Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Superconducting cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing single crystal grain niobium material for radio frequency superconducting cavity

InactiveCN102400216AImprove superconductivityImprove performancePolycrystalline material growthAcceleratorsNiobiumSingle crystal

The invention discloses a method for manufacturing a single crystal grain niobium material for a radio frequency superconducting cavity. The method comprises the following steps of: refining and purifying high-melting metallic niobium serving as a raw material to prepare niobium ingots, the crystal grain size of which is over phi 100 millimeters and the residual resistance ratio (RRR) value of which is over 300; and cutting single crystal grains, rolling in a rolling compaction manner, and preparing single crystal niobium plates or sheets by thermal treatment, wherein refining and purifying are performed on the high-melting metallic niobium for many times by adopting vacuum electron beams to produce the ingots with the crystal grain size of over phi 250 millimeters, the diameter of the biggest crystal grains is 100 to 140 millimeters, and the RRR value of the ingots is over 300.

Owner:NINGXIA ORIENT TANTALUM IND

Superconducting accelerator, superconducting cavity for same and manufacturing method of superconducting accelerator

InactiveCN103179775AIncrease heat dissipation surface AkiQuench suppressionAcceleratorsCooling/ventilation/heating modificationsSuperconducting acceleratorSuperconducting cavity

The invention relates to a superconducting accelerator, a superconducting cavity for the same and a manufacturing method of the superconducting accelerator. A heat radiation structure is arranged on the outer surface of the superconducting cavity. The manufacturing method of the superconducting cavity includes steps that the outer surface of the superconducting cavity is grooved or drilled so as to form the heat radiation structure or welding heat radiation structure on the outer surface of the superconducting cavity. Quenching of the superconducting cavity can be effectively suppressed.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

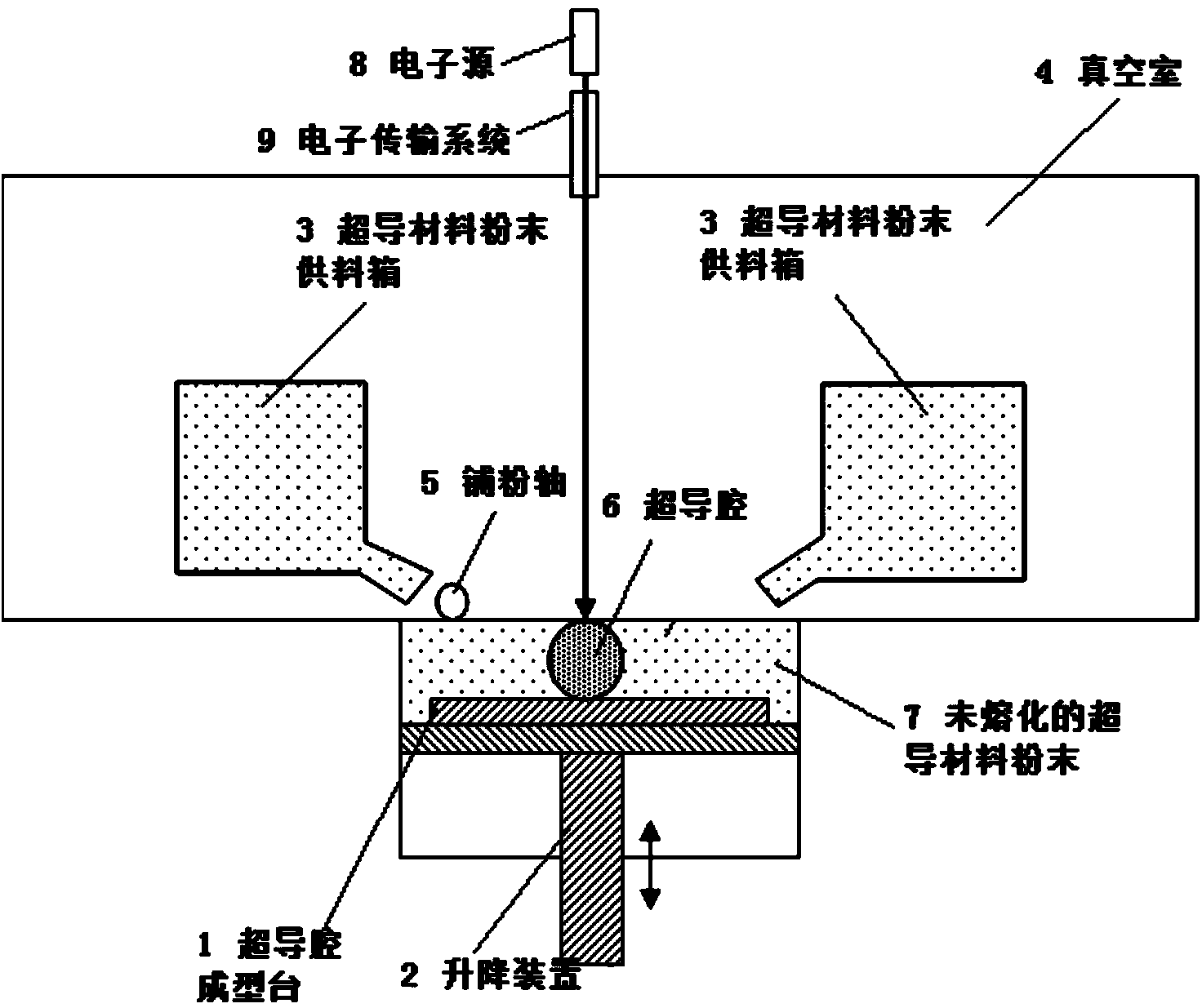

Method for manufacturing superconducting cavity

The invention mainly relates to manufacturing of a radio frequency superconducting accelerating cavity. A method for manufacturing a superconducting cavity includes the steps that CAD software is utilized to generate a superconducting cavity model, and layering software is utilized to conduct layering on the superconducting cavity model; a vacuum system is utilized to provide a vacuum environment for a forming chamber; a forming table of the forming chamber is paved with superconducting material powder; according to description of a software model of a superconducting cavity slice layer, electron beam energy is 'printed' on a powder layer, and a superconducting material slice layer entity is generated and becomes a part of the superconducting cavity; a next slice layer continues to be machined on the first slice layer entity until the whole machining process of the superconducting cavity is finished. According to the method, the development cycle of the superconducting cavity is shortened; no welding joint exists in the whole superconducting cavity, and the development yield of the superconducting cavity is increased; purity of superconducting materials can be guaranteed; the superconducting cavity is not limited by stamping forming conditions, and the performance of the superconducting cavity can be improved; in the manufacturing process, the redundant superconducting material powder can be reutilized, and therefore production cost is lowered.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

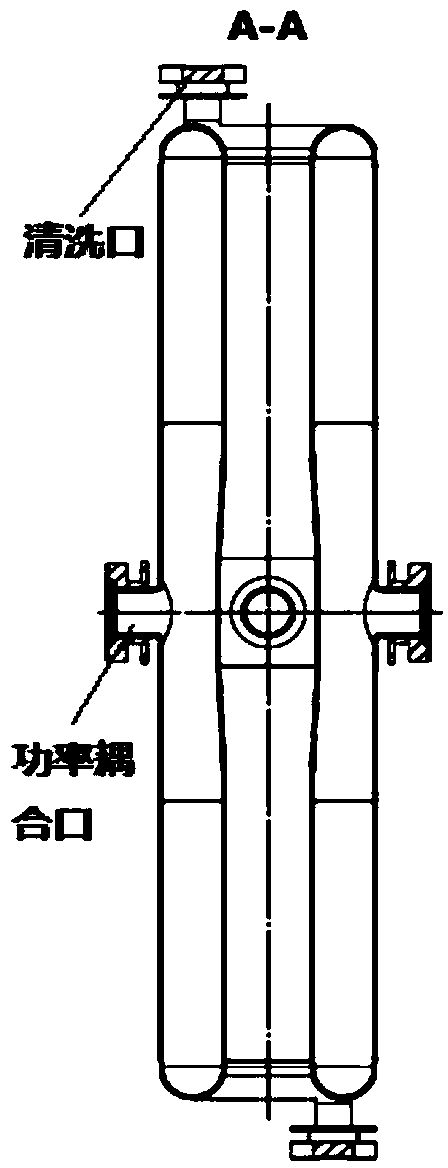

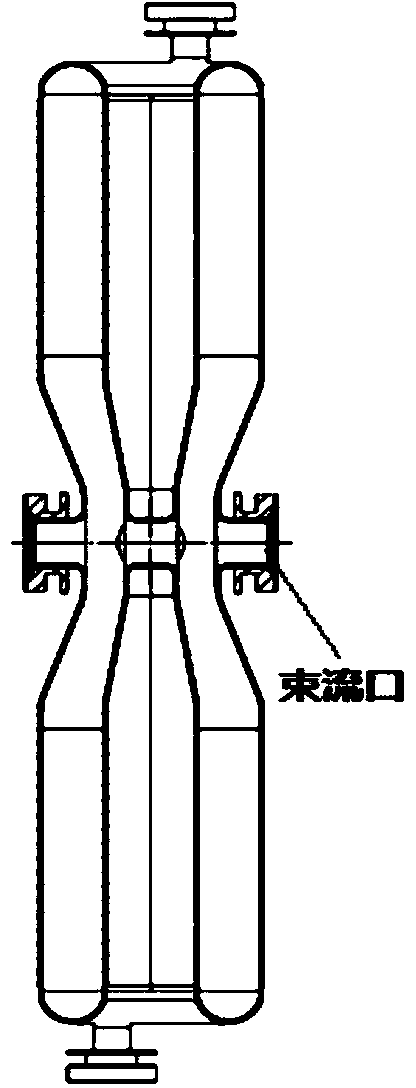

Radio frequency superconducting cavity with slit waveguide structure for superconducting accelerator

InactiveCN101707850ARaise the ratioAttenuated Diode ModeAcceleratorsSlot-waveguideHigh volume manufacturing

Owner:PEKING UNIV

Explosive welding manufacturing method of high-purity niobium-oxygen-free copper composite plate

InactiveCN109604806AGuaranteed SuperconductivityReduce oxygen contentNon-electric welding apparatusNiobiumMechanical stability

The invention discloses an explosive welding manufacturing method of a high-purity niobium-oxygen-free copper composite plate. The method comprises the following steps that a high-purity niobium plateserves as a composite plate, an oxygen-free copper plate is used as a substrate, and high-purity niobium is manufactured in an explosive welding mode; and the quality purity of the high-purity niobium plate is not less than 99%, the thickness of the high-purity niobium plate is not larger than 2 mm, the oxygen content in the oxygen-free copper plate is less than 2 ppm, and the thickness of the oxygen-free copper plate is larger than 10 mm. According to the method, the composite surface of the high-purity niobium plate and the oxygen-free copper plate are subjected to high-speed collision through explosion welding to form a solid-phase metallurgical bonding to be combined, the defect that the oxidation of the high-purity niobium plate and oxygen absorption of the oxygen-free copper plate in the heating rolling process are avoided, the problem that the high-purity plates with relatively large elongation rates are difficult to cold rolling and rolling is solved, and the excellent superconducting performance of the high-purity niobium material is kept, and meanwhile, the thickness of a superconducting cavity is increased by the oxygen-free copper plate, and thus the mechanical stability of the superconducting cavity is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

