Early transition metal high-entropy alloy for biomedicine application

A technology of transition group metals and high-entropy alloys, applied in the field of high-entropy alloys, can solve the problems of poor wear resistance of stainless steel and titanium alloys, and achieve the effect of good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Ti by Vacuum Non-consumable Arc Melting 25 Zr 25 Nb 25 Ta 25 Alloy ingot (nominal composition is atomic percentage, the same below)

[0030] Using commercially available pure metal Ti, Zr, Nb, Ta element rods, blocks and other bulk materials (purity higher than 99.5%, mass percentage) as starting materials, arc smelted into quaternary elements in an argon atmosphere purified by titanium Master alloy ingot. The alloy ingot needs to be smelted several times to ensure the uniformity of the composition.

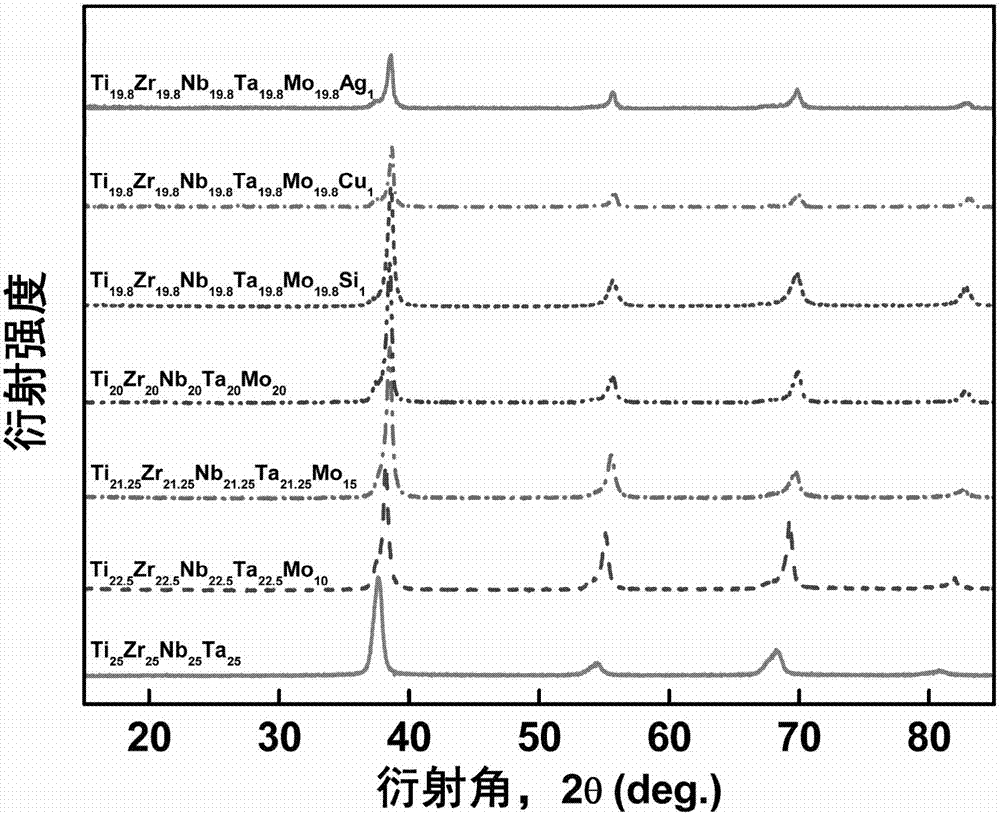

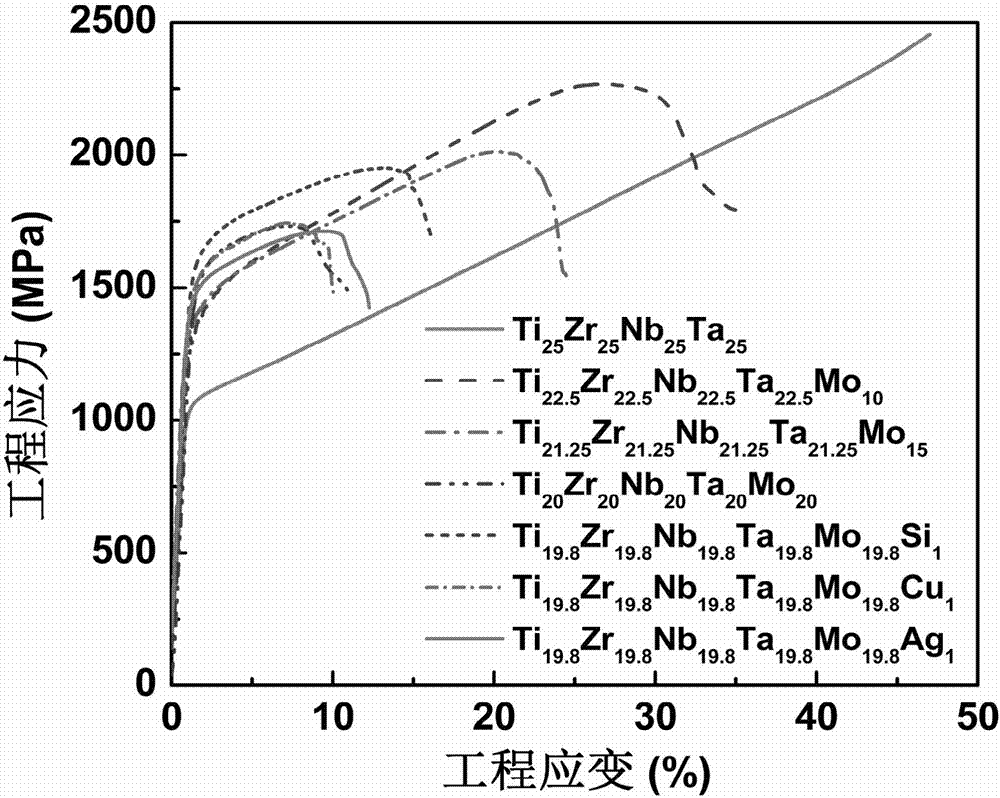

[0031] A block sample of 5mm×5mm×1mm is cut from the alloy ingot and used for X-ray diffraction (XRD) analysis after mechanical grinding. It is a single-phase bcc structure. The diffraction spectrum is as figure 1 . A block sample of 8mm×8mm×2mm was cut from the alloy ingot, and subjected to strict mechanical grinding and polishing after hot mounting. The Vickers hardness was measured on a Vickers microhardness tester at room temperature. The results are shown i...

Embodiment 2

[0033] Preparation of Ti by Non-consumable Vacuum Arc Melting 22.5 Zr 22.5 Nb 22.5 Ta 22.5 Mo 10 Alloy ingot

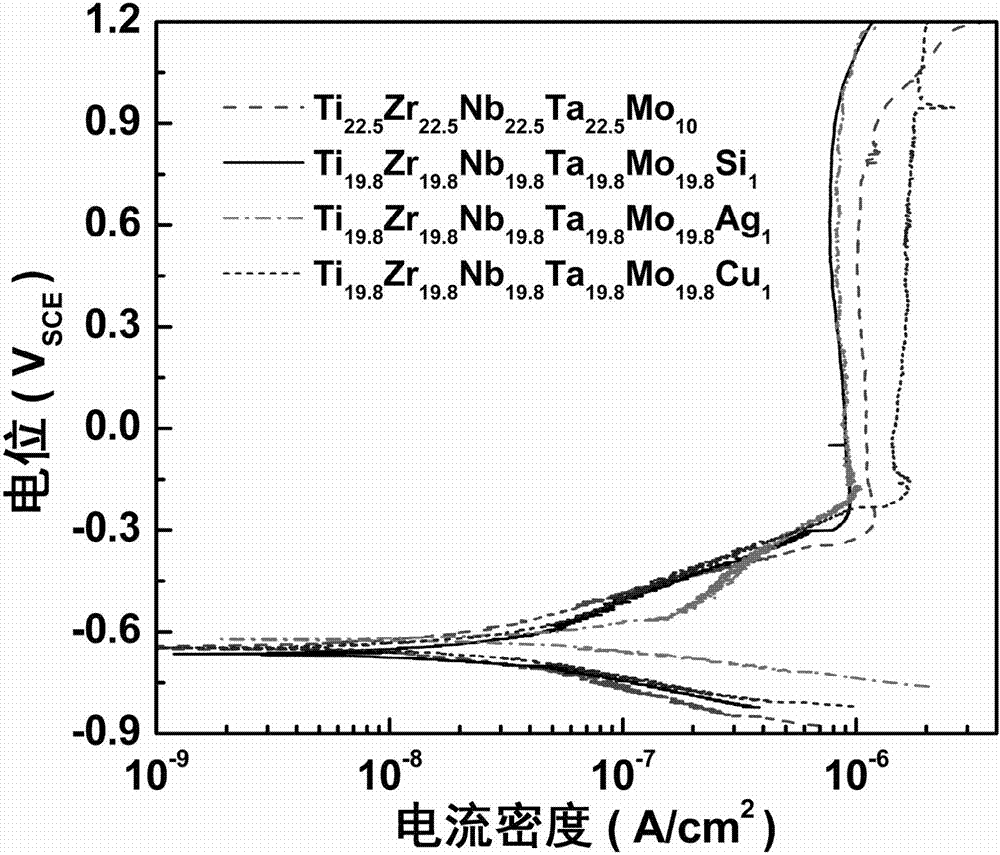

