Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Solve the small friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

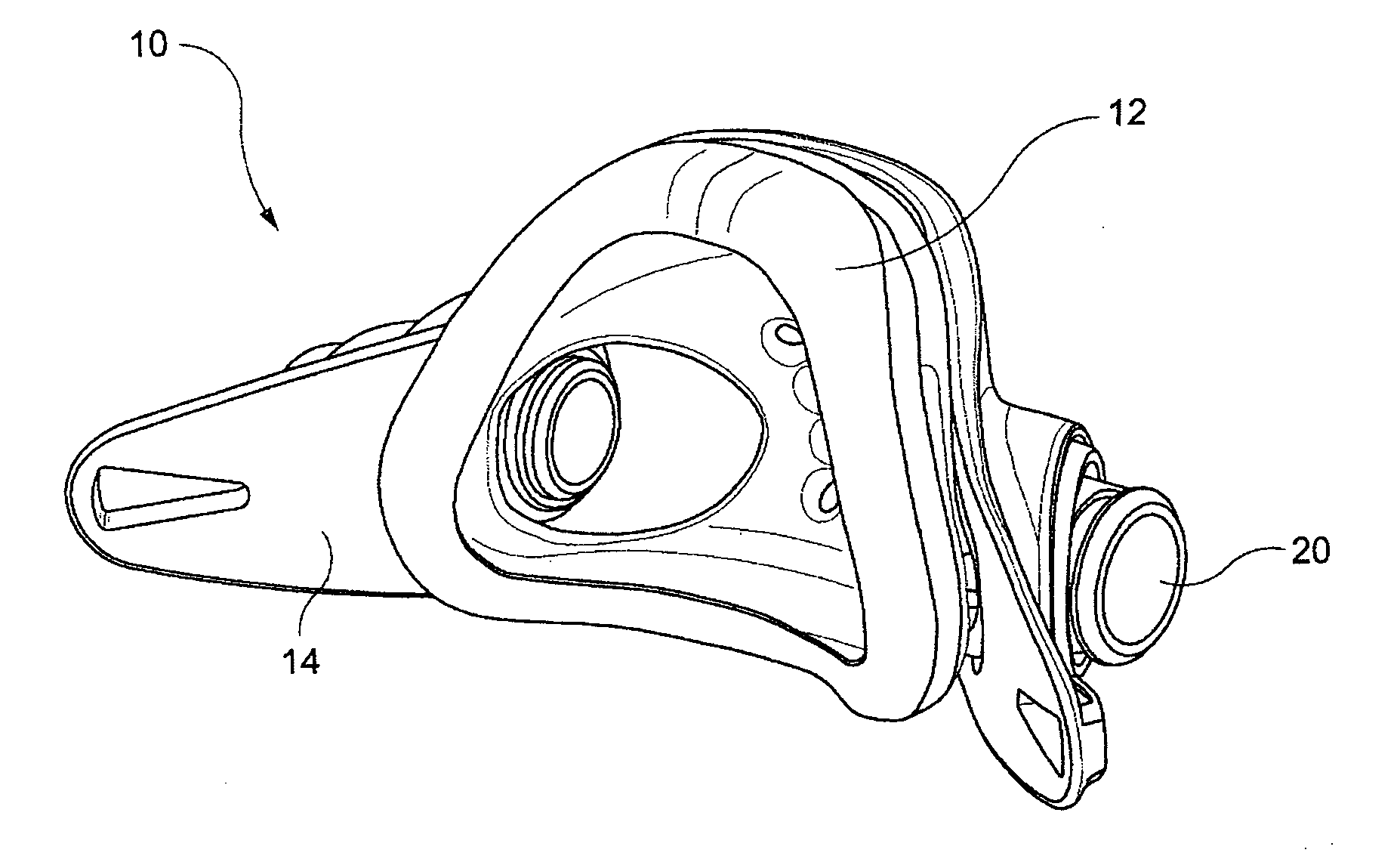

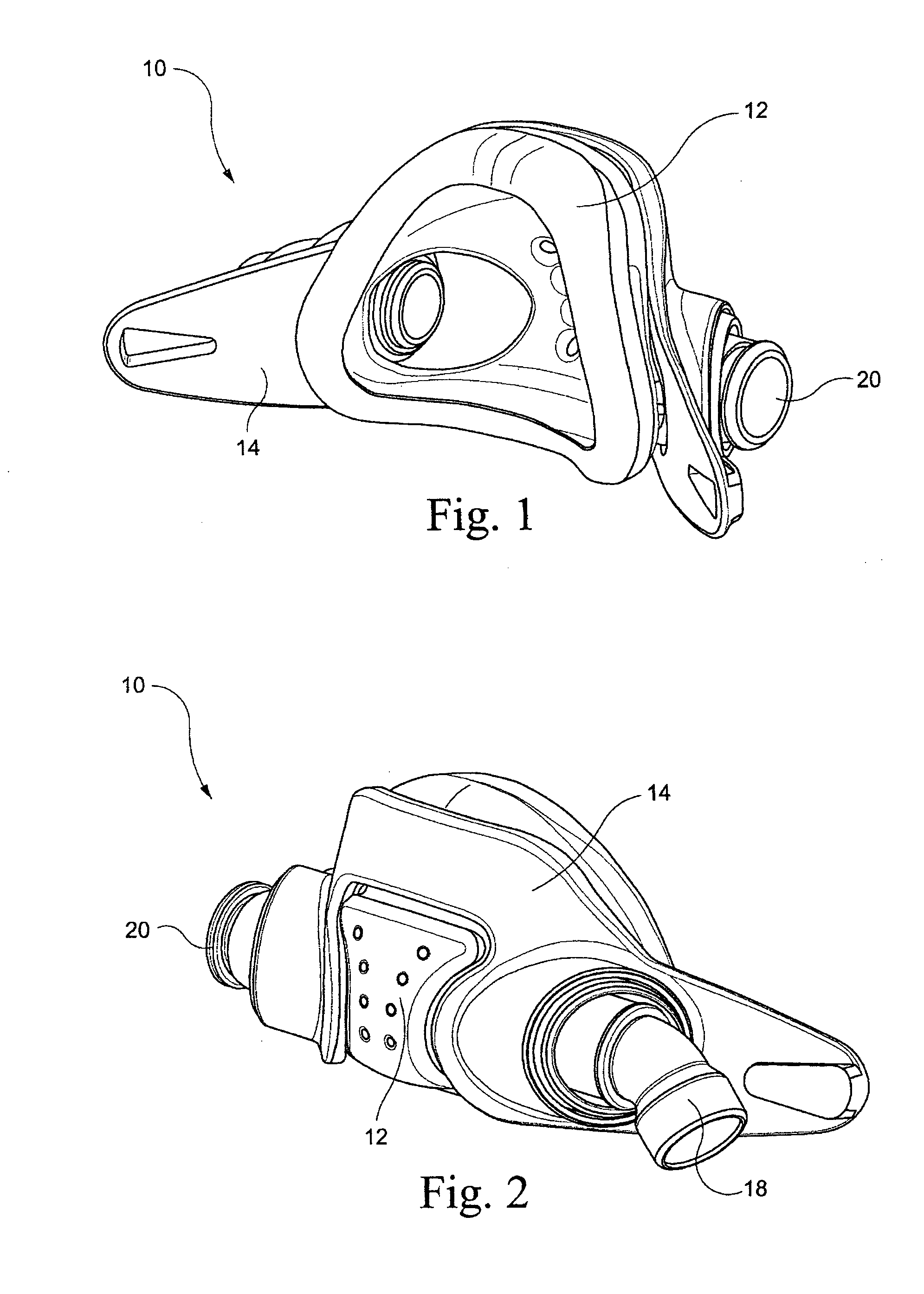

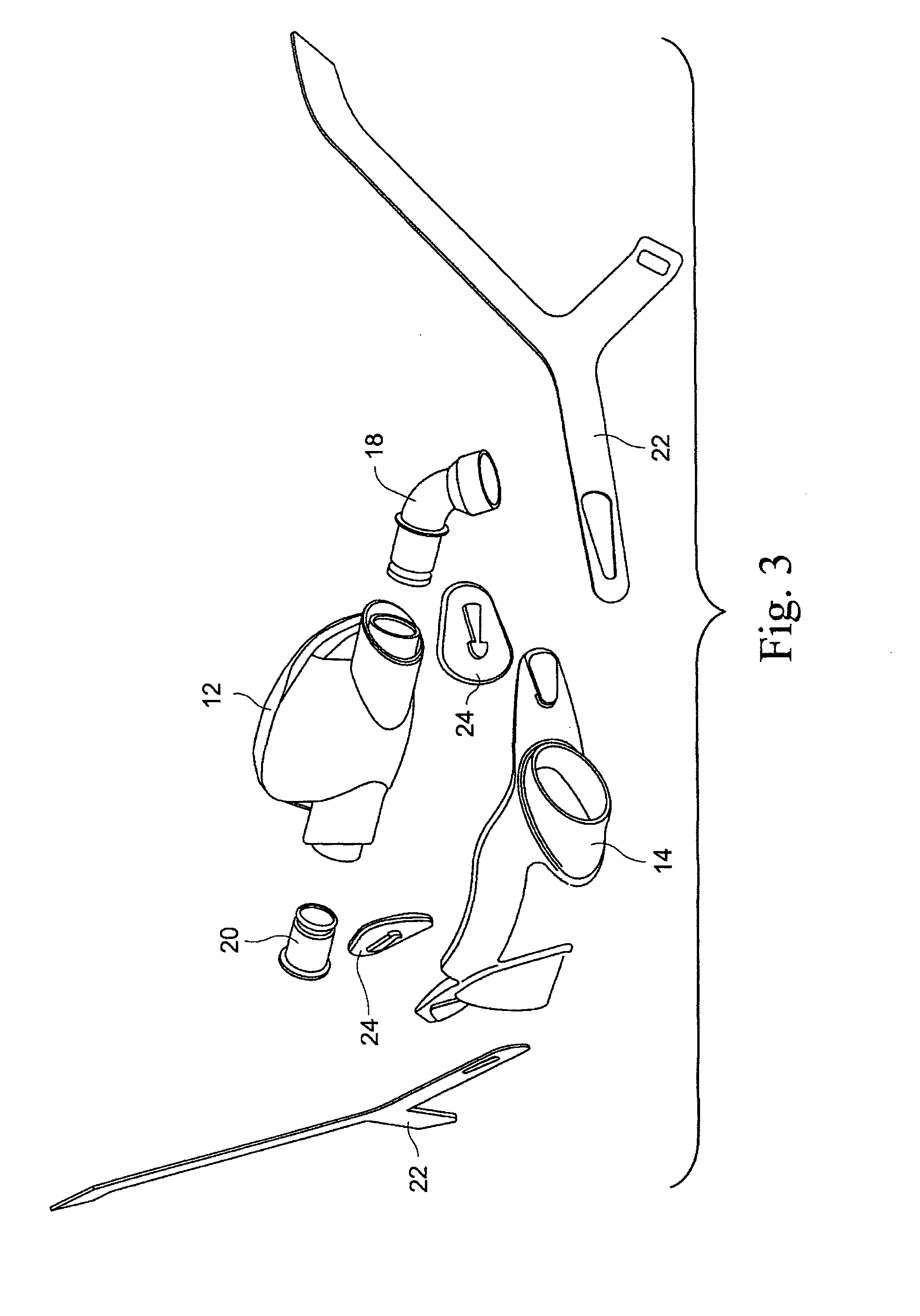

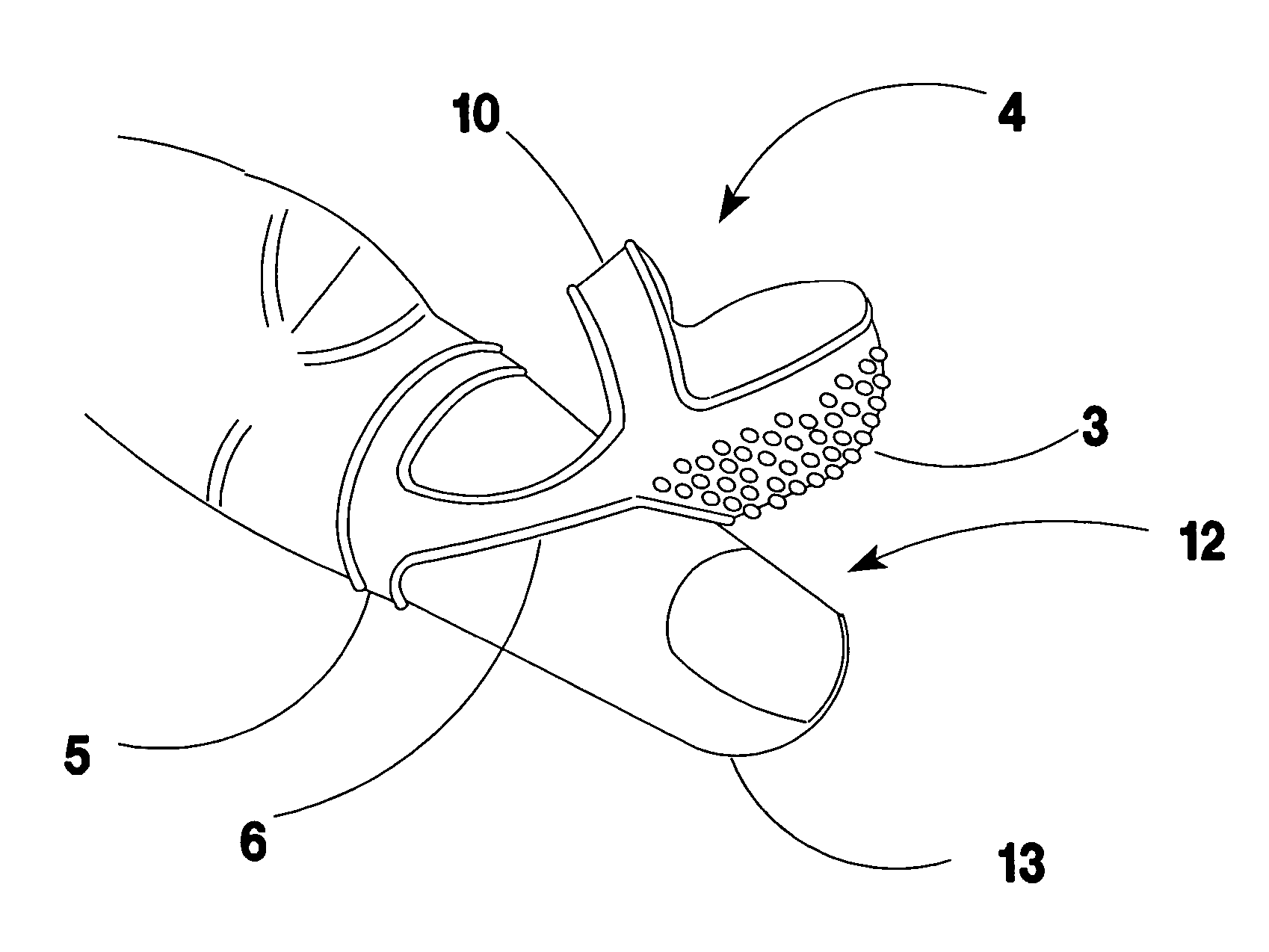

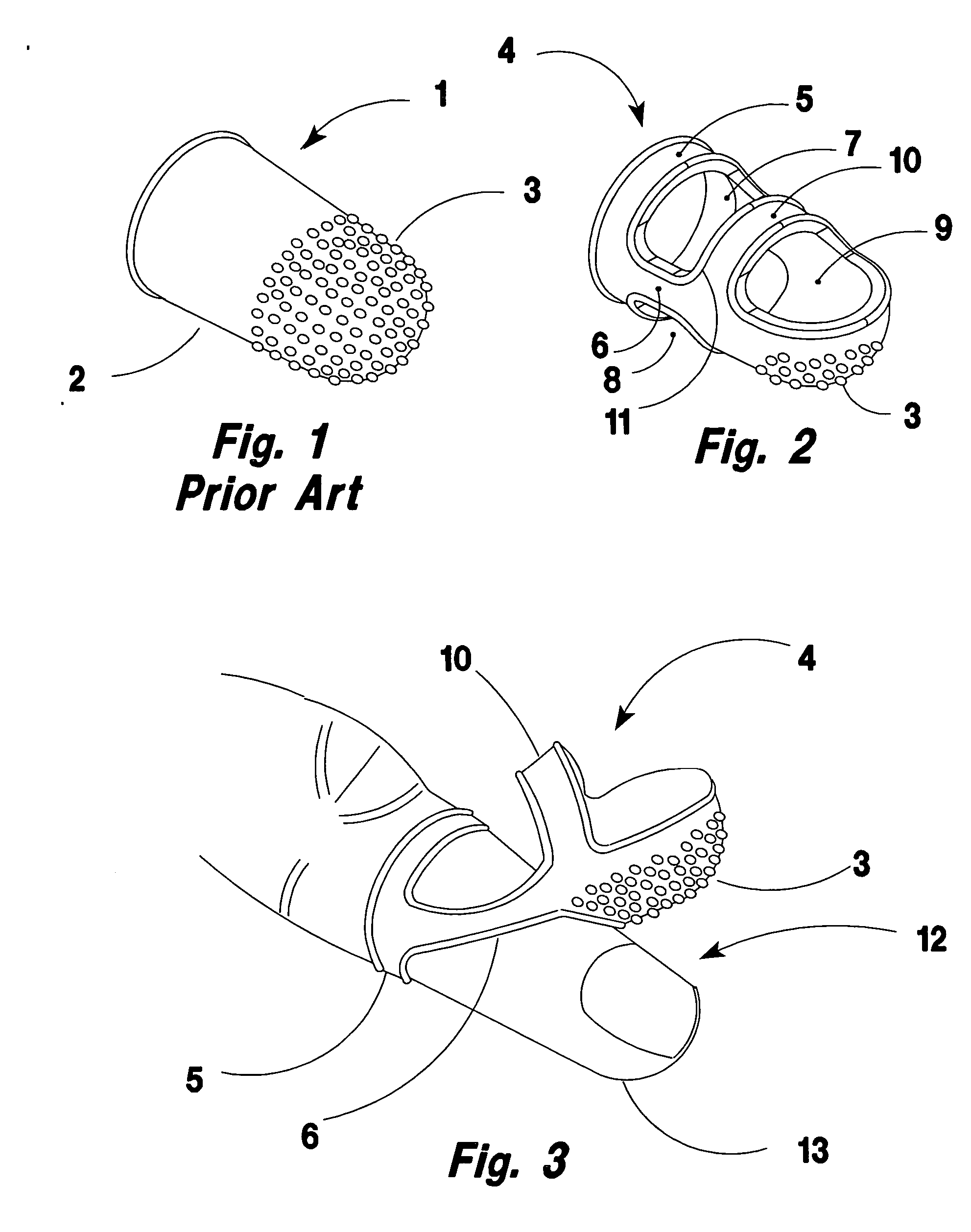

Respiratory mask

ActiveUS20100313891A1Solve the small frictionWeight bulkRespiratory masksBreathing masksNoseRespiratory mask

A respiratory mask for use with a patient, and that is suited for use with children, includes a flexible cushion arranged to interface with and deliver air to the patient's nose. The cushion has a tube connection portion at one or both sides adjacent the patient's nares, the tube connection portion being arranged to connect to an air delivery tube. This location, plus the very low profile of the mask, allows a patient (e.g. an infant) to sleep on their face more comfortably. A more rigid support structure adjacent the cushion is provided to stabilize the cushion and prevent it from collapsing. Headgear is also provided and arranged for releasable attachment to the support structure.

Owner:RESMED LTD

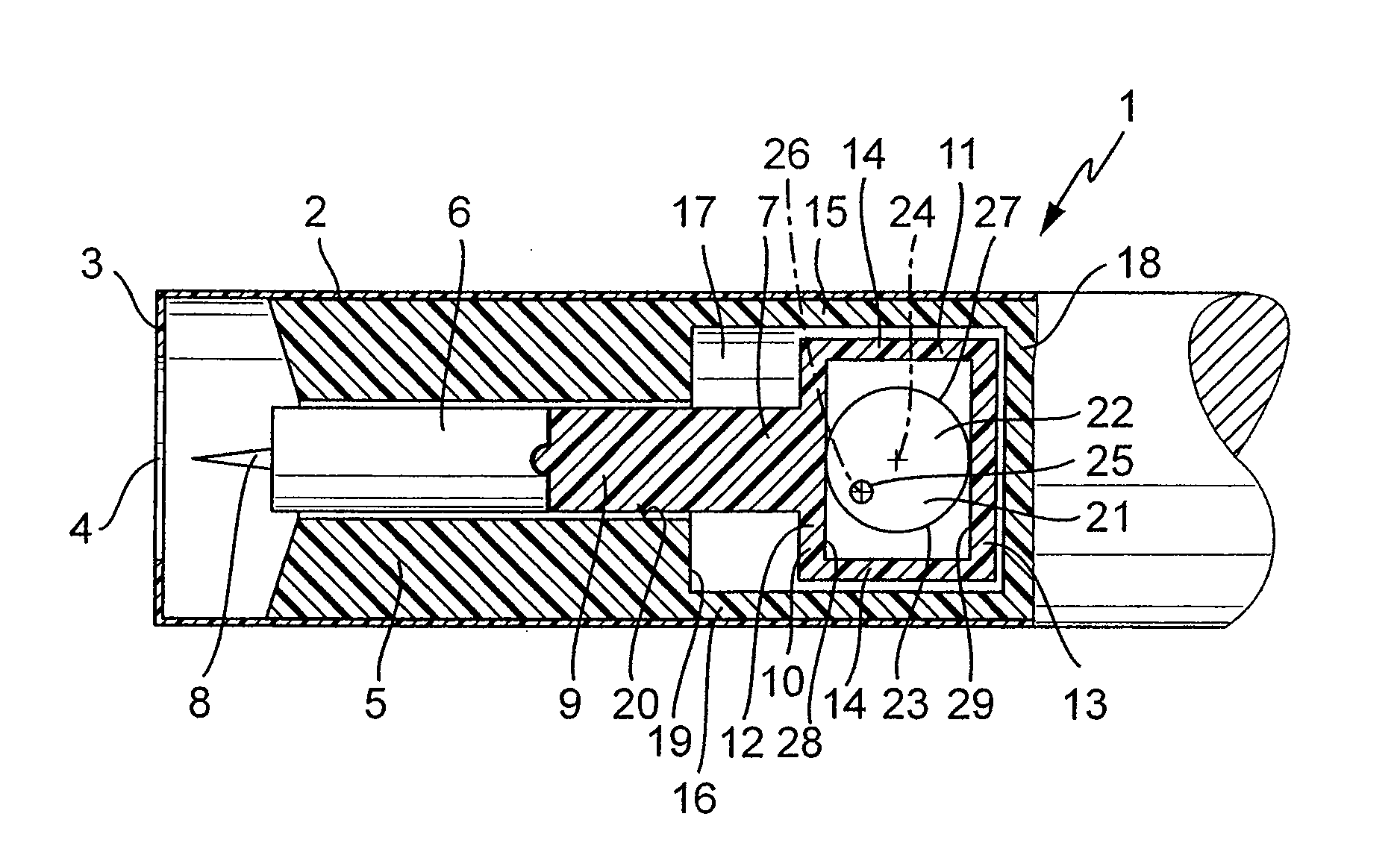

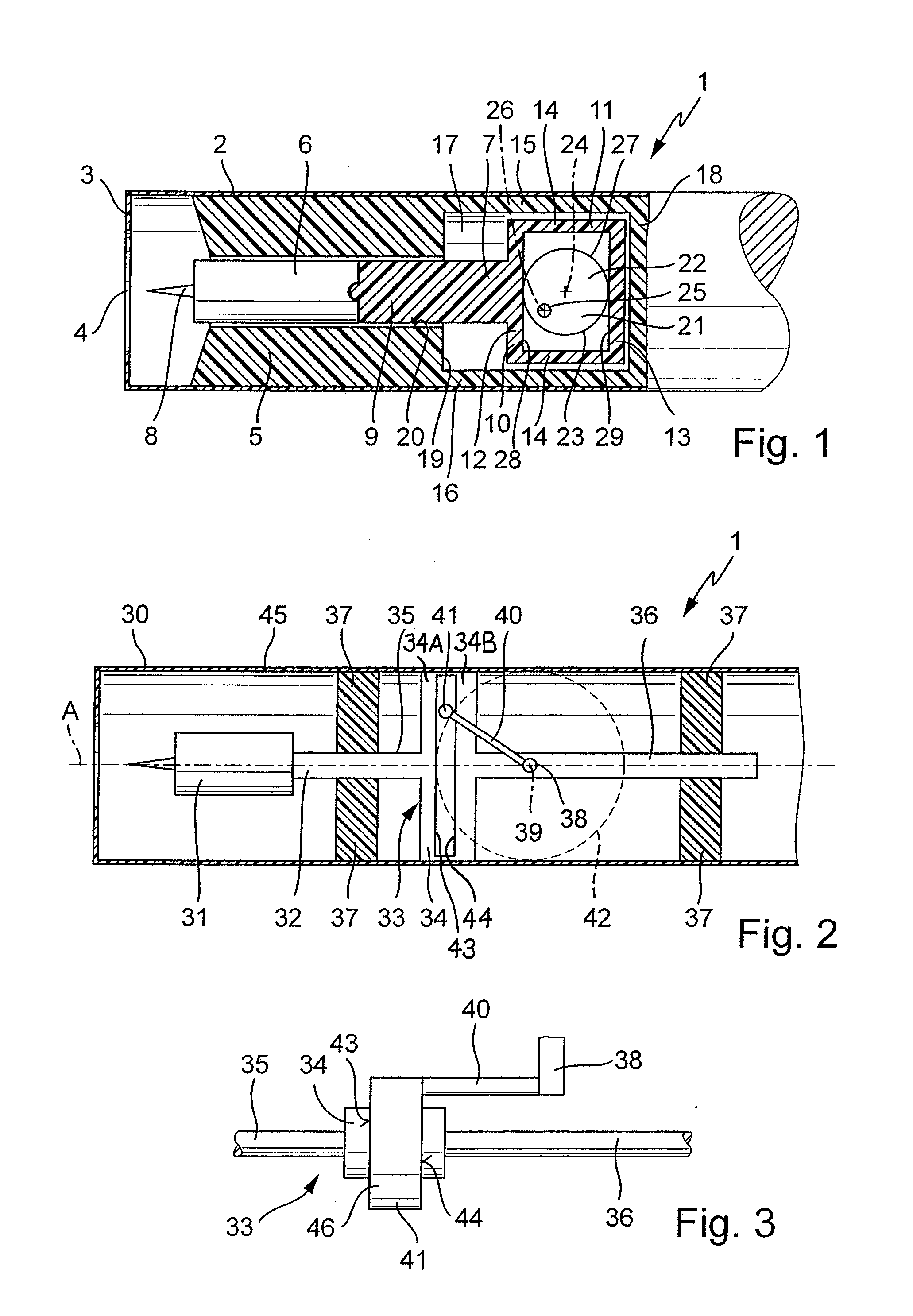

Blood withdrawal system

InactiveUS20080033469A1Reduce frictionHandling device is simpleCatheterDiagnostic recording/measuringEngineeringBody region

A blood withdrawal system for producing blood from a body part for diagnostic purposes, comprising a housing with a lancet guide capable of guiding a lancet on a predetermined puncturing path and a lancet drive for driving a puncturing movement of a lancet on the predetermined path. The lancet drive comprises a drive rotor driven by a drive spring and rotates about an axis during the puncturing movement, and a coupling mechanism which converts the rotational movement of the drive rotor into a puncturing movement, wherein the lancet is moved during a forward phase of the puncturing movement in the puncturing direction until its tip penetrates into the body part to create a wound and is retracted from the skin during a retraction phase of the puncturing movement. The coupling mechanism includes a translation element coupled to the lancet and guided by a guide on a movement path.

Owner:ROCHE DIABETES CARE INC

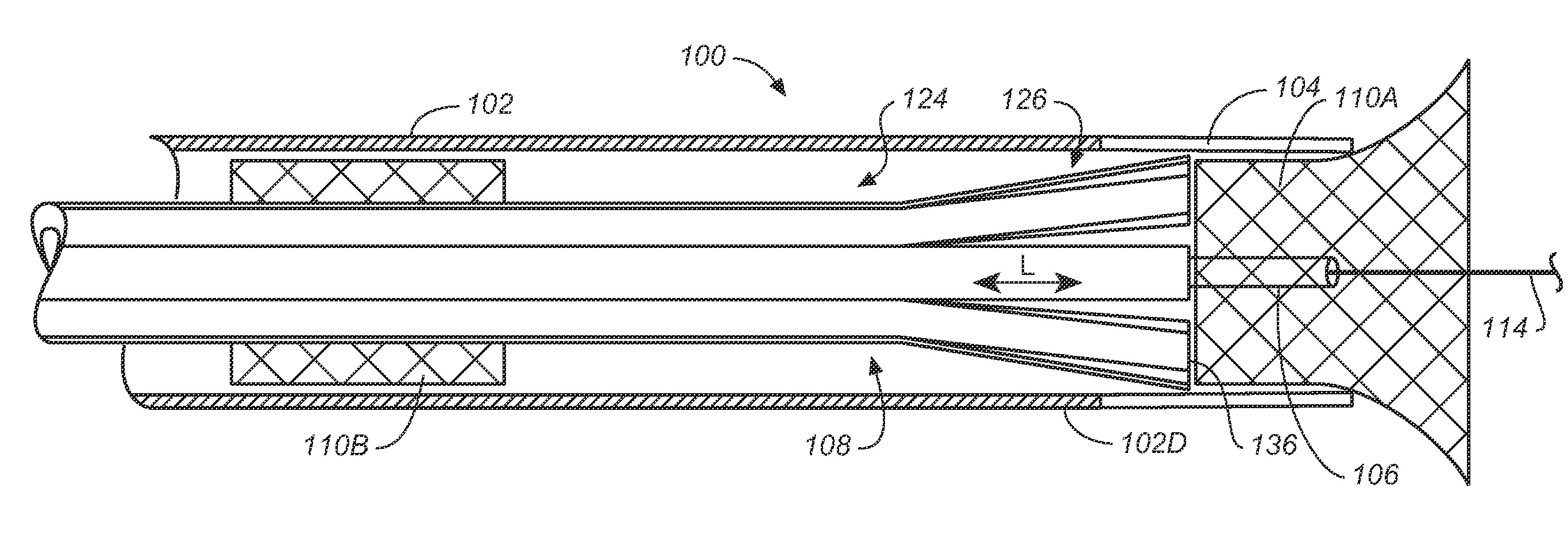

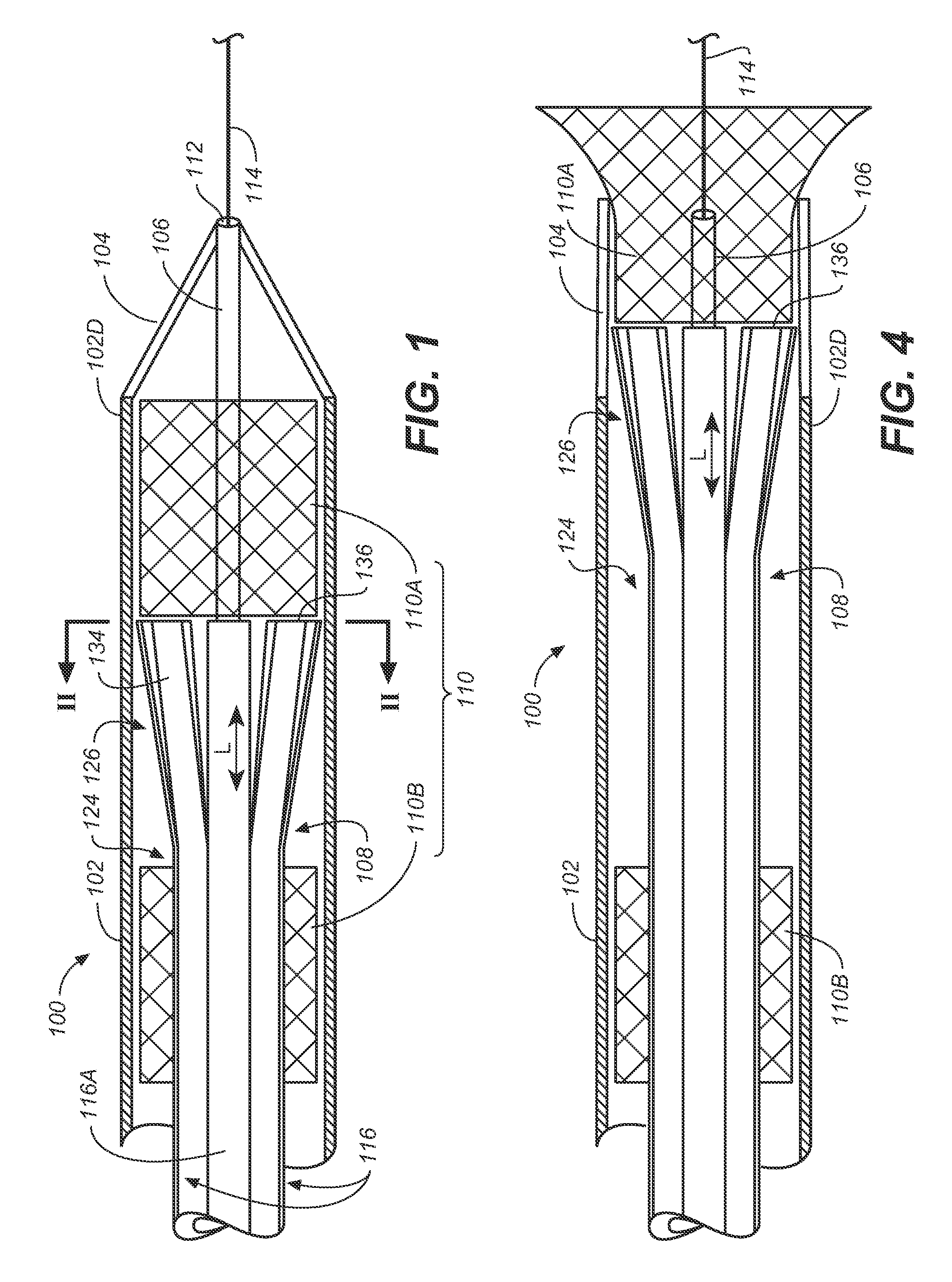

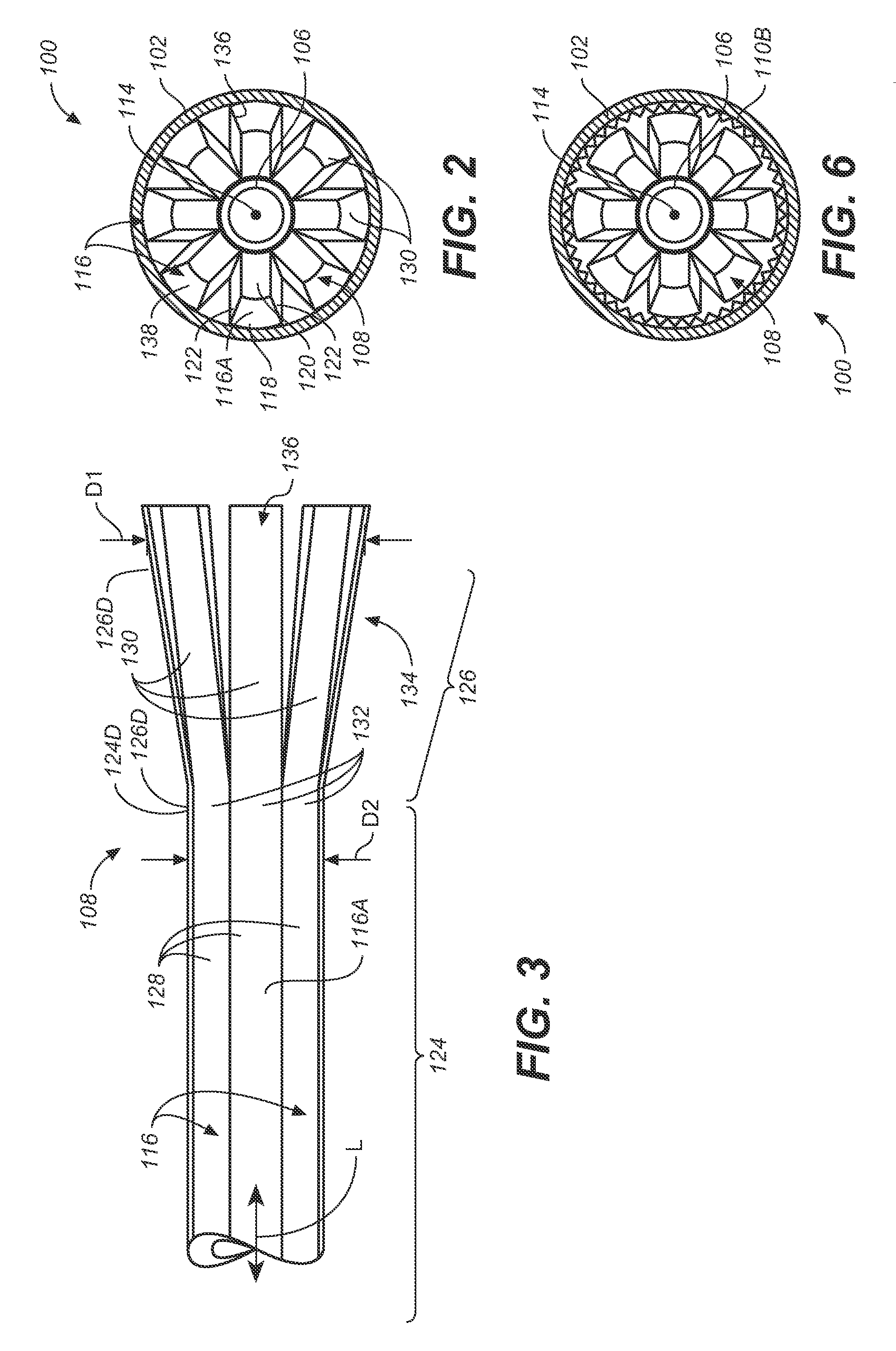

Multiple Stent Delivery System and Method

InactiveUS20080255653A1Easy to implementAccurate stent deploymentStentsBlood vesselsDelivery systemFar lateral

A method of deploying multiple stents using a multiple stent delivery system includes moving a distal stent into contact with a stent-holding surface of a compressible expanded tip of an inner member. A sheath is retracted relative to the inner member to deploy the distal stent by holding the distal stent stationary with the inner member and retracting the sheath. The sheath is advanced relative to the inner member to reposition a proximal stent to capture, be positioned behind a next stent to be deployed by being compressed and passing the compressible expanded tip through the next proximal stent. The sheath is retracted relative to the inner member to bring the next stent to a pre-deployment position and then deployment of the next proximal stent can take place as already performed for the first deployed stent.