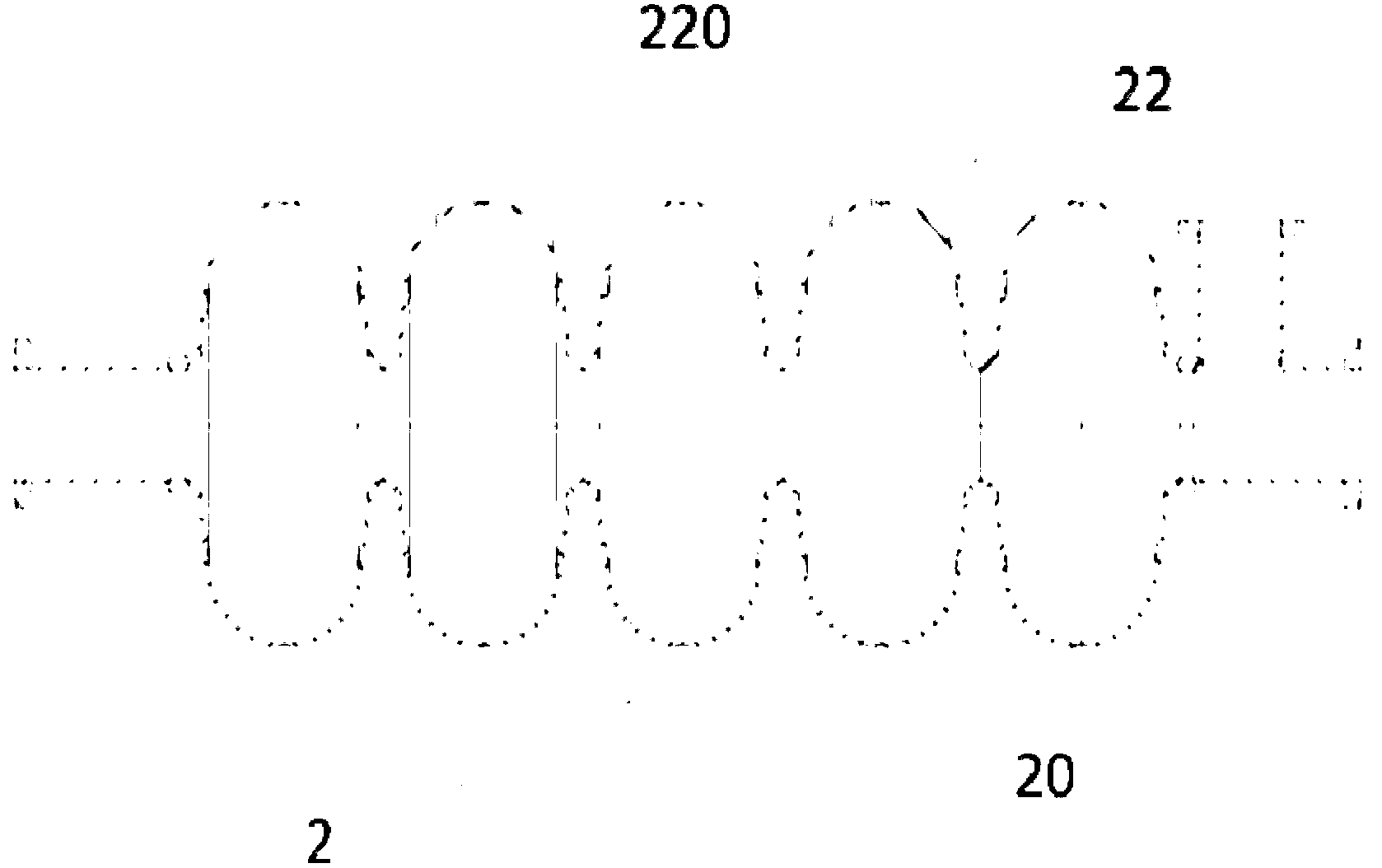

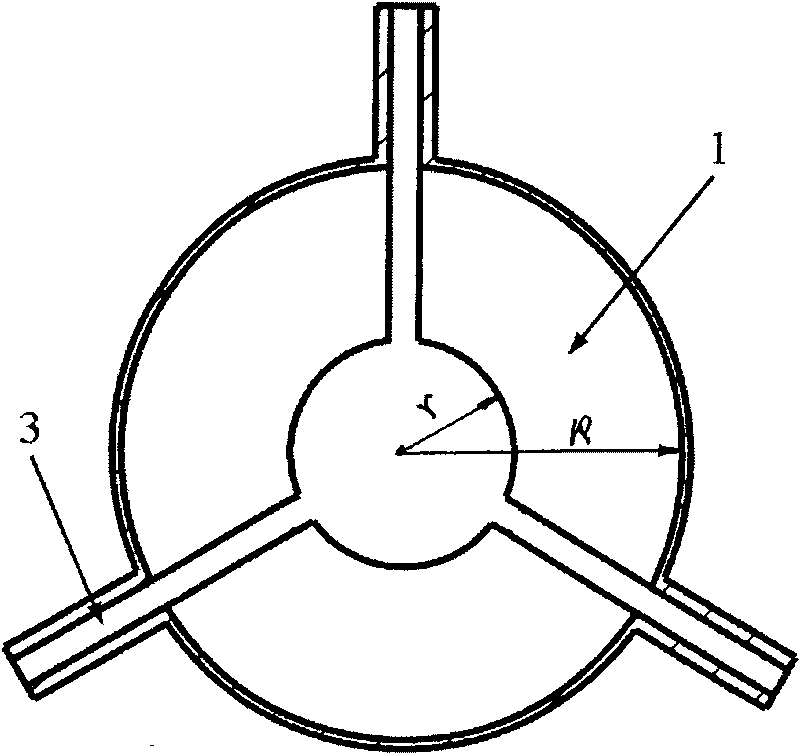

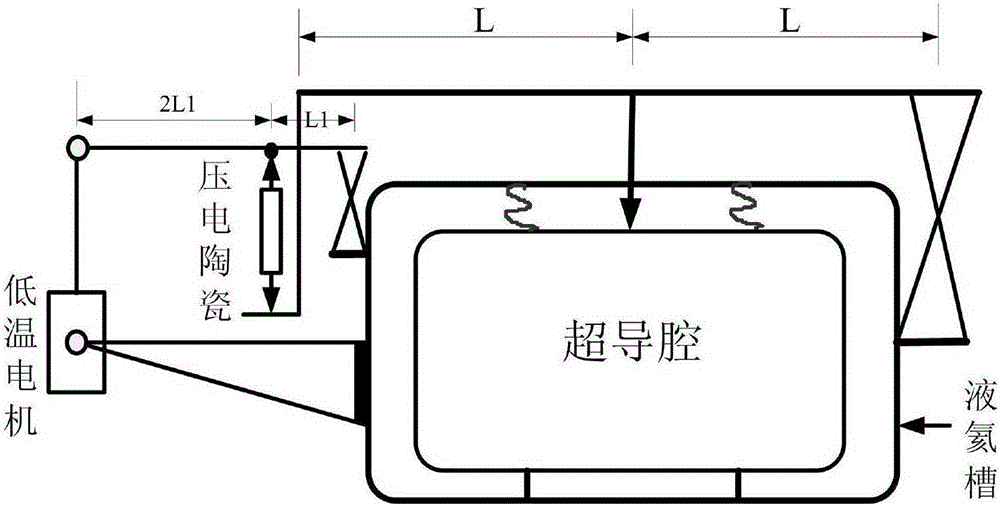

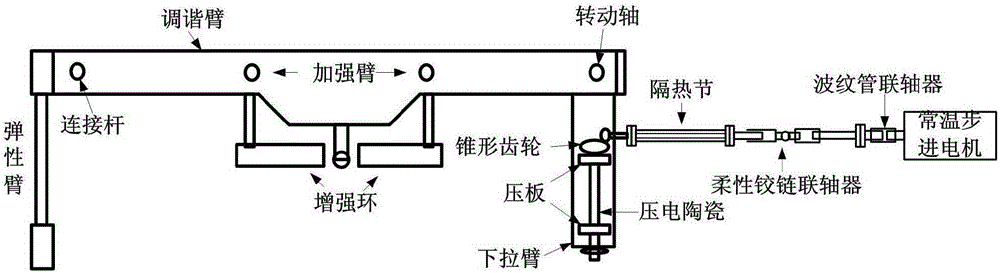

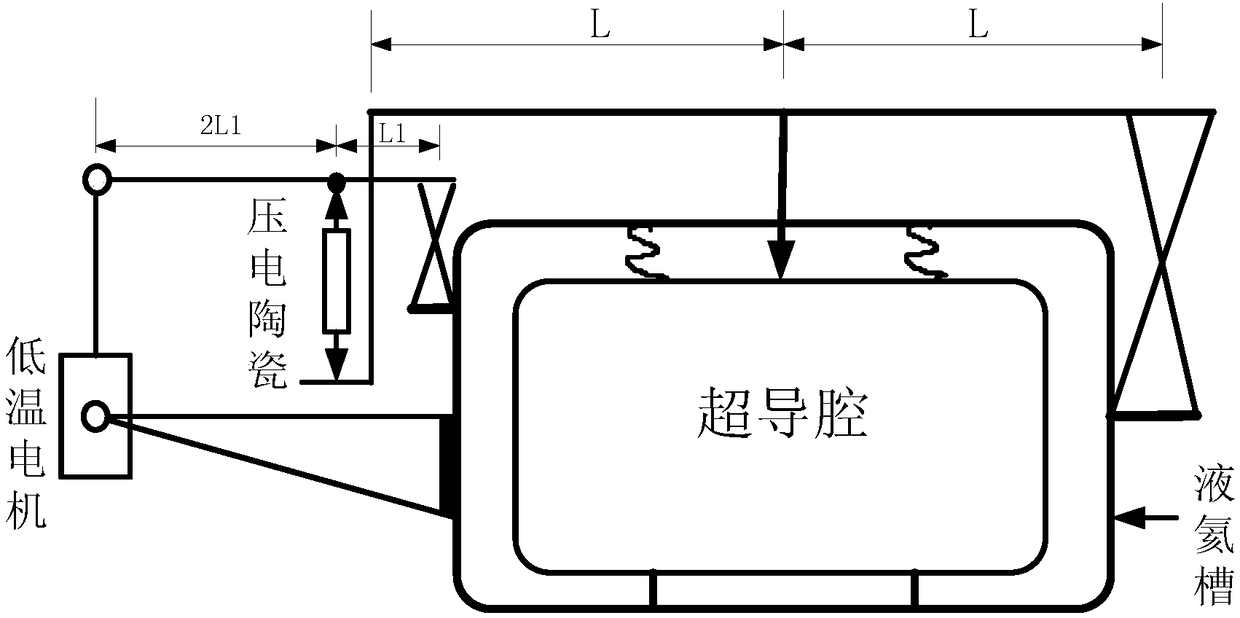

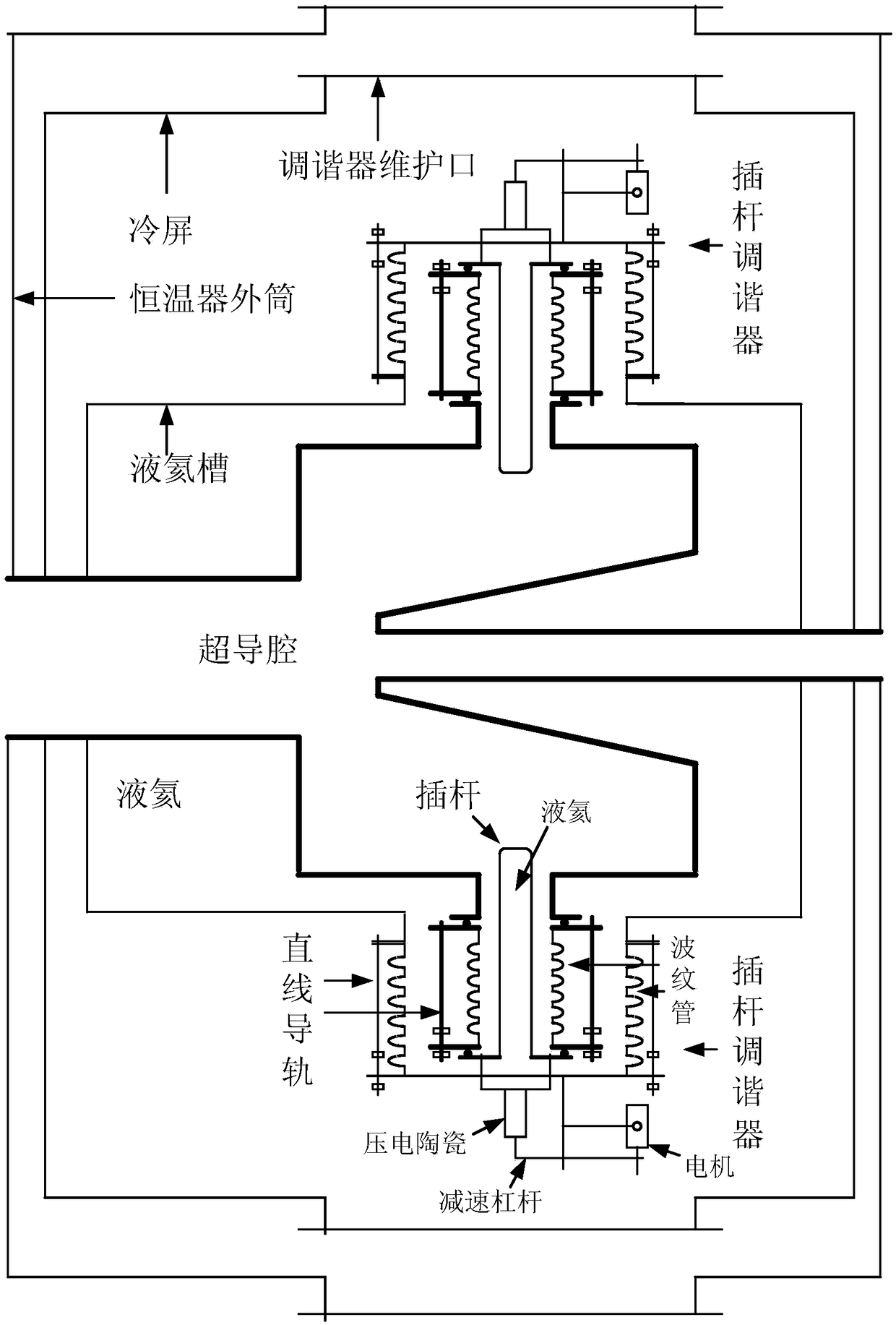

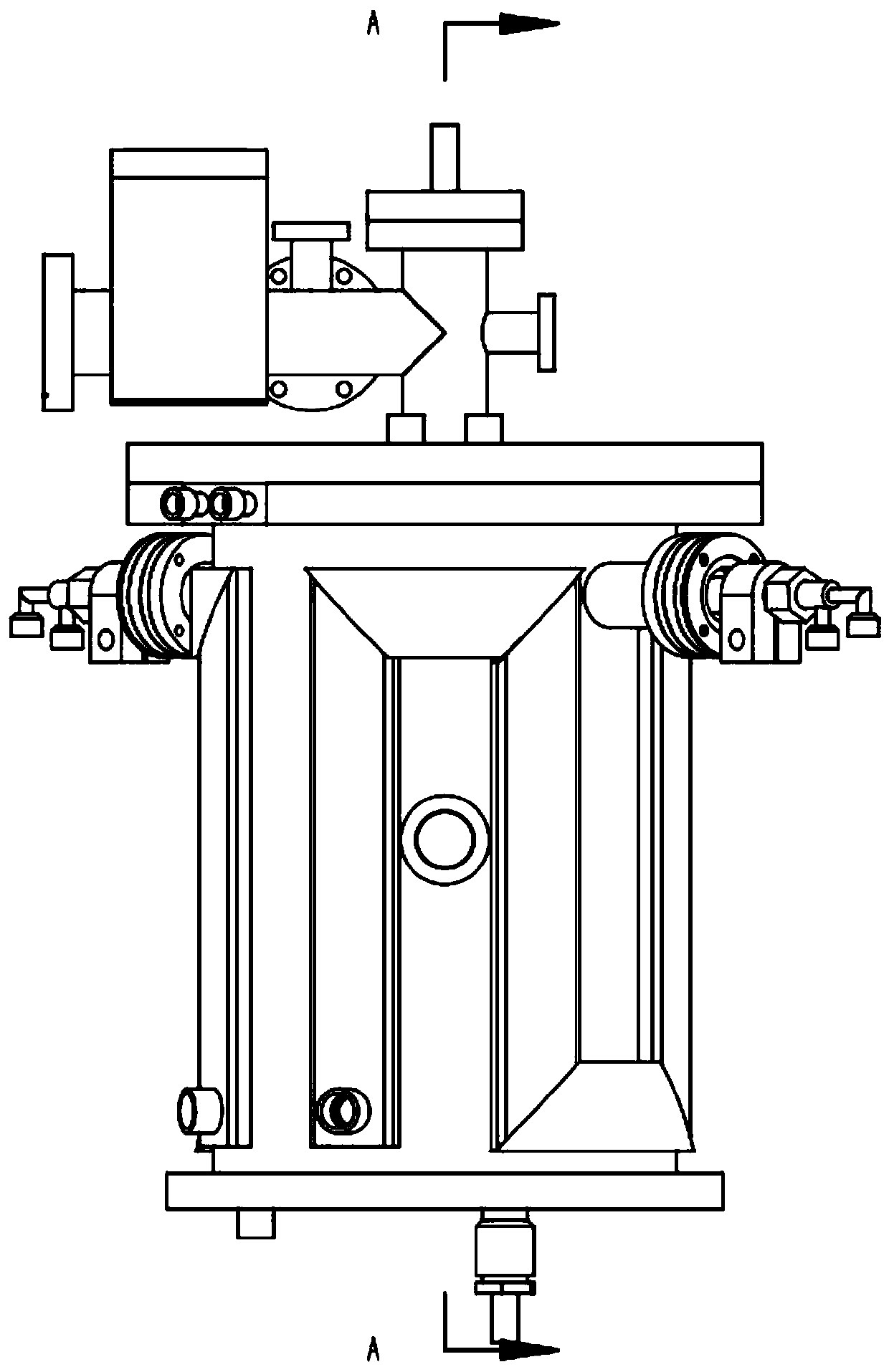

Spoke superconducting cavity tuner

ActiveCN105246242AIncreased Mechanical Tuning RangeAvoids damage from transverse shear forcesAcceleratorsThermostatCeramic

