Universal modified rosin liquid color master batch composition, and preparation method and application thereof

A modified rosin, a general-purpose technology, applied in the field of plastic processing, can solve the problems of screw slippage, incompatibility, affecting mechanical properties, etc., and achieve the effect of not easy screw slippage, good fluidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take by weighing 85.6 kilograms of rosin glycerides, 123 kilograms of cyclohexane 1,2-diisononyl dicarboxylate, and 5.34 kilograms of polydimethylsiloxane, put them into a heatable stirring device together, and start the mixer with an electric stirrer. Heating the container, adjusting the rotation speed to 50 rpm, stirring the components into a uniform mixed liquid, cutting off the power of the stirring device, cooling to room temperature, and obtaining the liquid carrier.

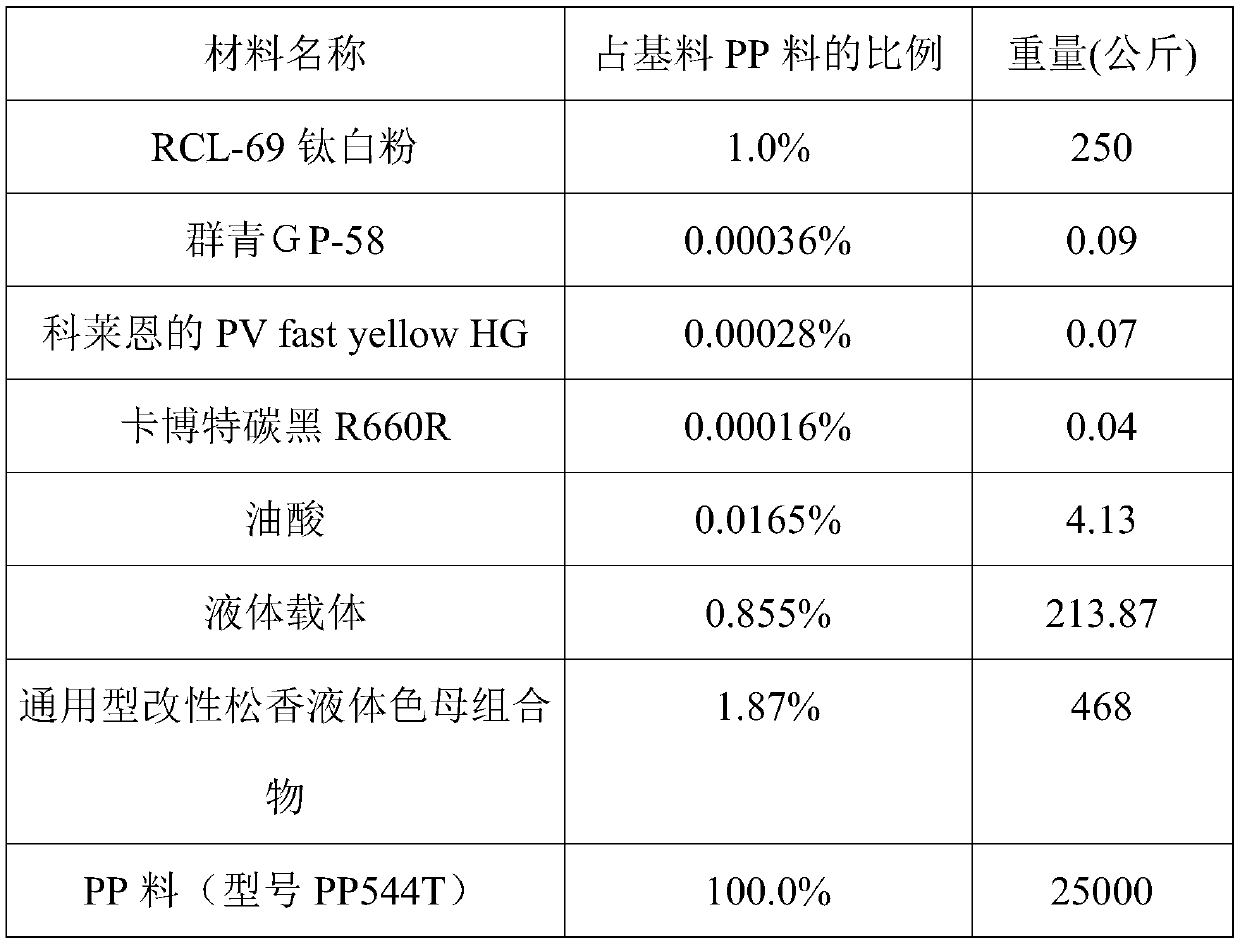

[0039] According to the ratio of materials shown in Table 1, take by weighing 250 kilograms of titanium dioxide powder of RCL-69 type, 70 grams of yellow pigments with the trade name of Clariant company PV Fast Yellow HG, 90 grams of inorganic pigment Ultramarine GP-58, and 40 grams of special carbon black R660R and 4.13 kilograms of oleic acid, and 213.87 kilograms of the above-mentioned prepared liquid carrier, put them in the bucket, and stir for 10 minutes at a slow speed of 200 rpm with a double...

Embodiment 2

[0047] Take by weighing 21.98 kilograms of rosin glycerides, 31.64 kilograms of non-phthalate plasticizers (composition is: 1,4-benzenedicarboxylic acid bis(2-ethylhexyl) ester>98%, 2-ethylhexyl Methyl terephthalate <2%), polydimethylsiloxane 1.375 kg, put them into a heatable stirring device together, start the heating container with an electric stirrer, adjust the speed to 50 rpm, each The components are stirred into a uniform liquid, the power of the stirring device is cut off, and cooled to room temperature to obtain a liquid carrier.