Owner:MEDTRONIC VASCULAR INC

Hinge, supporting module having the hinge, and display device having the supporting module

ActiveUS20140063750A1Different frictional force and rotational torqueDifferent friction forceDigital data processing detailsWing fastenersRatchetBrake

A hinge for pivotally interconnecting first and second brackets includes a shaft having a shaft body extending through the first and second brackets and formed with an engaging end portion proximate to the second bracket, a fixing member connected to the engaging end portion, a ratchet sleeved rotatably on the shaft body between the fixing member and the second bracket, a friction mechanism having an urging unit sleeved on the shaft body between the ratchet and the fixing member and pressing the ratchet toward the second bracket, and a brake mechanism disposed on the second bracket and having a pawl member releasably engaged to the ratchet.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Ventilated and swing away finger cot for handling paper documents

InactiveUS20070118947A1Reduce allergic reactionsSolve the small frictionGarment special featuresBook markersFinger-stallEngineering

A rubber finger cot for handling paper sheets. The cot has an elastic hinge means for swinging the working tip away from the finger tip to a parked position on the top of the finger. Thereby, permitting the finger to be used for tasks requiring tactile feel or the natural shape of the finger tip such as typing and keyboarding while the cot remains installed on the finger.

Owner:LED PROD

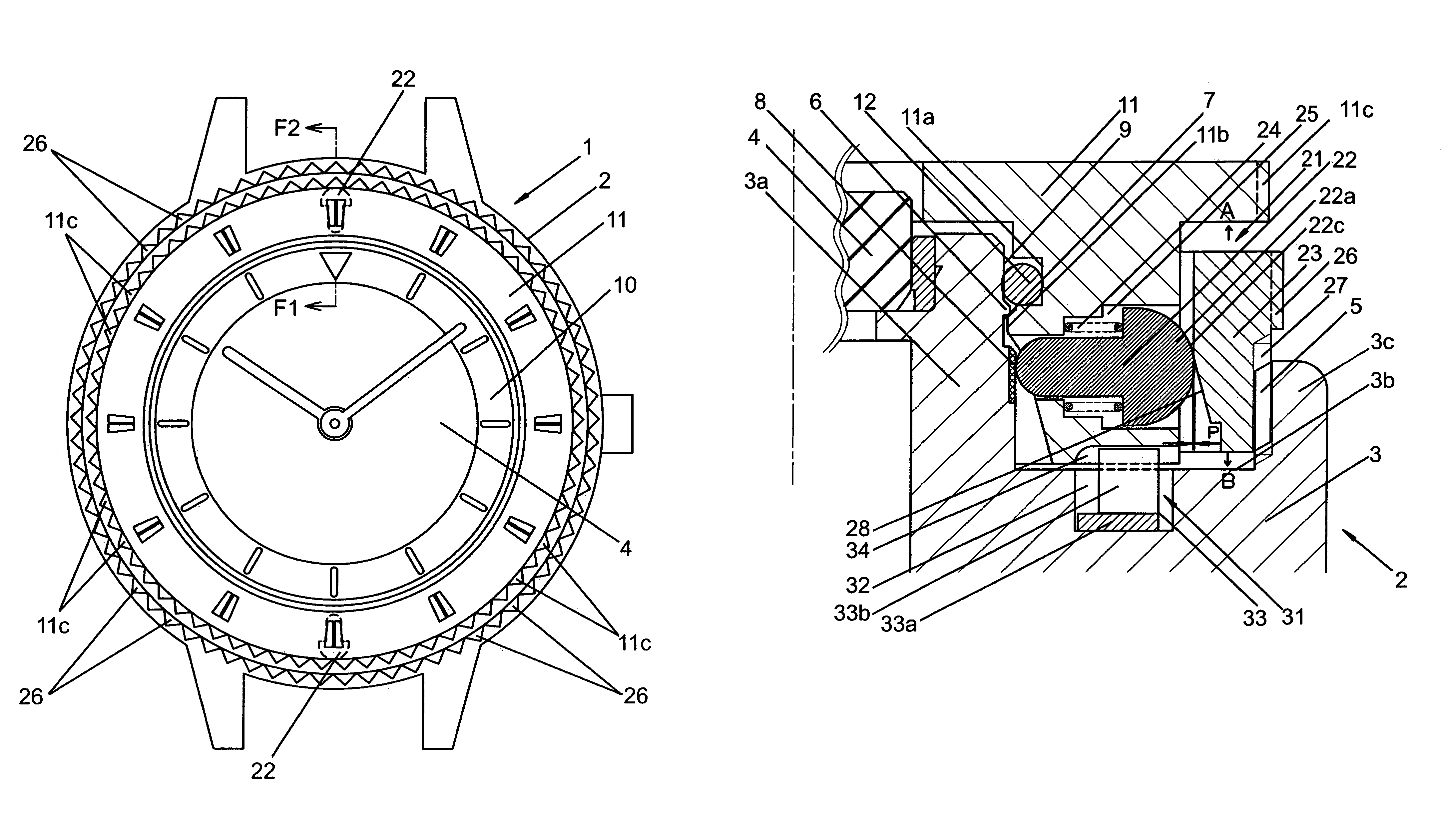

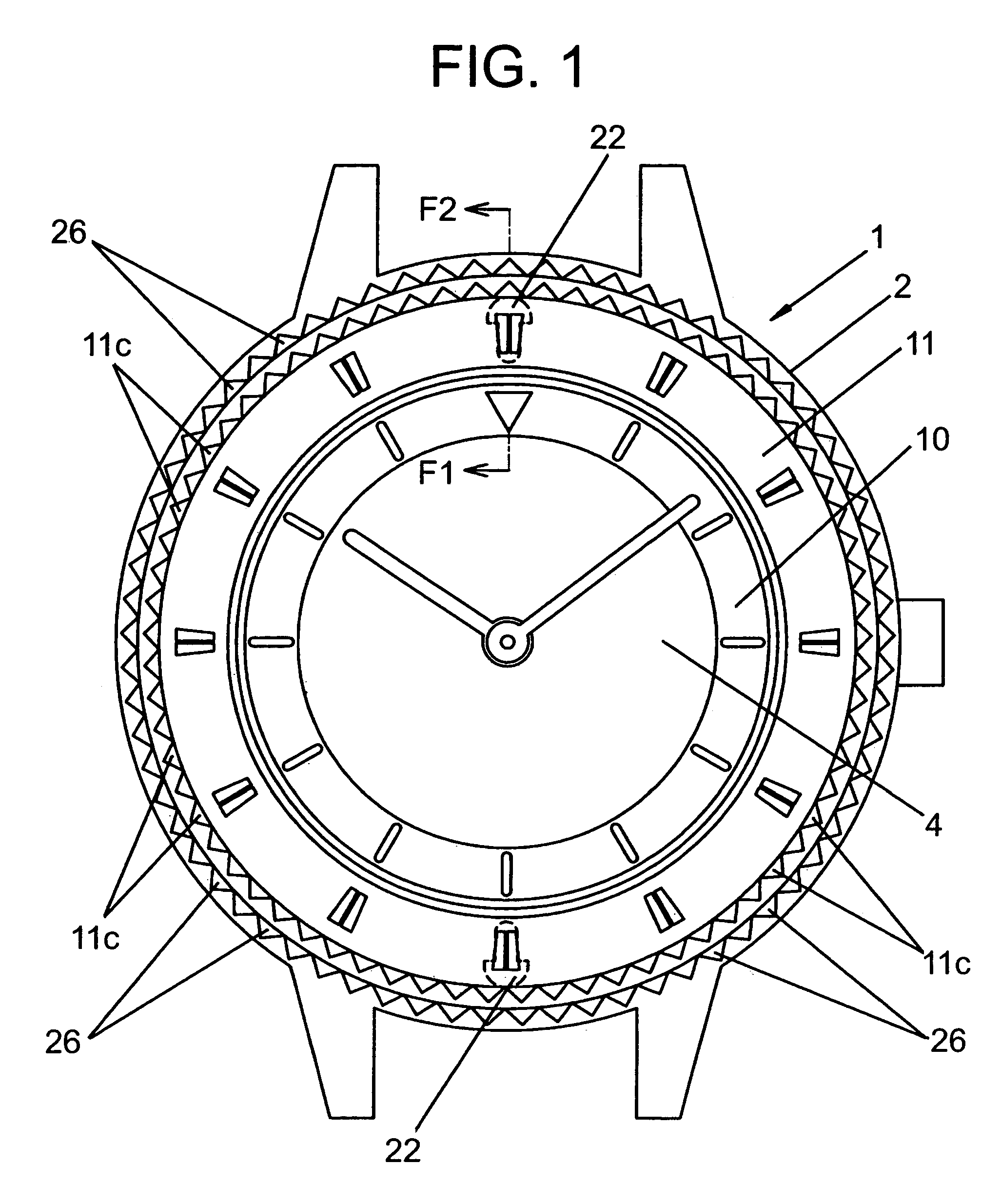

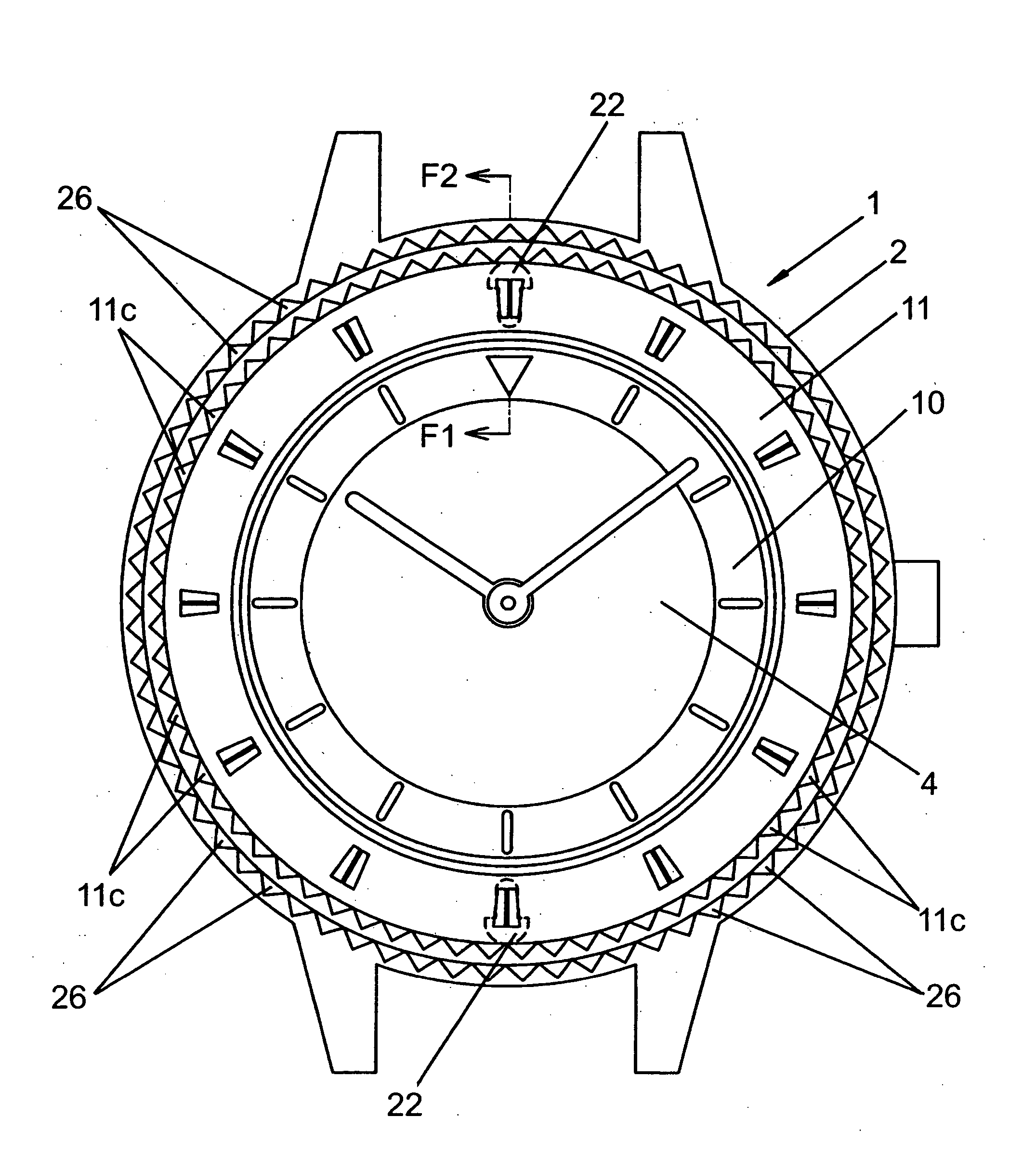

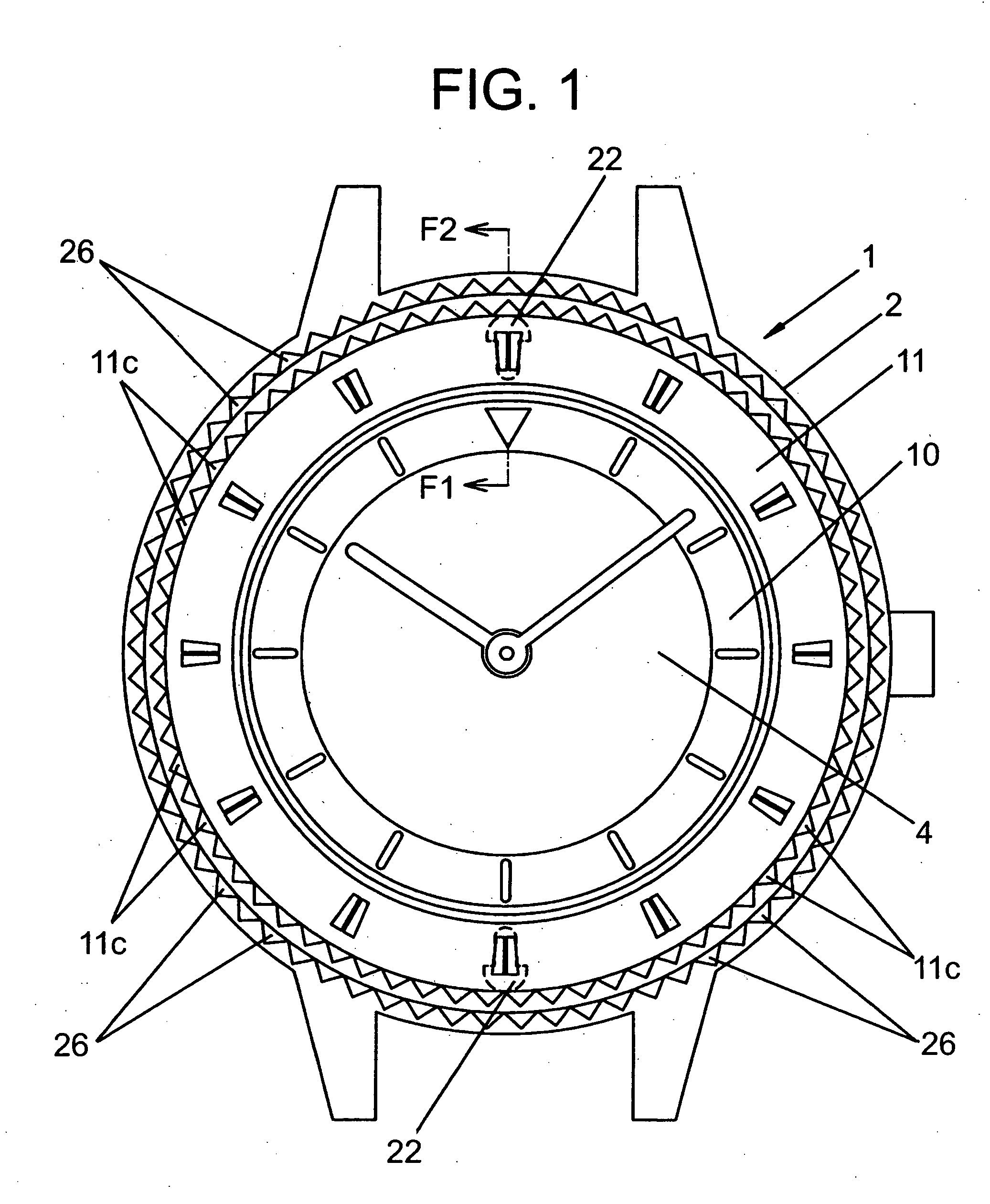

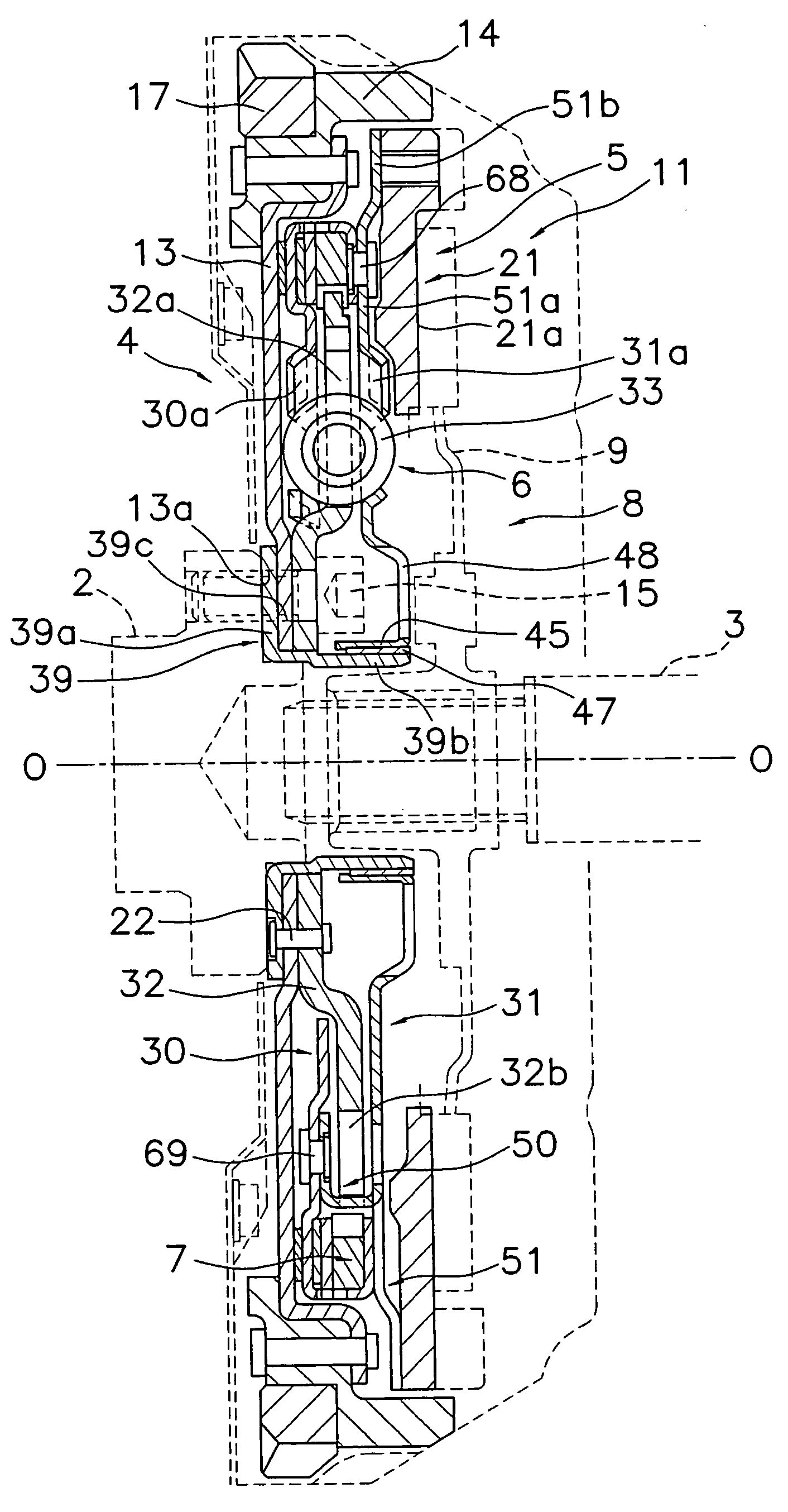

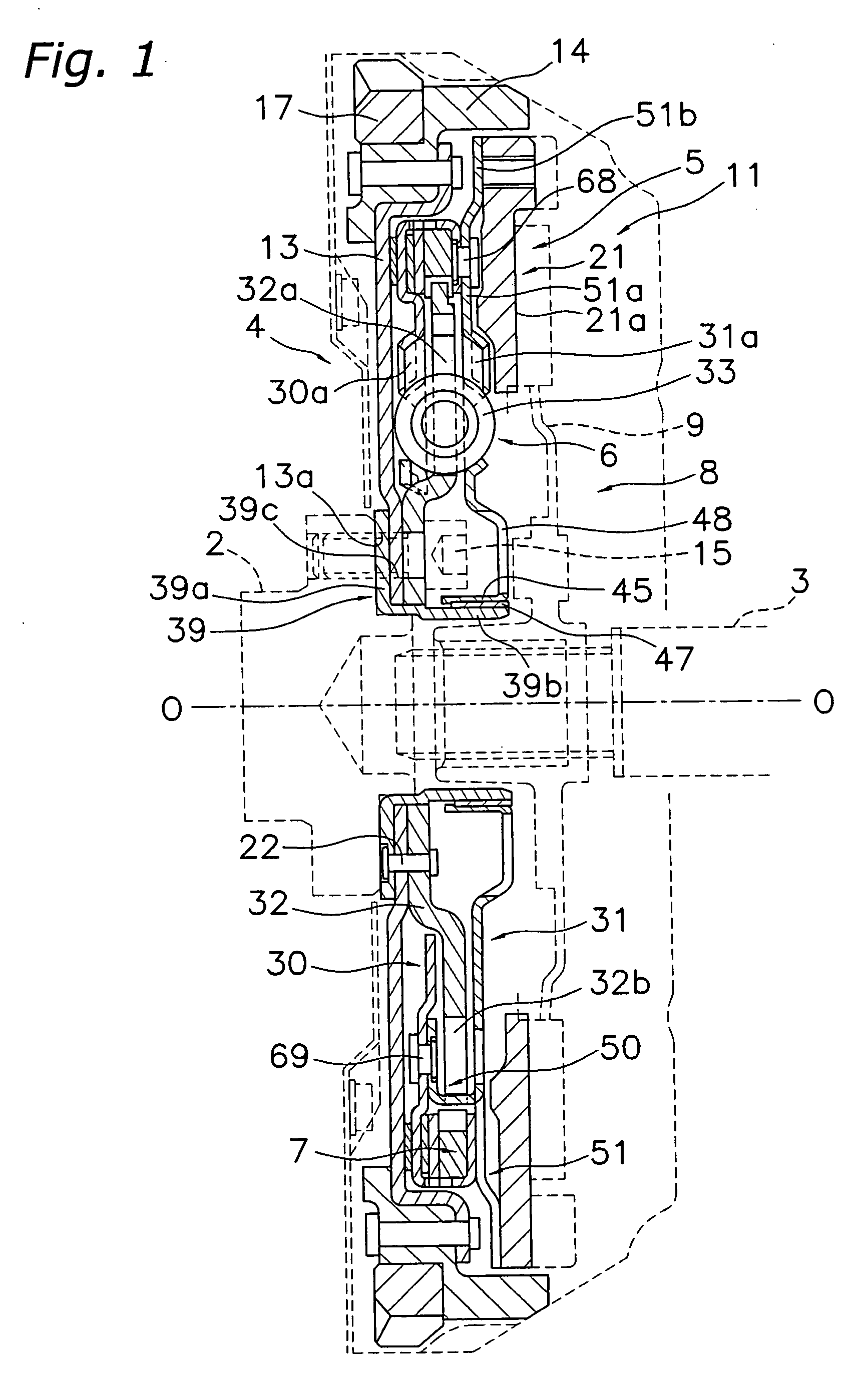

Portable timepiece

ActiveUS7137732B2Increase resistanceFrictional resistanceVisual indicationClockwork casesContact pressureEngineering

A portable timepiece has a bezel rotatably disposed on a case body, and an elastically deformable gasket interposed between the case body and the bezel in an elastically deformed state to exert a frictional force on the case body and the bezel sufficient to maintain the bezel in a stationary rotational position though permitting the bezel to be manually rotated to any desired position by overcoming the frictional force. One or more lock members are movably disposed on the bezel and contact a slip-preventing part provided on the case body. A manually rotatable holding ring engages with the lock members and is rotatable in one direction to increase the contact pressure between the lock members and the slip-preventing part to thereby prevent unintended rotation of the bezel, and is rotatable in the other direction to decrease the contact pressure to thereby permit manual rotation of the bezel by overcoming the frictional force exerted by the elastically deformed gasket. In this manner, inadvertent rotation of the bezel is prevented by structure other than the gasket thereby preventing undue wear of the gasket.