The invention discloses a Spoke superconducting cavity tuner. The Spoke superconducting cavity tuner comprises a tuning arm, a piezoelectric ceramic fixed seat, a moment steering apparatus, and a piezoelectric ceramic positioned in the internal of thermostat, and a stepper motor positioned in the external of the thermostat, wherein the piezoelectric ceramic is mounted on the piezoelectric ceramic fixed seat; one end of the moment steering apparatus is connected with the stepper motor through a main shaft of a tuner while the other end of the moment steering apparatus is connected with the piezoelectric ceramic; the moment steering apparatus is used for converting the rotation moment of the stepper motor to be a set angle and then transmitting to the piezoelectric ceramic; and the piezoelectric ceramic fixed seat is connected with the tuning arm. Compared with the prior art, the Spoke superconducting cavity tuner greatly enlarges the mechanical tuning range of the tuner, and is convenient to maintain.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

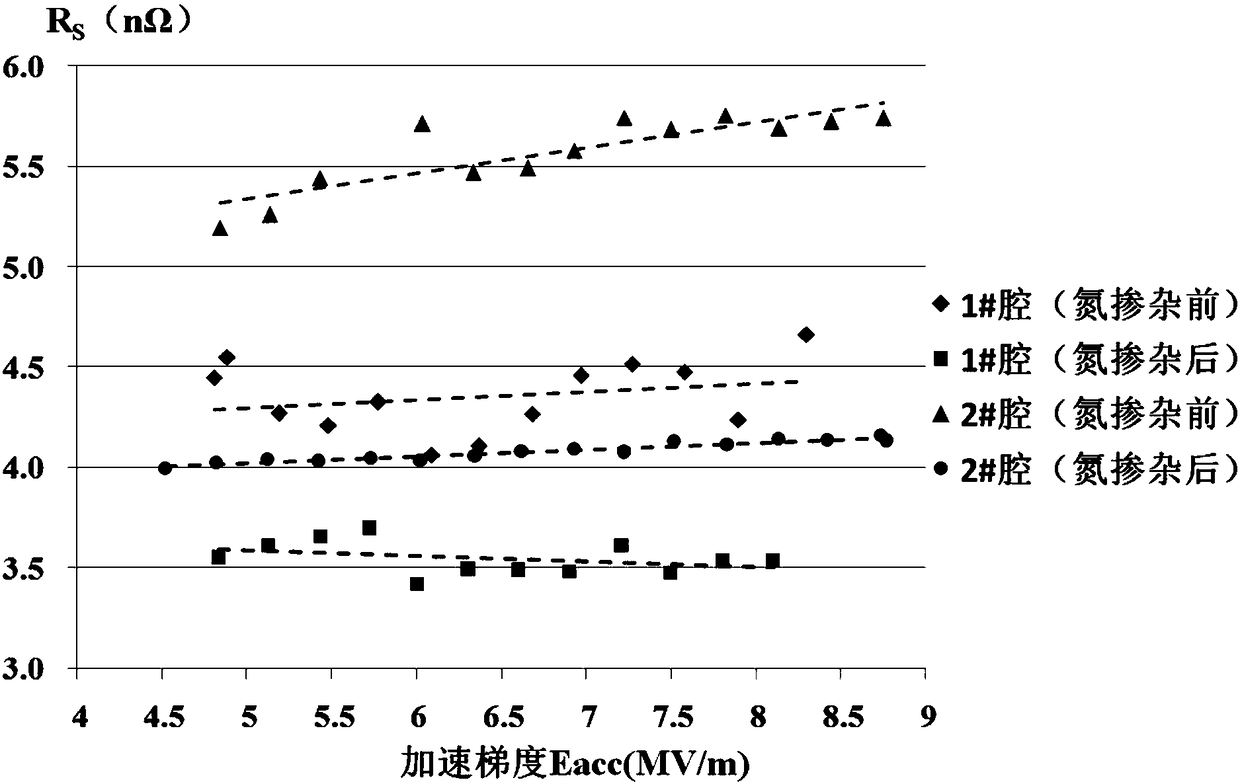

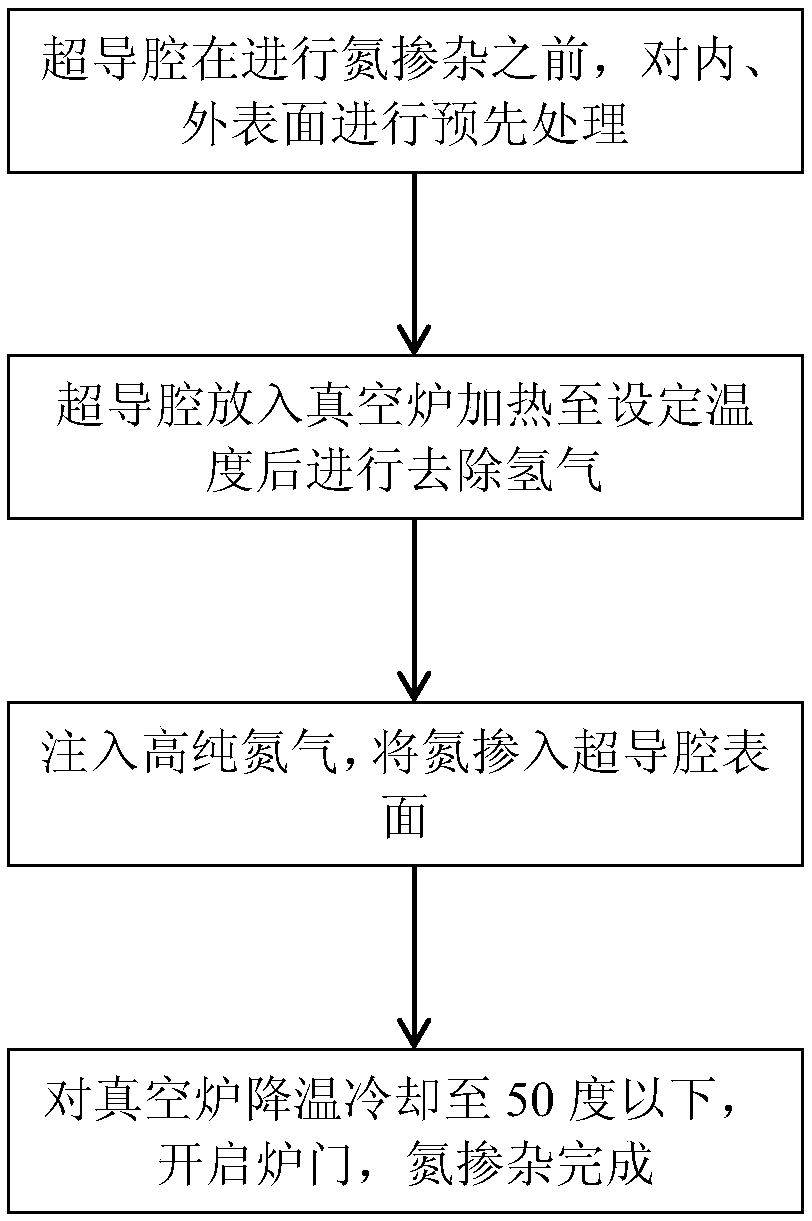

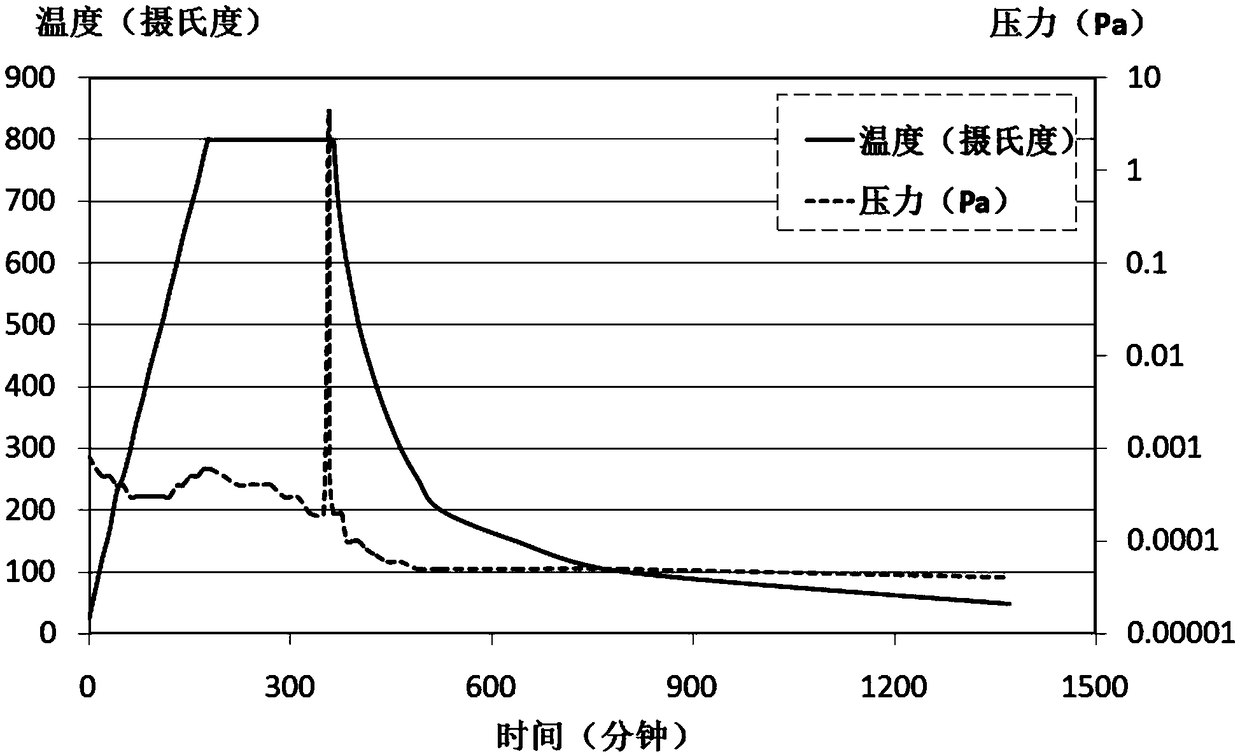

Superconducting cavity nitrogen doping method

ActiveCN108277450AReduce surface resistance RSReduce power consumptionSolid state diffusion coatingNitrogen removalHydrogen

The invention discloses a superconducting cavity nitrogen doping method. The method comprises the following steps that 1), a superconducting cavity is integrally put into an ultrasonic cleaning tank for cleaning, then the inside and the outside of the superconducting cavity are washed clean by using pure water, and are dried in the air, then buffering chemical polishing is carried out on the innersurface of the superconducting cavity, and then, the inner surface of the superconducting cavity is cleaned, and is dried in the air; 2), the superconducting cavity treated through the step 1) is putinto a vacuum furnace for heating, and after the superconducting cavity is heated to a set temperature, hydrogen removal treatment is carried out on the vacuum furnace at the set temperature and pressure; 3), after the hydrogen removal treatment is finished, a gas extraction valve of the vacuum furnace is closed, high-purity nitrogen is injected, the pressure in the vacuum furnace is kept at 2-4Pa, and the nitrogen is doped into the surface of the superconducting cavity; 4), after nitrogen injection is finished, the nitrogen removal treatment is carried out on the vacuum furnace; and 5), after the nitrogen removal treatment is finished, time is set for vacuum cavity heat preservation, and nitrogen doping of the superconducting cavity is completed. According to the method, the surface resistance of the superconducting cavity can be further reduced, so that the power consumption of the superconducting cavity is reduced.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