[0034] Using commercially available pure metal bars and blocks of Ti, Zr, Nb, Ta, Mo, and other bulk materials (purity higher than 99.5%, mass percentage) as starting materials, arc smelted in an argon atmosphere purified by titanium Five yuan master alloy ingot. The alloy ingot needs to be smelted several times to ensure the uniformity of the composition. The crystal structure, hardness, compressibility and electrochemical behavior of the alloy were measured using the same method as in Example 1. The composition alloy has a two-phase bcc structure, and no pitting corrosion occurs in the PBS solution. See the corresponding measurement results figure 1 , 2 , 3 and Tables 1, 2.

Embodiment 3

[0036] Preparation of Ti by Non-consumable Vacuum Arc Melting 21.25 Zr 21.25 Nb 21.25 Ta 21.25 Mo 15 Alloy ingot

[0037] Using commercially available pure metal bars and blocks of Ti, Zr, Nb, Ta, Mo, and other bulk materials (purity higher than 99.5%, mass percentage) as starting materials, arc smelted in an argon atmosphere purified by titanium Five yuan master alloy ingot. The alloy ingot needs to be smelted several times to ensure the uniformity of the composition. The crystal structure, hardness, compressibility and electrochemical behavior of the alloy were measured using the same method as in Example 1. The composition alloy has a two-phase bcc structure, and no pitting corrosion occurs in the PBS solution. See the corresponding measurement results figure 1 , 2 , 3 and Tables 1, 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com