Owner:SEIKO INSTR INC

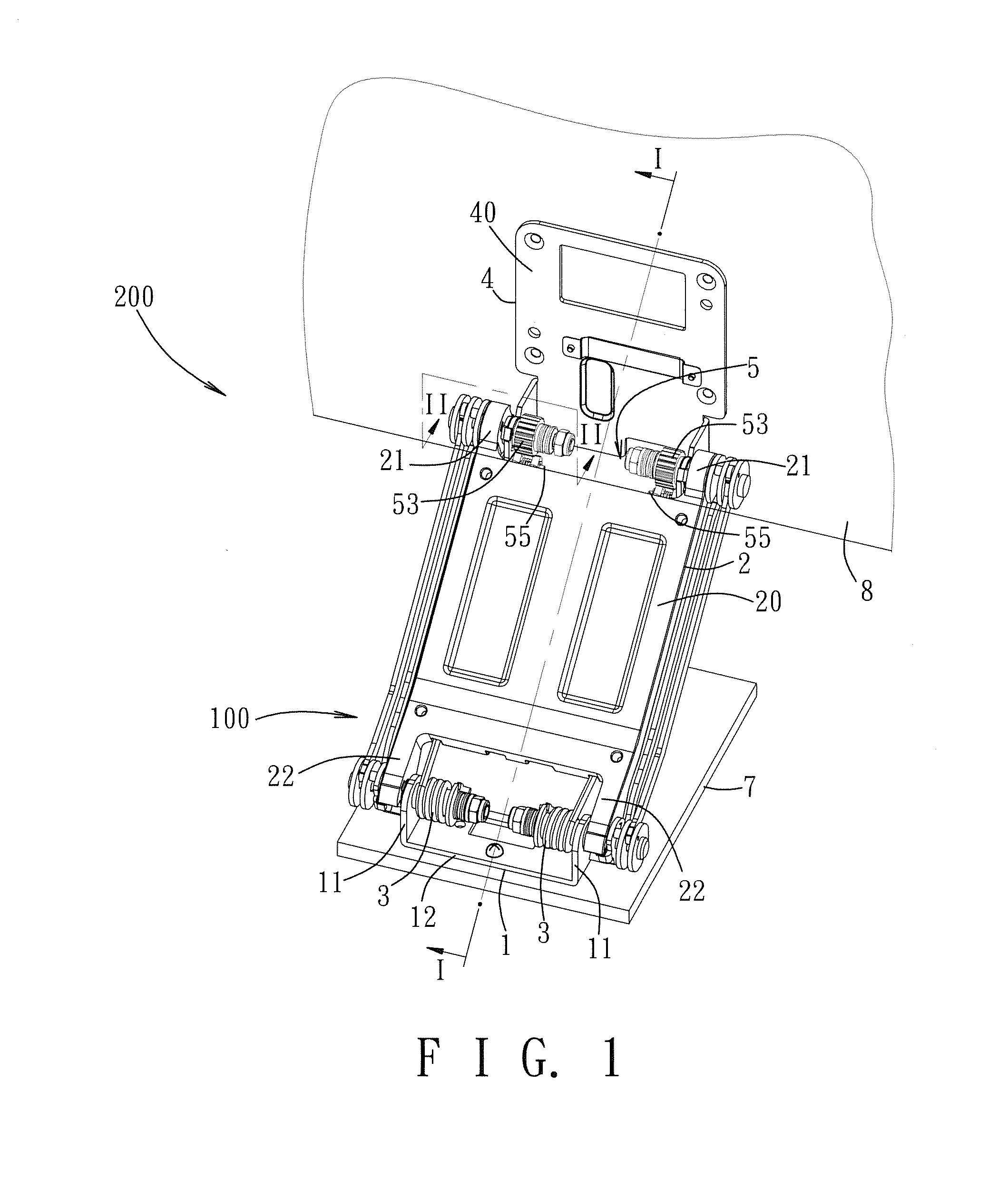

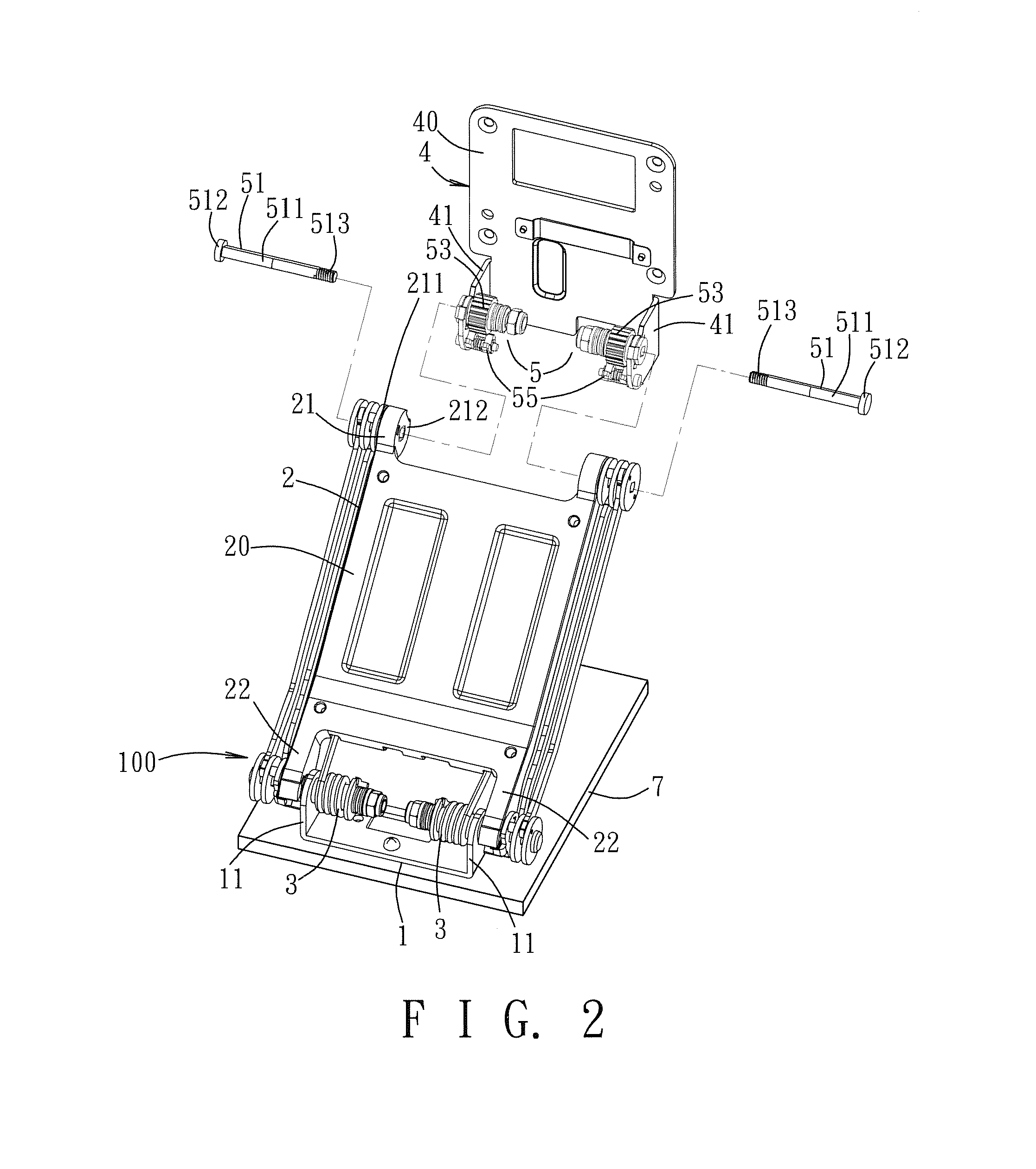

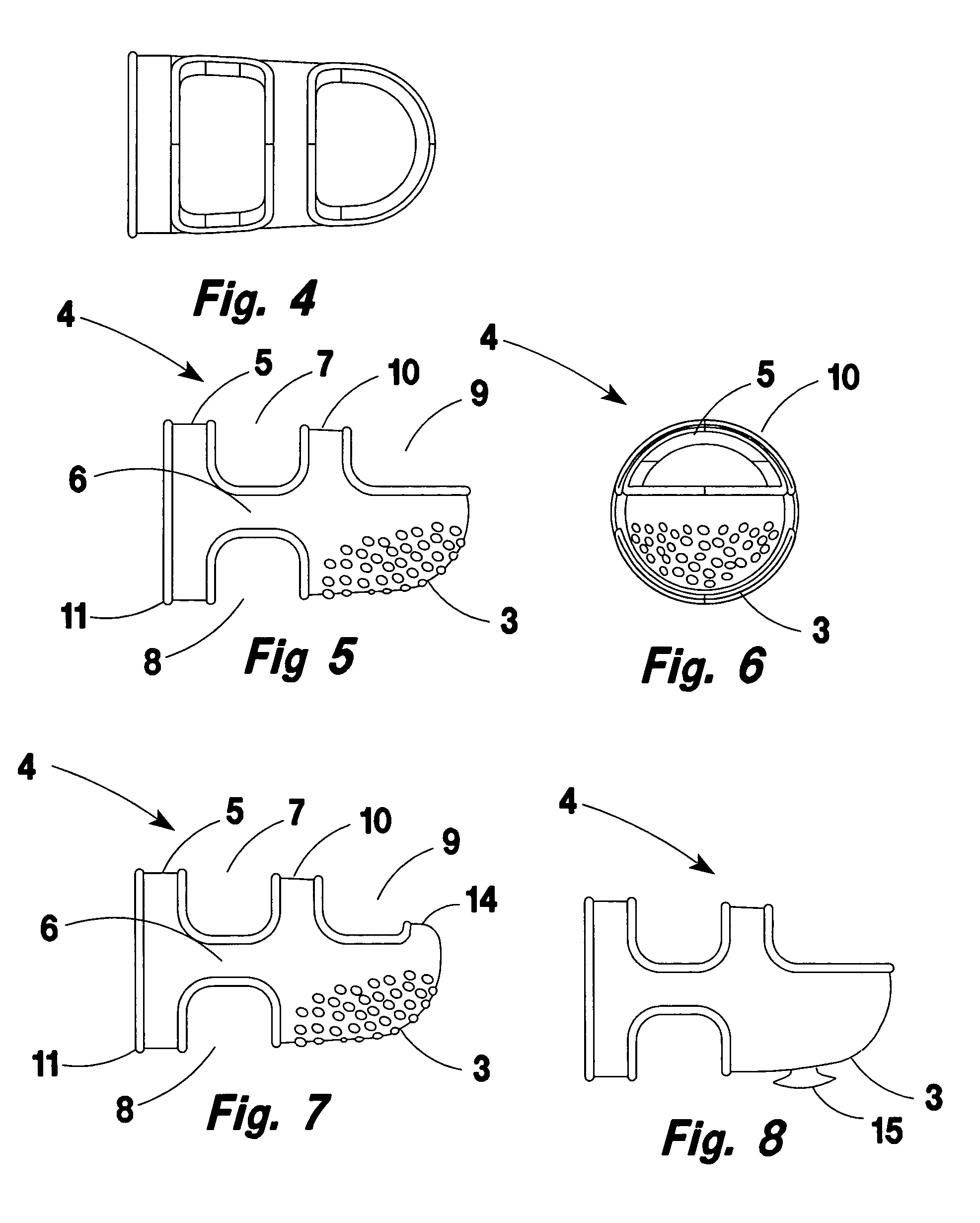

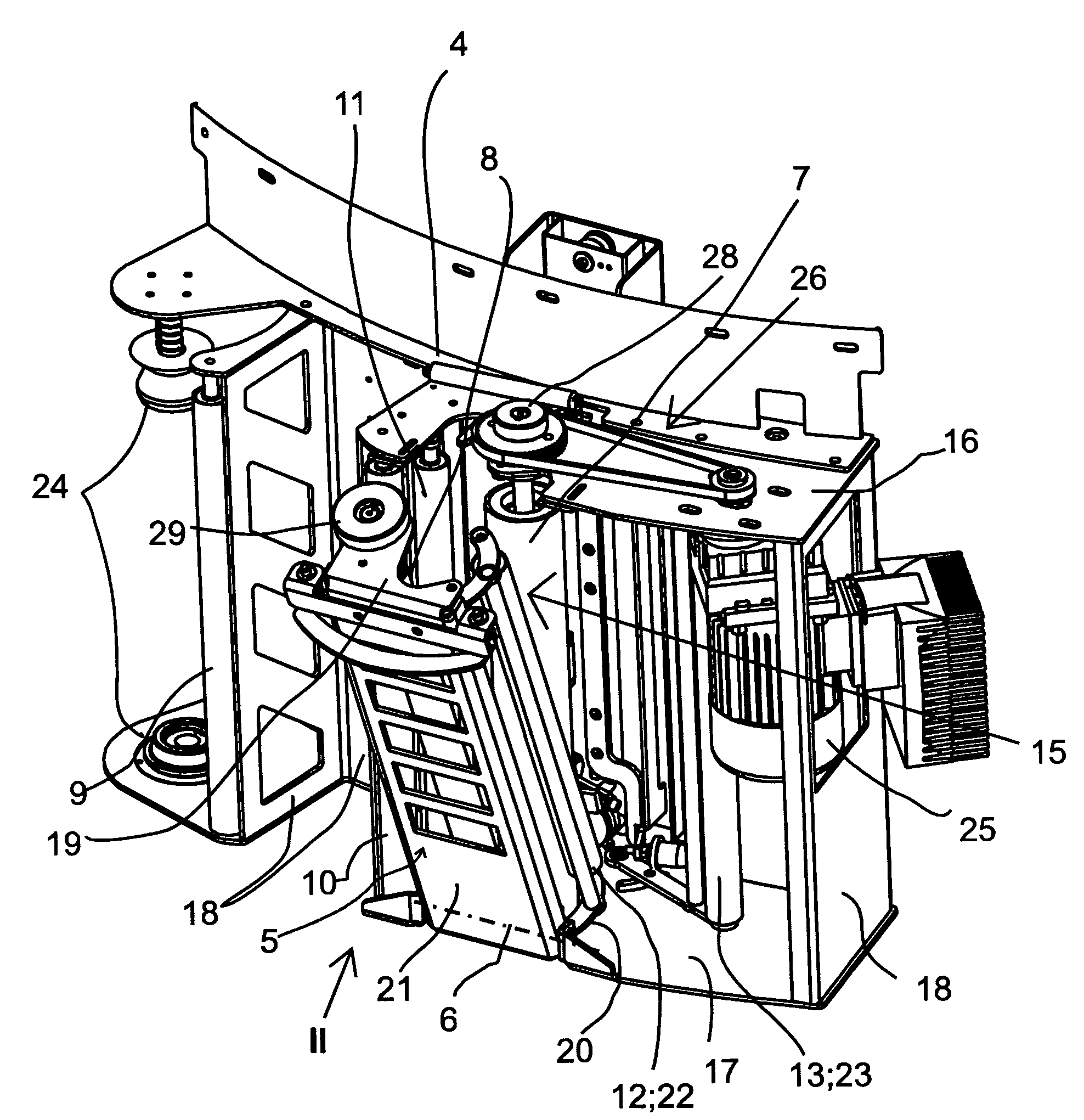

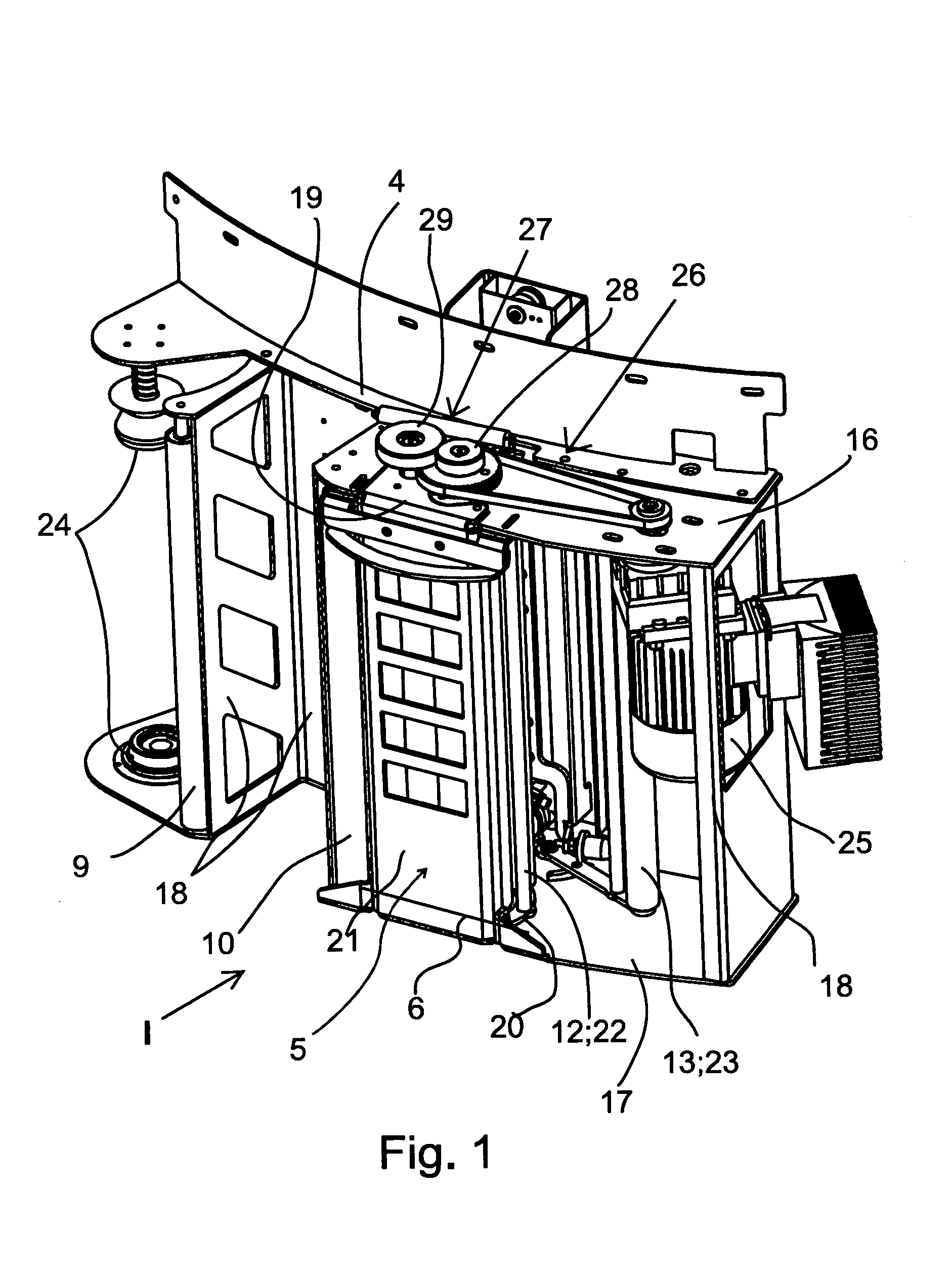

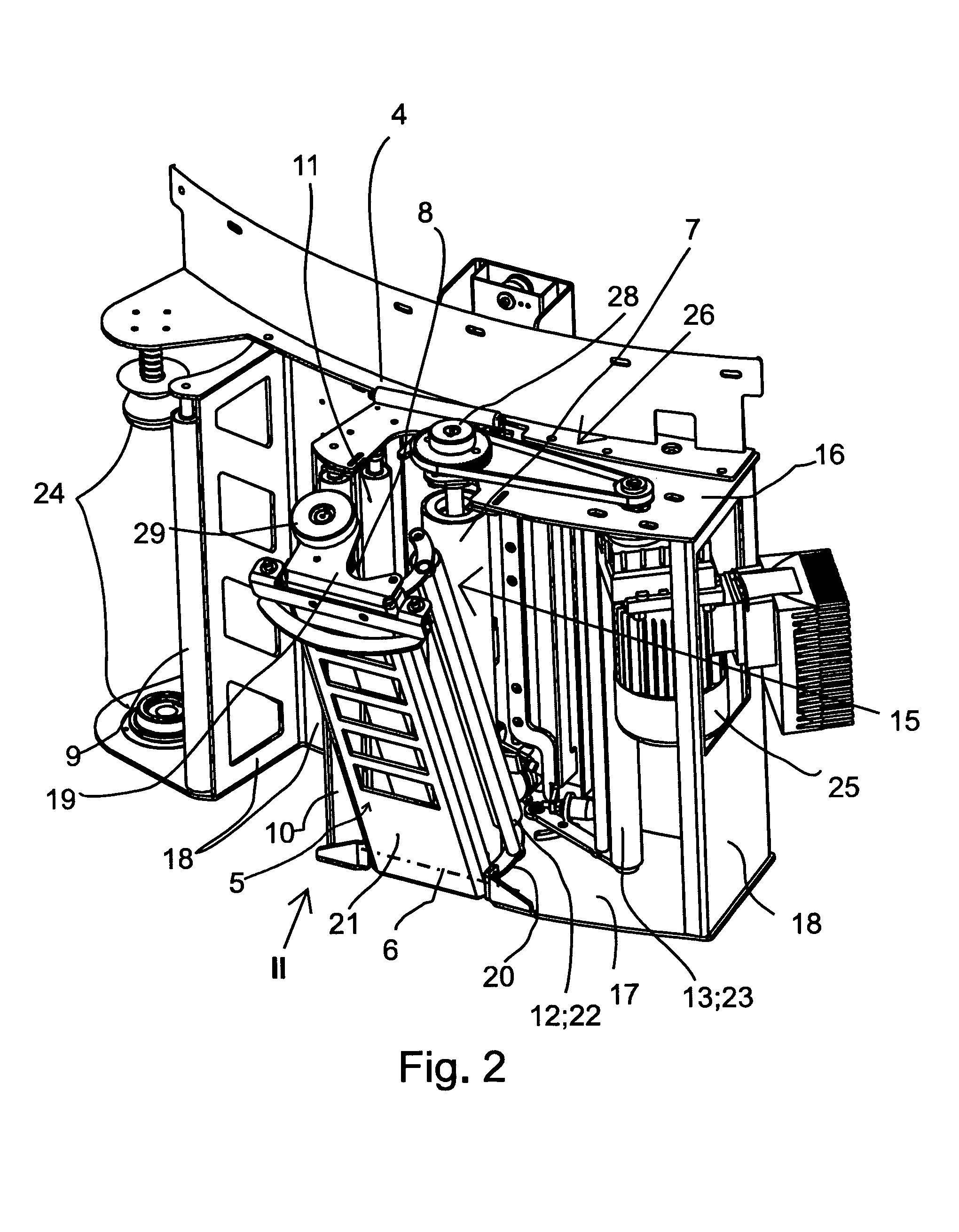

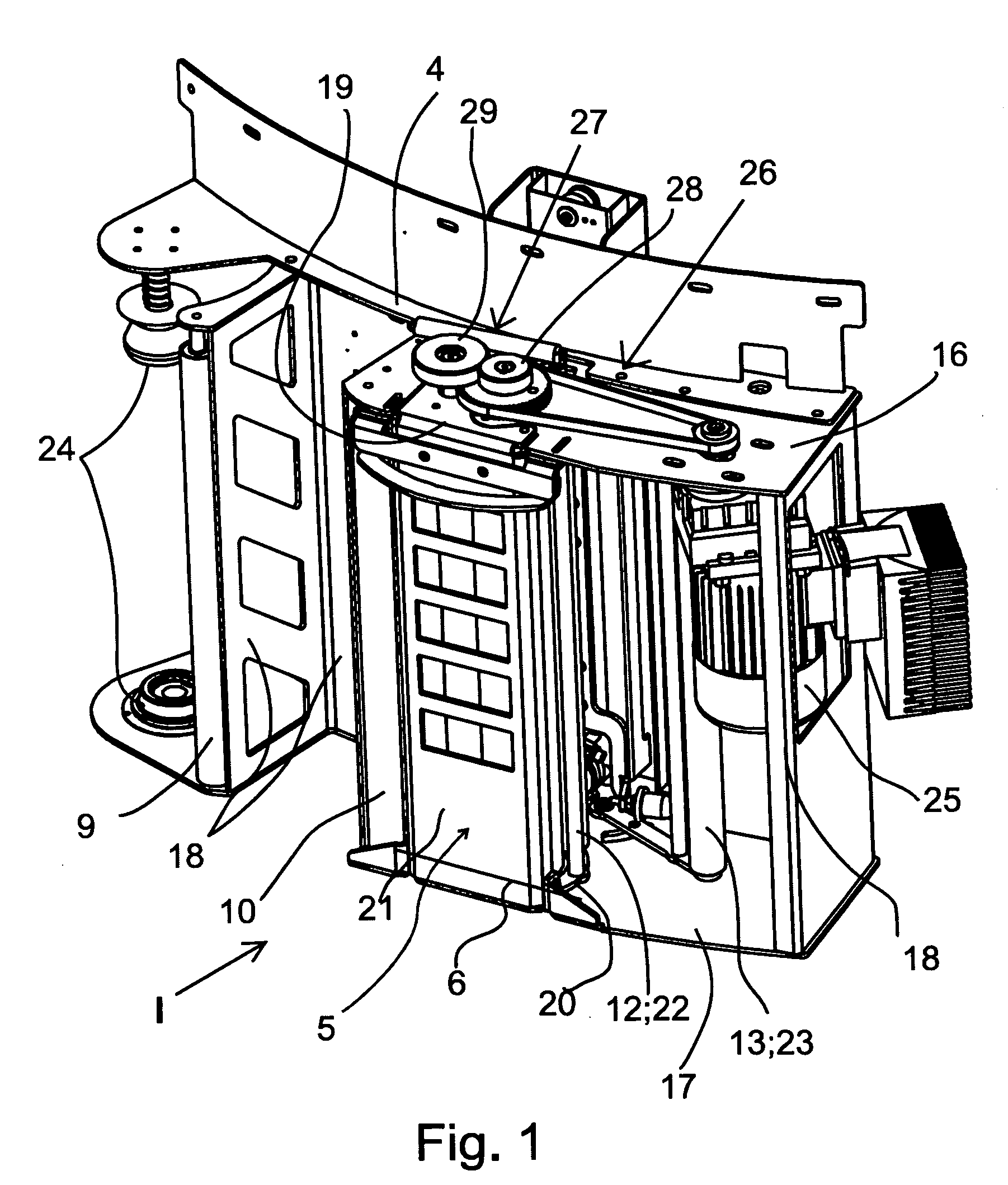

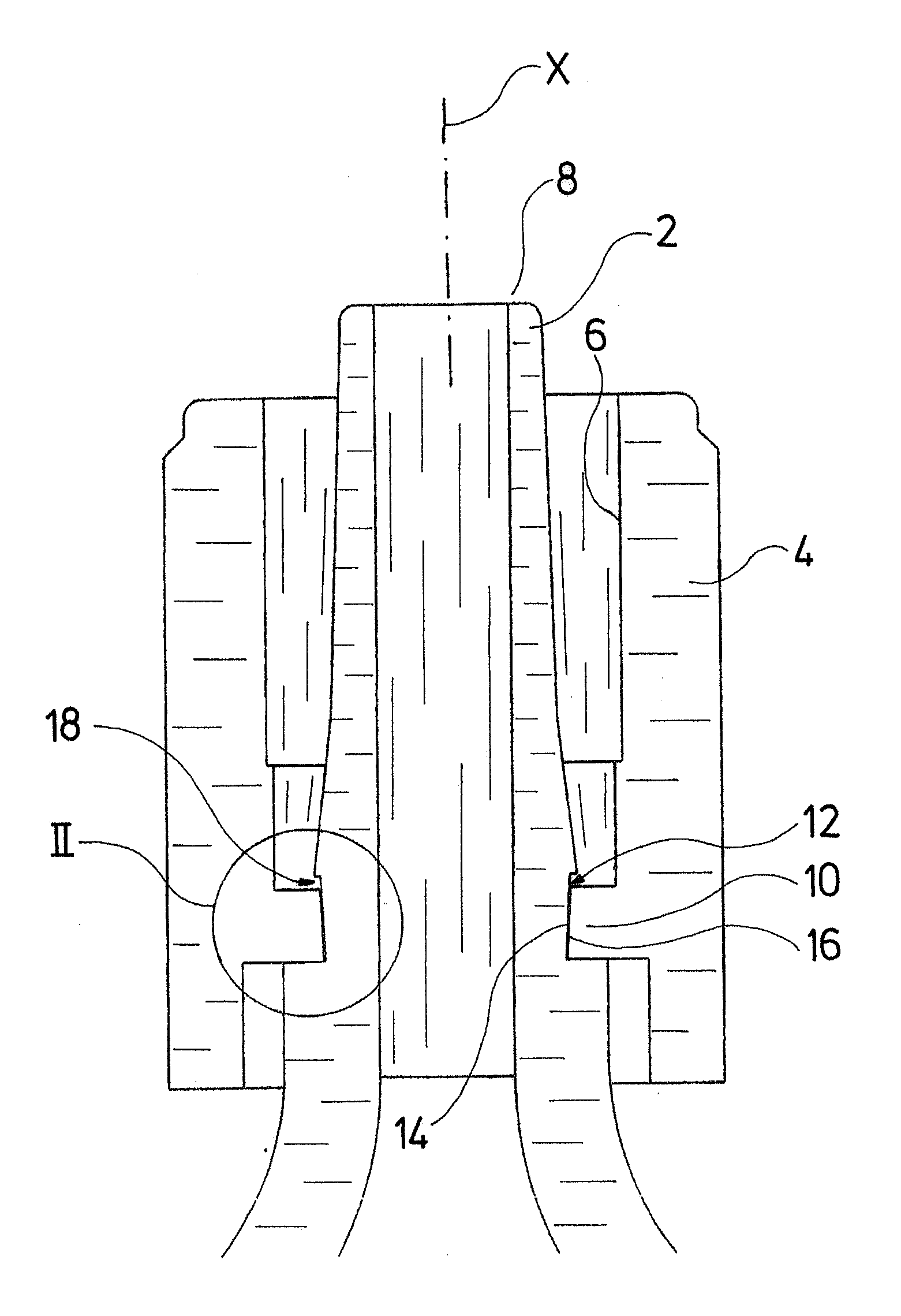

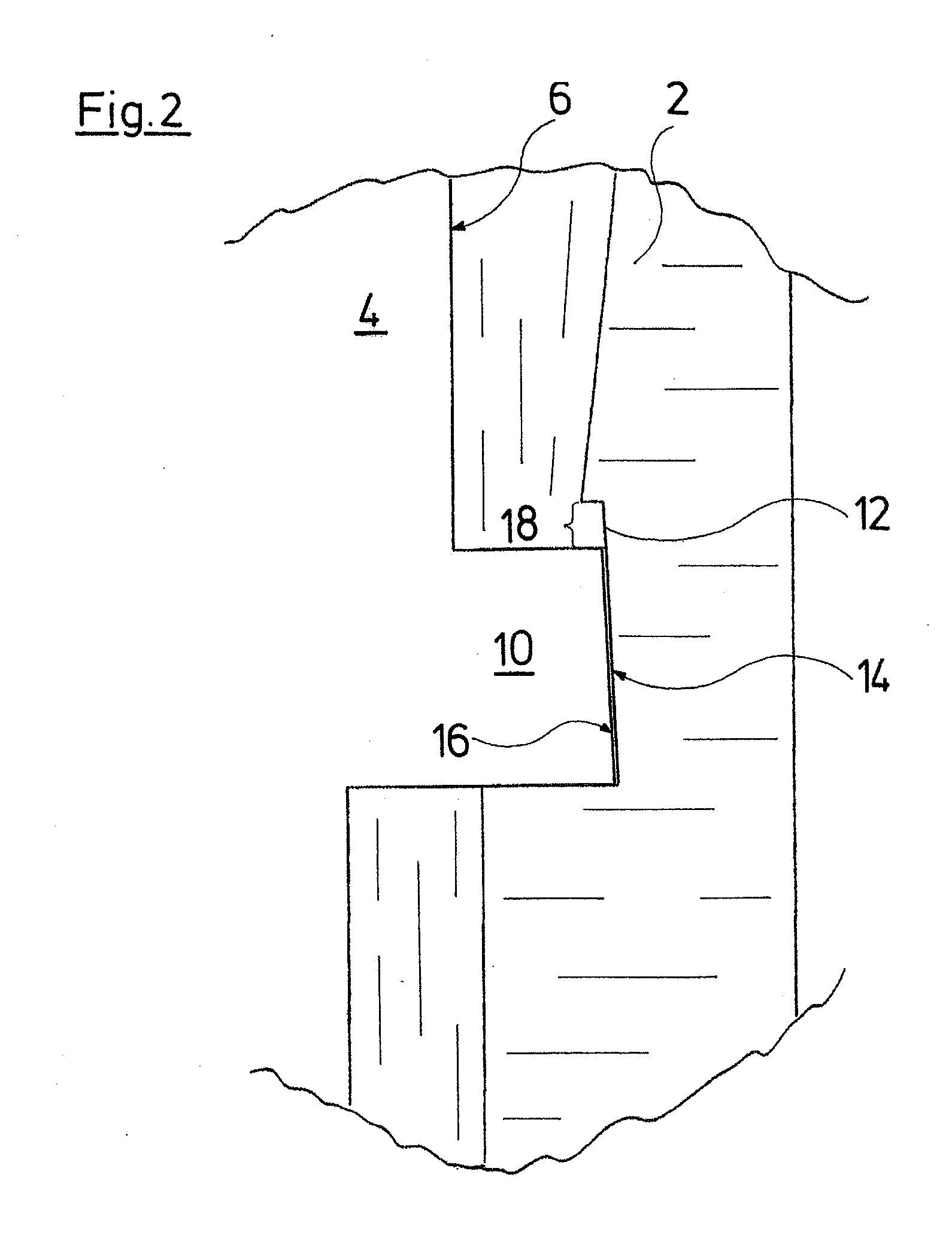

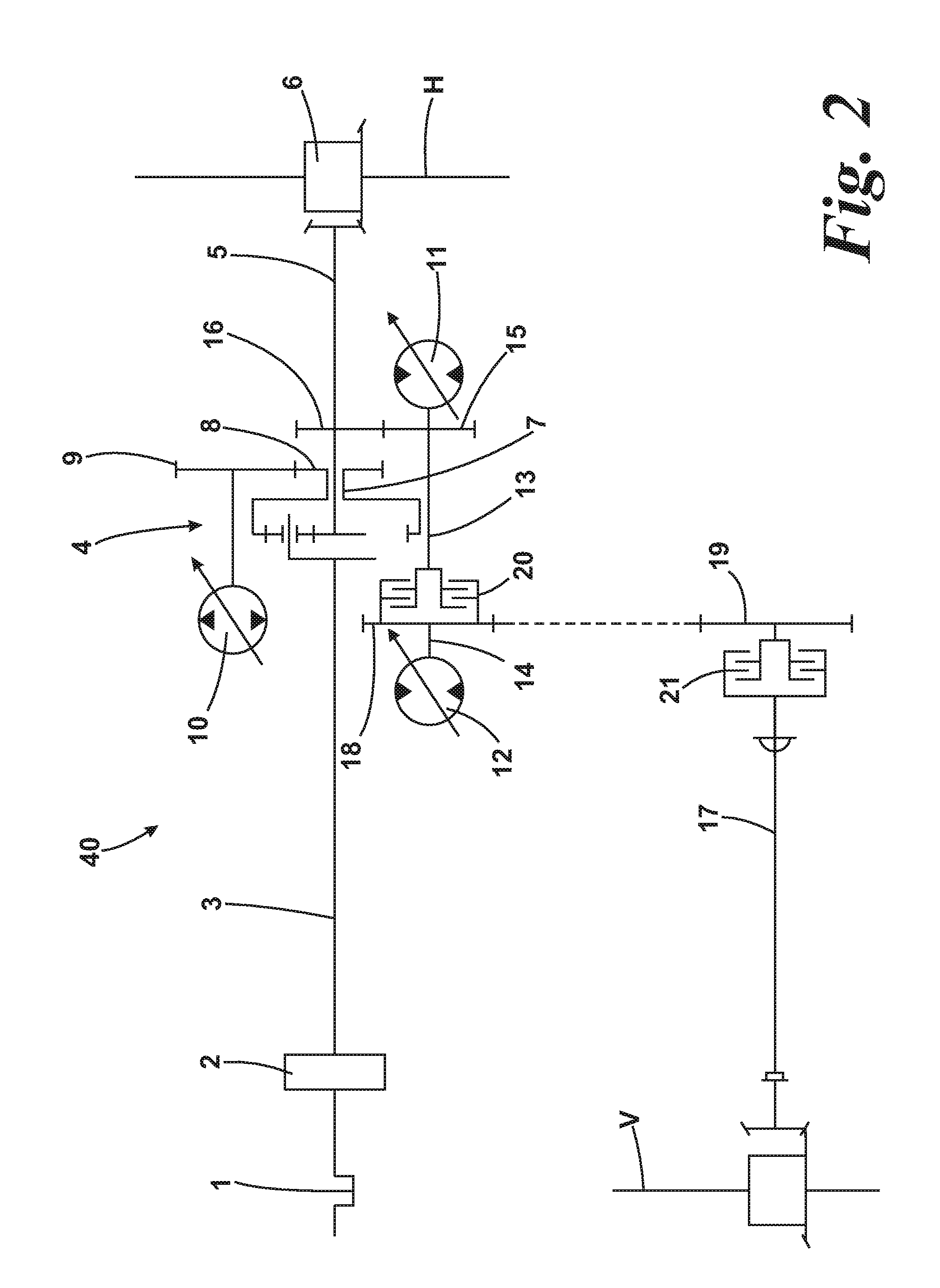

Film delivery device and use of same

ActiveUS7533515B1Threading of the film is particularly easyEasy threadingWrappers shrinkageWrapping material feeding apparatusMechanical engineeringEngineering

A film delivery device comprising a first assembly which can be connected to a wrapping machine and a second assembly (5) which is pivoted to turn, relative to the first assembly (4), about a horizontal hinge axis (6) between a closed position (I) and an open position (II). A first prestretch roller (7) is in the first assembly (4). A second prestretch roller (8) is in the second assembly (5). The film can be threaded by S-threading between the prestretch rollers (7,8). The second assembly (5) is hinged at the lower end to the lower end of the first assembly (4) to turn about the horizontal hinge axis (6). The second assembly (5) comprises a pivoted and spring-loaded first deflecting roller (22) which is arranged downstream relative to the first prestretch roller (7). In the open position (II) of the second assembly (5), that part of the first deflecting roller (22) which is close to the lower end thereof is resting against the surface of the first prestretch roller (7).