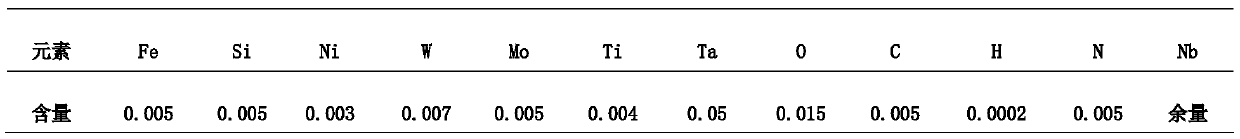

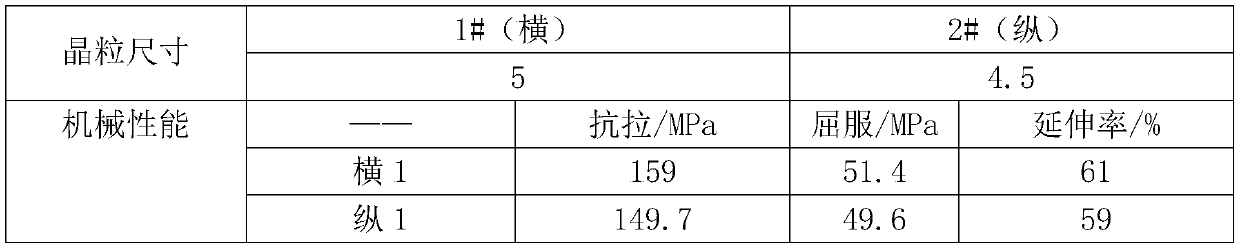

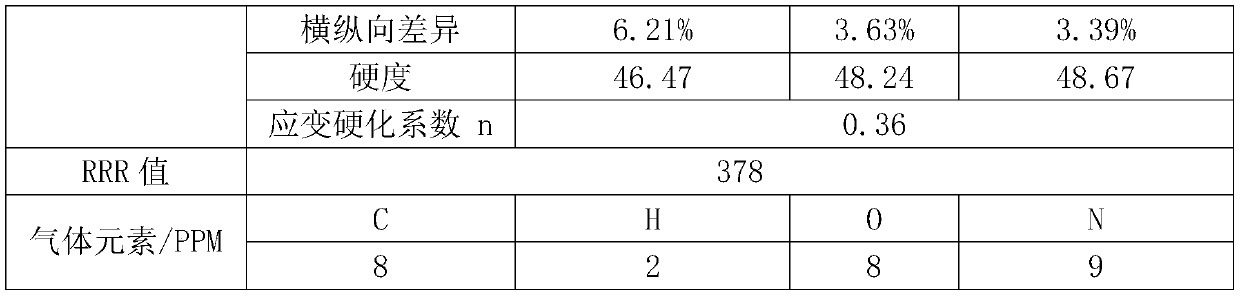

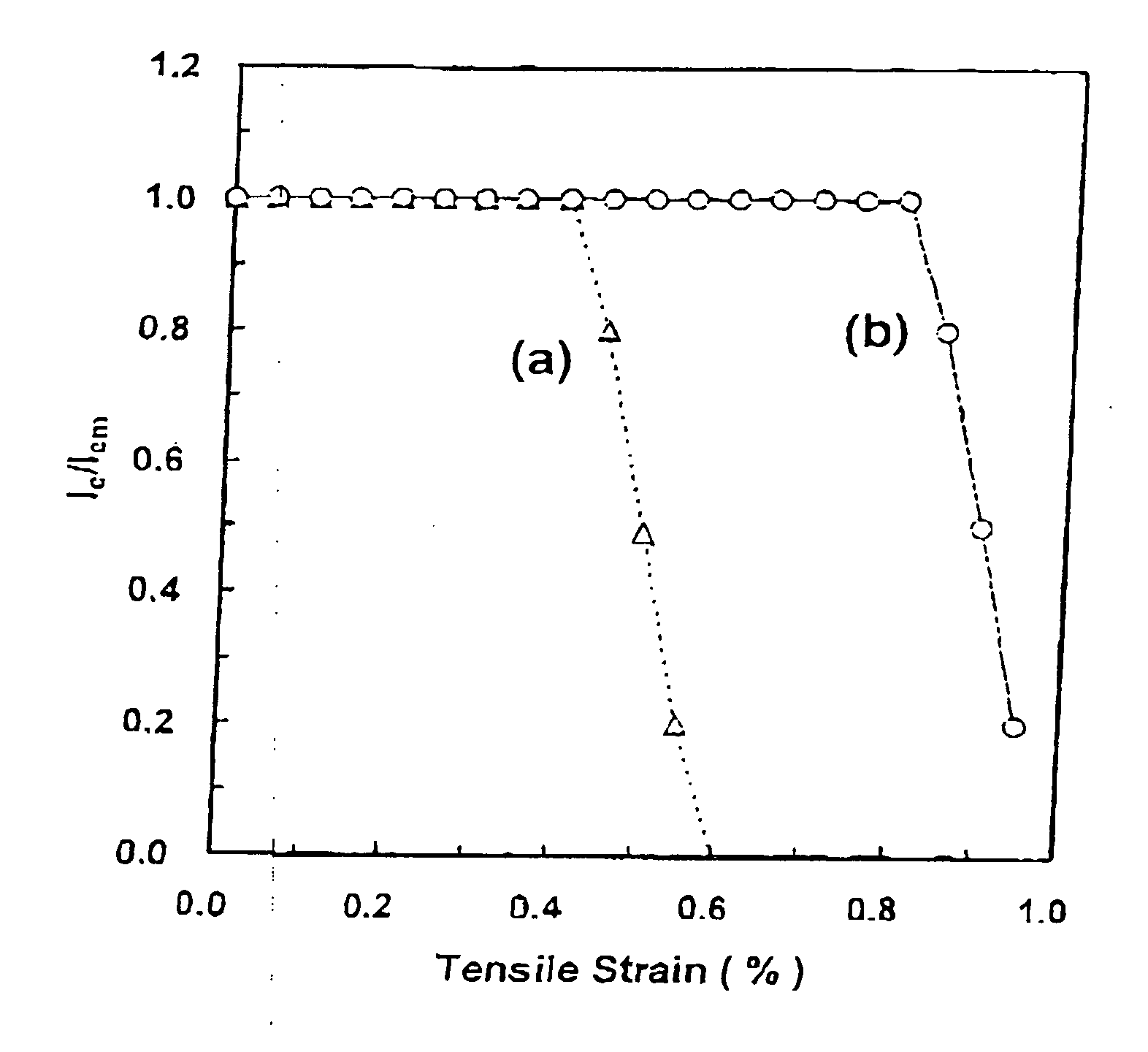

Machining method of high-RRR-value high-purity niobium material and niobium material for radio frequency superconducting cavity

PendingCN111515618AReduce horizontal and vertical differencesReduce bring inAcceleratorsHigh volume manufacturingNiobium

The invention relates to a machining method of a high-RRR-value high-purity niobium material and the niobium material for a radio frequency superconducting cavity. The machining method comprises the steps of ingot forging, blank saw cutting, blank surface machining, blank acid pickling, blank heat treatment, blank cogging, plate blank trimming, acid pickling, plate blank rolling, finished productdischarging, polish-grinding, acid pickling, finished product heat treatment, finished product shearing, primary fine polishing and finished product acid pickling. By means of the machining method, the grain size of a finished plate is kept between 4.5 grades and 5.5 grades, and the uniformity is good; the mechanical properties all meet the requirements, the transverse and longitudinal differenceis controlled within 15%, the tensile strength and yield are controlled within 10%, and the elongation is controlled within 10%; wherein the RRR value is controlled to be more than 300; the content ofgas elements can meet the requirements; and moreover, the product direct recovery rate is improved, the manufacturing cost of manufacturers can be greatly reduced, and mass production can be realized.

Owner:NINGXIA ORIENT TANTALUM IND

Method for producing mgb2 superconductor

InactiveUS20070004048A1Superconductors/hyperconductorsSemiconductor/solid-state device manufacturingElectric power transmissionAlloy

A alloy (Mg—X) of metal (X) and Mg in a liquid phase is made to react with B in a solid phase at a low temperature to manufacture a superconductor, which contains a large amount of MgB2 potential for MRI, linear motorcar, superconducting cavity, electric power transmission cable, high-magnetic field magnet for medical units, electric power storage (SMES), and the like and is formed in the shape of bulk, wire, and foil, by heat treatment performed at a low temperature for a short time and at low cost.

Owner:NAT INST FOR MATERIALS SCI

Rare earth doped niobium material for radio frequency superconducting cavity and preparation method thereof

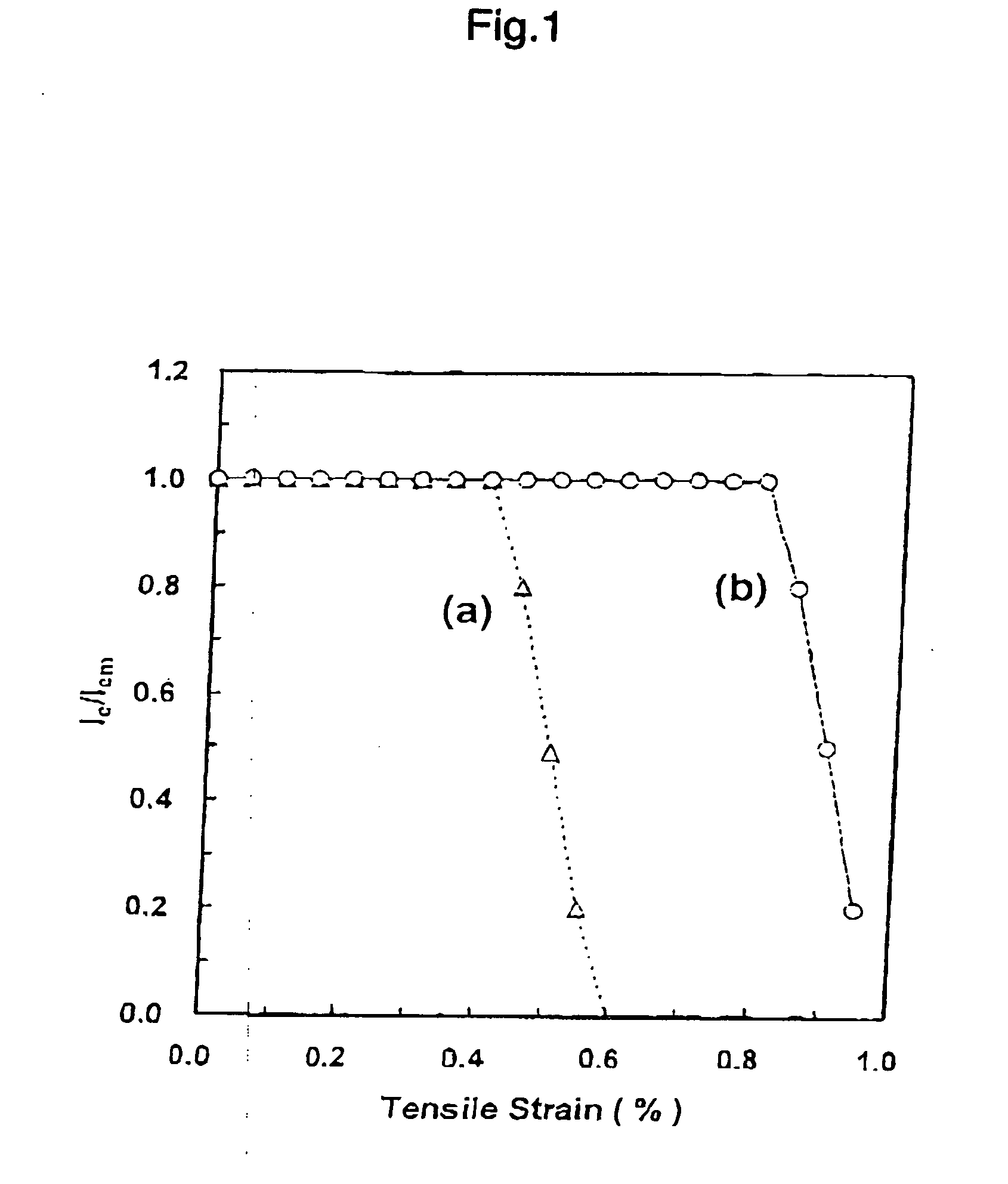

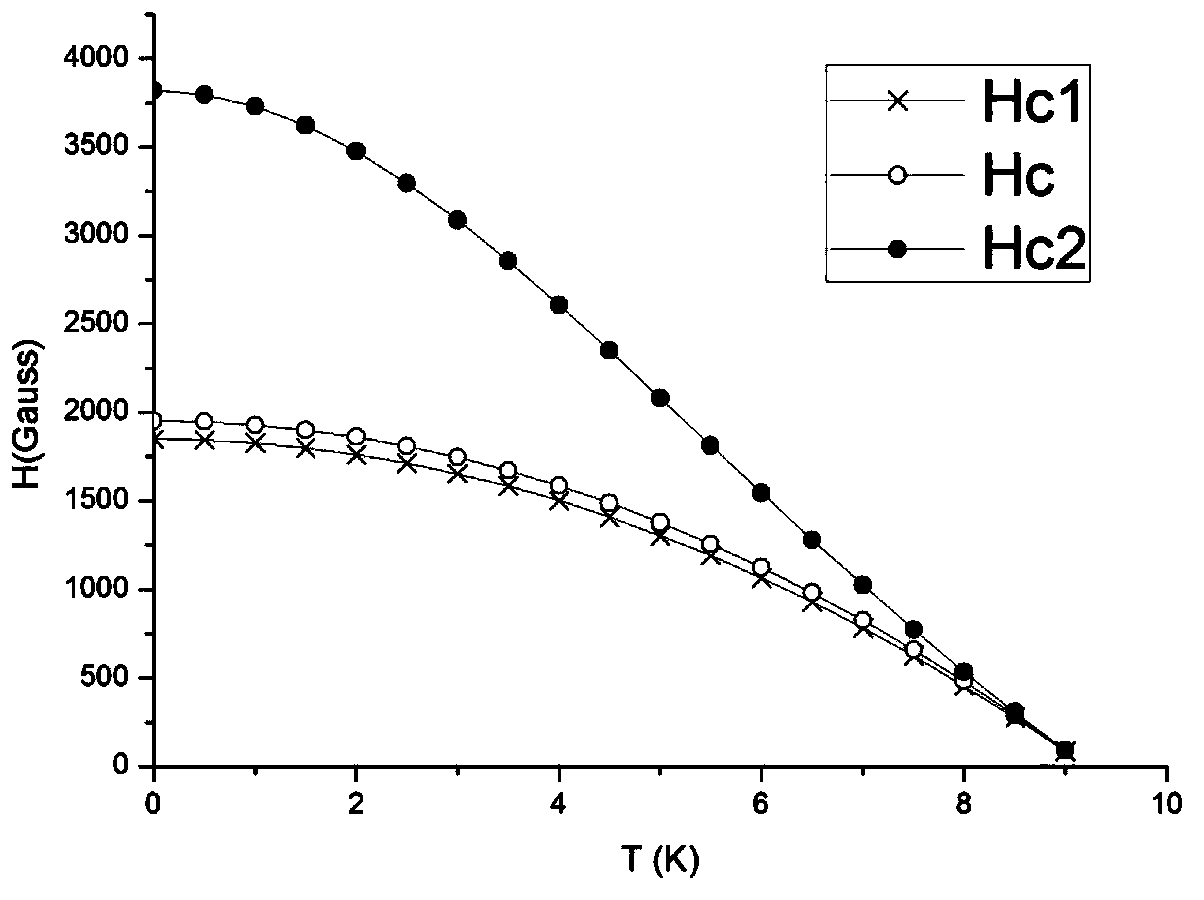

InactiveCN103397236AReduce the mean free pathHigh Quench Magnetic FieldElectric discharge heatingVacuum evaporation coatingNiobiumRare earth

The invention relates to a rare earth doped niobium material for a radio frequency superconducting cavity, belonging to the technical field of superconducting accelerators. The rare earth doped niobium material is a high-purity niobium material doped with a scandium or yttrium element, and the atomic ratio content range of the doped scandium or yttrium is 0.01%-0.5%. The preparation method comprises a smelting doping way or an ion injection way. In the rare earth doped niobium material prepared by the smelting doping way, impurity atoms can be uniformly distributed in the niobium material; and in the rare earth doped niobium material prepared by the ion injection way, the impurity atoms can be only distributed in a 500nm range of the surface layer of the niobium material. The niobium material disclosed by the invention can reduce the electron mean free path of the material and improve. According to the invention, the electron mean free path of the niobium material disclosed by the invention can be reduced and a lower critical magnetic field and an upper critical magnetic field can be improved. The radio frequency superconducting cavity prepared by the material has a higher quenching magnetic field and can work under a higher magnetic field and provide a higher acceleration electric field. A smelting doping method disclosed by the invention is relatively simple, and the preparation speed is high. By adopting an ion injection method, the doping content is easy to control, and the using quantity of the scandium or the yttrium is also saved.