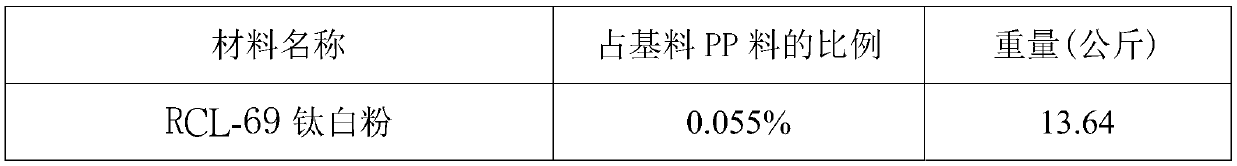

[0048] According to the ratio of materials shown in Table 2, take by weighing model is 13.64 kilograms of titanium dioxide of RCL-69, the trade name of Clariant is 22.73 kilograms of red pigments of PV Fast Red D3G, and the trade name is 11.36 kilograms of P.R.254 pigment red of 3330A , 2.38 kg of Shanghai Sanzheng Polymer Material Co., Ltd.’s product model is CH-6 hyperdispersant, Shanghai Sanzheng Polymer Material Co., Ltd.’s product mode...

Embodiment 3

[0057]Take by weighing 7 kilograms of rosin methyl resin and 3 kilograms of non-phthalate plasticizers (composition is: 1,4-benzenedicarboxylate bis(2-ethylhexyl) ester) and put into heatable stirring device, start the heating container with an electric stirrer, adjust the speed to 50 rpm, stir the components into a uniform liquid, cut off the power of the stirring device, cool to room temperature, and obtain the liquid carrier.

[0058] According to the ratio of materials shown in Table 3, the model of Clariant dyestuff red is Sandoplast Red BB 31.25 grams, solvent reactive red 195 dye 3.13 grams, dispersant ethylene bis stearamide 7.778 kilograms, and 0.35 kilograms model CH-6 10 kg of the hyperdispersant and the above-mentioned prepared liquid carrier, put them into a bucket, stir at a slow speed of 200 rpm for 10 minutes with a double-helix twin-shaft electric stirrer, and then stir at a fast speed of 700 rpm for 50 A general-purpose modified rosin liquid color masterbatch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com