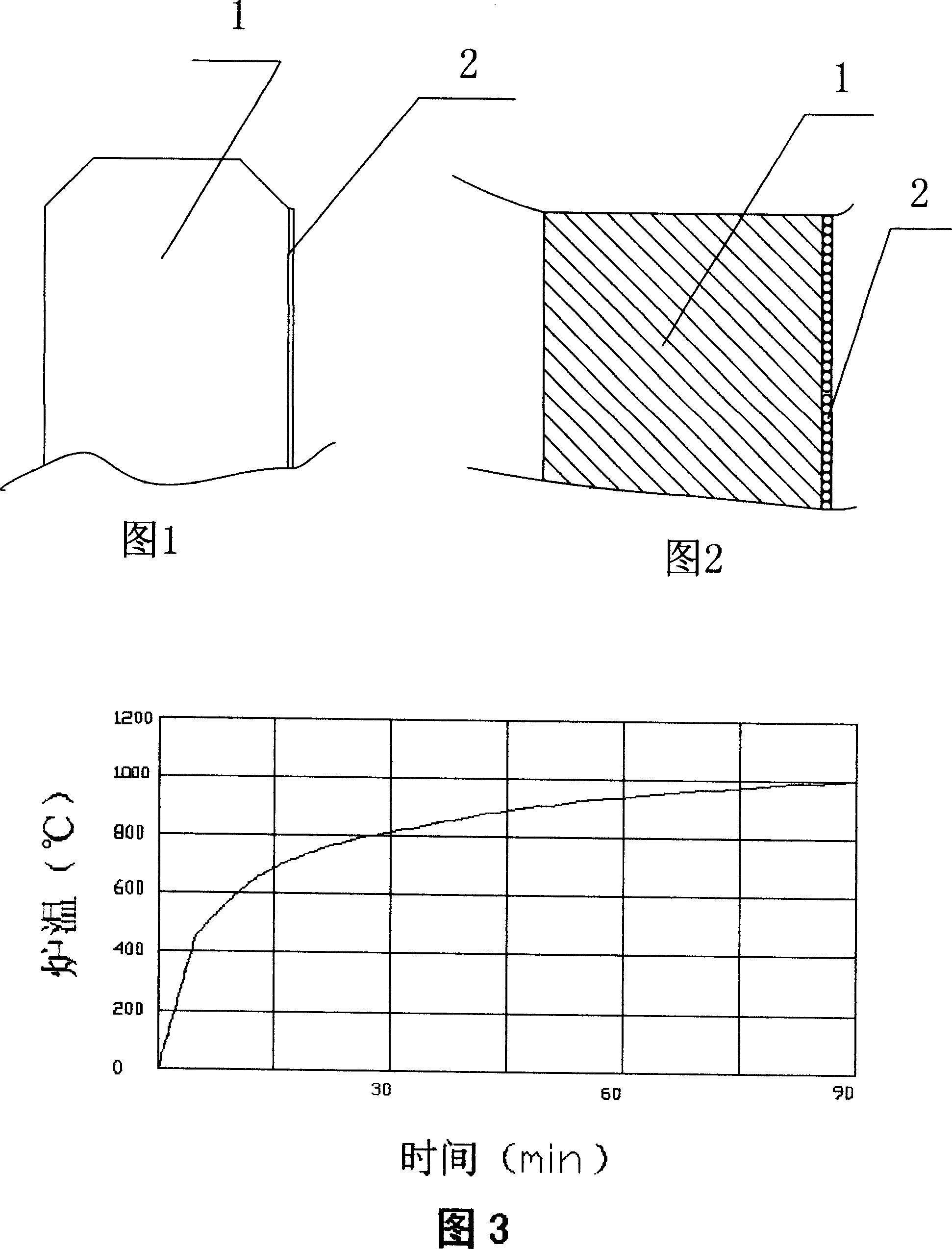

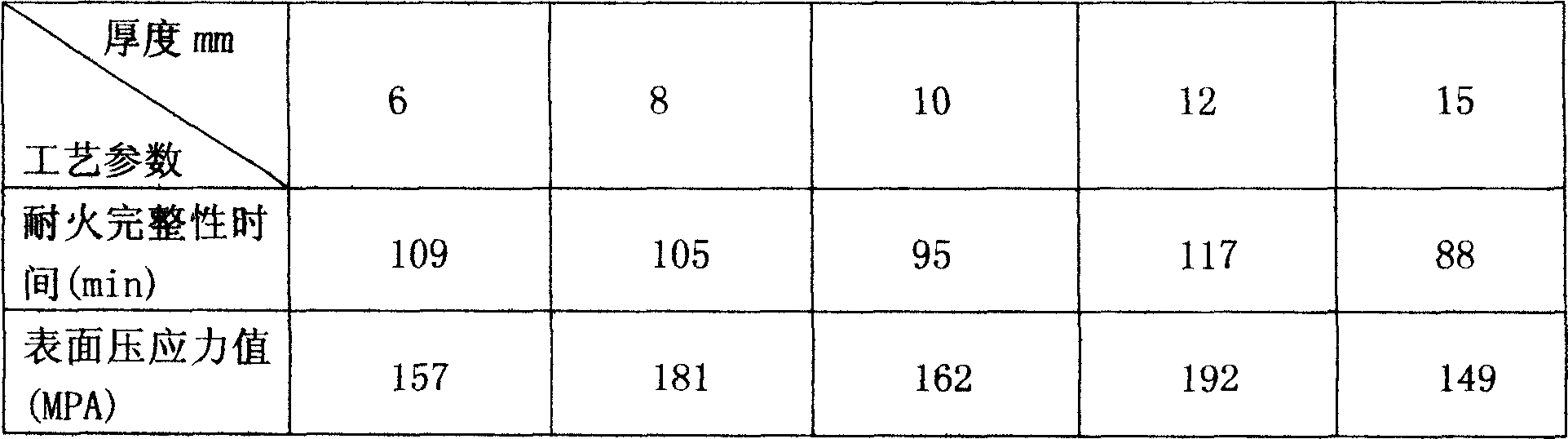

[0096] Embodiment 1: use analytical balance and marked acid solution test tube, prepare cesium potassium salt solution as the ion exchange raw material of fireproof glass: the composition formula of spraying solution is: cesium nitrate 1%, potassium nitrate: 40%, acetone 42% ; Formic acid 10%; Switzerland seven or eight 7%. Take 2 pieces of 610mm*610mm*6mm transparent float glass, glass type C-6, processing requirements: the size tolerance is ±1, and the appearance has no obvious defects; place the cleaned semi-finished product on a special laminated frame, and spray the above-mentioned The prepared cesium potassium solution is sent to the preheated tempering furnace after 2 hours of natural air drying at room temperature, and the process parameters for producing fireproof glass are adjusted. The specific parameters are shown in Table 4 below. The heating time is 170s-750s, and the cooling The time is 210s-800s.

Embodiment 2

[0097] Embodiment 2: Take a piece of 610mm*610mm*8mm glass type C-8, and implement the same steps as Example 1.

Embodiment 3

[0098] Embodiment 3: Take one piece each of 1930*864 and 610*610*10mm, glass type C-10, and the implementation steps are the same as in Embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com