Owner:赵夔

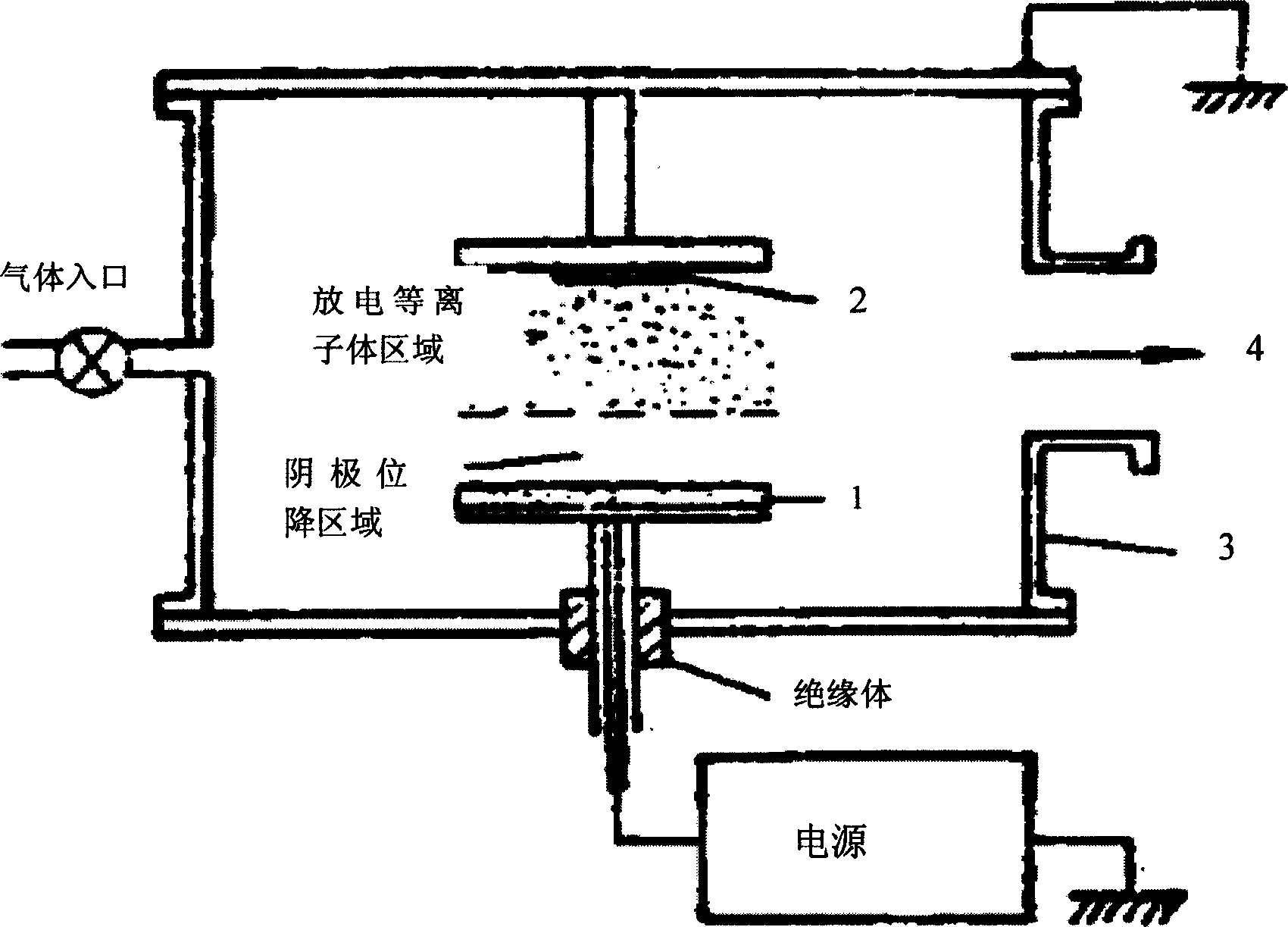

Dry treatment method for superconductor cavity

The invention offers superconducting cavity dry type processing method. Its features are that the superconducting cavity is used as cathode; substrate is used as anode; inert gases is ionized in vacuum; the surface of the superconducting cavity is processed sputtering by plasma; the substrate is metal or alloy with the function of adsorbing gas. Compared with chemical polishing and electro-polishing, it has the advantages of clean, no acid harm, no pollution, simple structure, and easy control. In addition it offers MP practice for superconducting cavity at room temperature to limit cavity MP.

Owner:PEKING UNIV

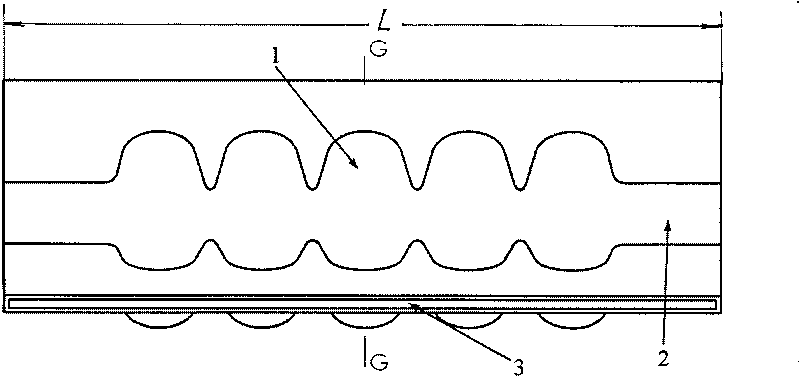

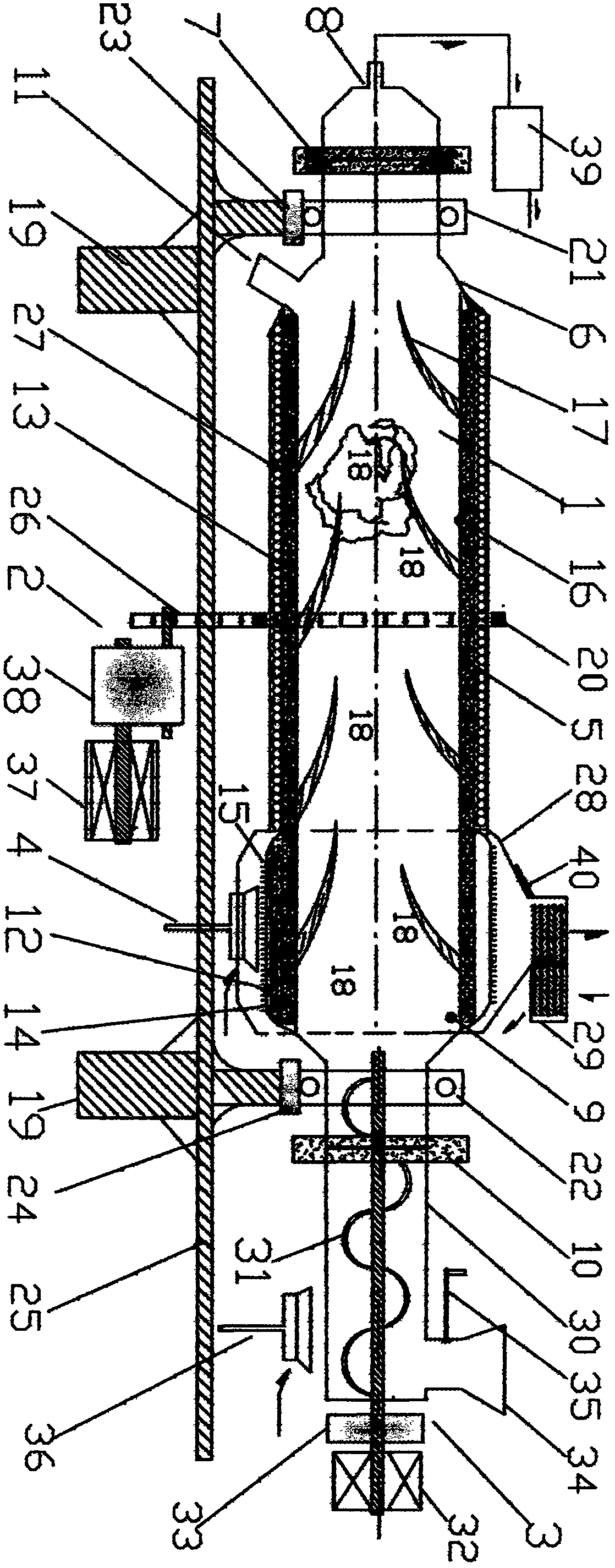

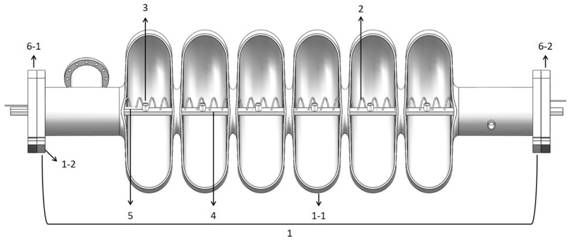

Horizontal double-layer tube rotary superconducting waste pyrolysis gasifier

InactiveCN109424964AOvercome the defects of single-layer heating technologyConducive to continuous cracking and gasificationIncinerator apparatusActivated carbonCombustor

The invention provides a horizontal double-layer tube rotary superconducting waste pyrolysis gasifier, which is composed of four parts of a double-layer tube gasifier body, a gasifier body rotary driver, a feeder and a burner. The horizontal double-layer tube rotary superconducting waste pyrolysis gasifier is characterized in that the double-layer tube gasifier body is a round cylinder with two round tubes sleeving together, a superconducting cavity and heating tank with the two ends sealed are formed between the two layers of the round cylinder, the superconducting cavity and the heating tankcommunicate an inner surface installed liquid absorbing coreand a high-temperature superconducting working medium, heat exchanging fins are installed around the heating tank, and stirring plates areinstalled on the inner walls of the heating tank and the superconducting cavity. Radiant heat generated by heating the rotary gasifier body outside the gasifier body with fuel gas produced by the waste pyrolysis gasifier for the burner is rapidly and uniformly transmitted to waste in the gasifier body through the heating tank, the high-temperature superconducting working medium, the superconducting liquid absorbing core and the superconducting cavity to complete efficient pyrolysis and gasification of the waste. According to the horizontal double-layer tube rotary superconducting waste pyrolysis gasifier, external heating of the pyrolysis furnaceis conducted, the temperature of a waste high-temperature reaction zone is constant, the risks of adhesion, bulking, blocking and coking due to local overheating of the waste in the gasifier body in traditional pyrolysis furnaces are avoided, releasing of harmful pyrolysates is shielded, production of dioxin is inhibited, pyrolytic solid residue can be used as activated carbon to make chemical raw materials, and comprehensive economic benefits are high.