Owner:M HALOILA

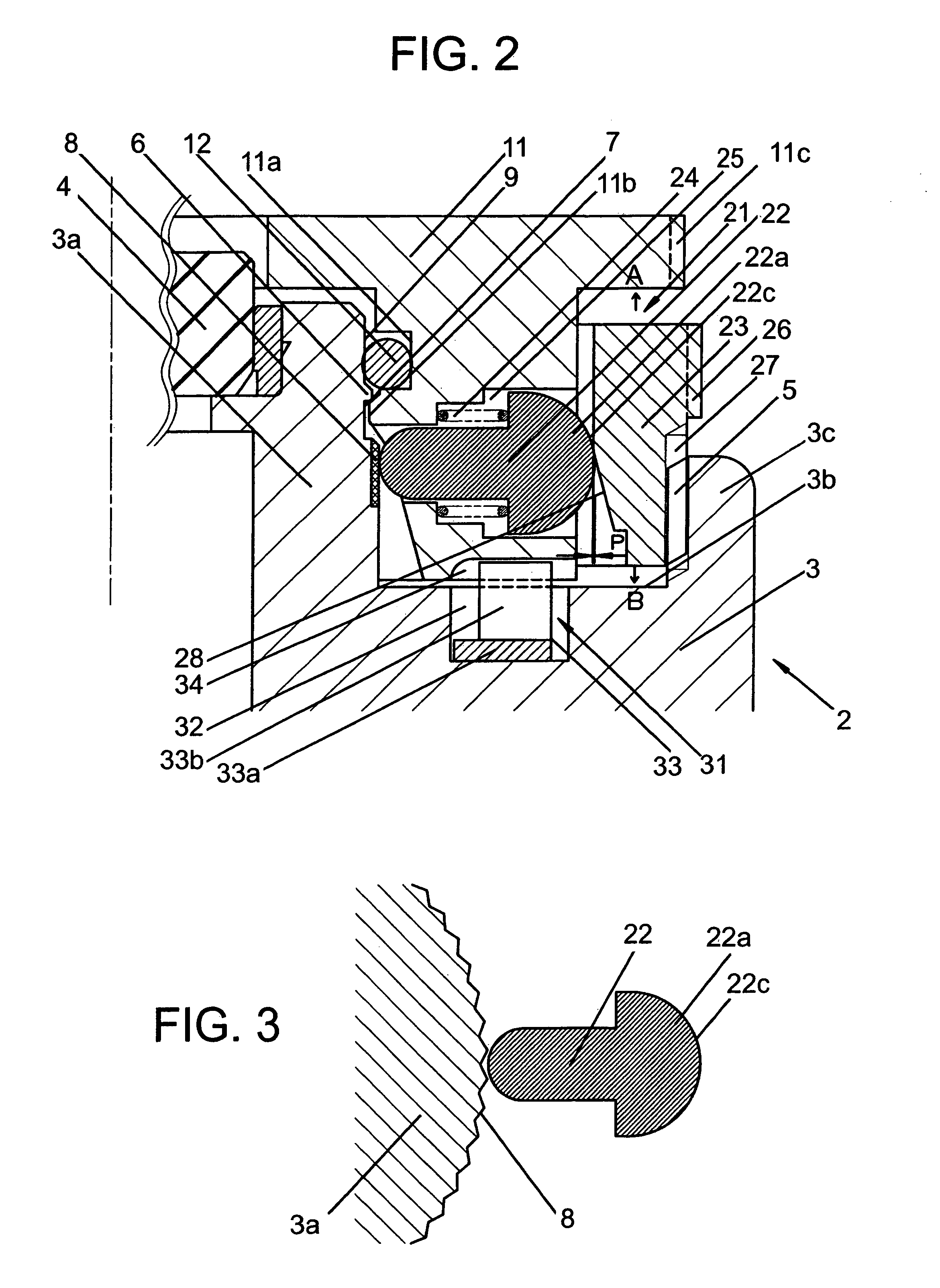

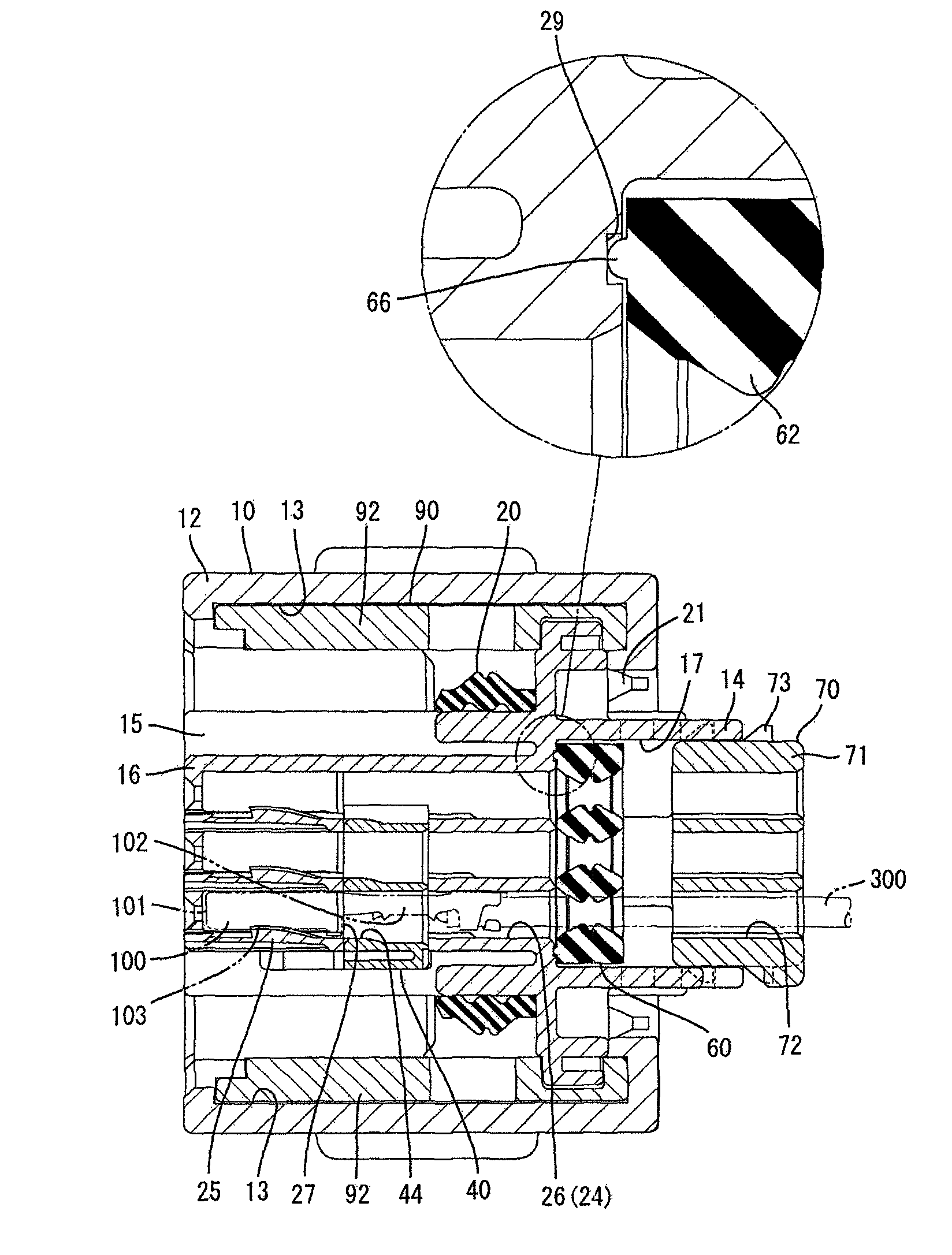

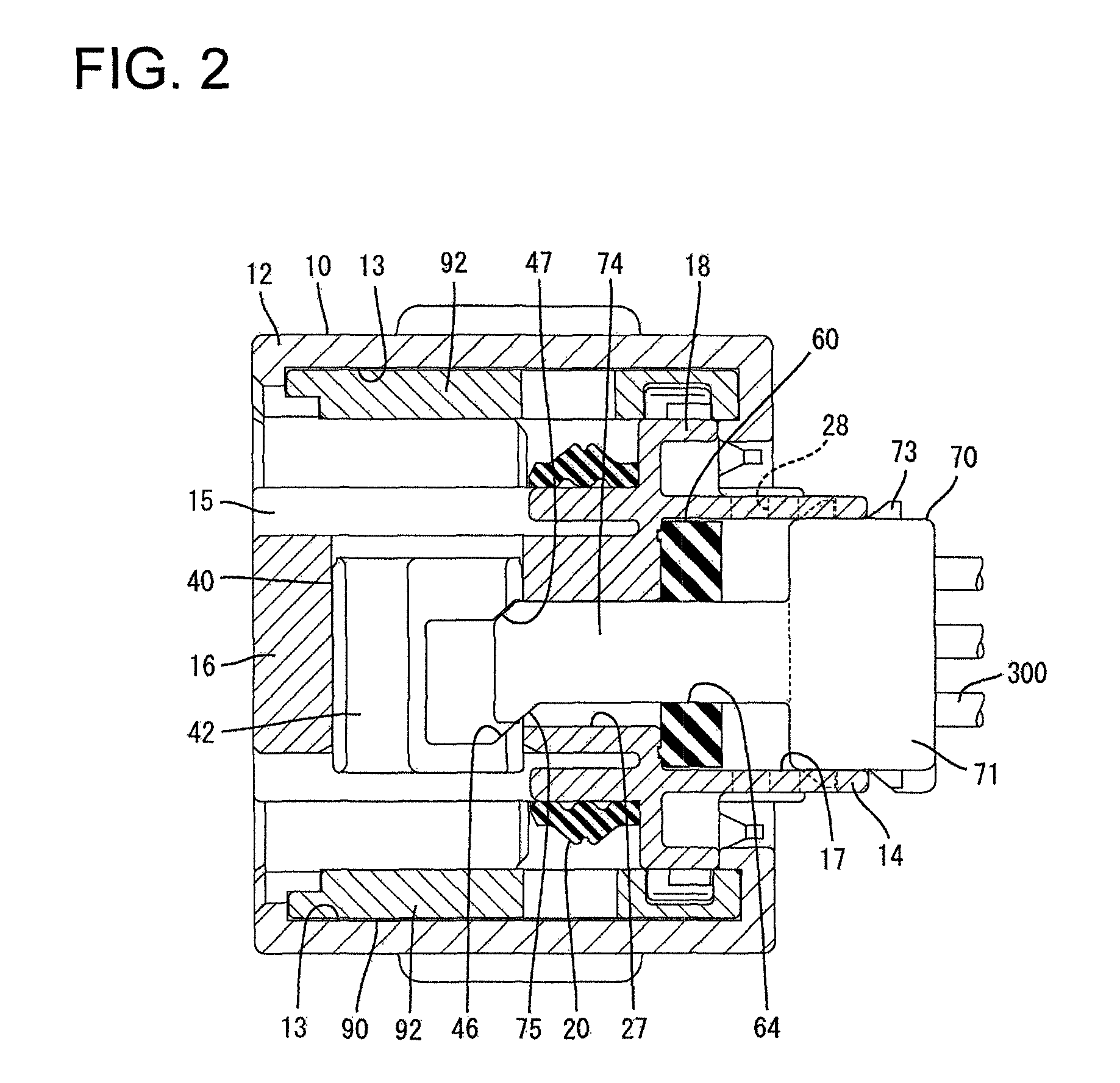

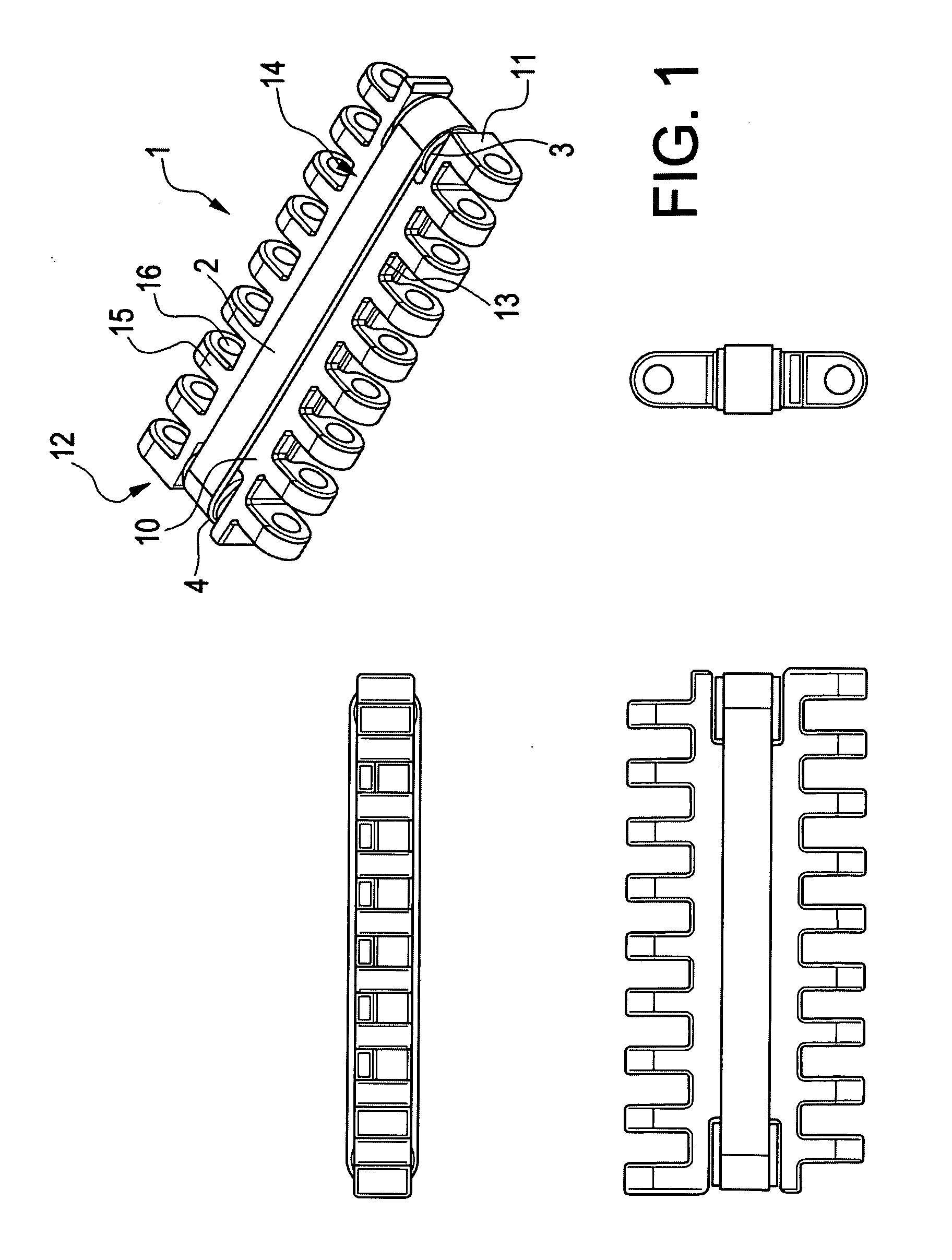

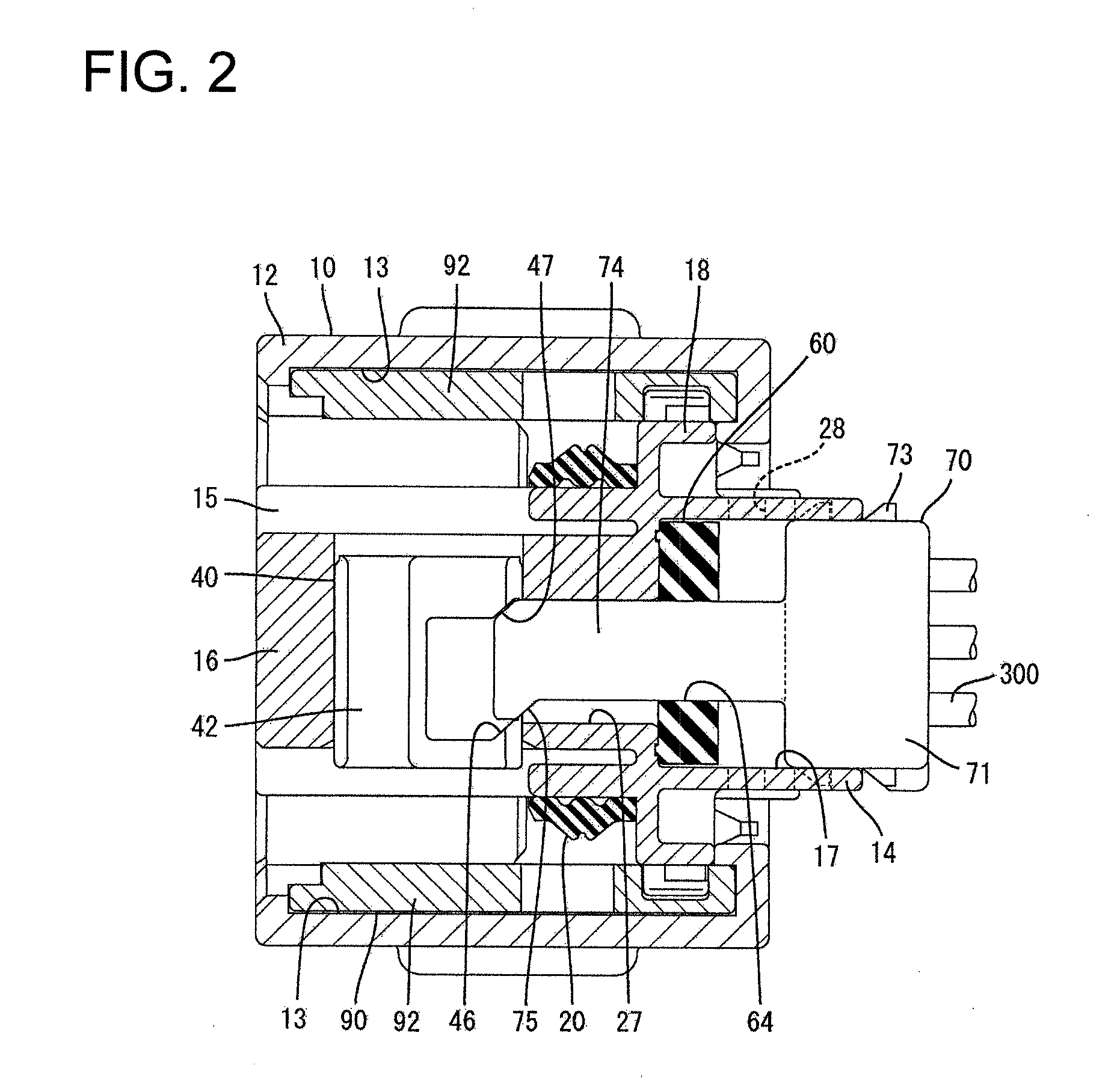

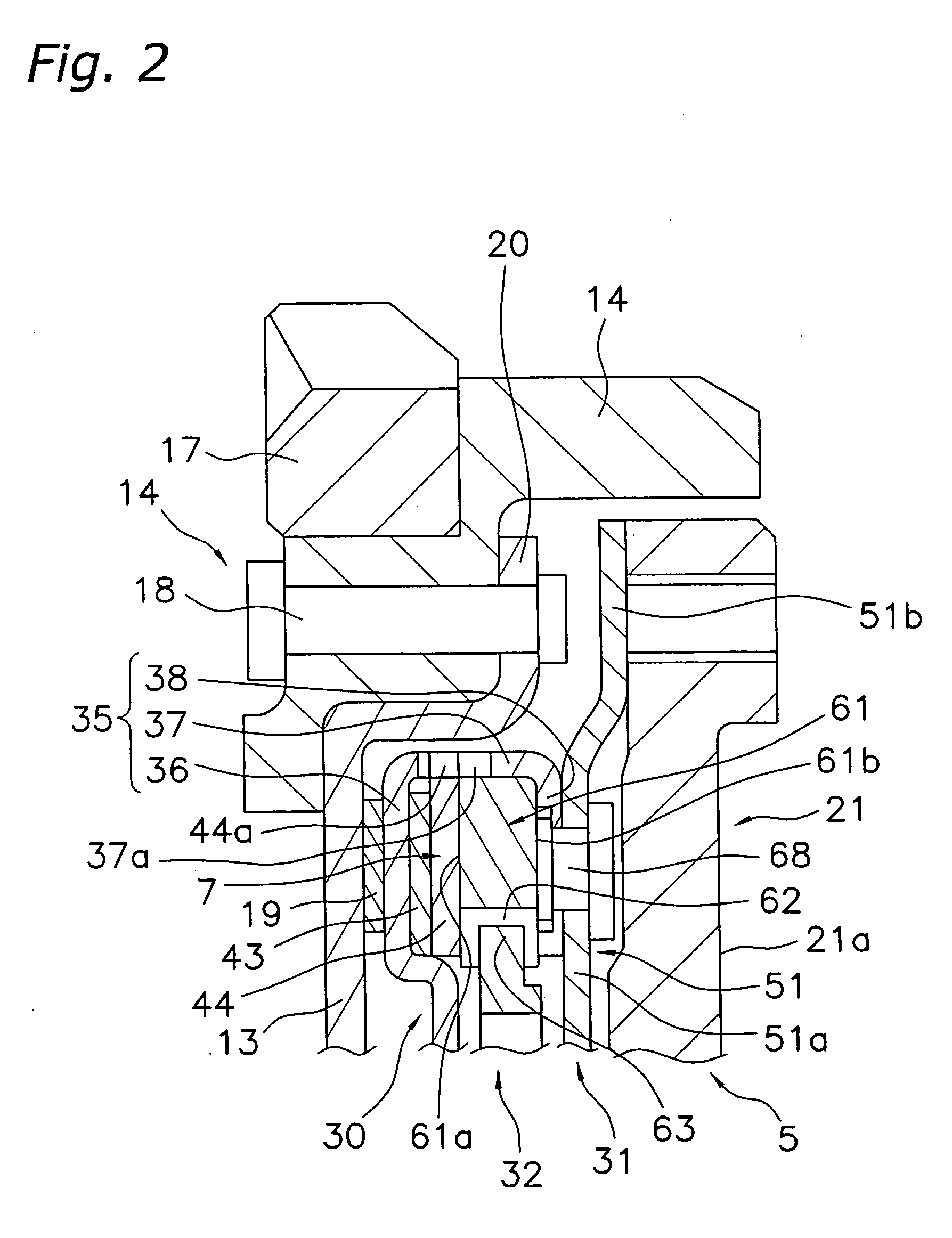

Fluidproof connector

InactiveUS8215987B2Reduce workloadSolve the small frictionSecuring/insulating coupling contact membersCouplings bases/casesEngineeringSliding contact

A retainer (40), a rubber plug (60) and a rubber plug pressing member (70) are mounted in a housing (10). The retainer (40) is movable between a partial locking position and a full locking position, and the rubber plug pressing member (70) is movable between an initial position and a pushed-in position. The rubber plug pressing member (70) is formed with arm portions (74) projecting therefrom. The retainer (40) is formed with unlock linking portions (46) for linking a movement of this retainer (40) from the full locking position to the partial locking position and a movement of the rubber plug pressing member (70) from the pushed-in position to the initial position with each other by coming into sliding contact with the arm portions (74).

Owner:SUMITOMO WIRING SYST LTD

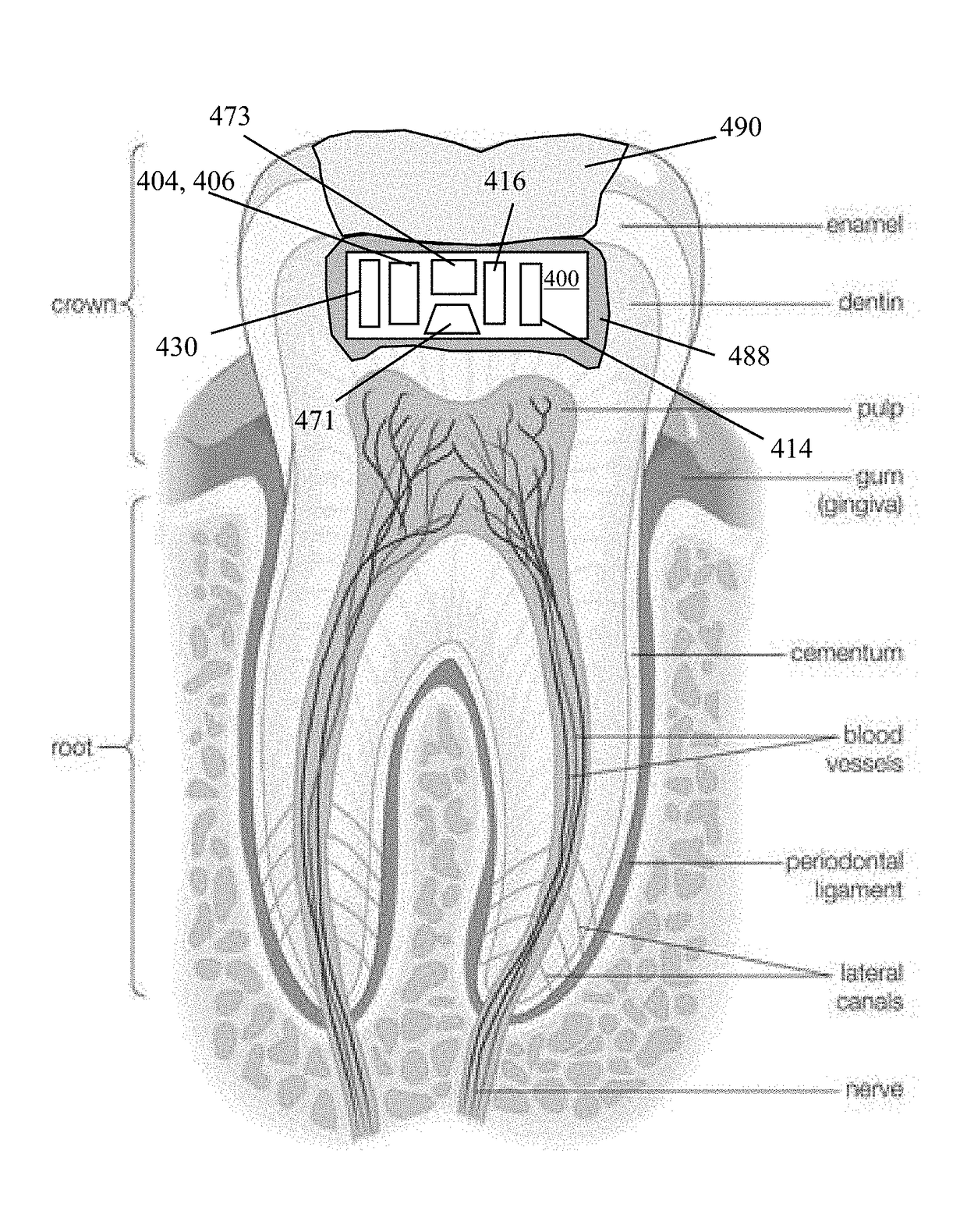

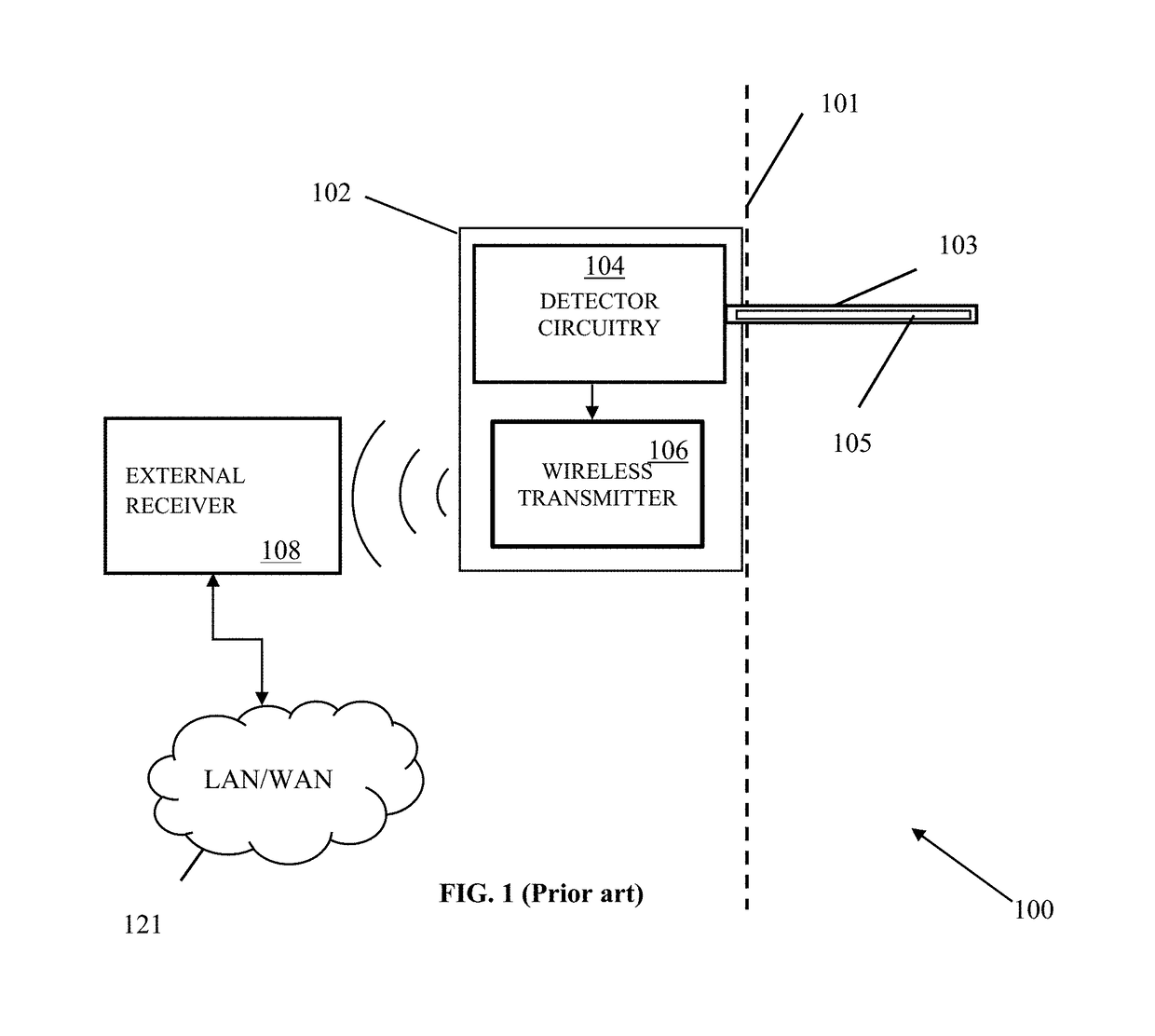

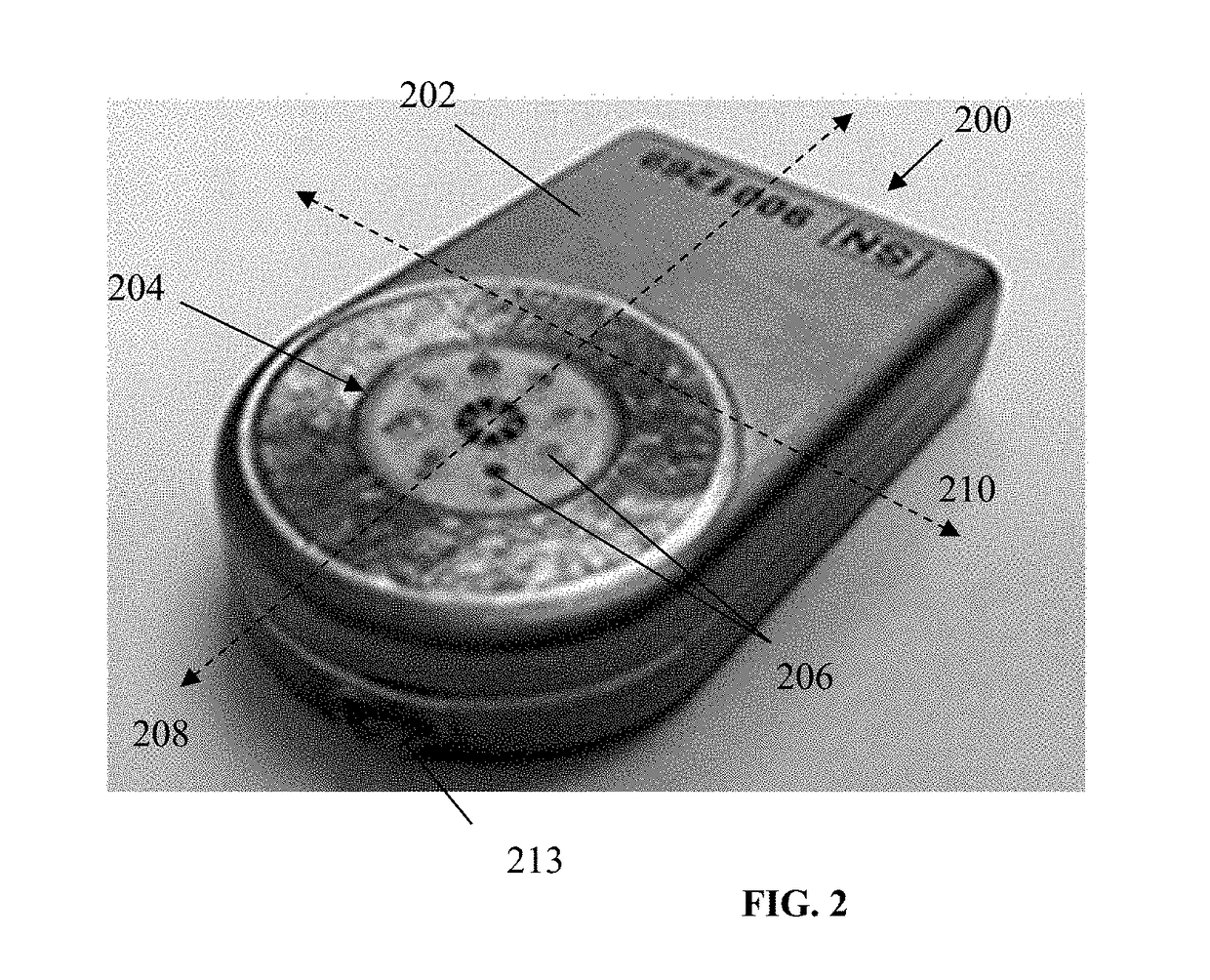

Analyte sensor receiver apparatus and methods

InactiveUS20180153450A1Enhances and enables performanceReduces wearer weightEndoradiosondesCatheterGlucose sensorsAnalyte

Receiver apparatus for use with an analyte sensor, and methods of operation and manufacturing. In one embodiment, the analyte sensor is an implanted / implantable blood glucose sensor, including oxygen-based detector elements. The receiver apparatus is a wireless-enabled small form-factor device with limited functionality that can be easily worn or kept with the user on a continual basis, thereby obviating the need for a more fully featured receiver or smartphone for extended periods of time (e.g., one week). The exemplary oxygen based analyte sensor, with high degree of stability over time, enables the user to divorce themselves from the more fully functioned receiver or smartphone, since no external calibration of the sensor is required during the extended period. In one variant, the device is a lightweight wristband. Other variants include e.g., pendants, finger-worn rings, arm or head bands, skin patches, and even dental, subcutaneous, or prosthetic implants.

