Soft and hard material combined seal with cast electronic chip and manufacturing method of seal

A technology of electronic chips and manufacturing methods, which is applied in printing, stamping, etc., can solve the problems that the advantages and disadvantages cannot complement each other, and the display of electronic chips is correct, so as to achieve the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

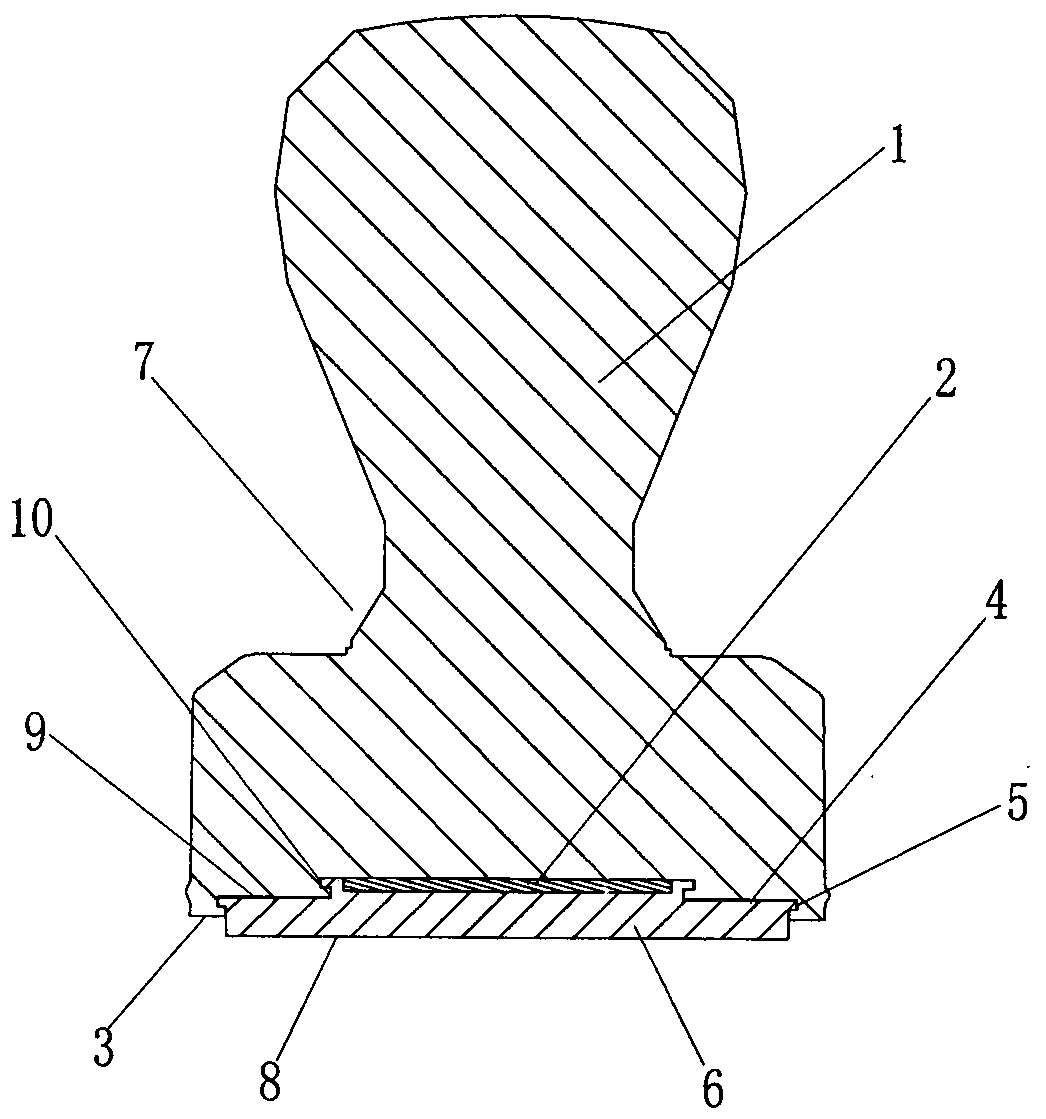

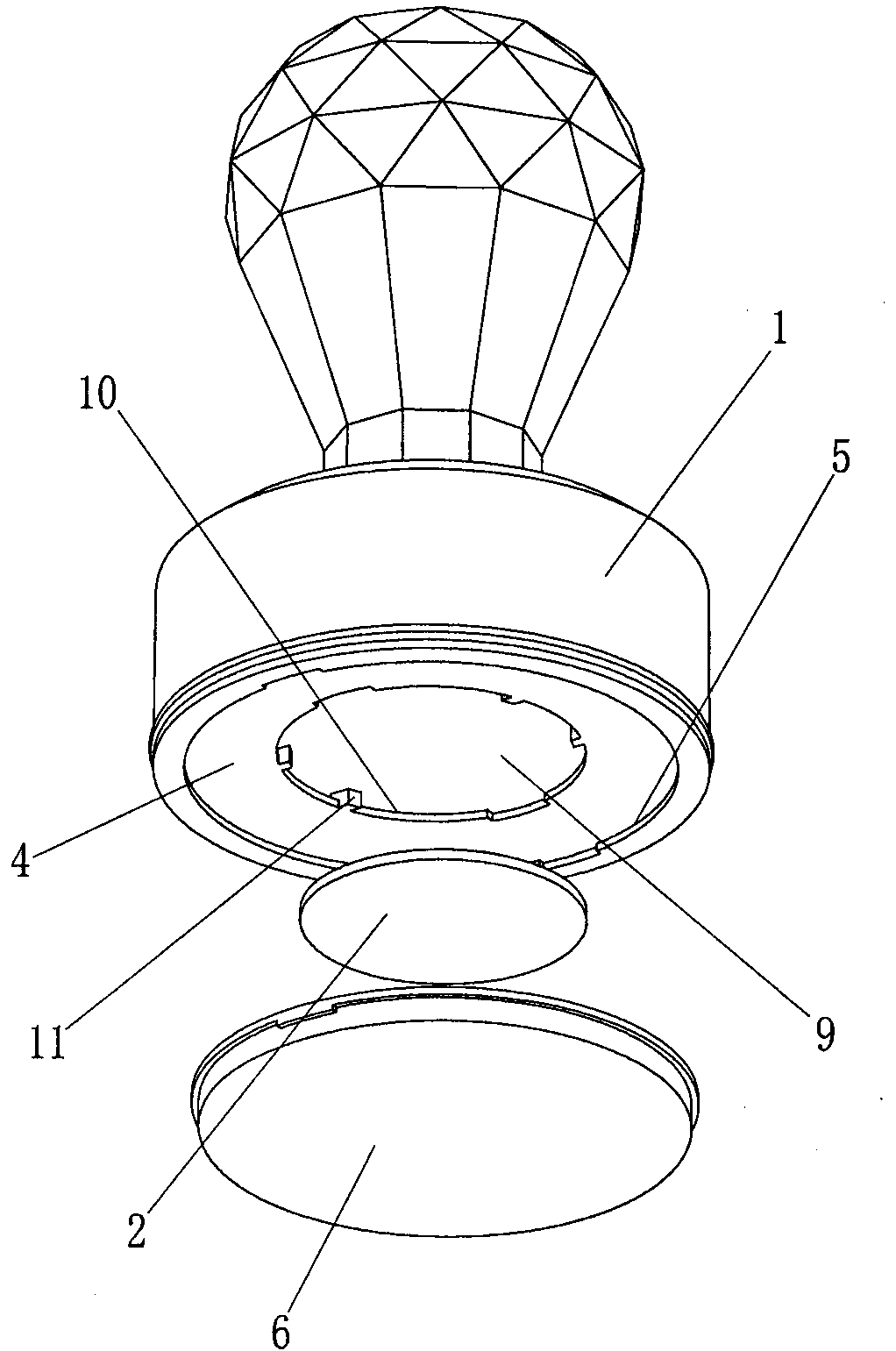

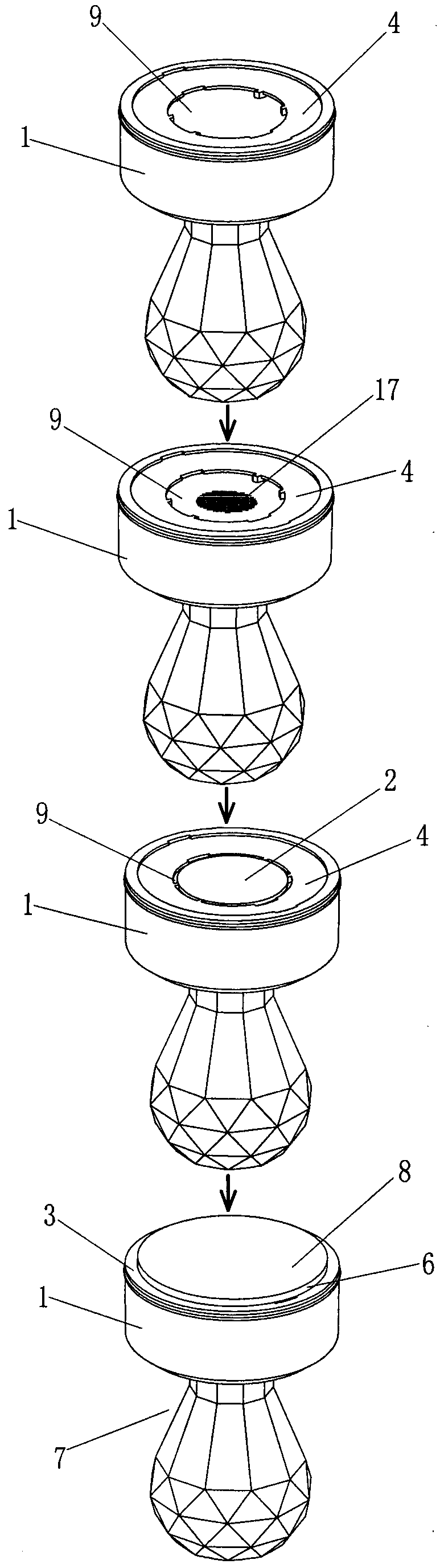

[0037] refer to Figure 1 ~ Figure 2 , this combination of soft and hard materials contains a stamp marked with an electronic chip, including a stamp main body 1 and an electronic chip assembly 2 arranged in the stamp main body 1, and the seal has a chapter surface for making articles, and is characterized in that: the stamp The main body 1 is a hard transparent body, and the lower end surface 3 of the stamp main body 1 is provided with an axially indented inner concave part 4, and the wall of the inner concave part 4 is provided with a radially inner concave ring groove 5. The electronic chip assembly 2 is fixed on the middle position of the concave part 4, the concave part 4 is filled with a soft transparent body 6, and the soft transparent body 6 protrudes from the The end surface of the outer part of the lower end surface 3 of the stamp main body 1 is a plane, constituting the seal surface 8 of the stamp 7 .

[0038] The main body 1 of the stamp is injection molded by pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com