Owner:西安美润环保工程技术有限公司 +1

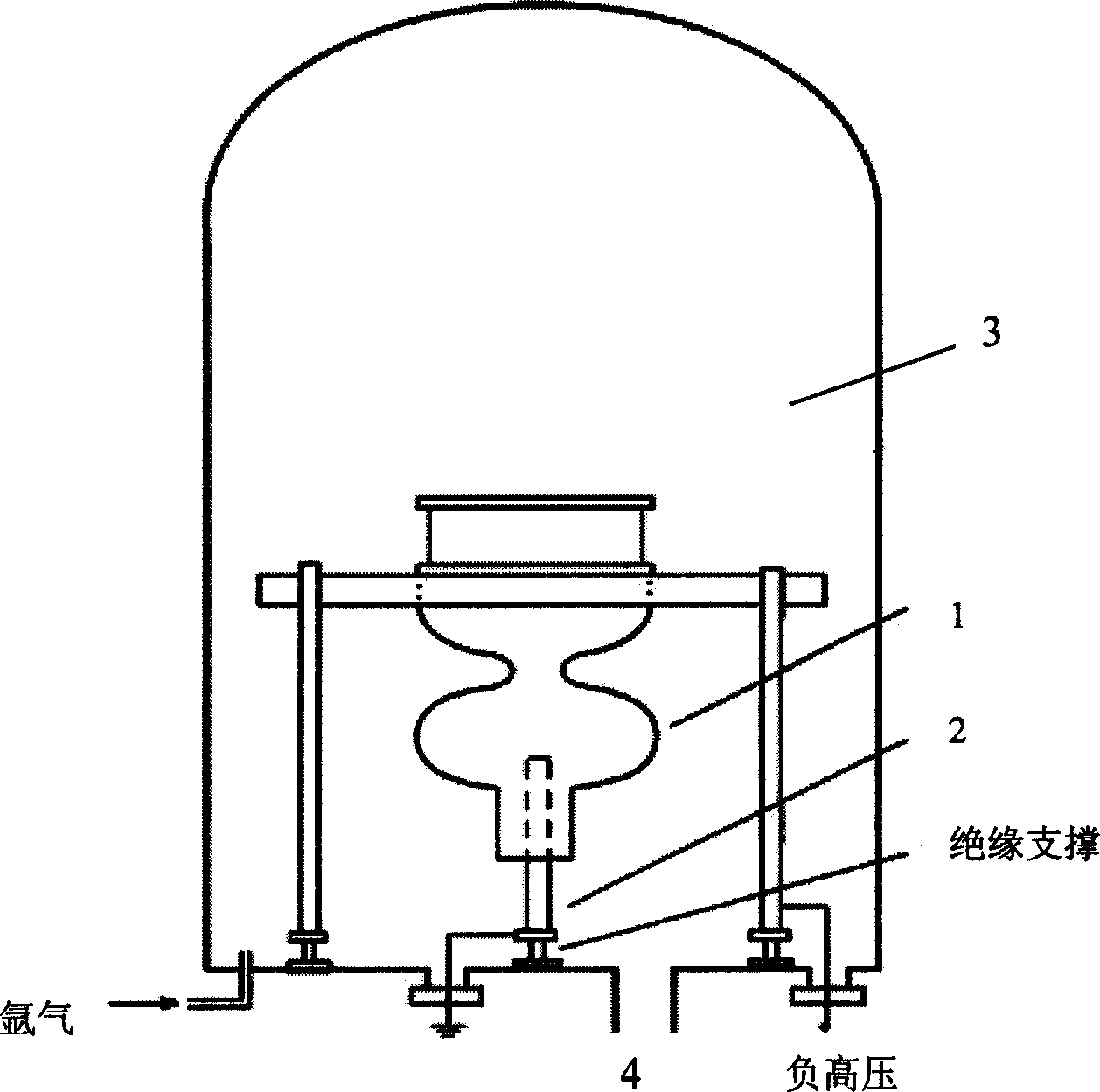

Method for plating triniobium stannide film on inner surface of pure niobium cavity and vacuum furnace

ActiveCN111074208ASolve the brittleSolve usabilityVacuum evaporation coatingSputtering coatingNiobiumCrucible

The invention discloses a method for plating a triniobium stannide film on the inner surface of a pure niobium cavity and a vacuum furnace. The vacuum furnace is characterized by including a double vacuum structure consisting of an external vacuum system and an internal vacuum system, wherein the external vacuum system is internally provided with a heater heating the internal vacuum system and a temperature measuring probe used for measuring the temperature of a set area of the internal vacuum system; and the internal vacuum system is internally provided with a niobium cavity hoisting device,the rotating hoisting device is used for connecting the niobium cavity to be plated with a film and a stannum crucible, and the niobium cavity is rotated circularly through a transmission mechanism. Through the vacuum furnace, the pure niobium cavity can be internally plated with a layer of pure, completely-covering and evenly-distributed triniobium stannide film, and thus application of triniobium stannide to a superconducting cavity is achieved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

Forging method for high purity niobium ingot used for radio frequency superconducting cavity

ActiveCN107470530AOvercome the disadvantage of small weight (less than 70kg)Improve the production efficiency of blank forgingMetal-working apparatusAcceleratorsNiobiumOxygen

The invention discloses a forging method for a high purity niobium ingot used for a radio frequency superconducting cavity. The forging method for the high purity niobium ingot used for the radio frequency superconducting cavity comprises the following steps that first, machining is conducted on the high purity niobium ingot used for the radio frequency superconducting cavity; second, the high purity niobium ingot is cut to obtain high purity niobium blank; third, vacuum annealing treatment is conducted on the high purity niobium blank; fourth, the high purity niobium blank is vertically placed on a lower hammer anvil of an oil hydraulic press, and multiple times of upsetting forging is conducted; fifth, the high purity niobium blank after upsetting forging is horizontally placed on the lower hammer anvil of the oil hydraulic press, and forging and pressing deformation is conducted by using an upper hammer anvil of the oil hydraulic press; sixth, shrinking tails at the ends of the high purity niobium forging blank are removed, and milling machining is conducted on the upper and lower surfaces of the high purity niobium forging blank; and seventh, vacuum annealing treatment is conducted on the high purity niobium forging blank to obtain the high purity niobium ingot. According to the forging method for the high purity niobium ingot used for the radio frequency superconducting cavity, machining of the high purity niobium ingot only by using a method of die forging blanking at present is broken through, relying on equipment of the high purity niobium forging technology is reduced, producing efficiency of the high purity niobium ingot is improved, introducing of impurity gap elements especially oxygen, nitrogen and hydrogen is reduced, and excessively fast reducing of residual resistance ratio of cast ingot is avoided.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of high-purity niobium ingot casting for radio frequency superconducting cavity

The invention discloses a preparation method of a high-purity niobium ingot casting for a radio frequency superconducting cavity. The preparation method comprises performing vacuum electronic torch melting on a niobium batten for 3-7 times, thereby obtaining the high-purity niobium ingot casting; the specific electric energy of the vacuum electronic torch melting is 8-12 degrees per kilometer, and the vacuum degree of the vacuum electronic torch melting is not greater than 5*10<-3>Pa. The preparation method is reasonable in design, simple, simple and convenient to operate; the practical problems existing in the traditional niobium ingot casting production process can be effectively solved and the requirements on stabilized and large-scale production of the high-purity niobium ingot casting for the radio frequency superconducting cavity are met; the vacuum electronic torch melting is performed for 3-7 times, and by controlling the specific electric energy, the RRR value and the components of the prepared niobium ingot casting both conform to the requirements of the high-purity niobium ingot casting for the radio frequency superconducting cavity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

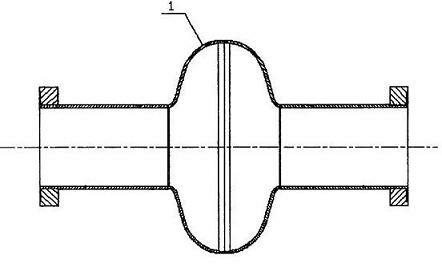

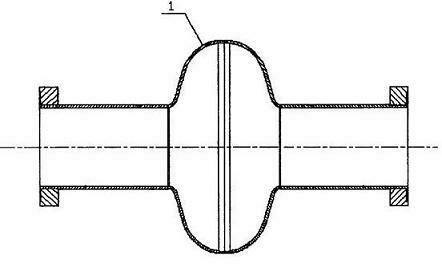

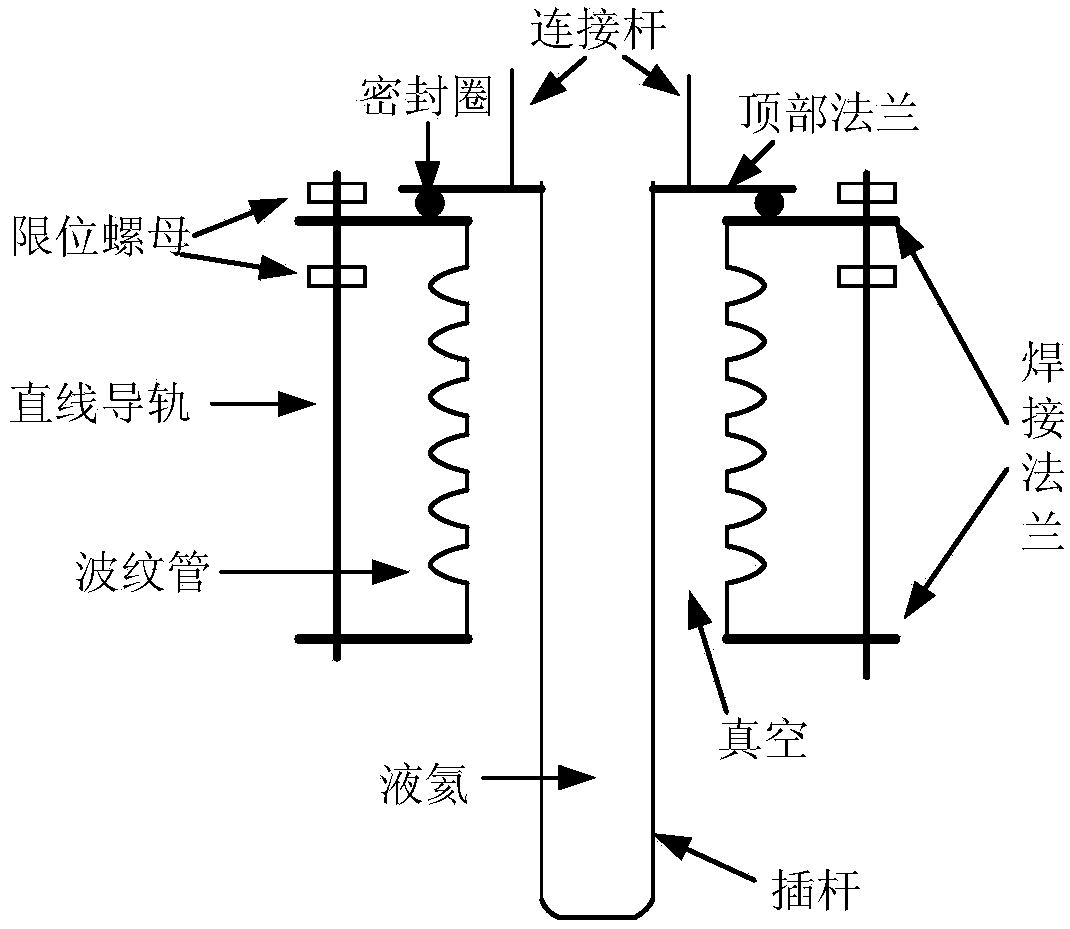

Low-temperature insertion rod tuner and superconducting cavity

The invention discloses a low-temperature insertion rod tuner and a superconducting cavity. The low-temperature insertion rod tuner comprises an insertion rod assembly and an adjusting assembly; the insertion rod assembly comprises a first telescopic device and an insertion rod, the upper end of the first telescopic device is connected with the adjusting assembly through a top flange, and the lower end of the first telescopic device is used for sealed connection with an opening arranged on the superconducting cavity, so that a closed system is formed between the insertion rod assembly and thesuperconducting cavity; and the adjusting assembly controls telescoping of the first telescopic device, and controls the length of the insertion rod in the first telescopic device inserted into the superconducting cavity. The low-temperature insertion rod tuner provided by the invention is relatively compact in structure, and the superconducting cavity body is not required to be deformed, and acting force required for frequency tuning is small. The tuning range of the tuner is directly determined by the amount of compression or stretching of a bellows, and the frequency of the superconductingcavity can be adjusted in a relatively large range.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