Owner:GLYSENS

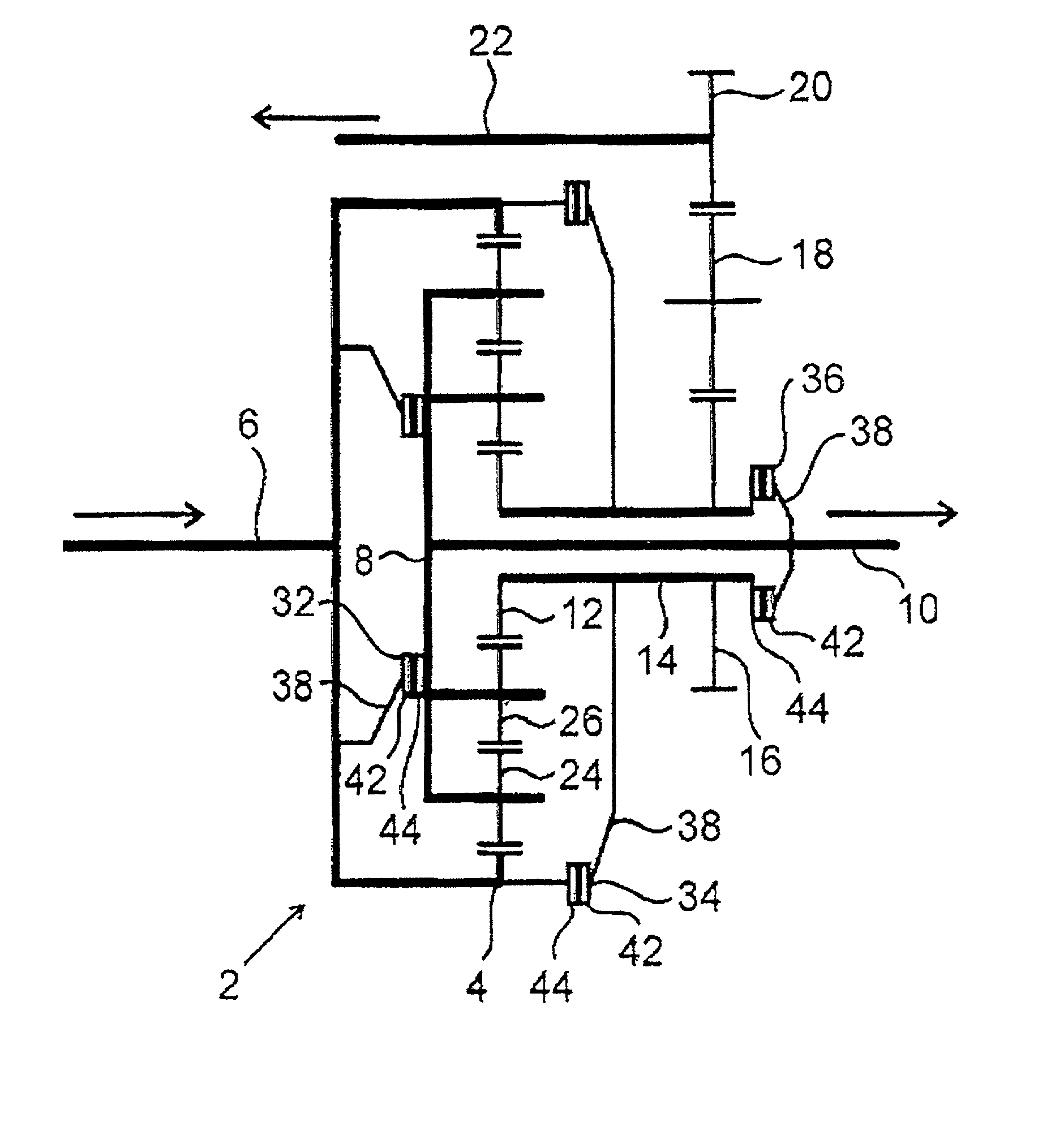

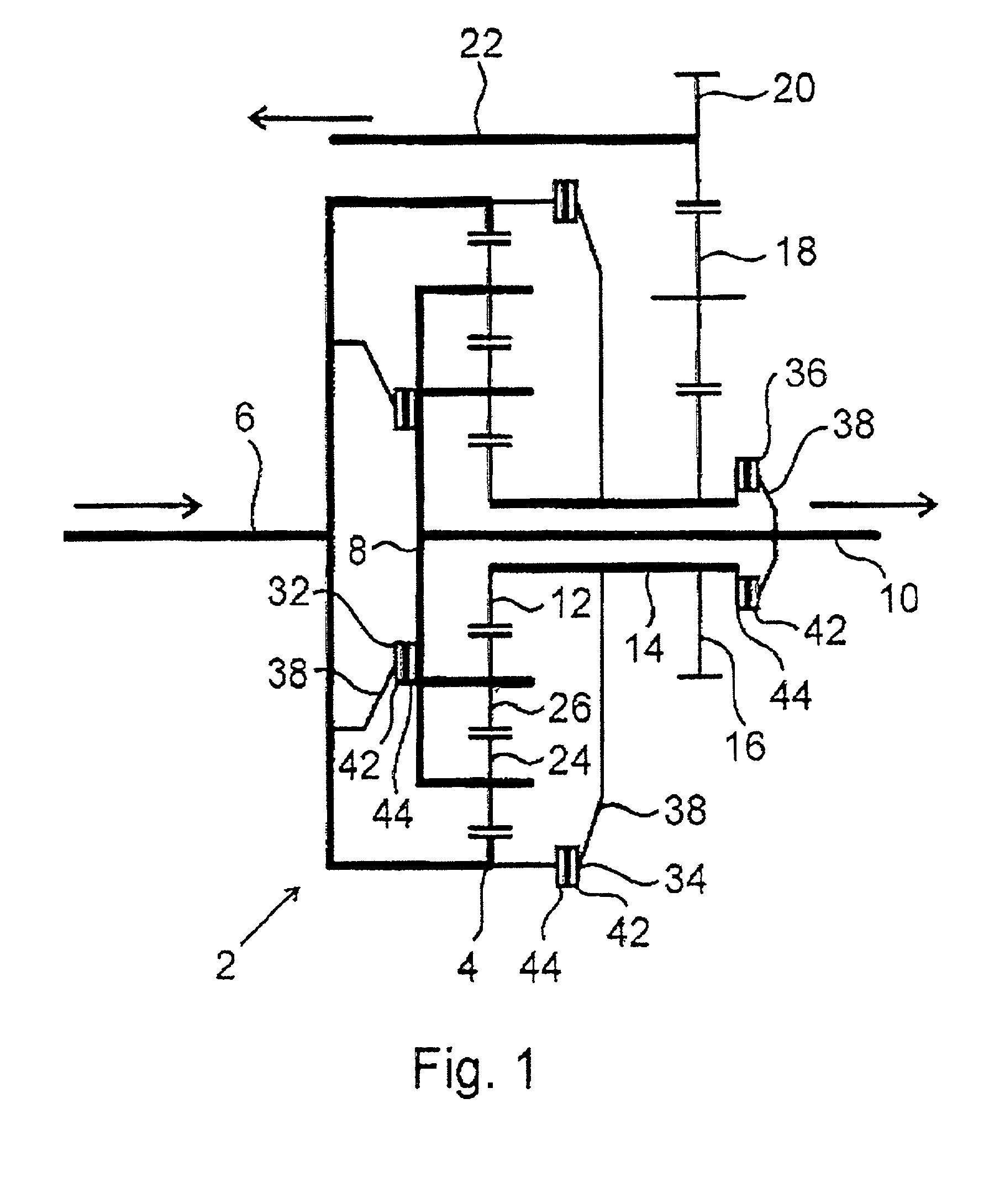

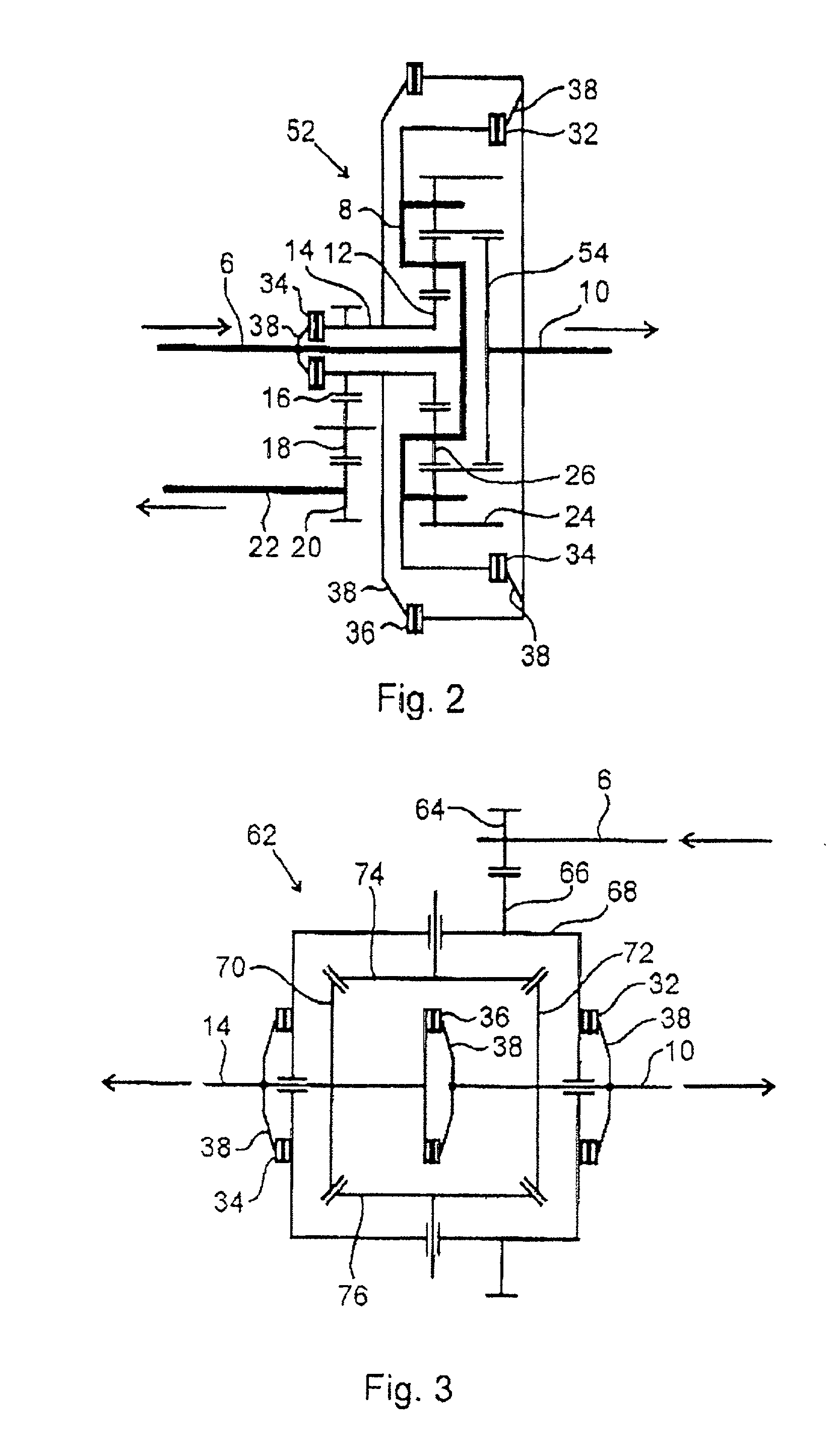

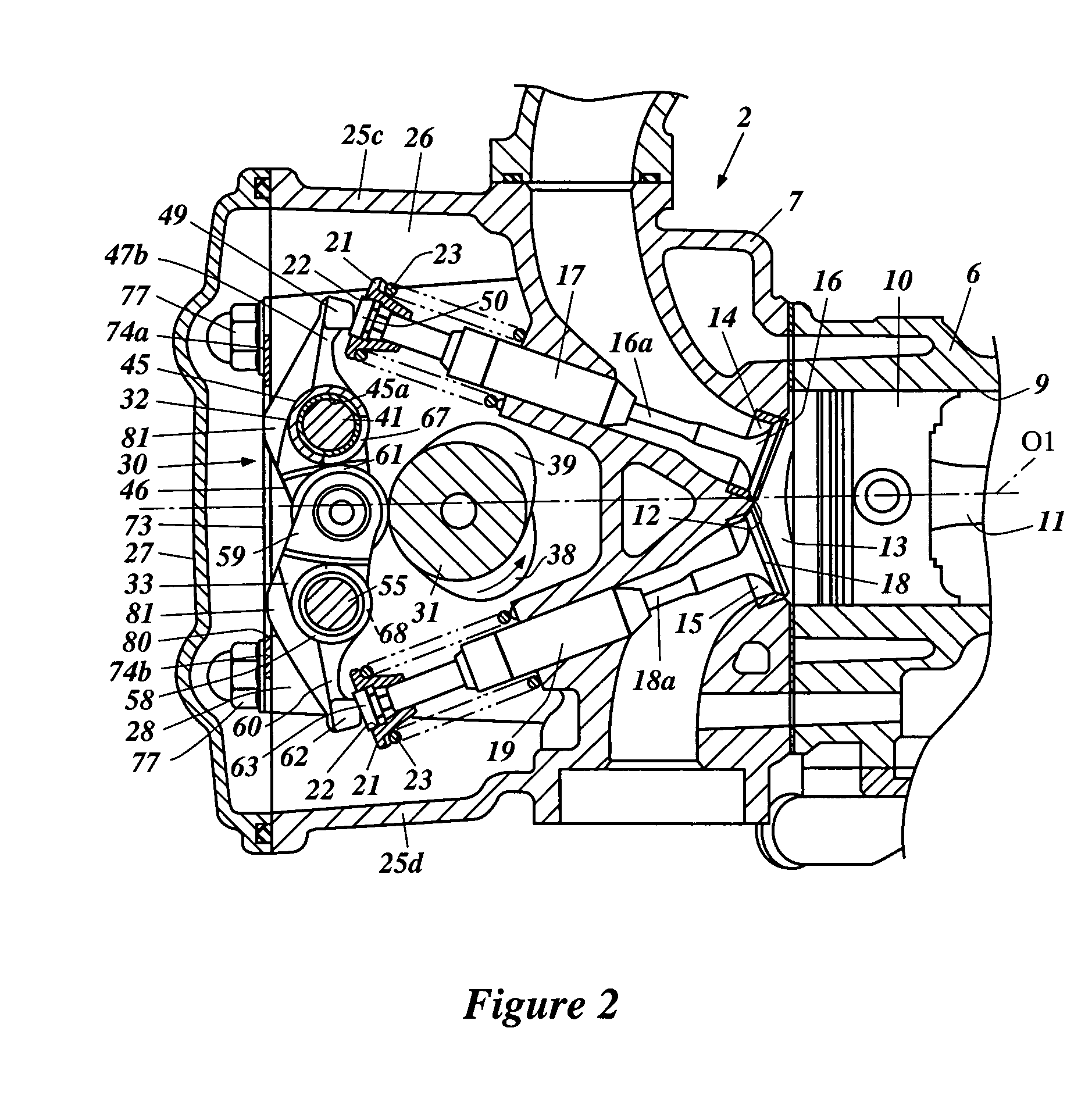

Motor-vehicle drive train

InactiveUS20020128117A1Reduces clutch-engagement pressureIncrease temperatureGearing controlEngine controllersControl theoryClutch

In a motor-vehicle drive train containing a differential, which has an differential input part and two differential output parts, a friction clutch with a limited transmittable torque is arranged between two of the differential parts, so that, with a small predetermined difference in torque between the two coupled differential parts, said friction clutch can slip to accommodate torque shocks. A temperature-dependent adjusting means is provided, which reduces the clutch engagement pressure with increasing clutch temperature.

Owner:CHEMTRON RES

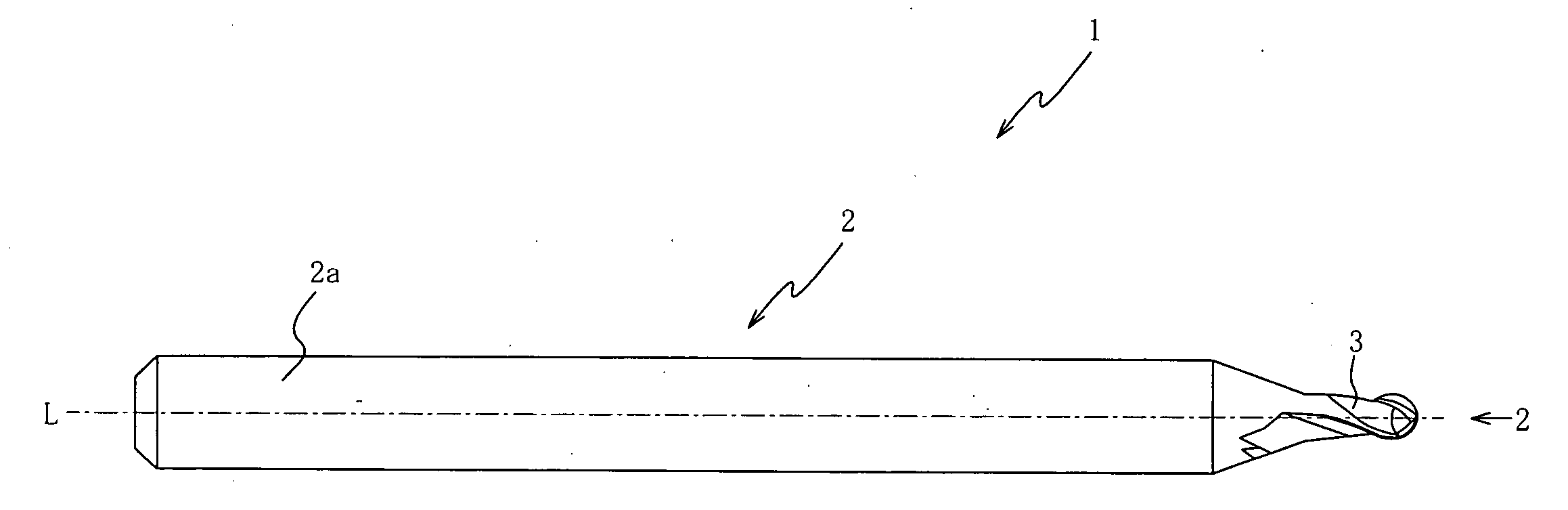

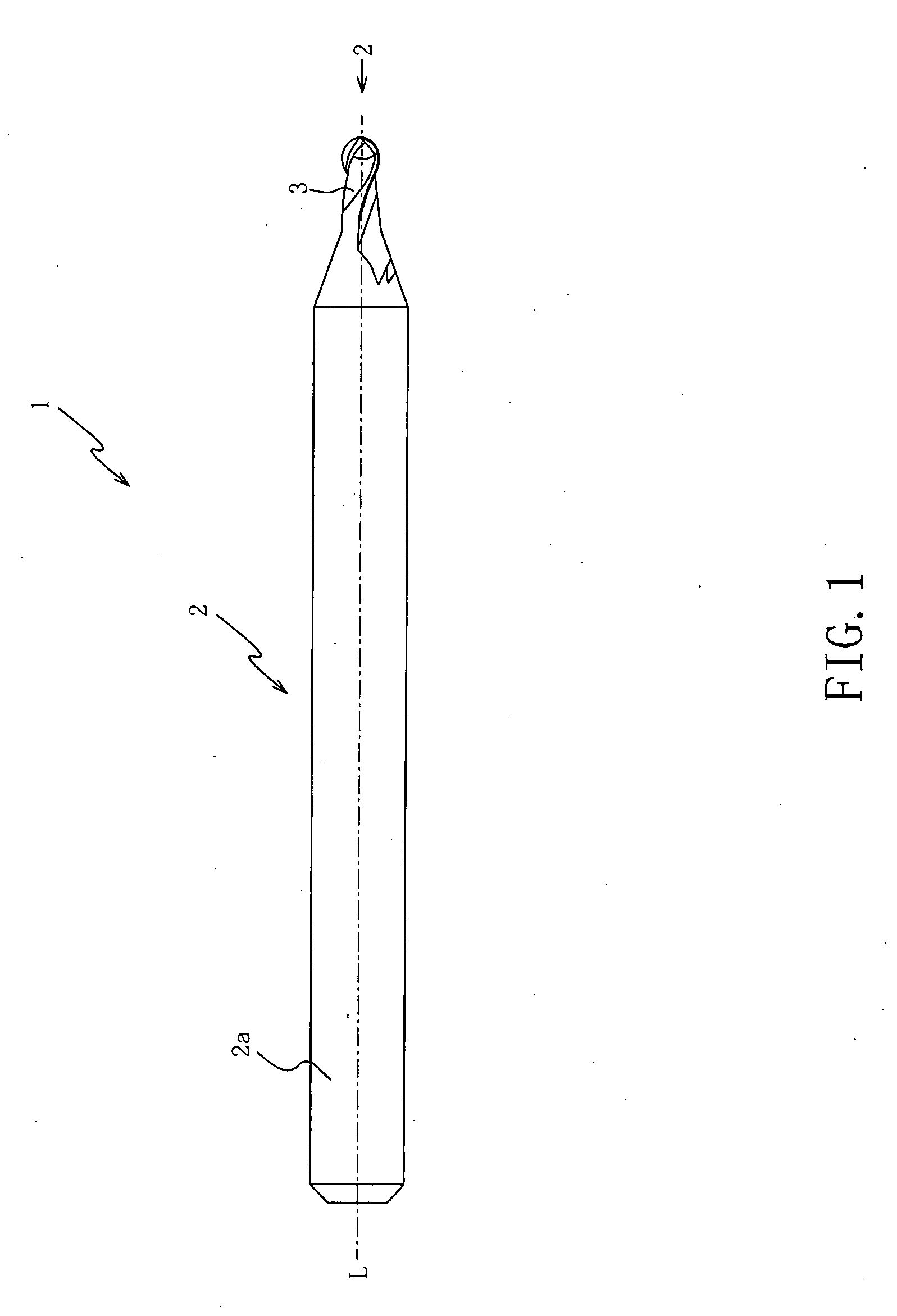

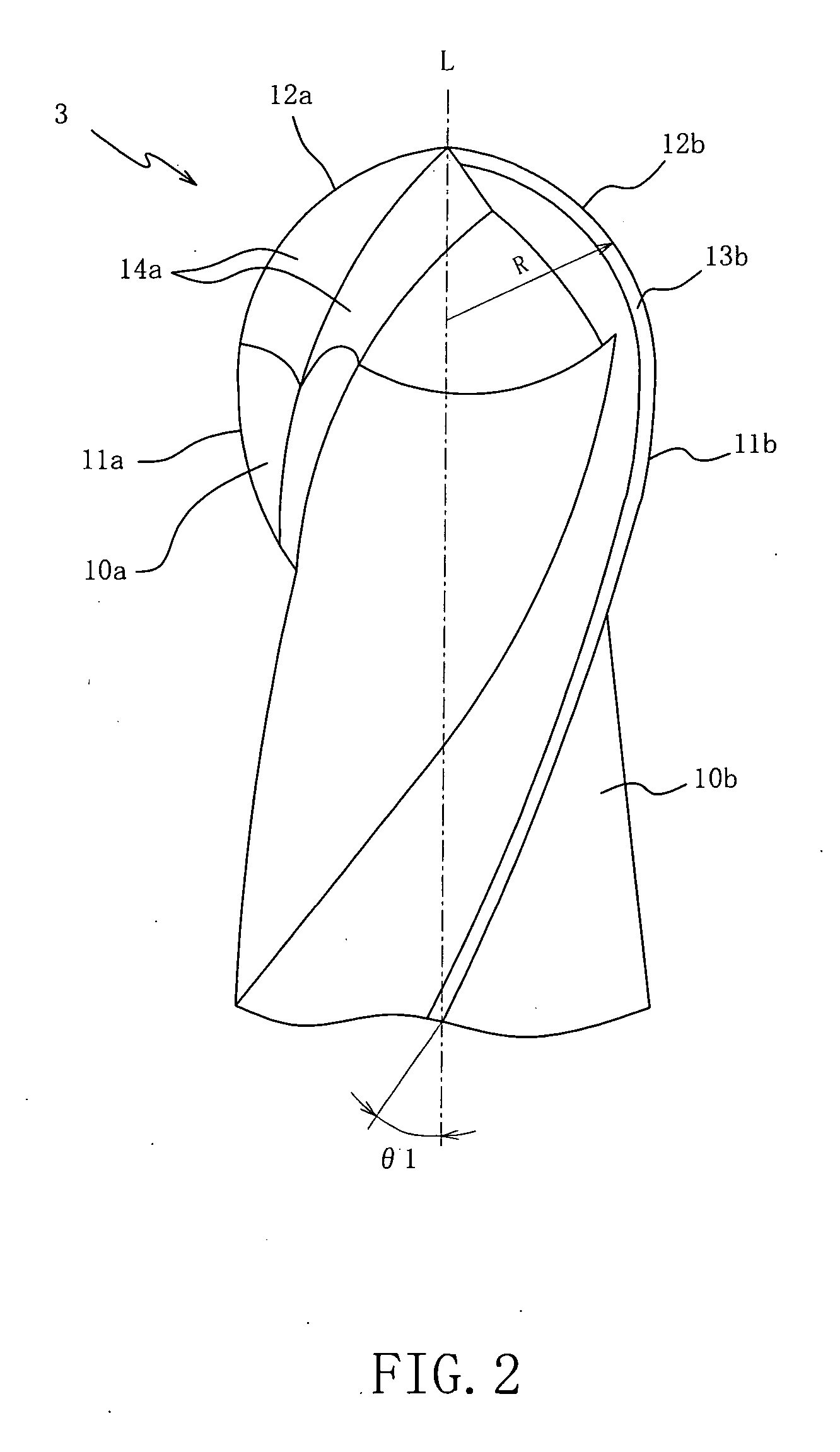

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

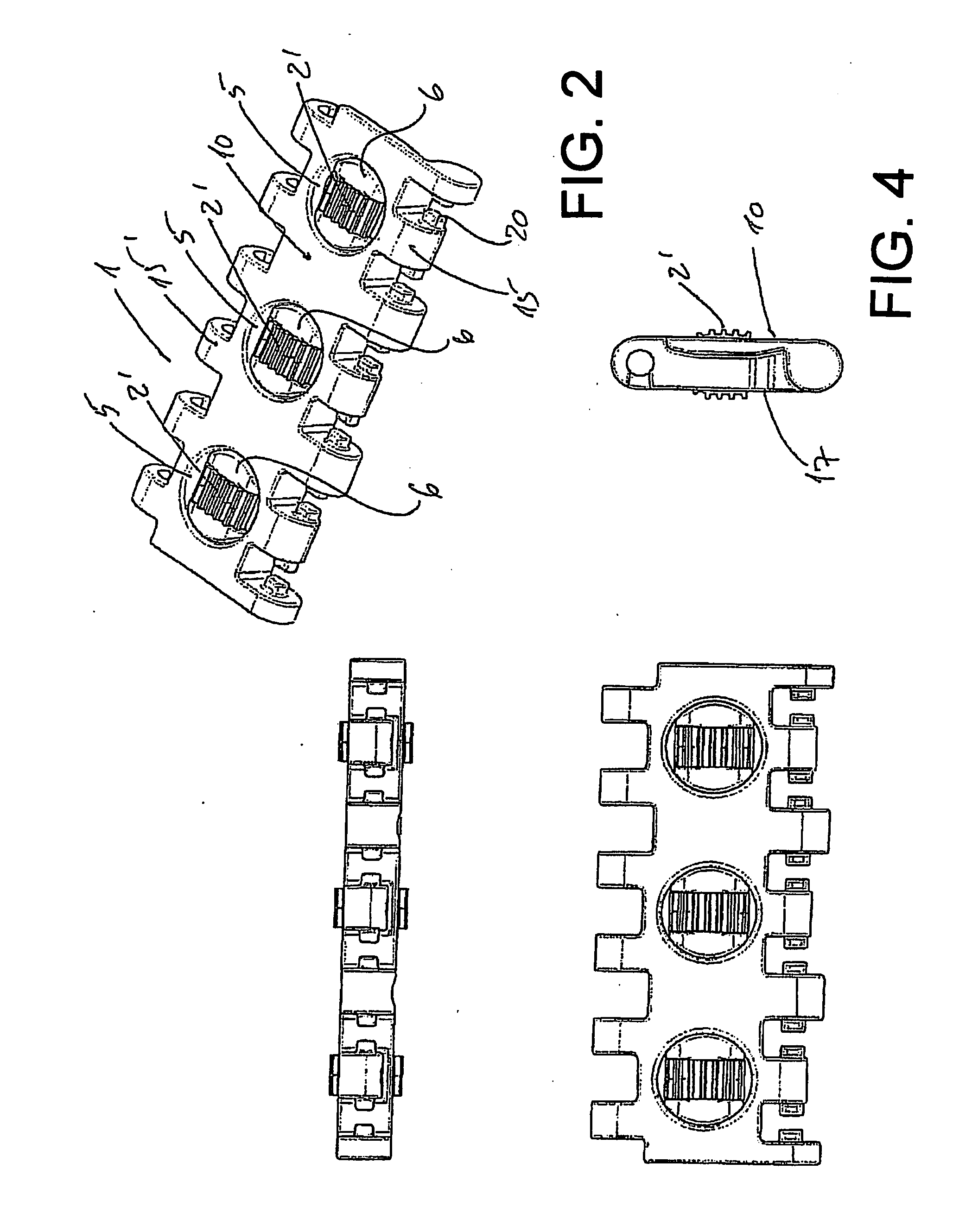

Vibration attenuating spring and damper mechanism using the same spring

InactiveUS6062548AHighly desirable dampening characteristicHigh strengthPlungersLeaf springsEngineeringLeaf spring

A damper mechanism for attenuating vibrations having a vibration attenuating spring element (1) which includes: a leaf spring (2) having a bent portion (4) and a pair of lever portions (5) extending from both ends of the bent portion (4); and an elastic member (3) disposed between the lever portions (5). When the leaf spring (2) is subjected to compressive forces, the lever portions (5) and the elastic member (3) are elastically deformed. Internal friction is generated in the elastic member (5). The functions typically provided by a conventional elastic member and a conventional resistance generating mechanism are realized by utilizing a simple spring element composed of the leaf spring (2) and the elastic member (3).

