Tool and production method for producing variable cross-section type I-shaped composite part

A technology of composite materials and manufacturing methods, which is applied in the field of tooling and manufacturing for manufacturing variable cross-section I-shaped composite material parts, and can solve the problems of inability to successfully complete molding manufacturing, surface and internal defects of parts, and pressure transmission in the web area The effect is not good and other problems, to achieve the effect of avoiding tooling deformation and scrapping, good overall performance, and reducing the difficulty of tooling combination and demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of tooling for manufacturing variable-section I-shaped composite material parts

[0036] A tooling for manufacturing variable-section I-shaped composite material parts: it is composed of an upper male mold (100), a lower male mold (200) and a partition (300).

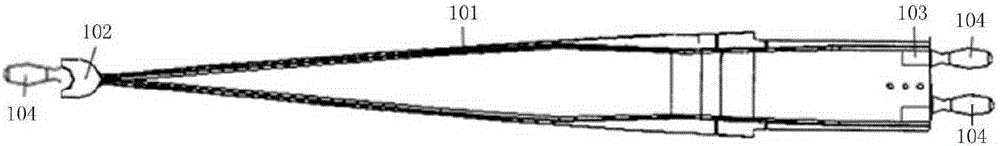

[0037] Such as image 3 As shown, the upper male mold (100) is an upper male mold main body of an integral structure composed of a main body part I (101), a positioning part I (102), a positioning part II (103) and a handle part (104).

[0038] Such as Figure 4 As shown, the lower male mold (200) is the main body of the lower male mold with an integral structure composed of the main body part II (201), the positioning part III (202), the positioning part IV (203) and the positioning pin (204) of the composite material equalizing plate, The main body of the lower male die is installed on the base plate (206), and the four corners of the lower male die (200) are provided with suspension rings...

Embodiment 2

[0041] Embodiment 2 A manufacturing method of a variable-section I-shaped composite material product

[0042] prepared as figure 1 and figure 2 The variable-section I-shaped composite material part shown is the I-shaped reinforcing rib in the rudder of a certain model, and the tooling of Embodiment 1 is adopted, and the steps are as follows:

[0043] 1) Making a composite equal pressure plate

[0044] The pressure equalizing plate is as follows: a carbon fiber layer is laid on a metal plate, and a rubber layer is pasted on the carbon fiber layer.

[0045] The steps to make a composite material uniform pressure plate are: laying carbon fiber prepreg on a metal plate, and using heating equipment to thermally compact the layup; after laying up, use a raw rubber belt of the same thickness for edge sealing around the blank to prevent The resin in the prepreg is excessively lost; put the blank into a vacuum bag, send it into an autoclave, and cure it at 120-180°C and 0.3-0.6MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com