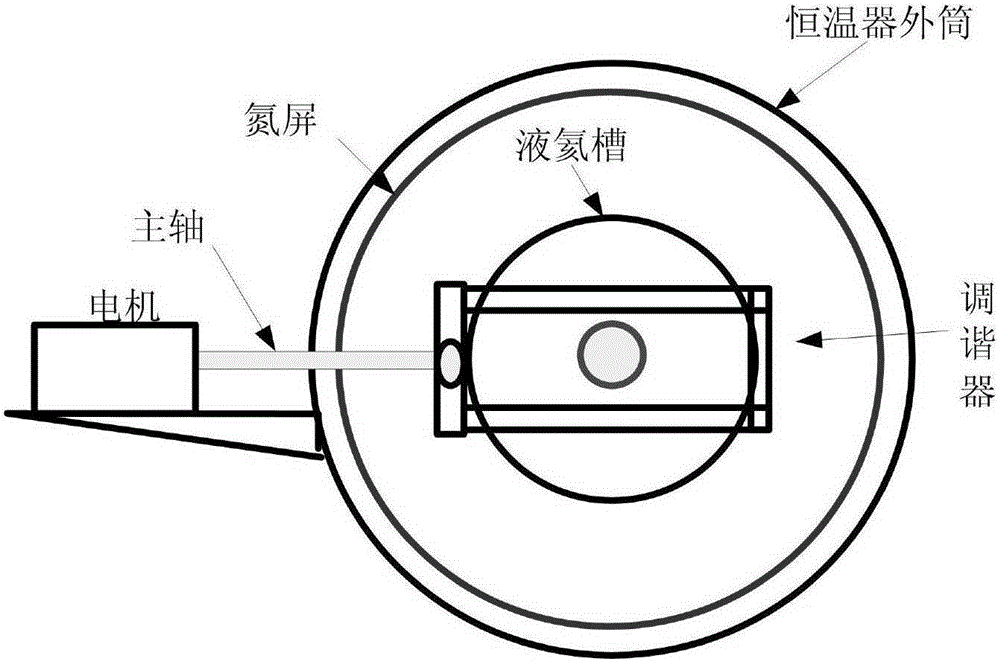

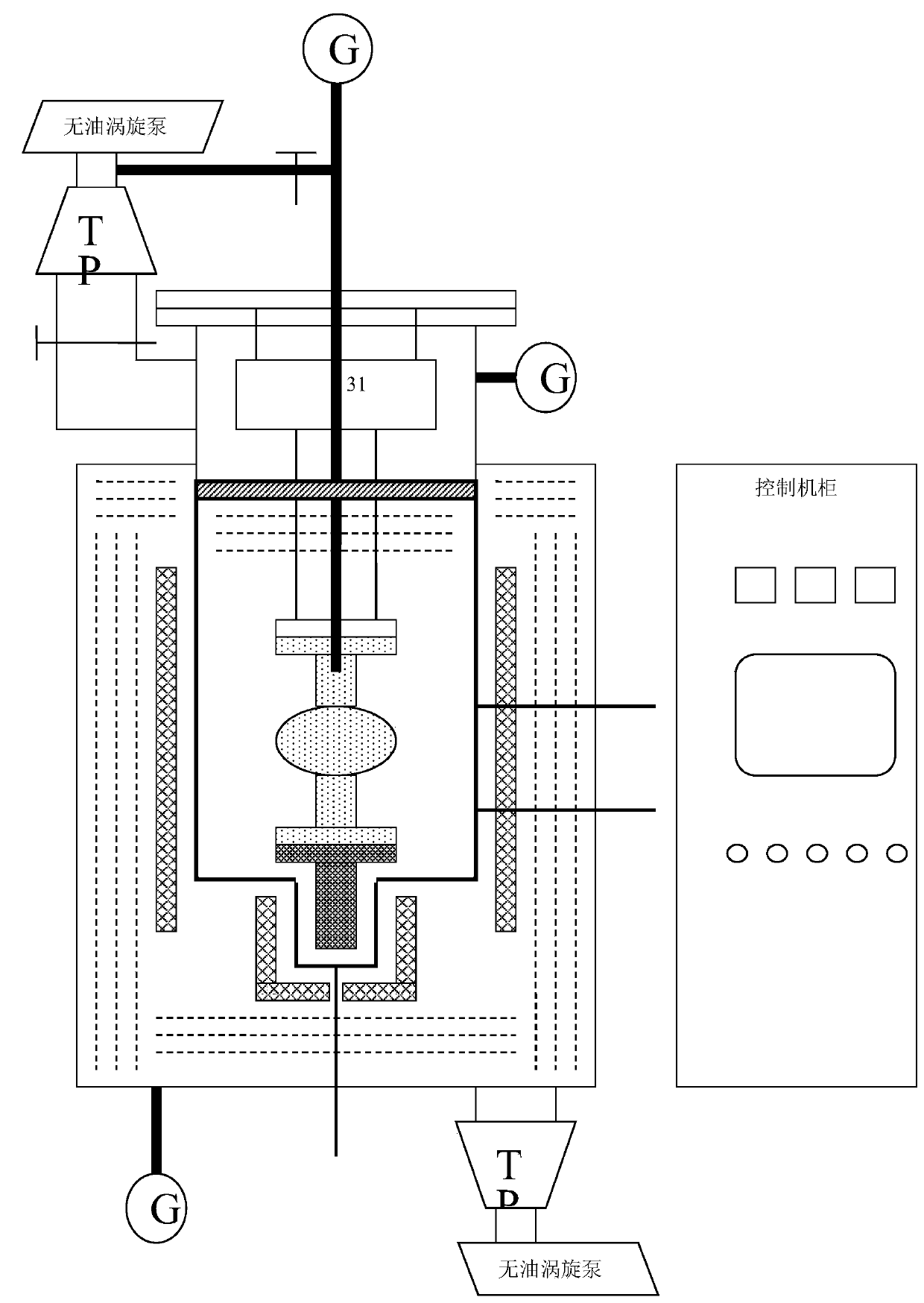

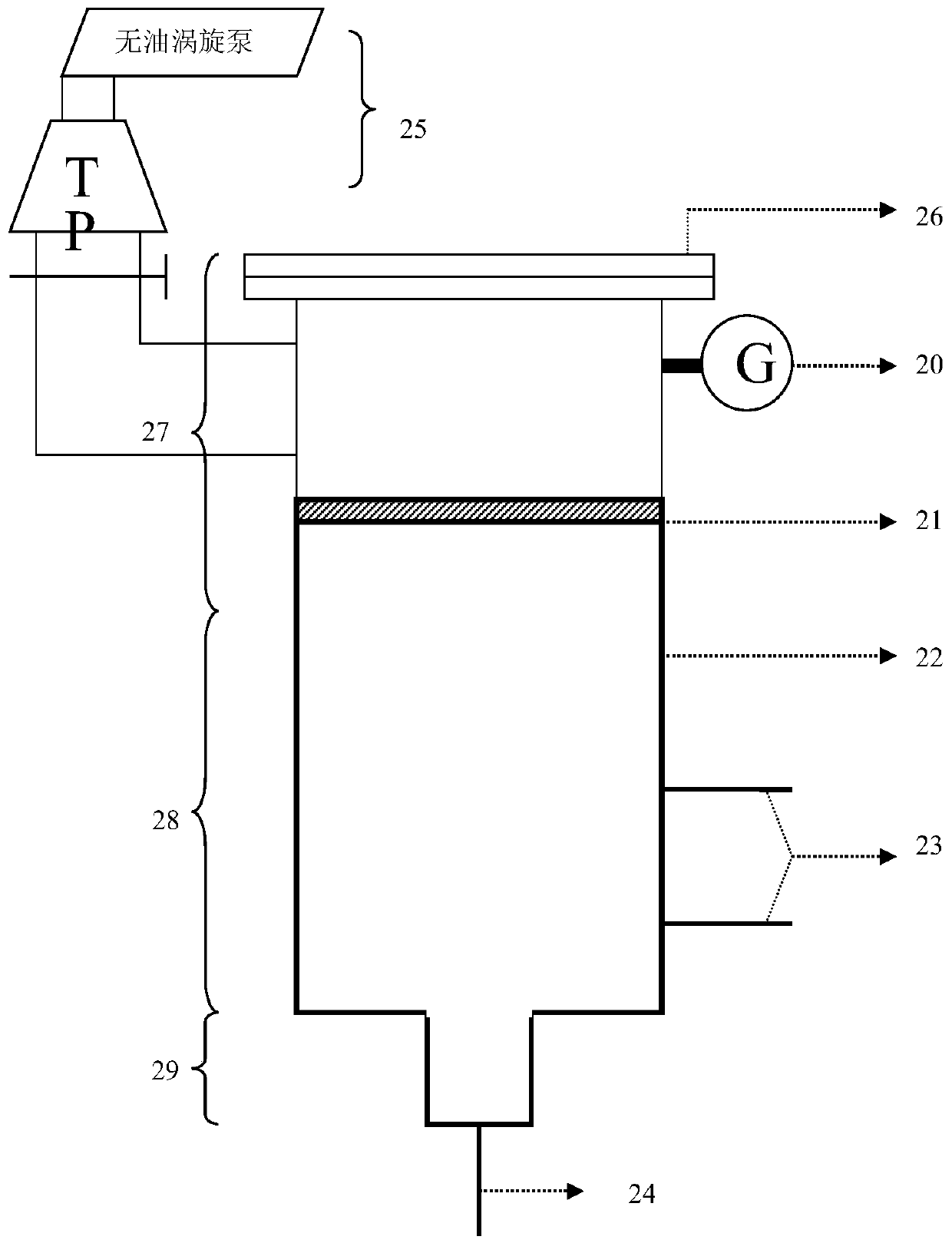

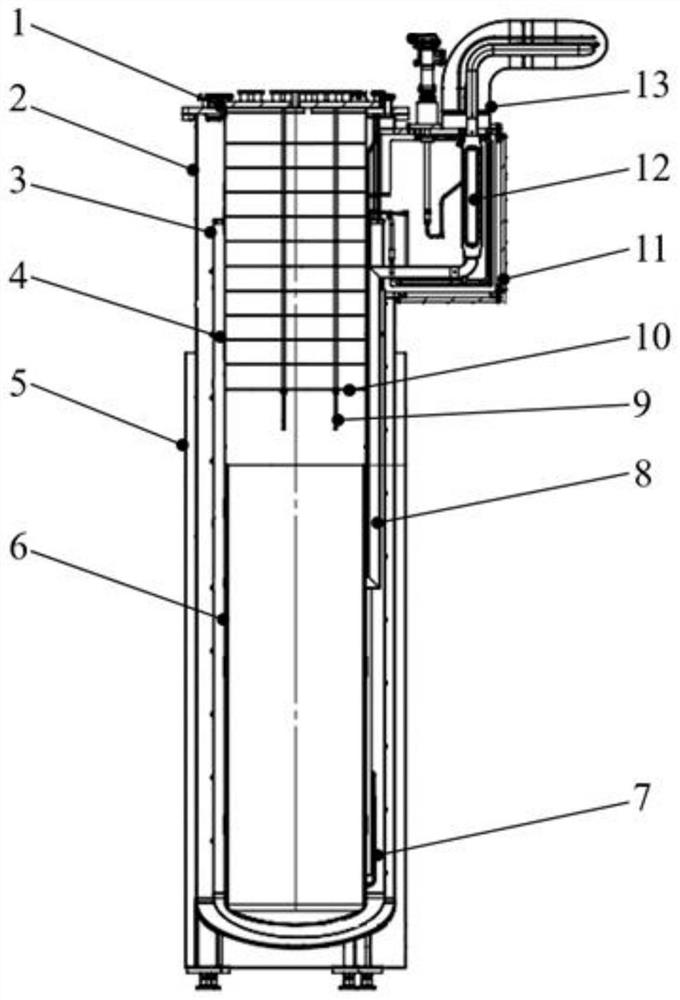

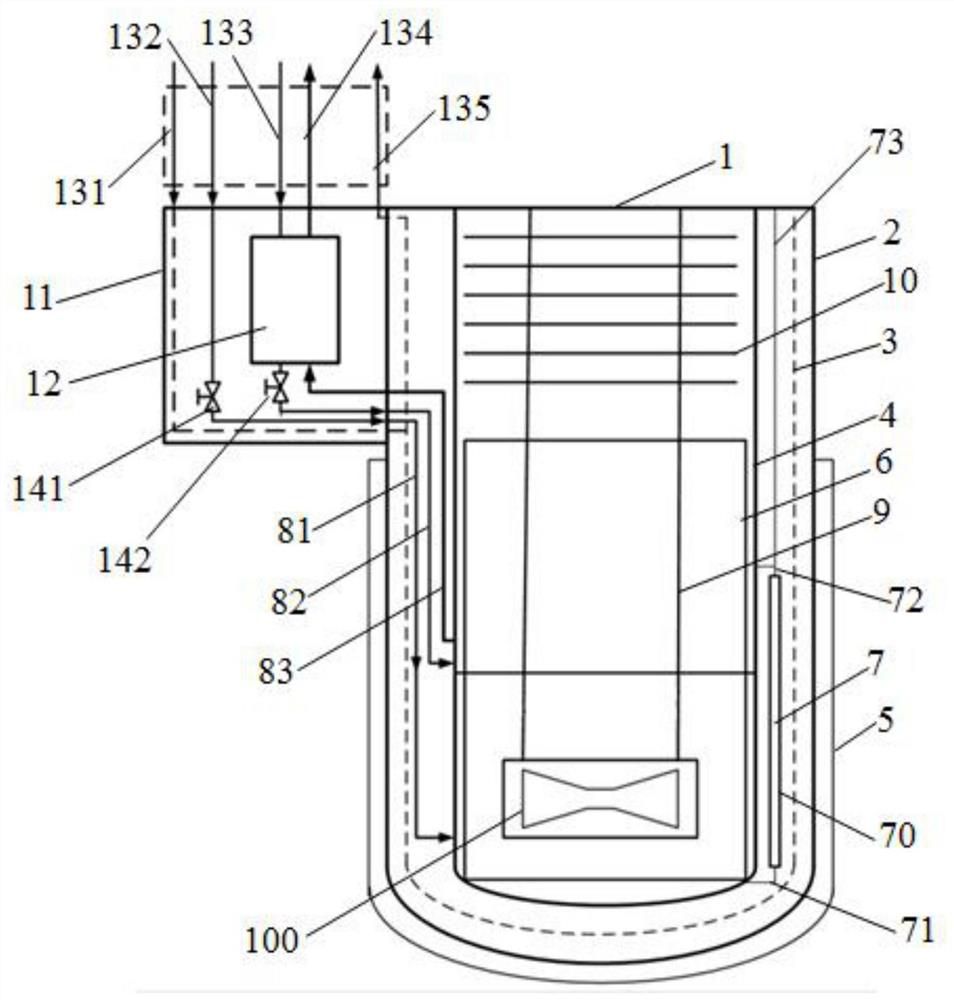

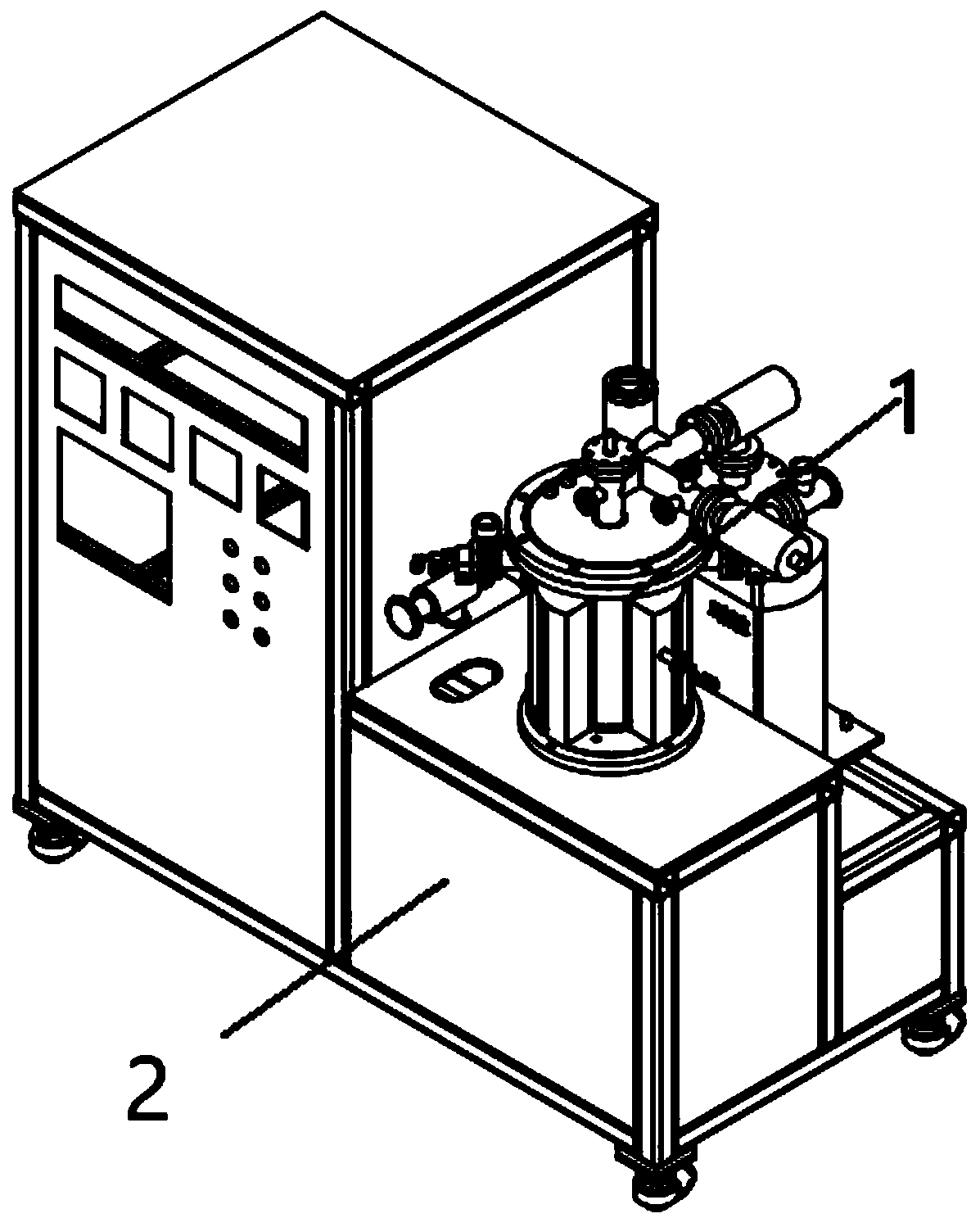

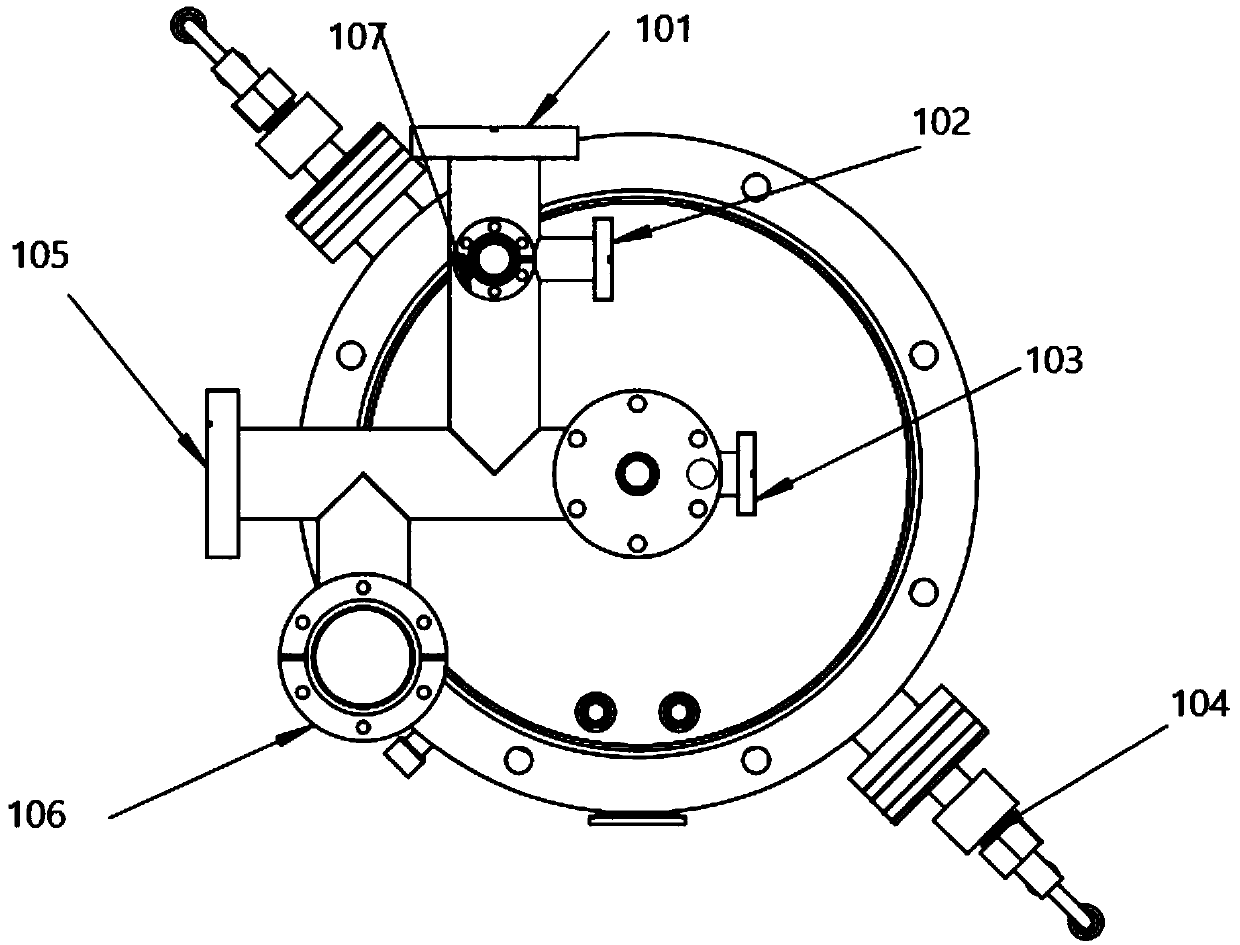

Superfluid helium Dewar low-temperature constant-temperature testing device

PendingCN111896578ASimplify Space UtilizationOptimize space utilizationMaterial heat developmentVacuum pressureEngineering

The invention discloses a superfluid helium Dewar low-temperature constant-temperature testing device. The device comprises a flange plate, an outer cylinder body, an inner cylinder body and a low-temperature pipeline system, the inner cylinder body is arranged in the outer cylinder body, an upper port of the outer cylinder body and an upper port of the inner cylinder body are connected in a sealed mode through the flange plate, four hanging rods are perpendicularly