Owner:EXEDY CORP

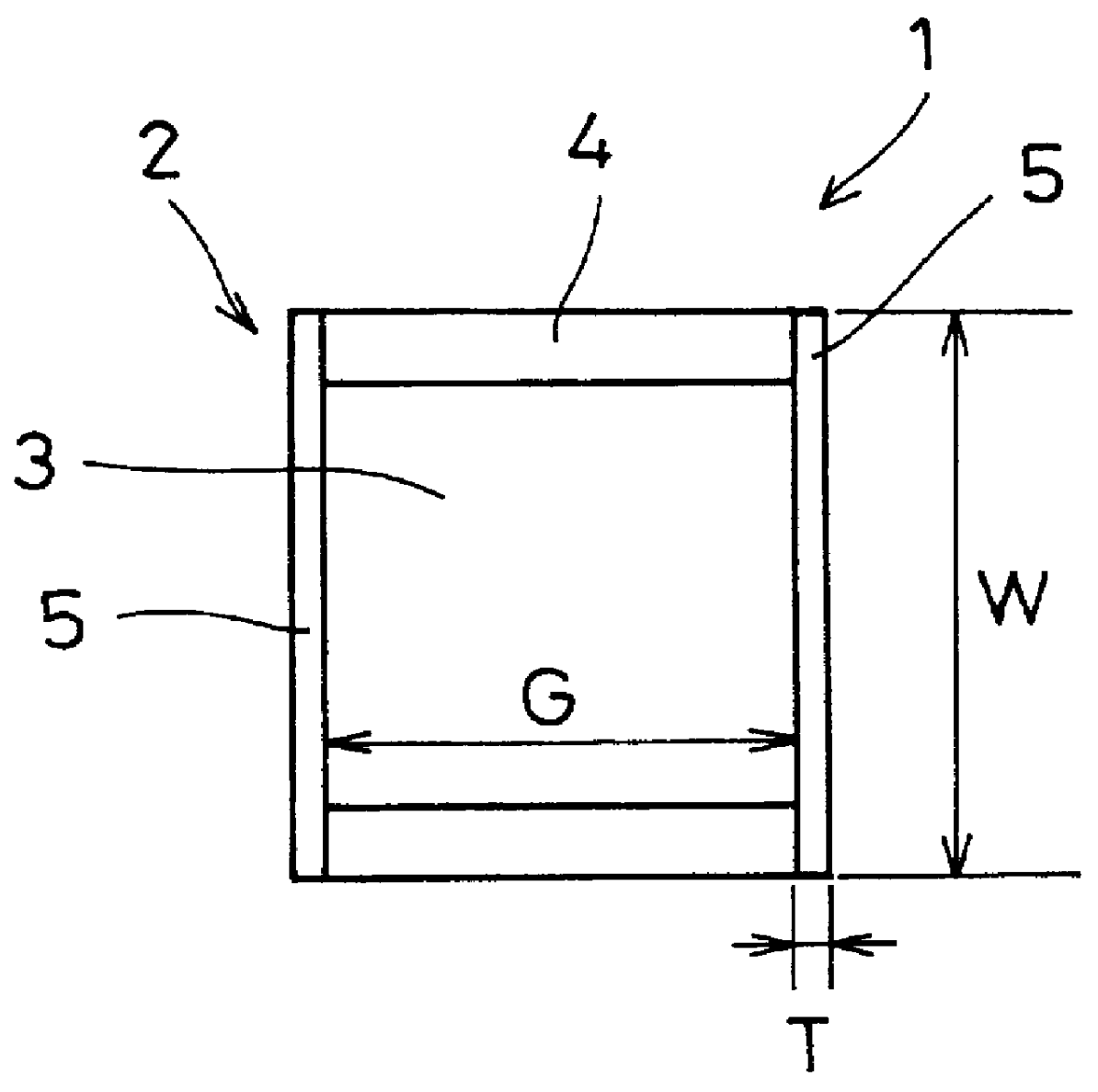

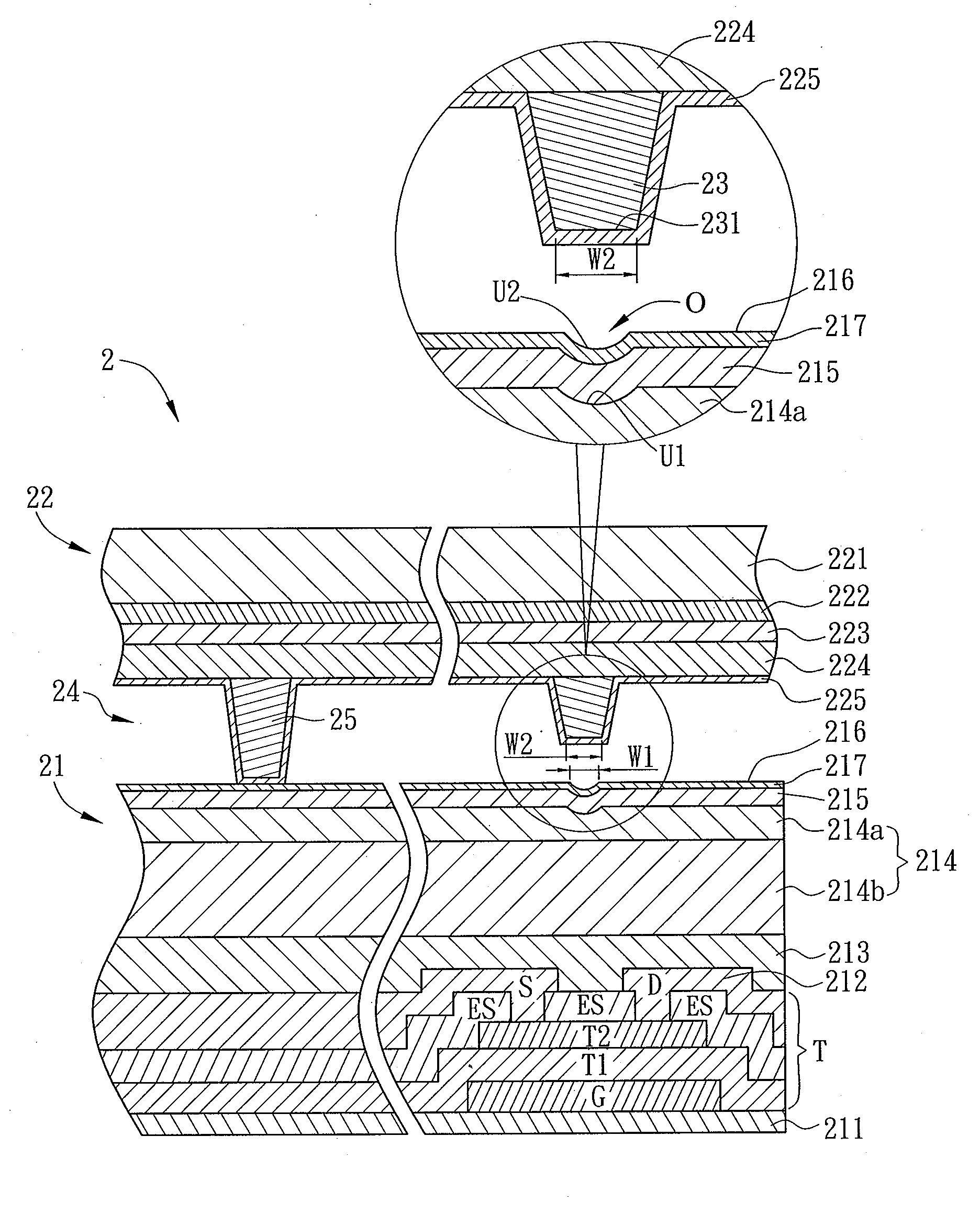

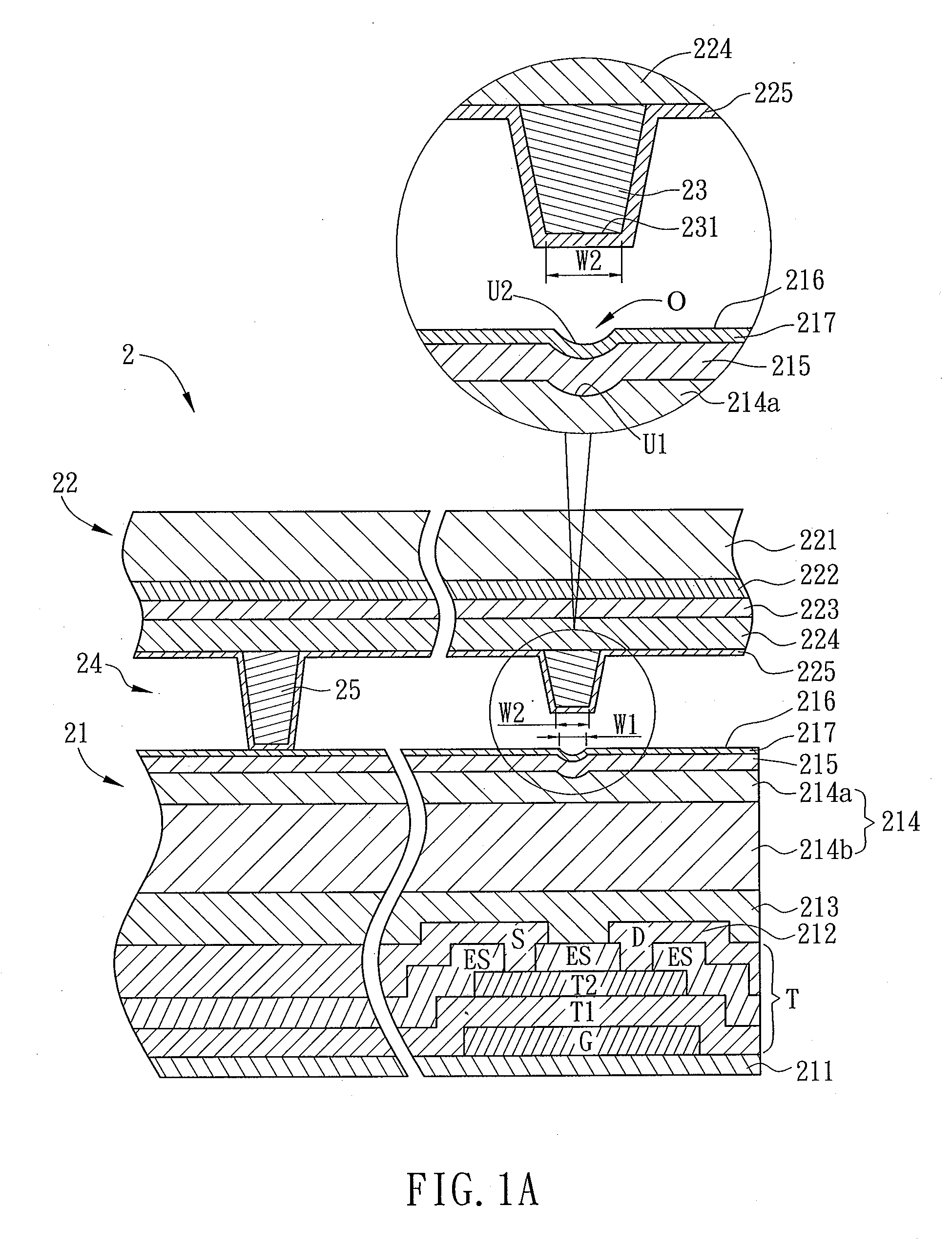

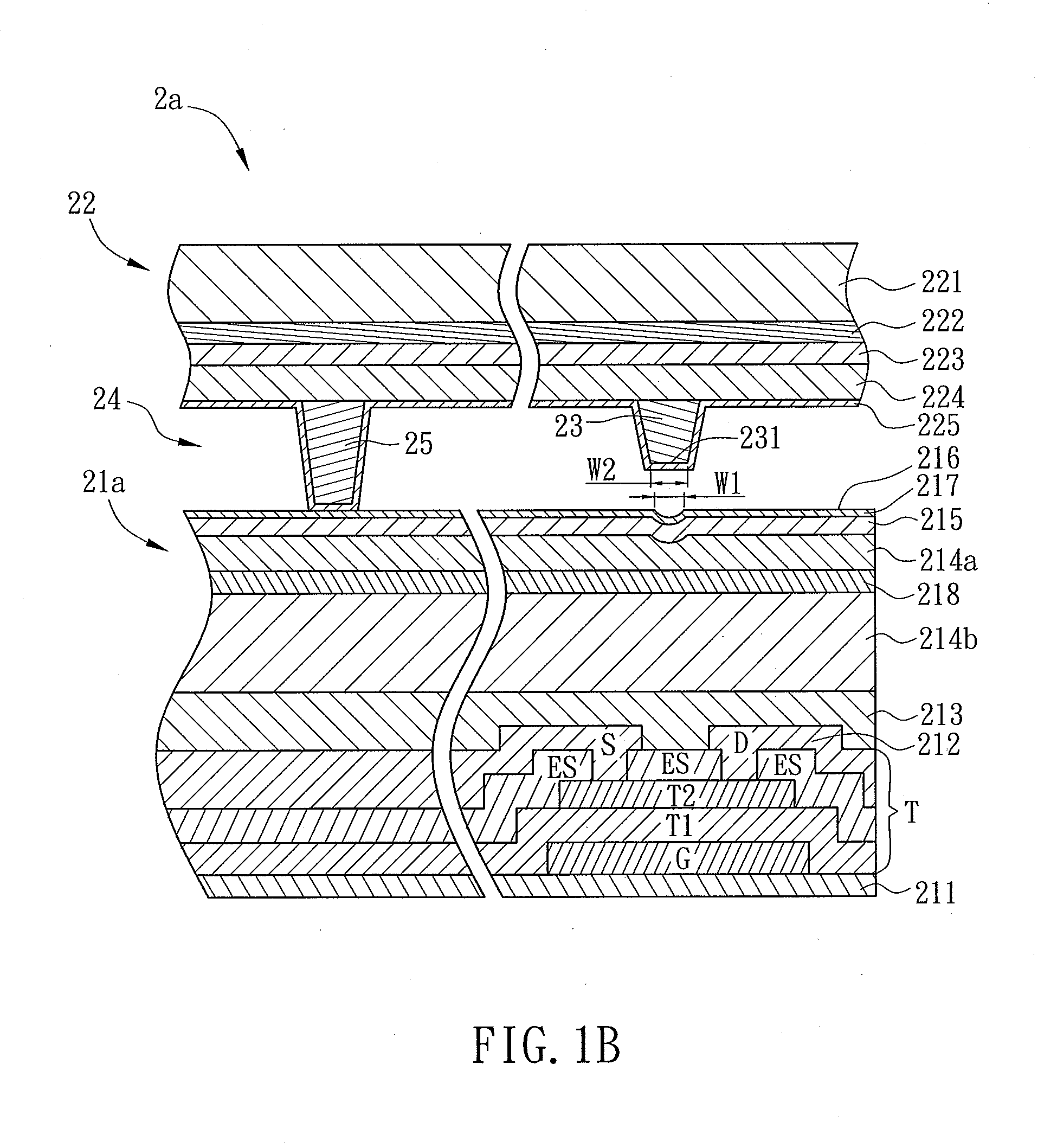

Liquid crystal display apparatus

ActiveUS20140071391A1Large lateral frictionMore contact areaNon-linear opticsLiquid-crystal displayMaterials science

A liquid crystal display apparatus comprises a first substrate, a second substrate and a first spacer. The first substrate includes a transparent substrate, a metal layer, an insulating layer and a first electrode layer. The metal layer is disposed on the transparent substrate. The insulating layer is between the metal layer and first electrode layer, and covers the metal layer. The insulating layer has a first indentation. A surface of the first substrate has a second indentation corresponding to the first indentation and having a first width. The second substrate is opposite to the first substrate. The first spacer is on the second substrate and has a top surface opposite to the second indentation. The top surface and the second indentation at least partially overlap, and the top surface has a second width larger than the first width.

Owner:INNOLUX CORP

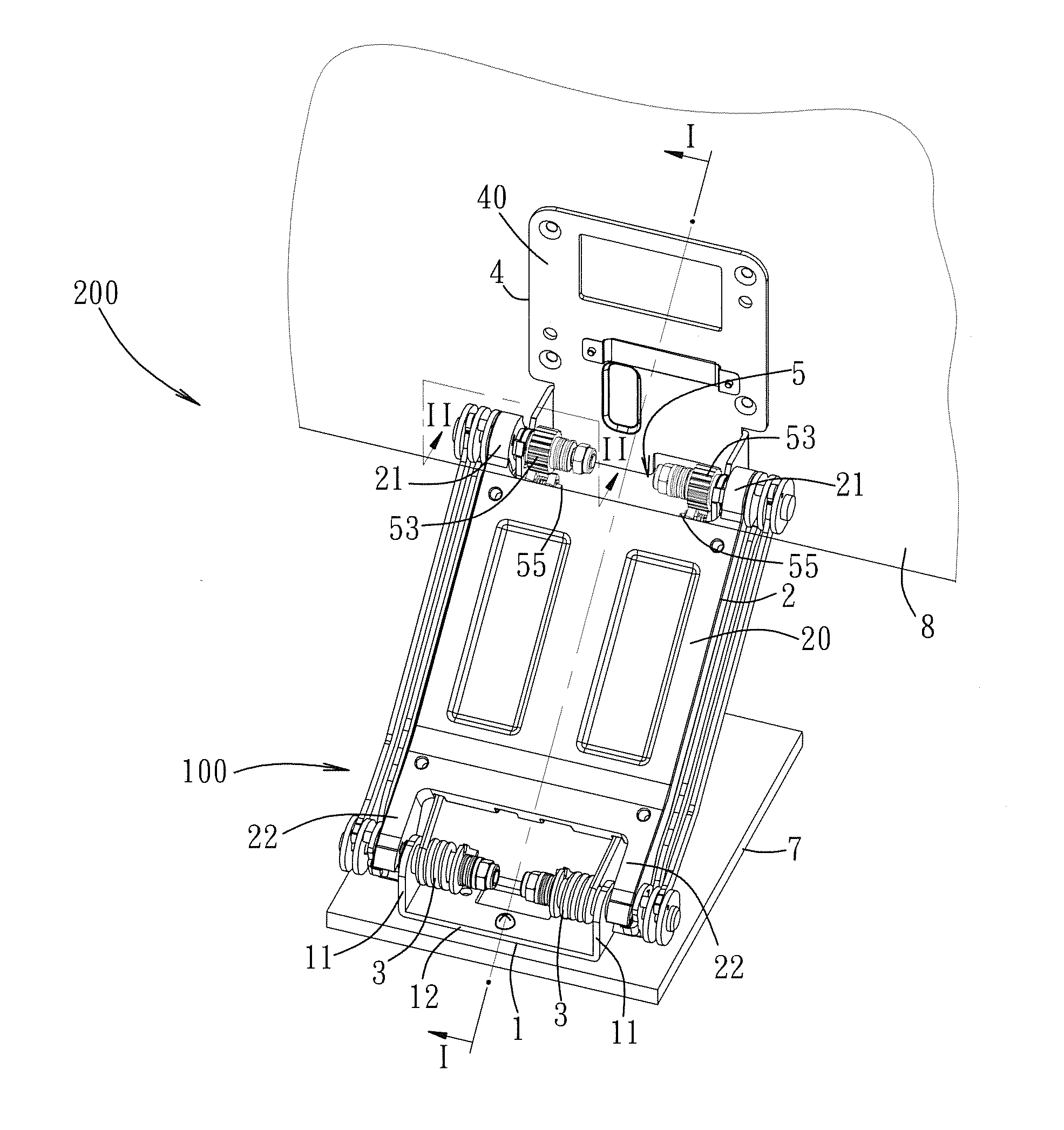

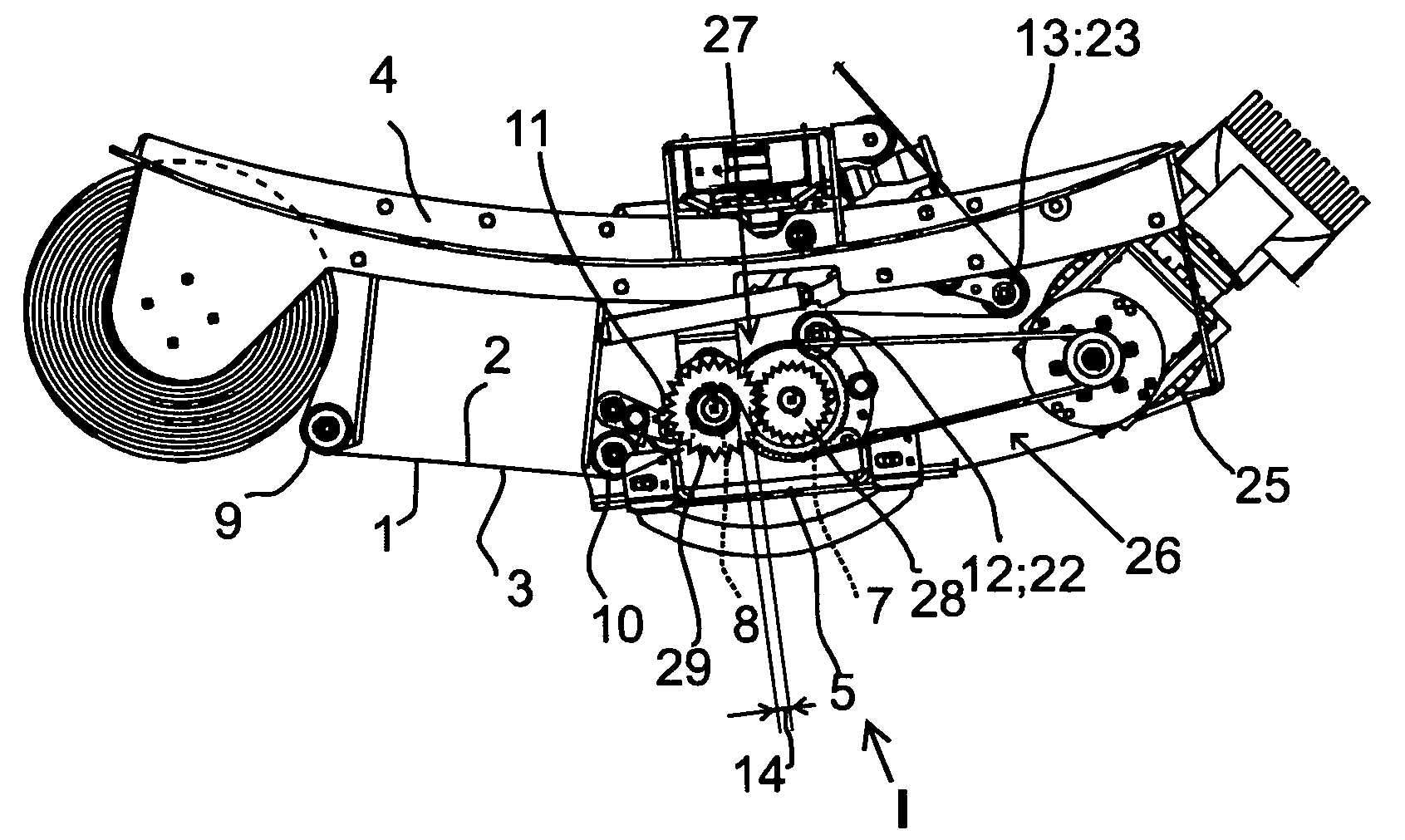

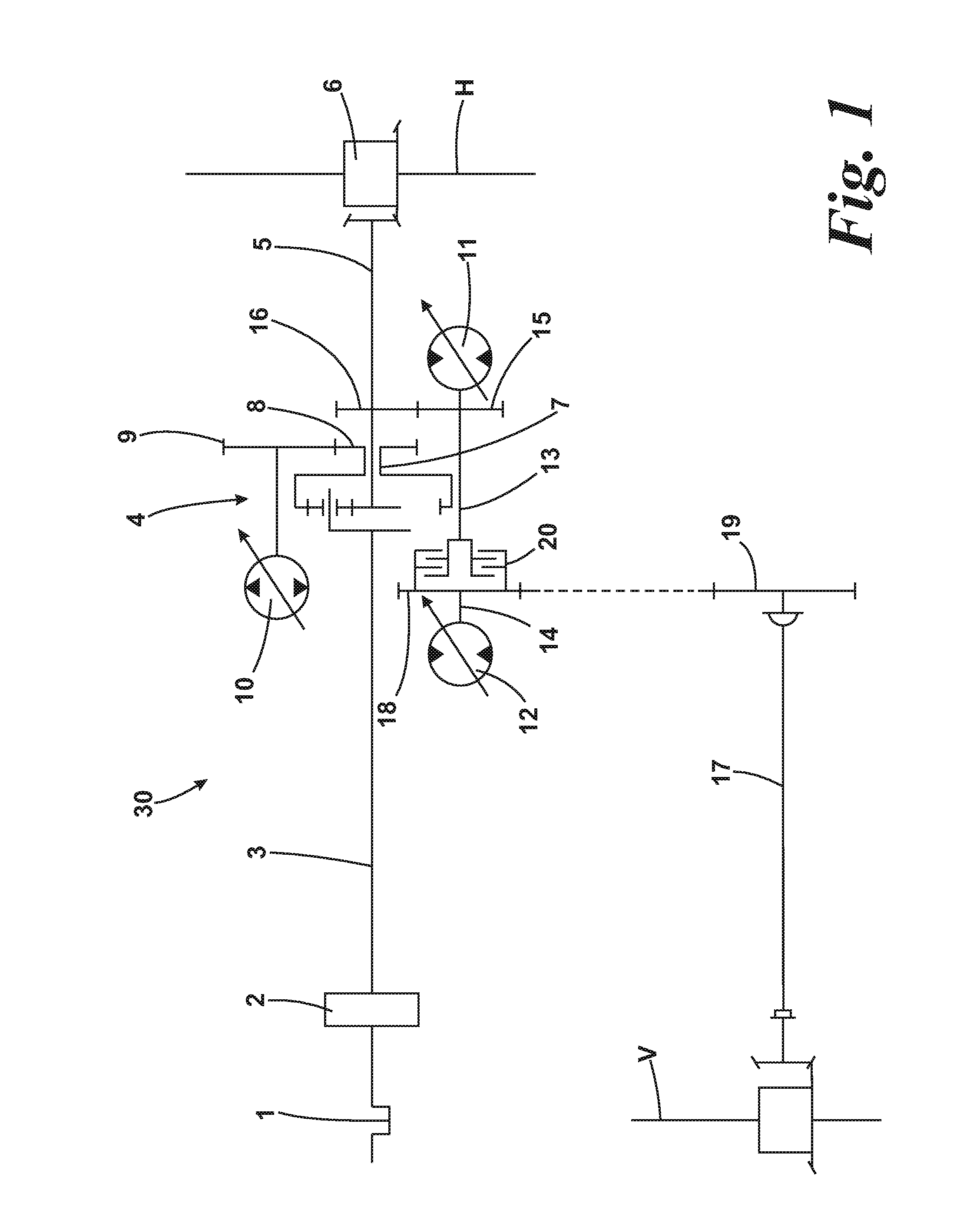

Film delivery device and use of same

ActiveUS20090120307A1Drawback can be obviatedThreading of the film is particularly easyWrappers shrinkageWrapping material feeding apparatusEngineeringMechanical engineering

A film delivery device comprising a first assembly (4) which can be connected to a wrapping machine and a second assembly (5) which is pivoted to turn, relative to the first assembly (4), about a horizontal hinge axis (6) between a closed position (I) and an open position (II). A first prestretch roller (7) is in the first assembly (4). A second prestretch roller (8) is in the second assembly (5). The film can be threaded by S-threading between the prestretch rollers (7, 8). The second assembly (5) is hinged at the lower end to the lower end of the first assembly (4) to turn about said horizontal hinge axis (6). The second assembly (5) comprises a pivoted and spring-loaded first deflecting roller (22) which is arranged downstream relative to the first prestretch roller (7). In the open position (II) of the second assembly (5), that part of the first deflecting roller (22) which is close to the lower end thereof is resting against the surface of the first prestretch roller (7).

Owner:M HALOILA

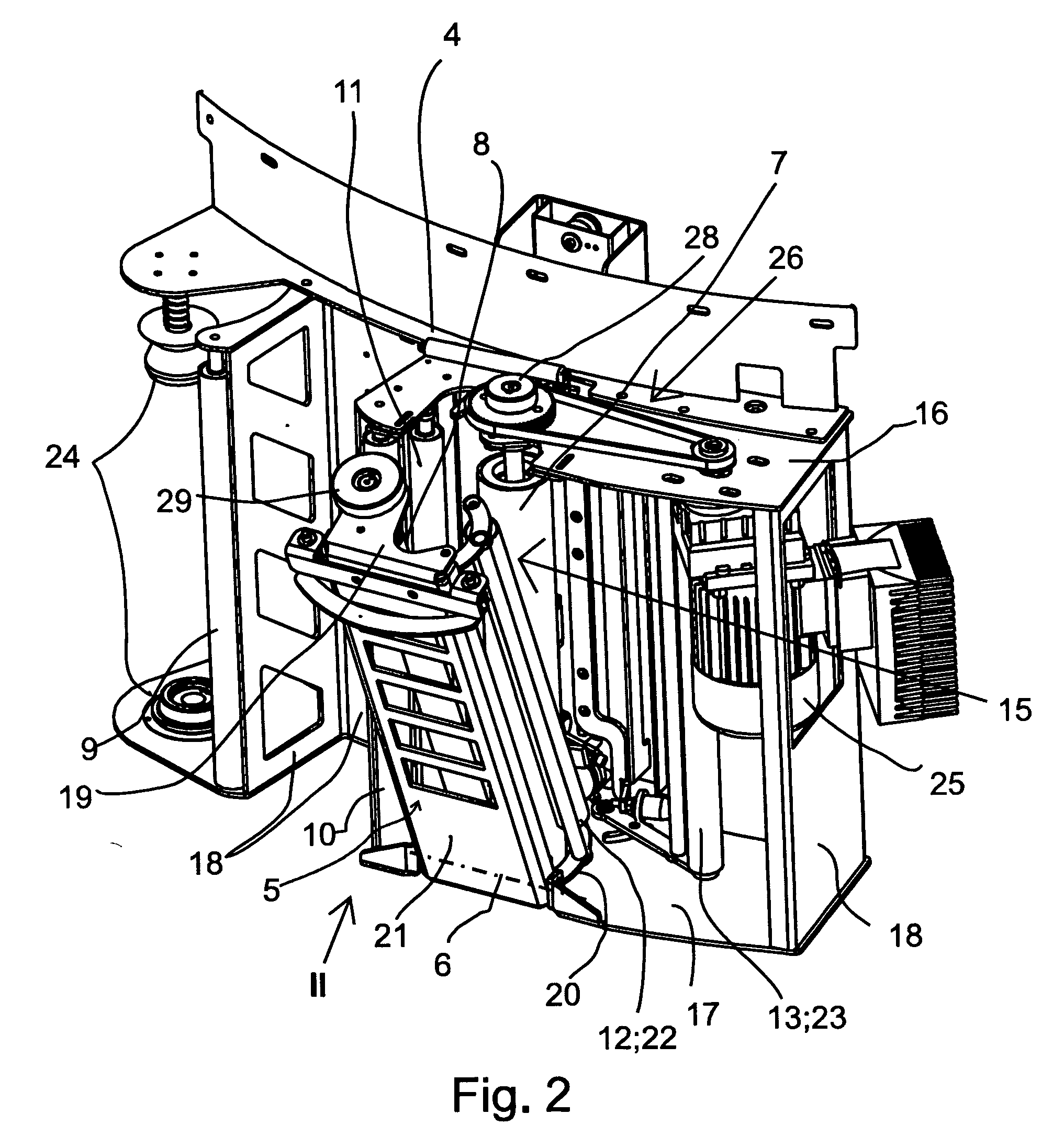

Transverse belt

ActiveUS20100078297A1Rapidly and safely accelerate and displaceSolve the small frictionConveyorsTrailing edgeLeather belt

Modular belt link for use in endless conveyor belts where each modular belt link has a top surface, a bottom surface having a material thickness between said top and bottom surfaces, a leading and trailing edge, and side edges arranged connecting said leading and trailing edge and said top and bottom surfaces, and where means are arranged along said leading and trailing edge for hingely connecting adjacent modular belt links characterised in that an endless belt is arranged for rotation around at least a portion of the modular belt link.

Owner:AMMERAAL BELTECH MODULAR

Luer lock connection

Owner:TRANSCOJECT

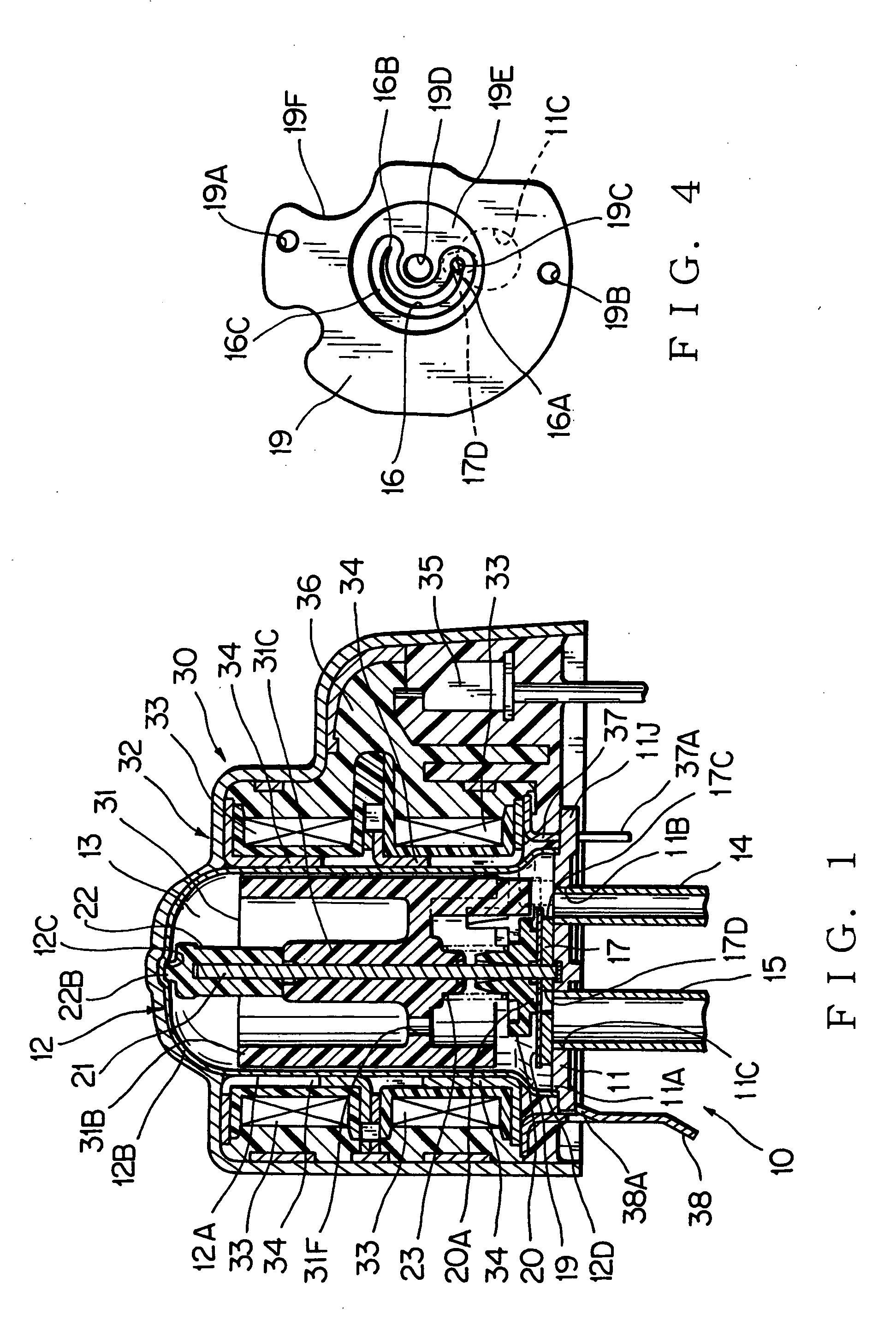

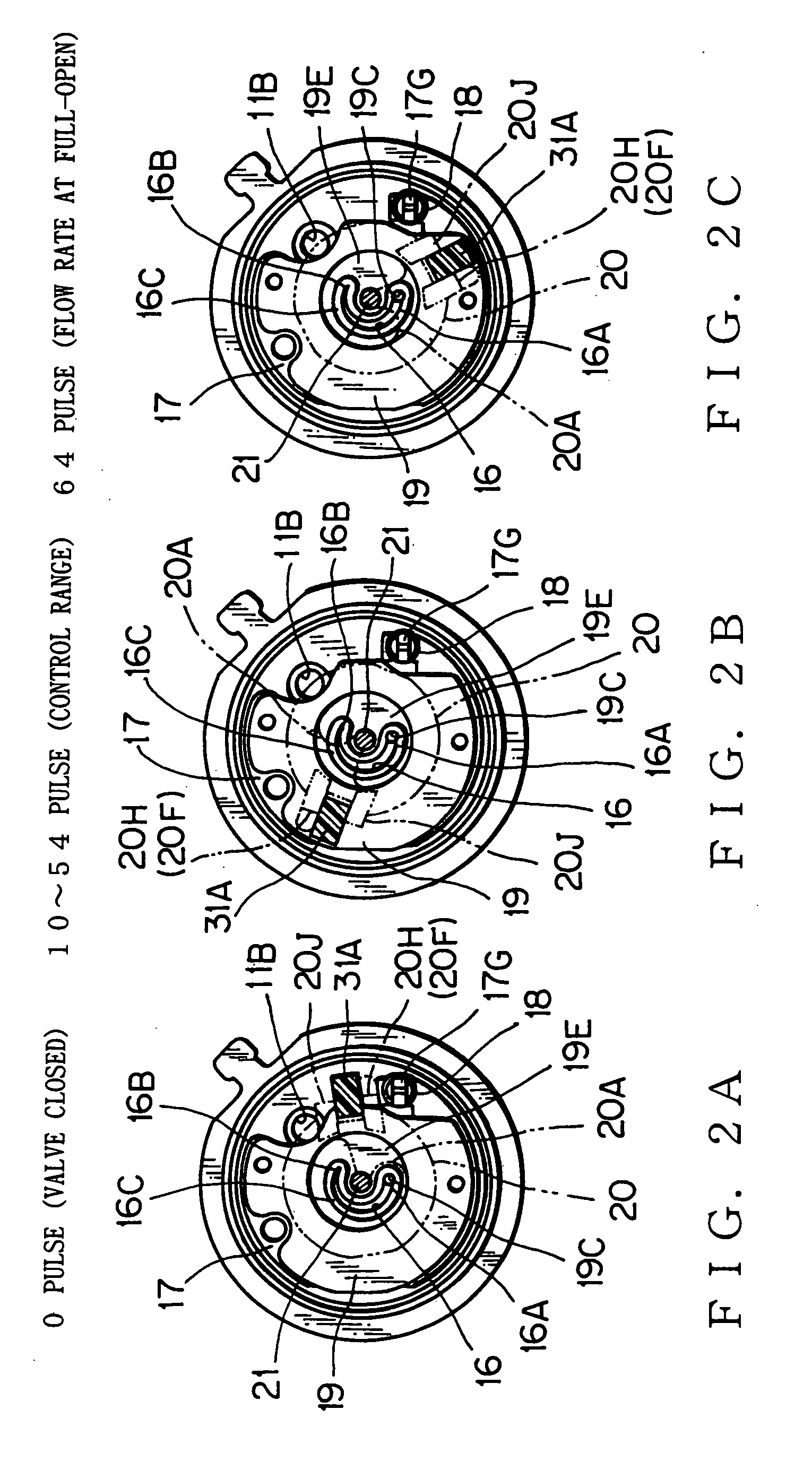

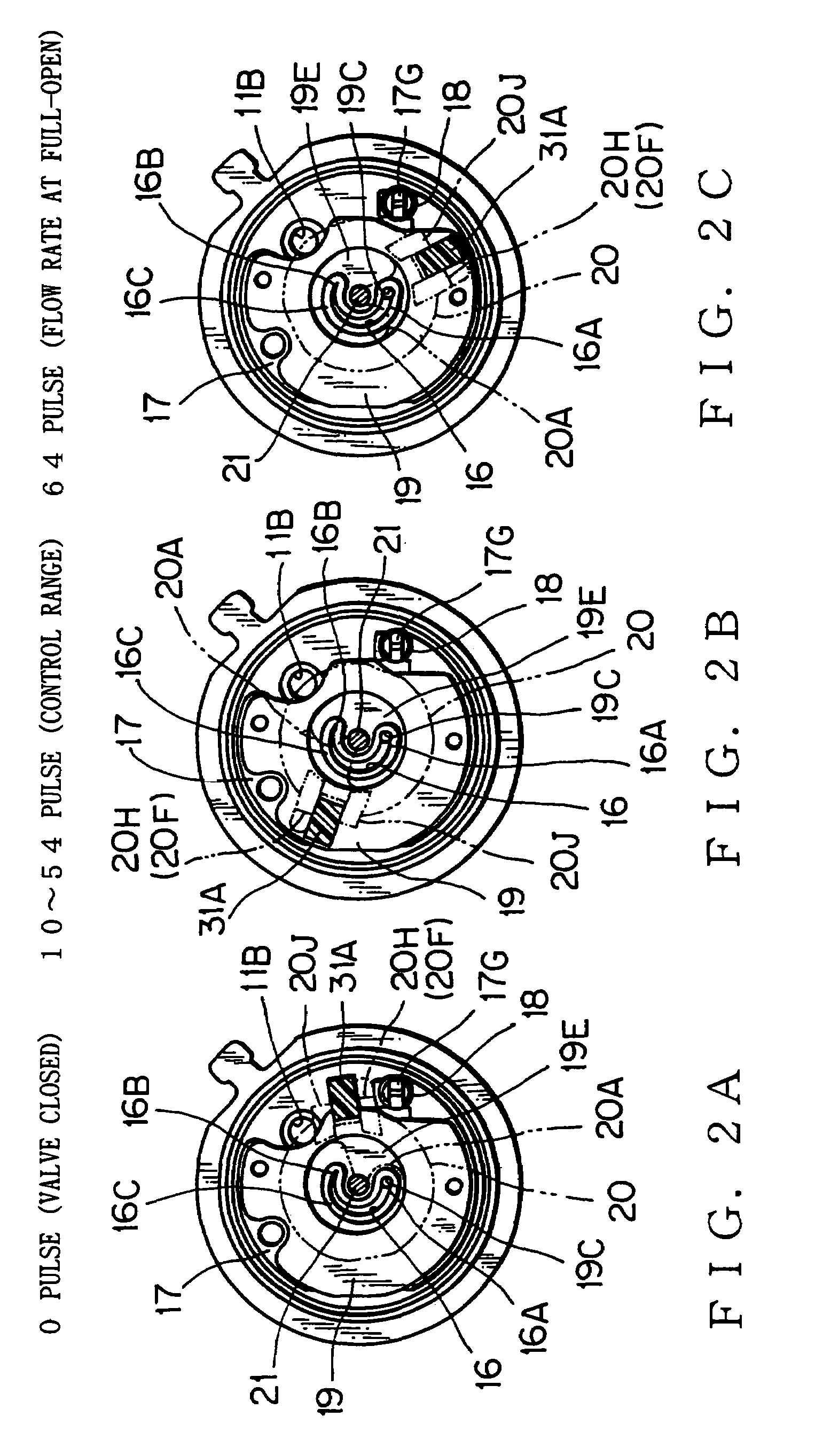

Electric control valve

ActiveUS20070040138A1Drive torque of be reducePrevent leakagePlug valvesOperating means/releasing devices for valvesEngineeringValve seat

The electric control valve, in which a throttled flow rate is quantitatively determined by the groove 16 by a rotating position of the valve body 20, the valve seat surface projects like a band from a border band 16C drawing an outline of the groove 16, and the end surface of the valve body 20 contacts slidingly on a top surface of the border band 16C.

