Halogen-free flame-retardant porcelain-white polycarbonate composite material with high glossiness

A polycarbonate and composite material technology, used in the field of halogen-free flame retardant high-gloss porcelain white polycarbonate composite materials, can solve the problem of poor processing fluidity, low temperature impact toughness, flame retardancy and stress crack resistance, strength and resistance. Insufficient combustion, loss of PC performance and other problems, to achieve the effect of reducing thermal processing procedures, low raw material cost and processing cost, and solving stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

[0020] In the following examples, the polycarbonate is Bayer Red Bull board corner crushing material; the halogen-free flame retardant is FR-SI9805 produced by Quansheng Company; the toughening agent is DuPont 1125AC; the antioxidants 168 and 1076 are purchased from Yuansheng Chemical , the two are compounded at a weight ratio of 1:1; the flow agent is Italian hair-based PETS-AP; the titanium dioxide is DuPont R103.

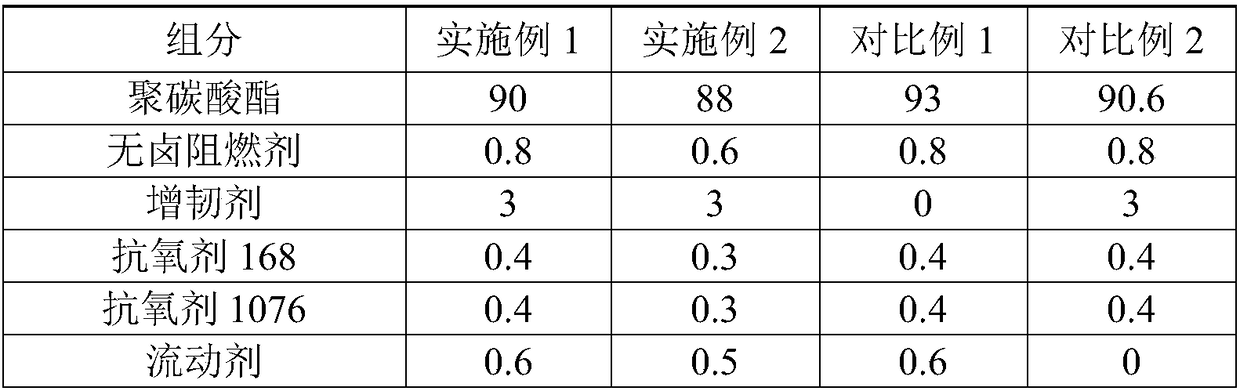

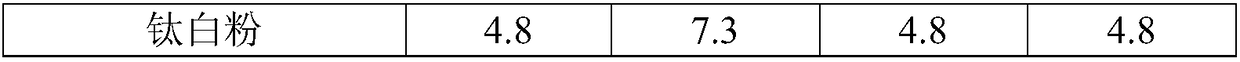

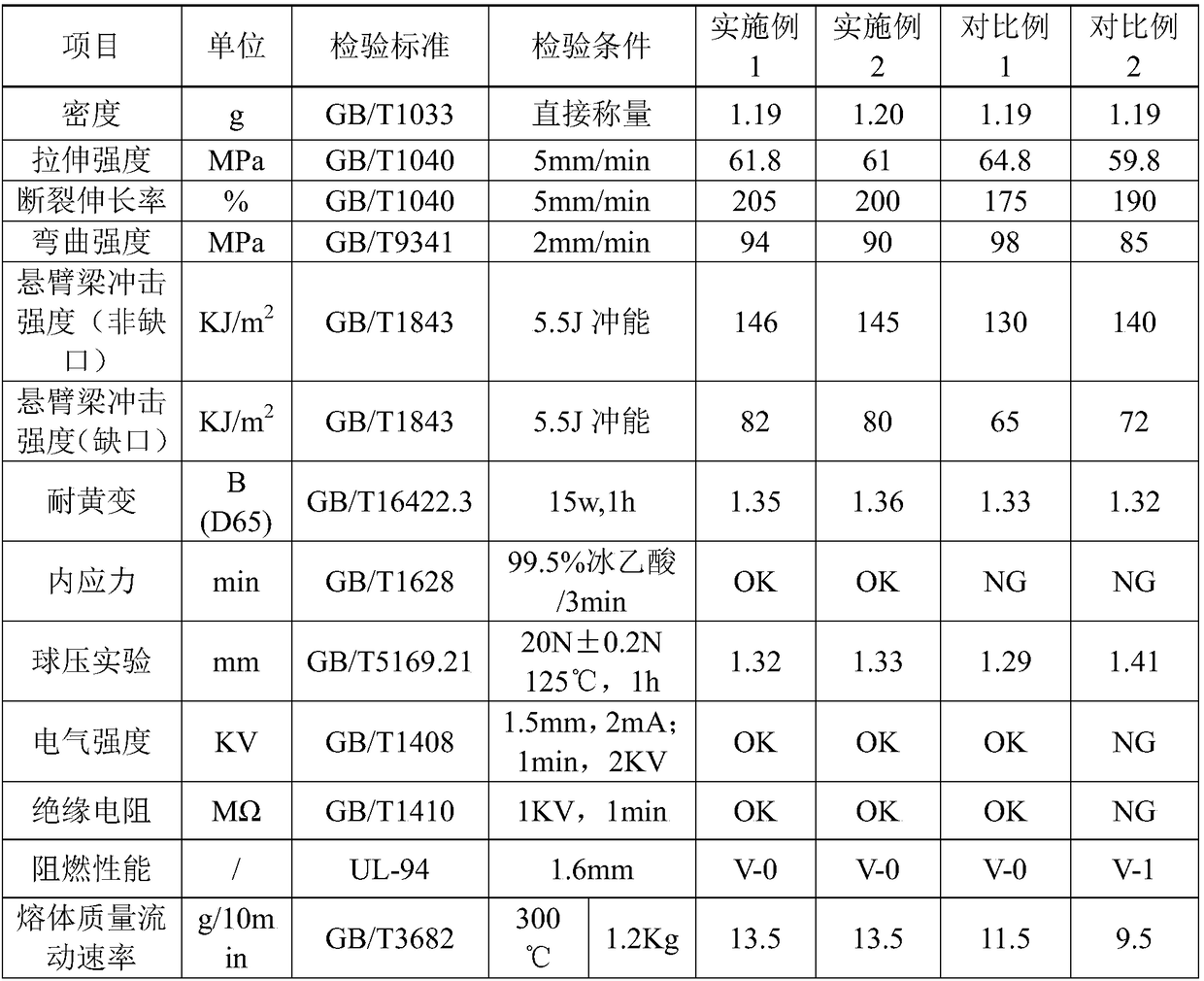

[0021] The raw material composition and proportioning ratio of Example 1-2 and Comparative Example 1-2 are shown in Table 1.

[0022] Table 1 (parts by weight)

[0023]

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com