Owner:SAGINOMIYA SEISAKUSHO CO LTD

Electric control valve

ActiveUS7316384B2Solve the small frictionDriving torque of the valve body increasesPlug valvesOperating means/releasing devices for valvesEngineeringElectric control

The electric control valve, in which a throttled flow rate is quantitatively determined by the groove 16 by a rotating position of the valve body 20, the valve seat surface projects like a band from a border band 16C drawing an outline of the groove 16, and the end surface of the valve body 20 contacts slidingly on a top surface of the border band 16C.

Owner:SAGINOMIYA SEISAKUSHO INC

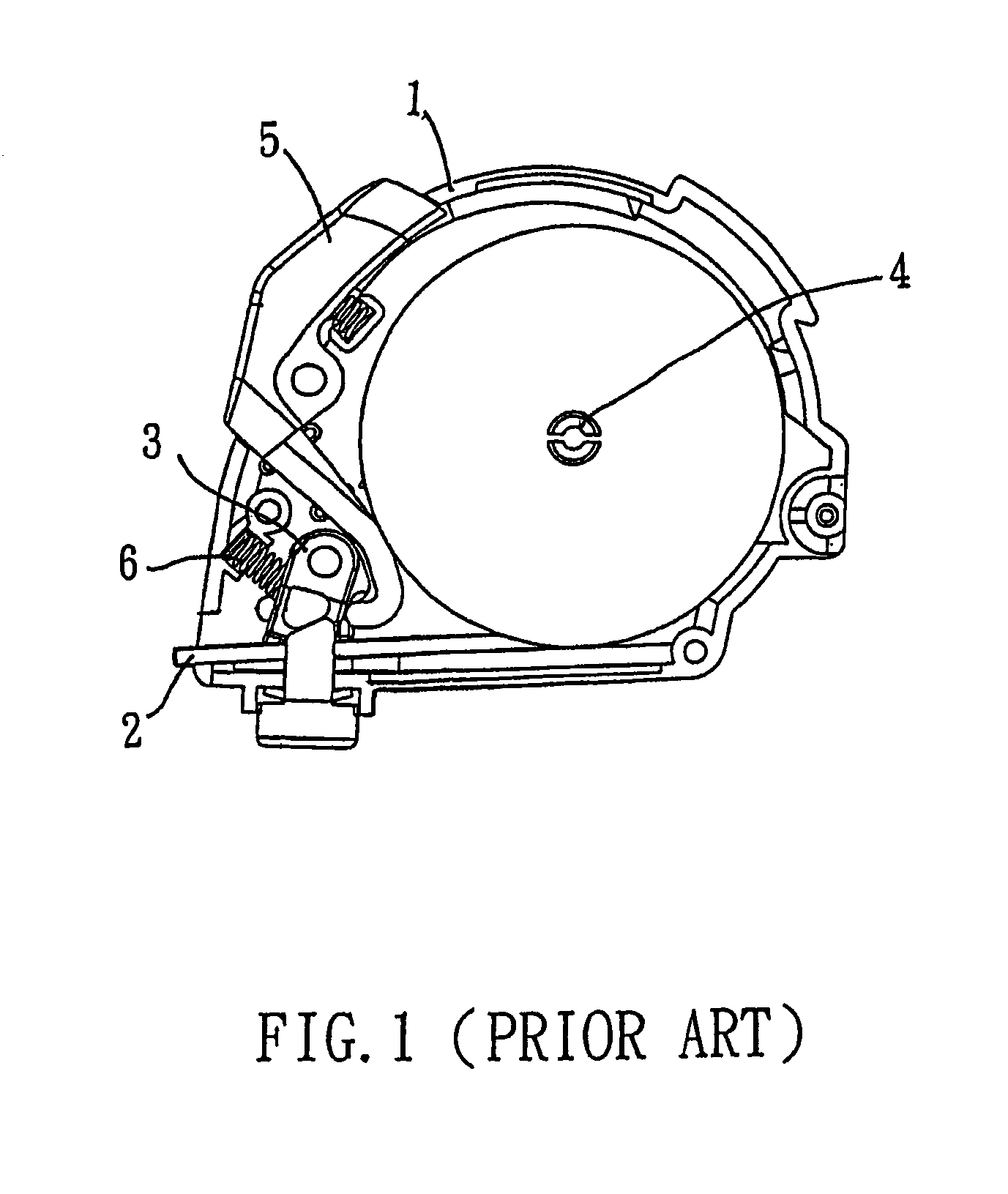

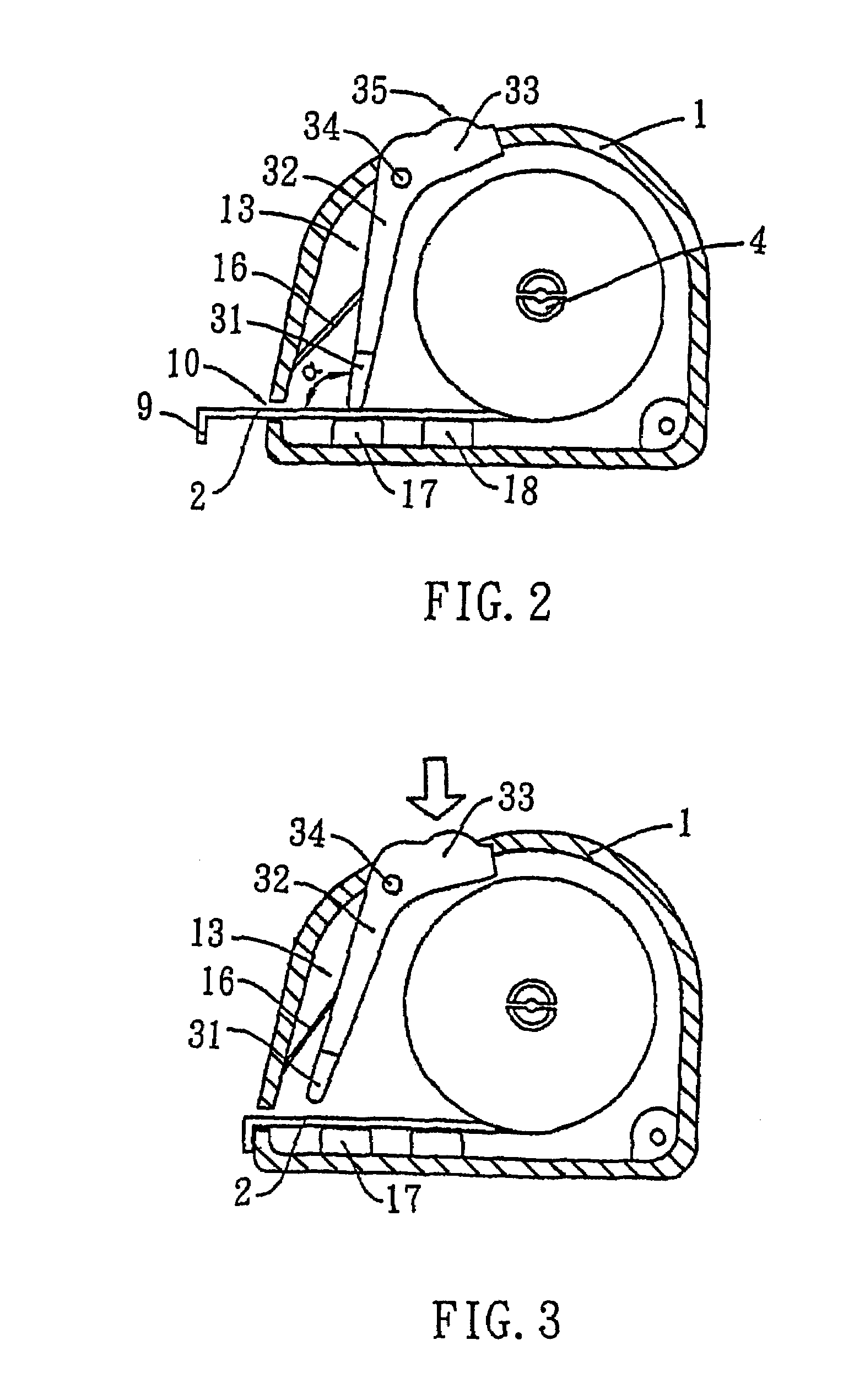

Automatic locking mechanism for a measuring tape device

A measuring tape device with automatic locking mechanism comprises of a casing, a bobbin that is set within the casing with a spring, a coilable tape that is contained in the casing. One end of the tape is connected to the spring and is wound around the bobbin, while the other end is extended outside through an aperture that is formed at the lower end to of casing, and this other end is connected to a hook member. The device also comprises of a stopper, it consists of an end that is positioned on the linear portion of tape, and an actuator that is connected to the end portion by a linkage part. The actuator is extruded outside and is settled at the surface of the casing. The device includes a hinge joint for fixating the stopper inside the casing and for allowing the stopper to rotate, and an elastic member placed between the casing and the linkage portion. The measuring tape device of present invention will lock the tape in place after the tape is extracted out from the casing, the locking mechanism of the tape is considered effective, and it has relatively low production cost, hence it is beneficial for mass production.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

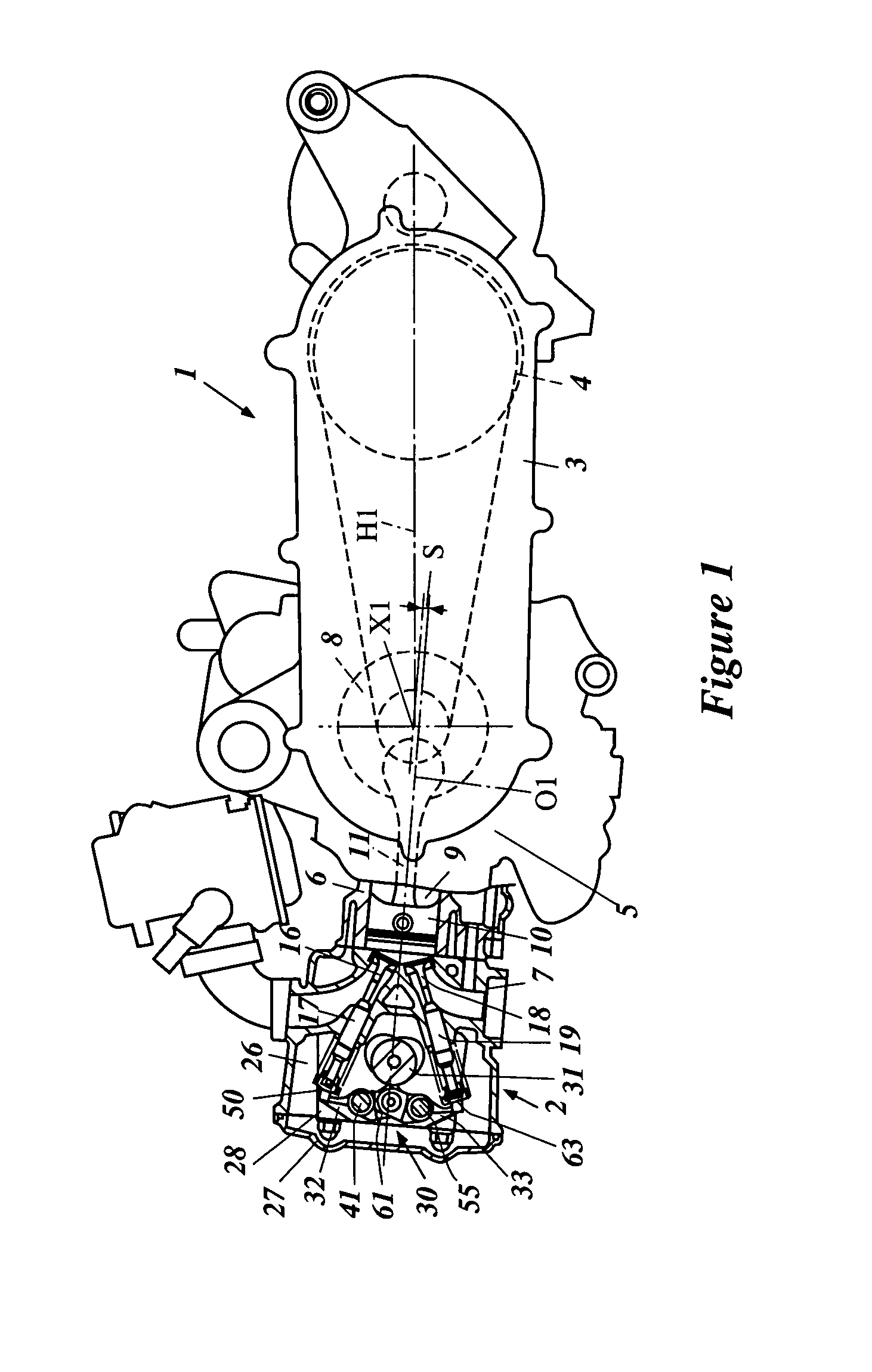

Valve drive system for four-stroke engine

ActiveUS20050061274A1Easy to adjust workConvenience to workValve arrangementsCam-followersFour-stroke engineEngineering

A valve drive system capable of reducing the friction resistance of rocker arms and facilitating replacement work of tappet-clearance adjusting shims. The valve drive system can comprise a rocker arm that is slidable between a first position at which the pushing portion engages the shim and a second position at which the pushing portion is disengaged from the shim, and held in the first position through a spring.

Owner:YAMAHA MOTOR CO LTD

Fluidproof connector

InactiveUS20110086544A1Good fluidGood waterproofnessSecuring/insulating coupling contact membersCouplings bases/casesEngineeringSliding contact

A retainer (40), a rubber plug (60) and a rubber plug pressing member (70) are mounted in a housing (10). The retainer (40) is movable between a partial locking position and a full locking position, and the rubber plug pressing member (70) is movable between an initial position and a pushed-in position. The rubber plug pressing member (70) is formed with arm portions (74) projecting therefrom. The retainer (40) is formed with unlock linking portions (46) for linking a movement of this retainer (40) from the full locking position to the partial locking position and a movement of the rubber plug pressing member (70) from the pushed-in position to the initial position with each other by coming into sliding contact with the arm portions (74).

Owner:SUMITOMO WIRING SYST LTD

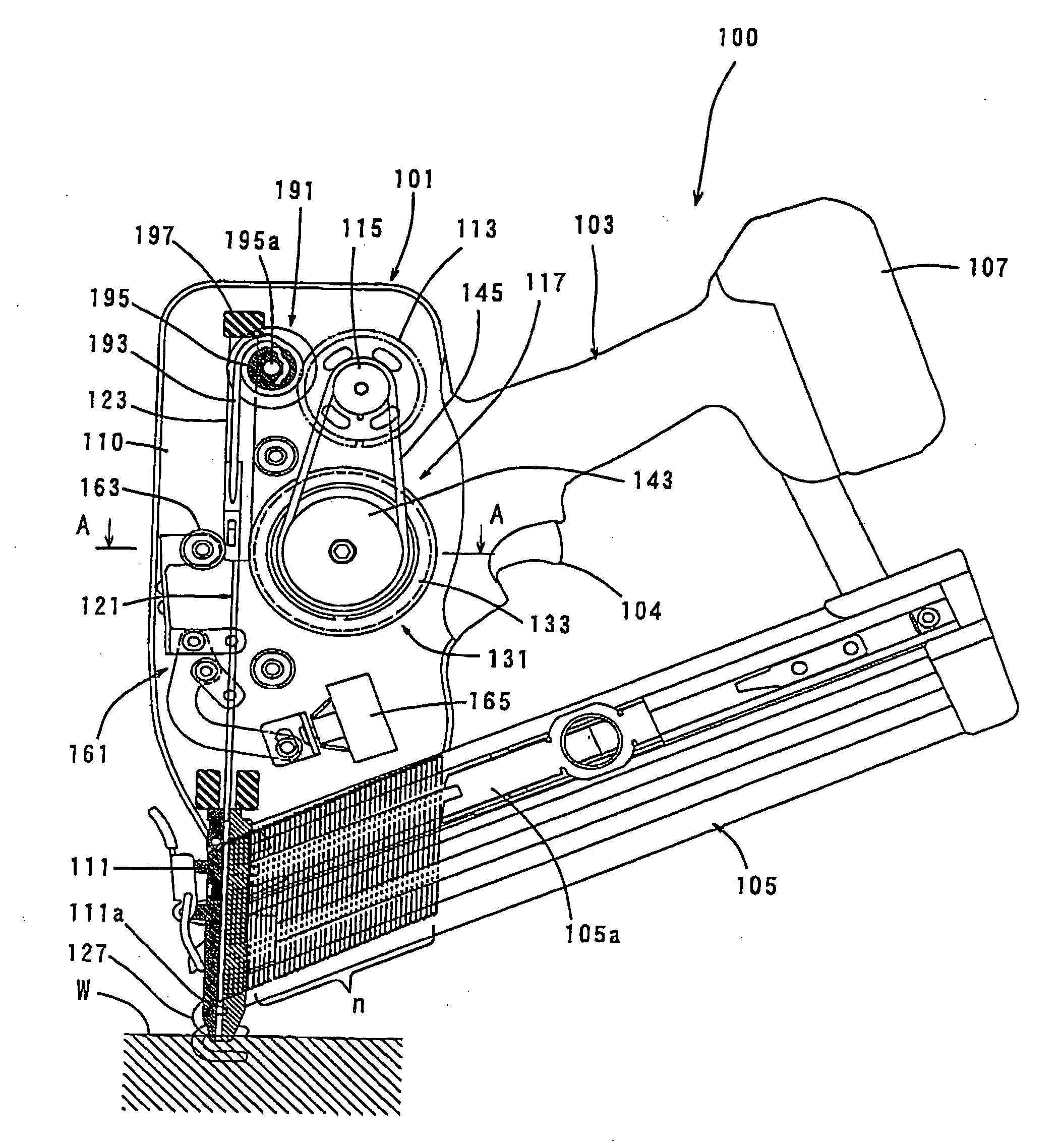

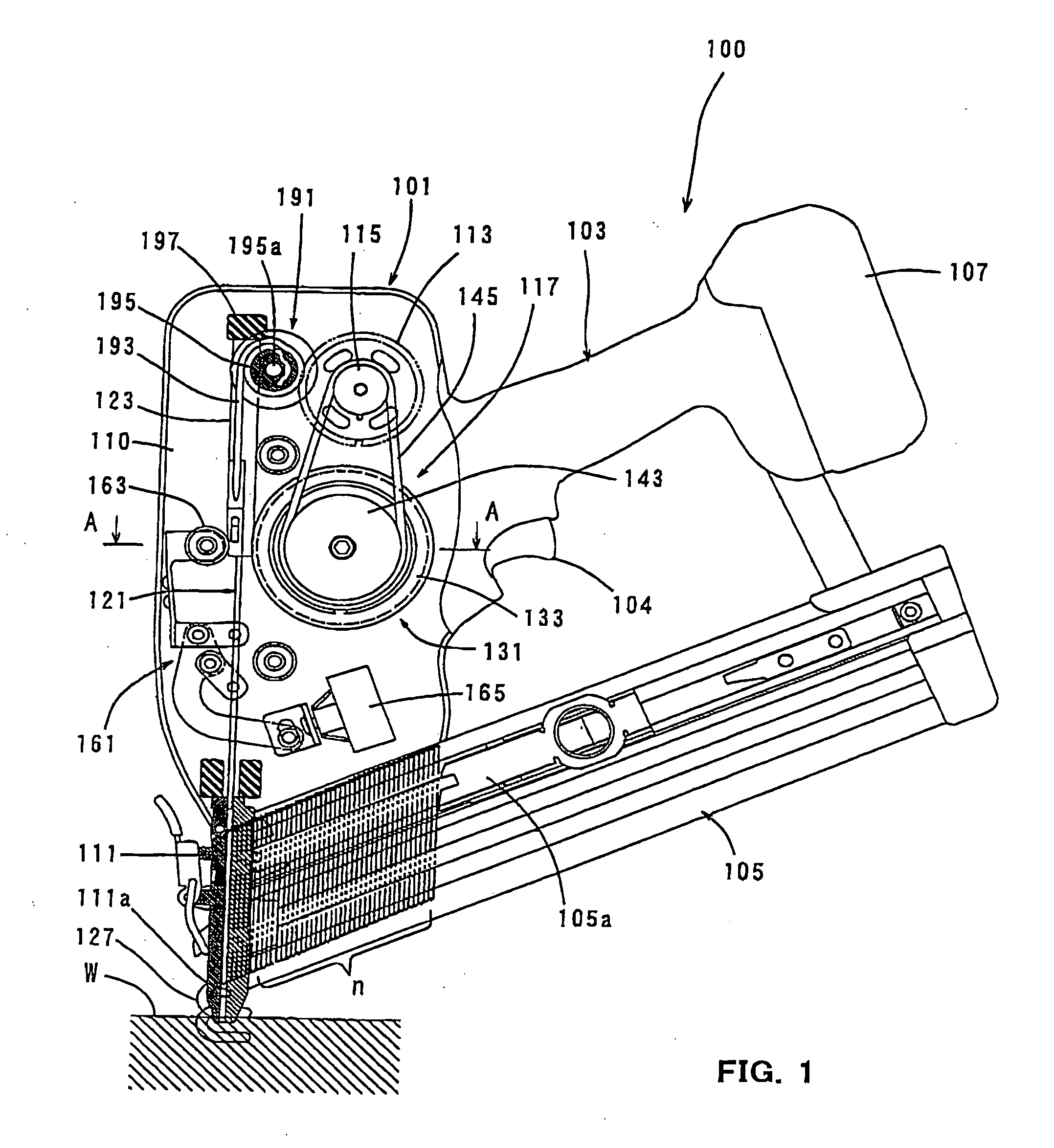

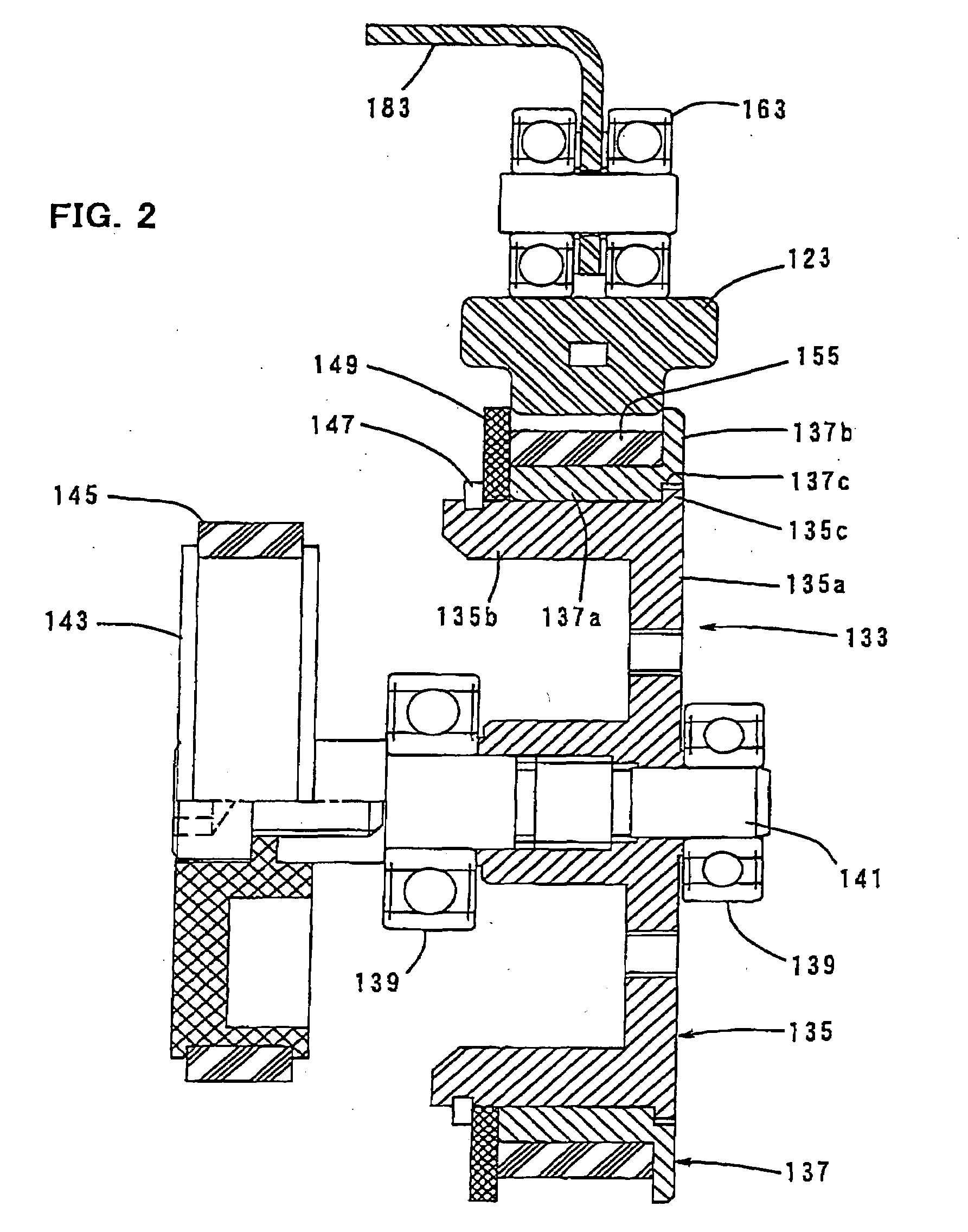

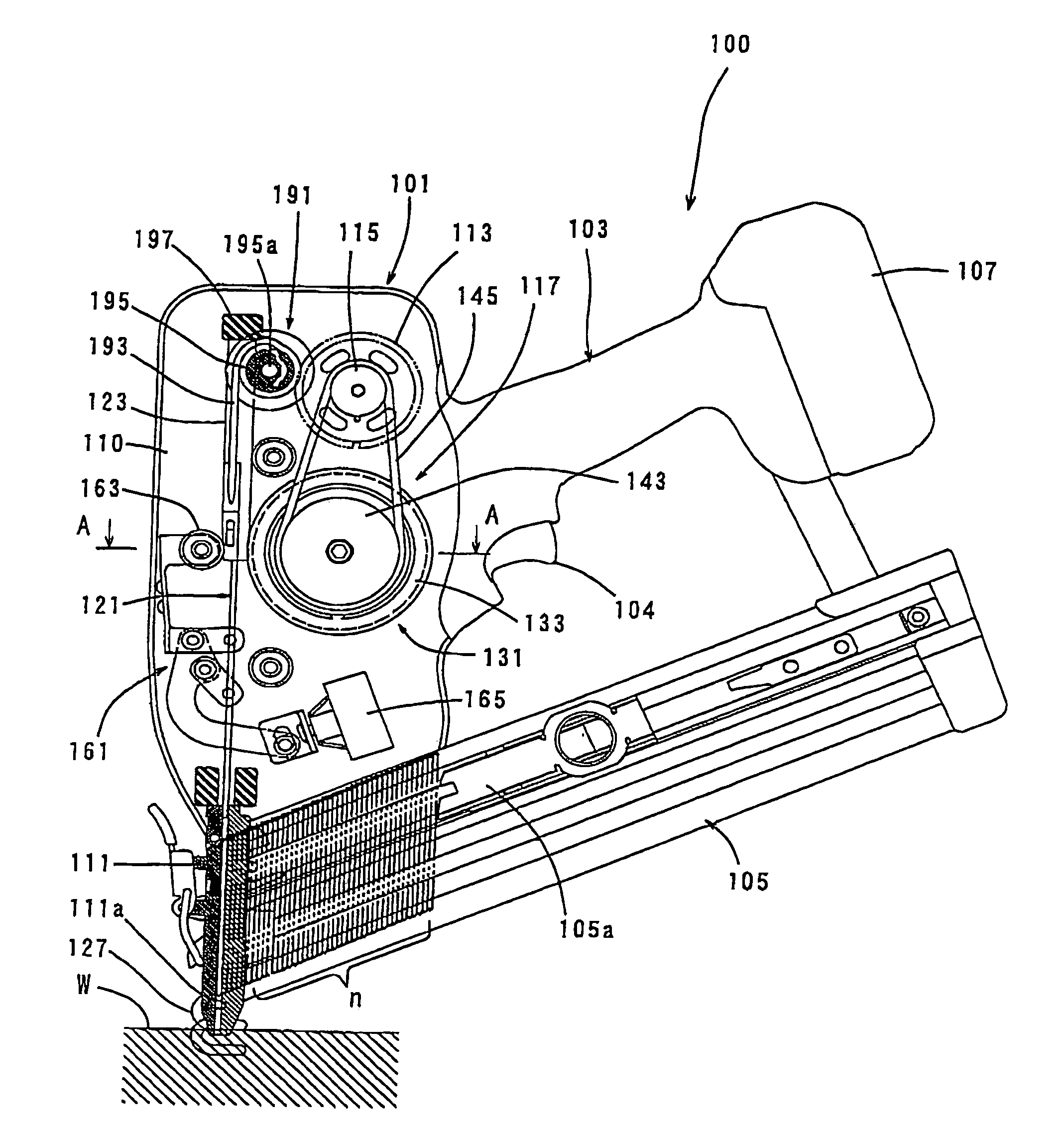

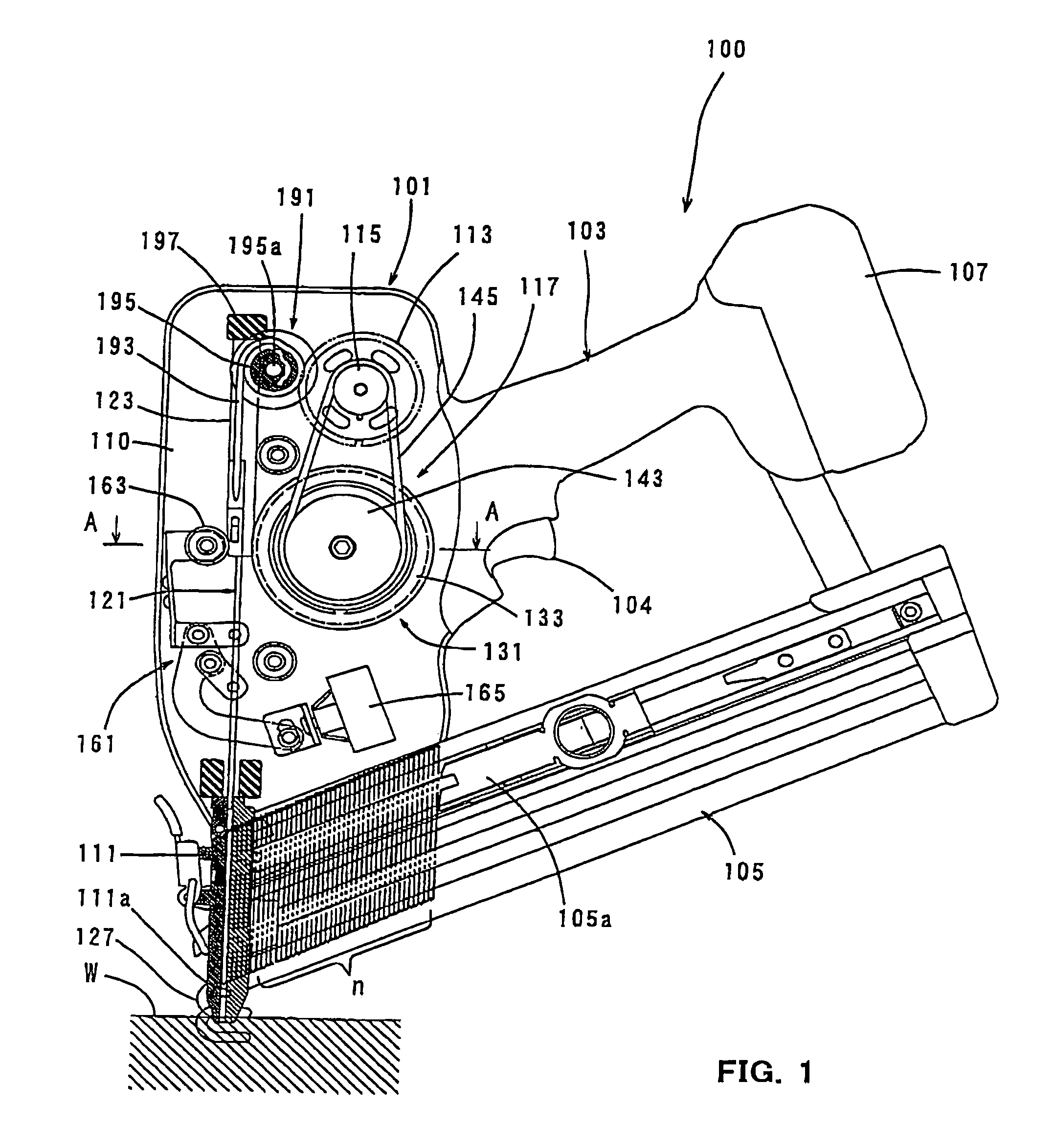

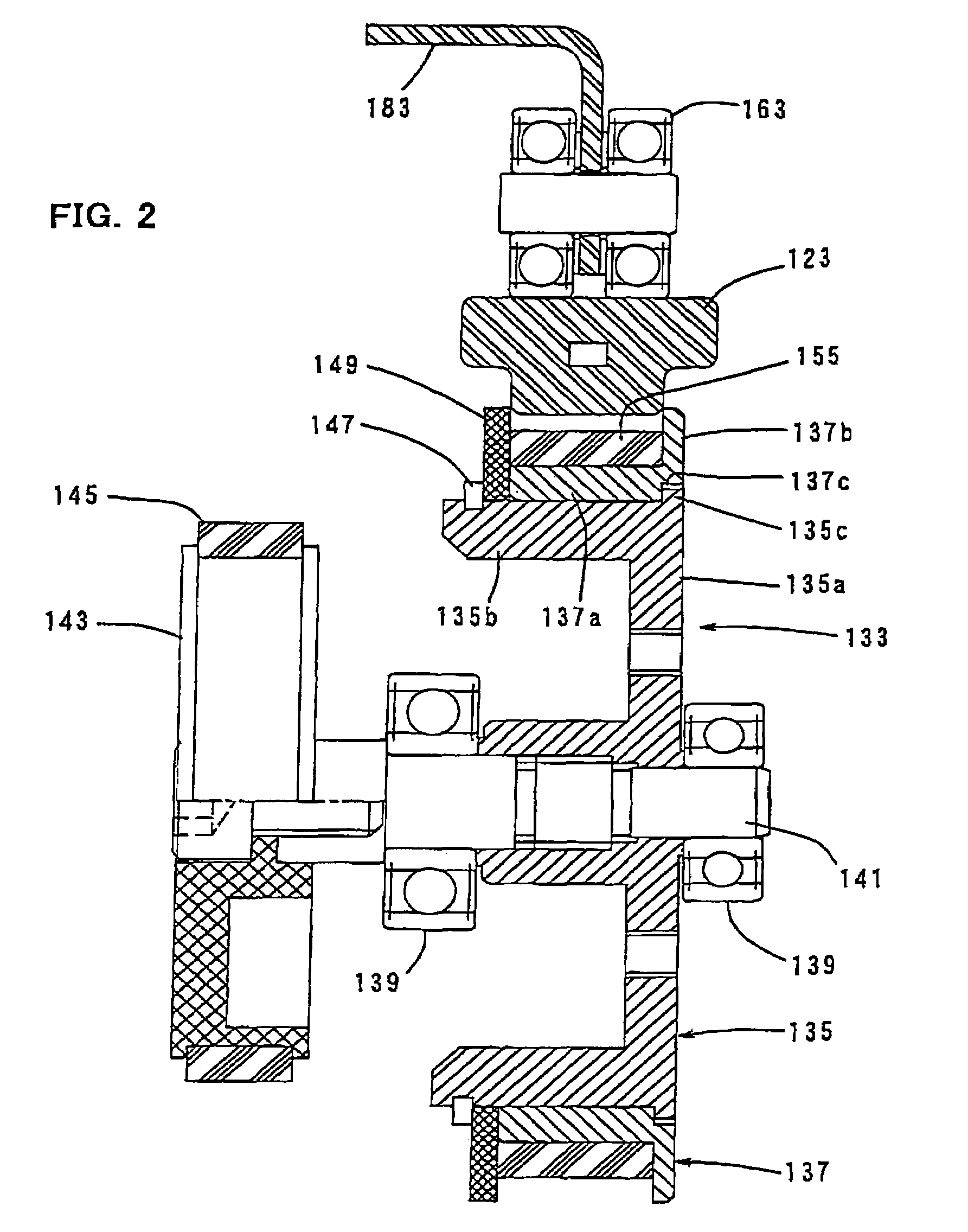

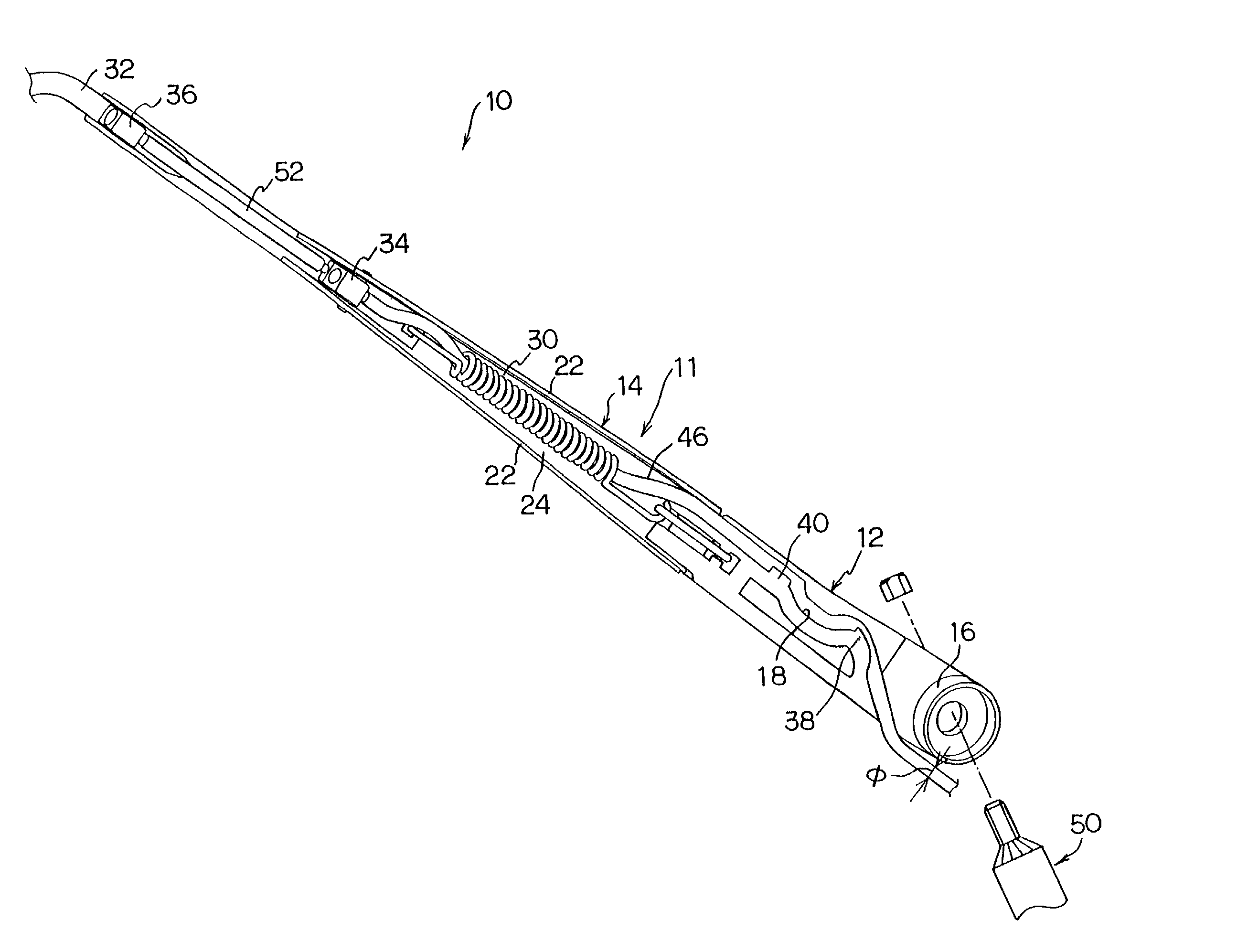

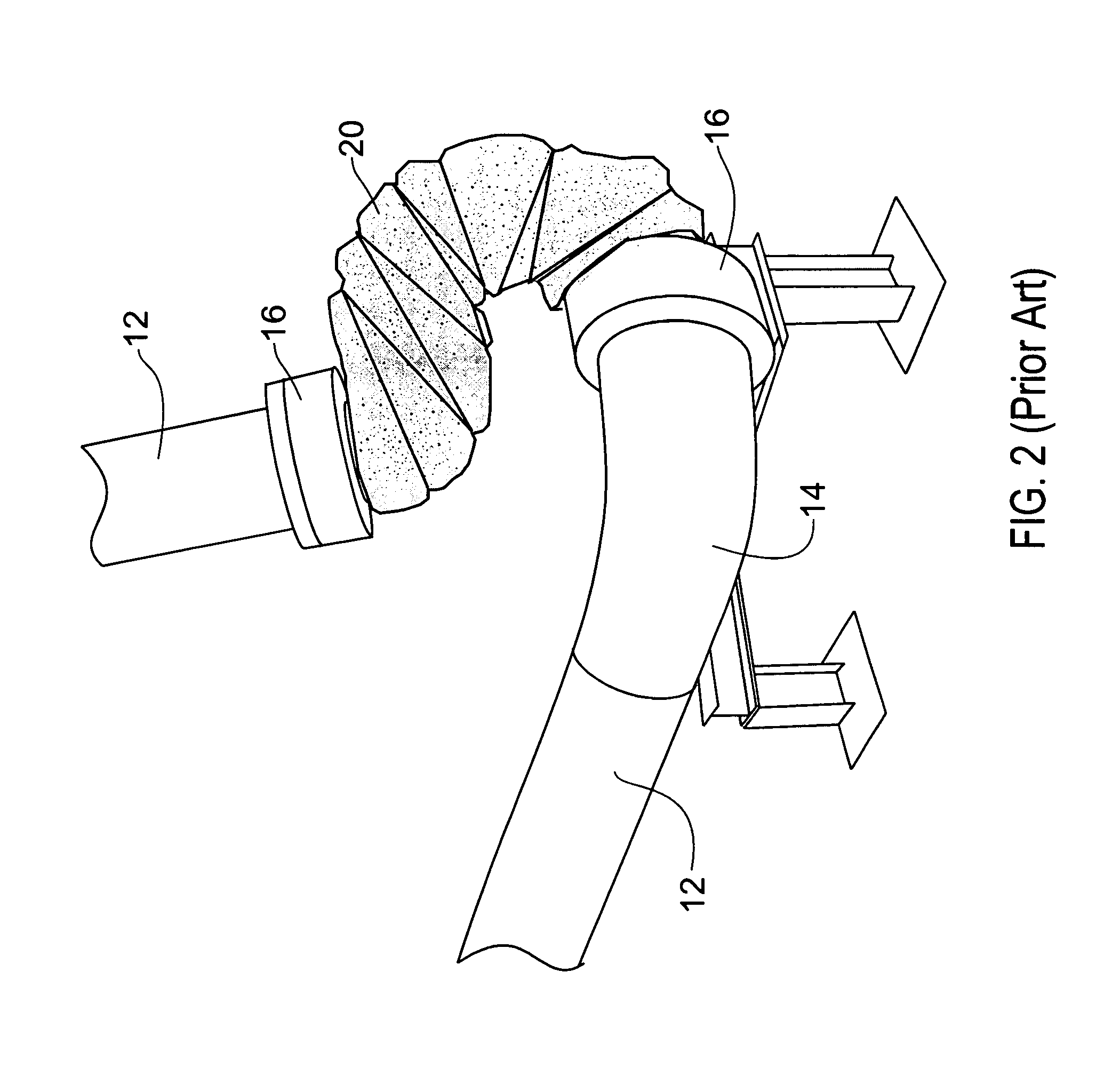

Driving tool

InactiveUS20080257933A1Increased durabilitySolve the small frictionStapling toolsNailing toolsFreewheelFlywheel

It is an object of the present invention to increase durability of a driving tool. A representative driving tool comprises an elongated operating member that drives in a driving material and a drive mechanism that drives the operating member. The drive mechanism comprises a rotating flywheel and the flywheel includes an inner wheel and an outer wheel which are concentrically disposed to each other. The inner circumferential surface of the outer wheel is fitted on an outer circumferential surface of the inner wheel. The outer circumferential surface of the outer wheel directly contacts the operating member and thus, the rotational force of the flywheel is transmitted from the inner wheel to the operating member via the outer wheel and the drive mechanism linearly moves. A frictional force between the outer circumferential surface of the inner wheel and the inner circumferential surface of the outer wheel is set to be smaller than a frictional force between the outer circumferential surface of the outer wheel and the operating member. With such construction, when the operating member contacts the rotating flywheel, slippage is caused between the inner wheel and the outer wheel such that only a smaller frictional force may be produced between the inner wheel and the outer wheel. Therefore, stress which acts upon the inner wheel and the outer wheel can be alleviated and as a result, wear of the flywheel and the operating member can be reduced to increase the durability.

Owner:MAKITA CORP

Driving tool having a two-part flywheel

InactiveUS7637408B2Increased durabilitySolve the small frictionStapling toolsNailing toolsFreewheelEngineering

Owner:MAKITA CORP

Windshield wiper device mounting washer nozzle and hose

InactiveUS20020133893A1Less timeManufacturing costSpray nozzlesWindow cleanersEngineeringDepth direction

An arm head of a windshield wiper device is provided on a backside thereof with an undulated groove formed by sidewalls. The sidewalls have plural hill portions protruding in opposite directions alternately in a width direction of the arm head so as to be opposed to one another in a longitudinal direction thereof. Tops of the hill portions on one width side of the arm head are integrally provided at upper surfaces thereof with projections extending perpendicularly to a depth direction of the groove to overhang the groove. A hose for delivering washer liquid to a washer nozzle is accommodated in the groove and firmly held by the hill portions and the projections without using an extra part such as a clip.

Owner:DENSO CORP +1

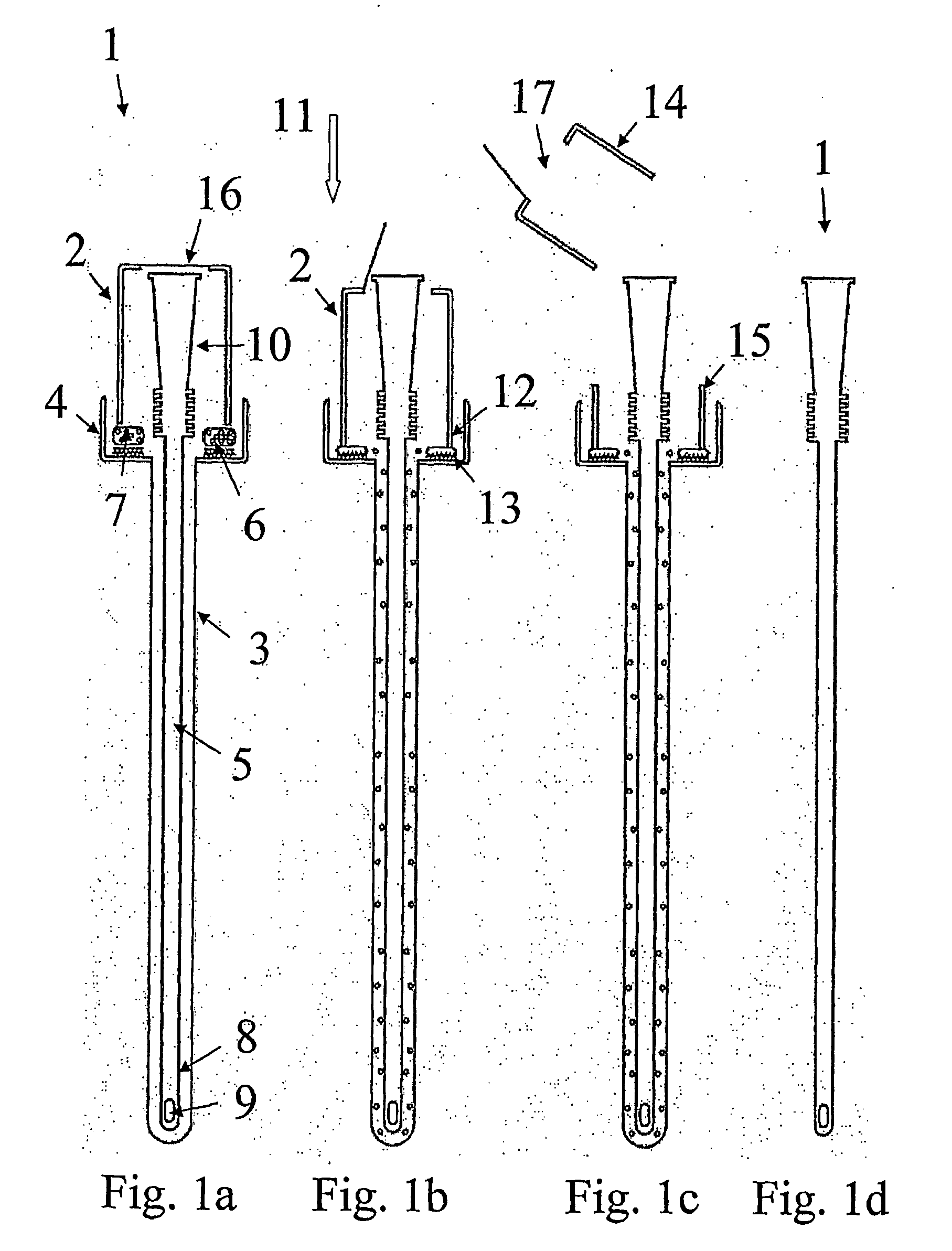

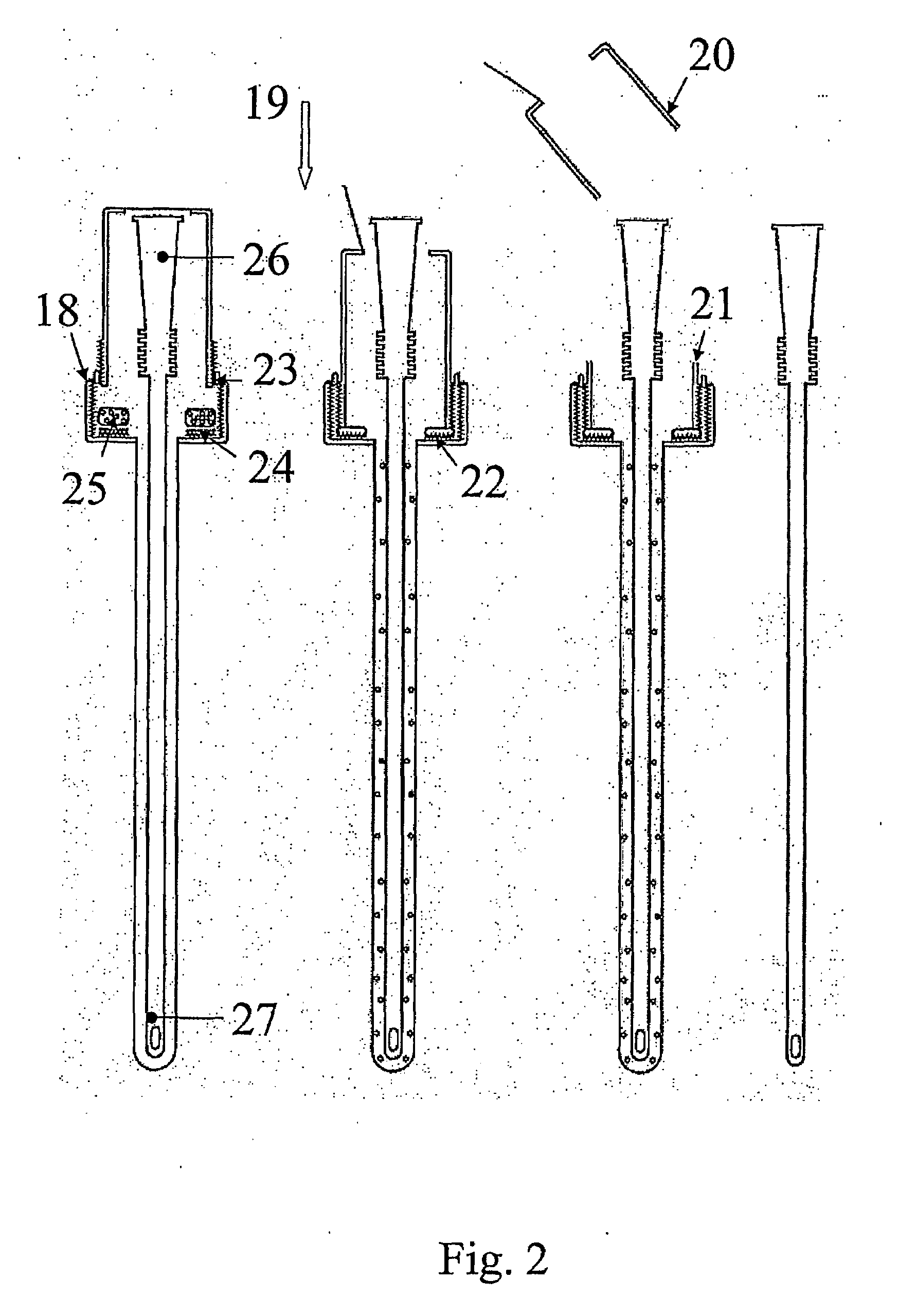

Package for a Medical Device

InactiveUS20080260576A1Promote wettingEasy to holdDispensing apparatusDiagnosticsUrinary catheterEngineering

The invention provides an assembly for preparing a medical device, in particular a urinary catheter, by releasing a fluid medium onto the device. The device is packed in a package which contains the fluid medium confined in a compartment. To ensure preparation of the device, the package is adapted to open the compartment and the package in one and the same opening action, preferably so that the compartment opens at the latest when the package opens. In that way, removal of the device from the package requires opening of the compartment and the device is therefore wetted automatically as part of the opening procedure.

Owner:COLOPLAST AS

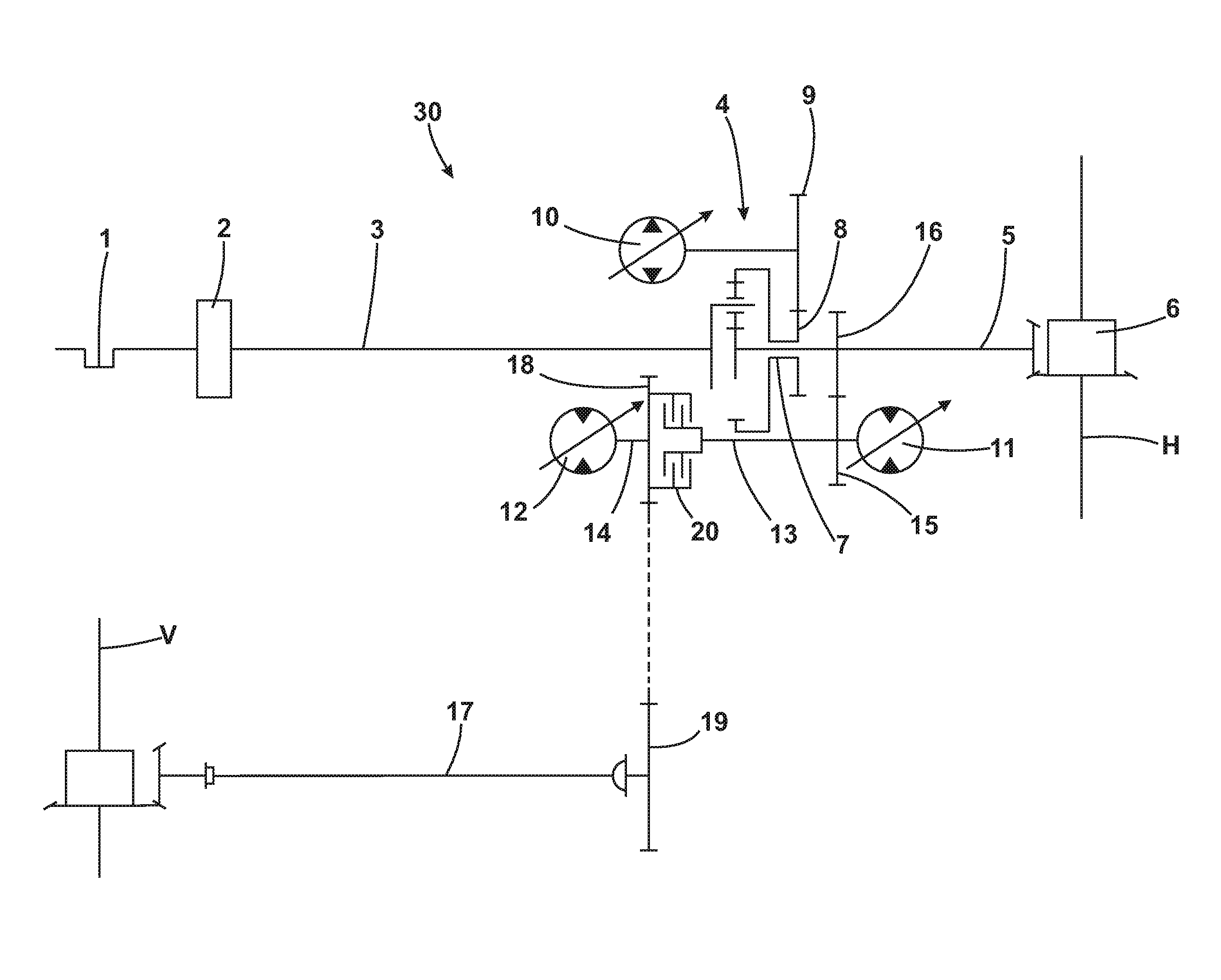

Drive Arrangement For Vehicles With At Least Two Drivable Vehicle Axles

ActiveUS20080280719A1Solve the small frictionSubstantial leakageGearing controlFluid gearingsAgricultural tractorElectric motor

Owner:AGCO GMBH

Heat trace or control cable support with insulating jackets

ActiveUS7485801B1Sufficient flexibilitySlight frictionThermal insulationInsulated cablesRubbingWrap around

A structure is provided that applies support to wiring such as heat trace wiring to the joints and elbows of a marine arm allowing enough flexibility to avoid significant friction in the wiring while accommodating movement of the joints. A removable insulation blanket having internal retention members of wire positioning is wrapped around the joints of the marine arm and the wiring is looped outside the insulation blanket and over the joints to prevent unnecessary friction rubbing of the wiring due to joint movement.

Owner:MARATHON PETROLEUM

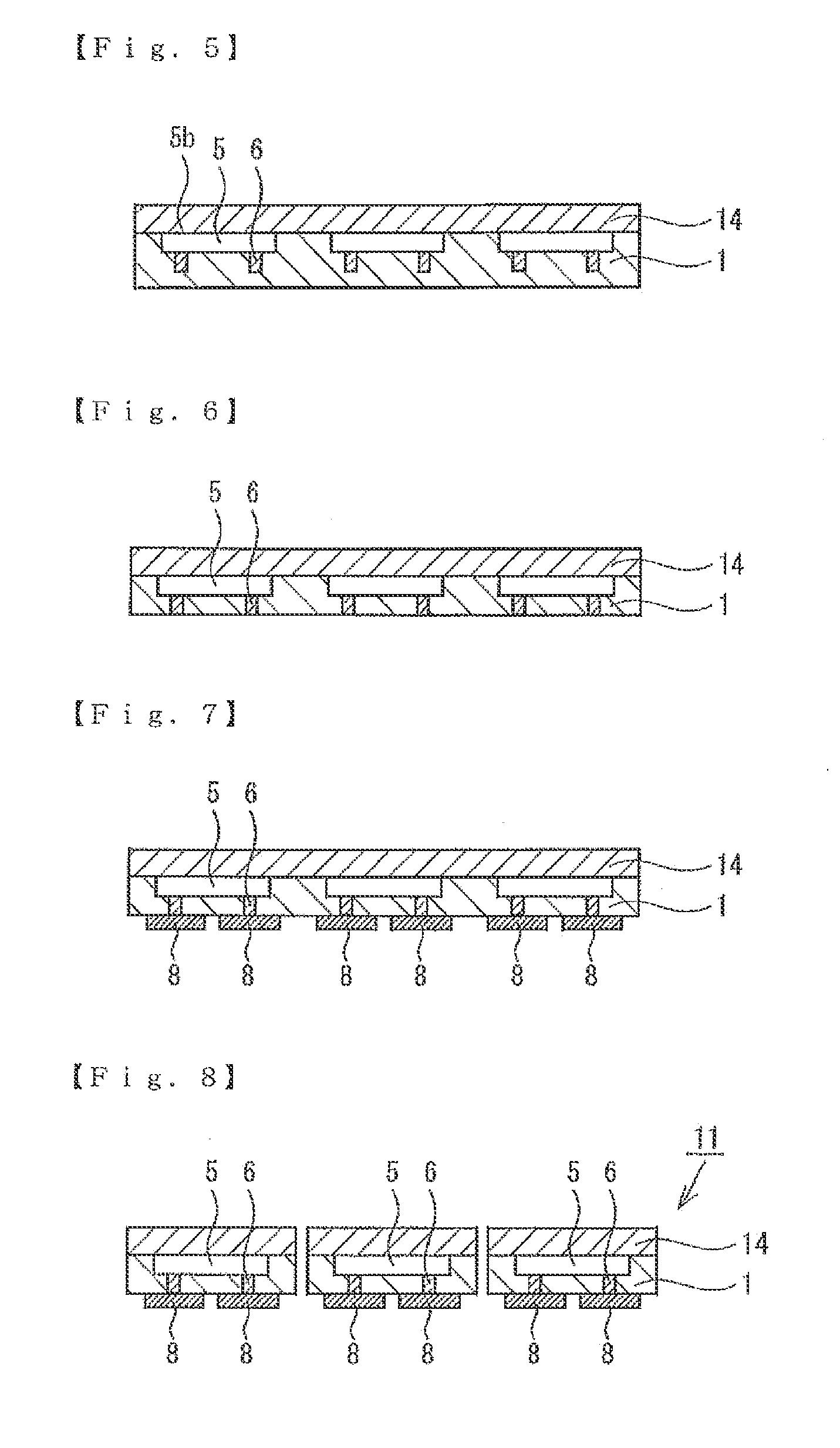

Method of manufacturing semiconductor device

InactiveUS20130157419A1Simple processLow production costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The objective of the present invention is to provide a method of manufacturing a semiconductor device having less contamination of a semiconductor chip and good productivity. The present invention is a method of manufacturing a semiconductor device having a semiconductor chip, with the steps of preparing a plurality of semiconductor chips, preparing a resin sheet having a thermosetting resin layer, arranging the plurality of semiconductor chips on the thermosetting resin layer, arranging a cover film on the plurality of semiconductor chips, and embedding the plurality of semiconductor chips in the thermosetting resin layer by a pressure applied through the arranged cover film, in which the contact angle of the cover film to water is 90° or less.

Owner:NITTO DENKO CORP

Portable timepiece

ActiveUS20050141347A1Large frictional resistanceIncrease resistanceVisual indicationClockwork casesEngineeringCover glass

To provide a portable timepiece capable of suppressing a bezel from carelessly rotating and deviating, without impairing a rotation operability of the bezel. An annular bezel is rotatably disposed around an annular protrusion part of a case band to whose inner periphery there is attached a cover glass. A gasket made of an elastic material, which makes the bezel stationary to a desirable rotated position with respect to the case band, is interposed between the bezel and the case band under a state giving a frictional force to these. A holding mechanism, which holds the bezel to a stationary state with respect to the case band and can release this holding state, is provided separately from the gasket. By this, a rotation operability of the bezel is made light by restricting the rotation of the bezel by means of the holding mechanism to thereby suppress a careless rotation of the bezel and thus by the fact that the gasket is caused not to bear a function suppressing the rotation of the bezel.

Owner:SEIKO INSTR INC

Frictional resistance generation mechanism

InactiveUS20040248655A1Solve the small frictionHigh hysteresis torqueYielding couplingFlywheelsEngineeringFrictional resistance

Owner:EXEDY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com