connected to the end cover face of the bottom of the flange plate, and a liquid nitrogen cold shield is arranged between the outer cylinder body and the inner cylinder body; the low-temperature pipeline system comprises a distribution valve box, a liquid nitrogen cold shield constant-temperature loop, a liquid helium inner barrel precooling cooling branch, a liquid helium inner barrel constant-temperature branch and a nitrogen vacuum pressure reduction branch. The superfluid helium Dewar testing device disclosed by the invention is good in space utilization rate and small in heat leakage, the heat leakage of the superconducting cavity during each test is reduced, the operation difficulty is simplified, and the testing efficiency is improved.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

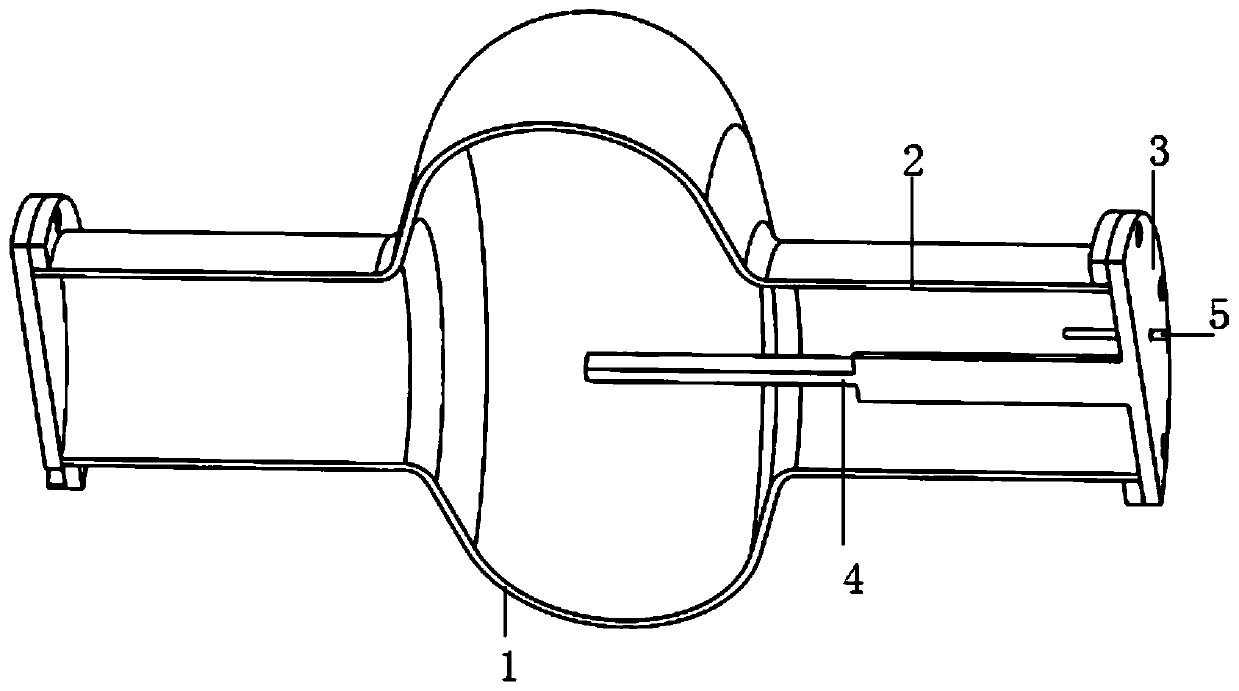

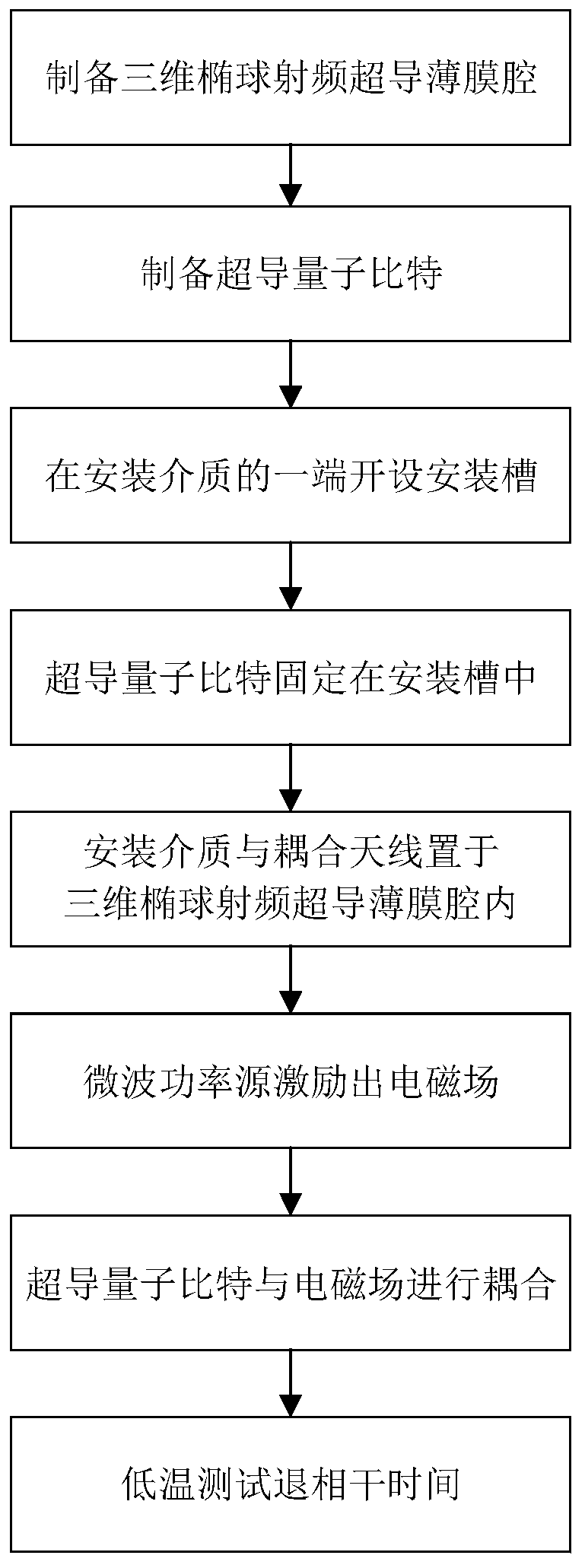

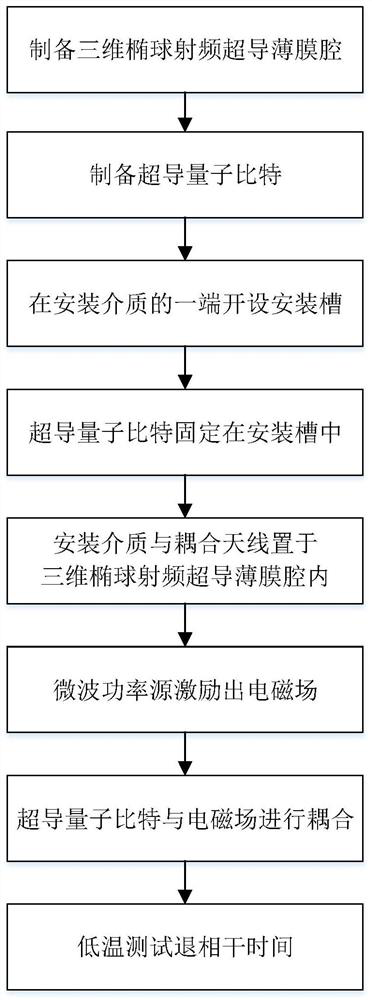

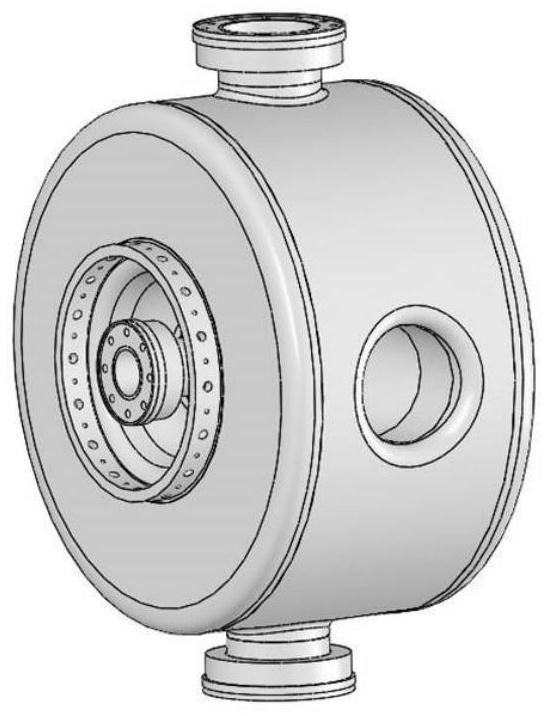

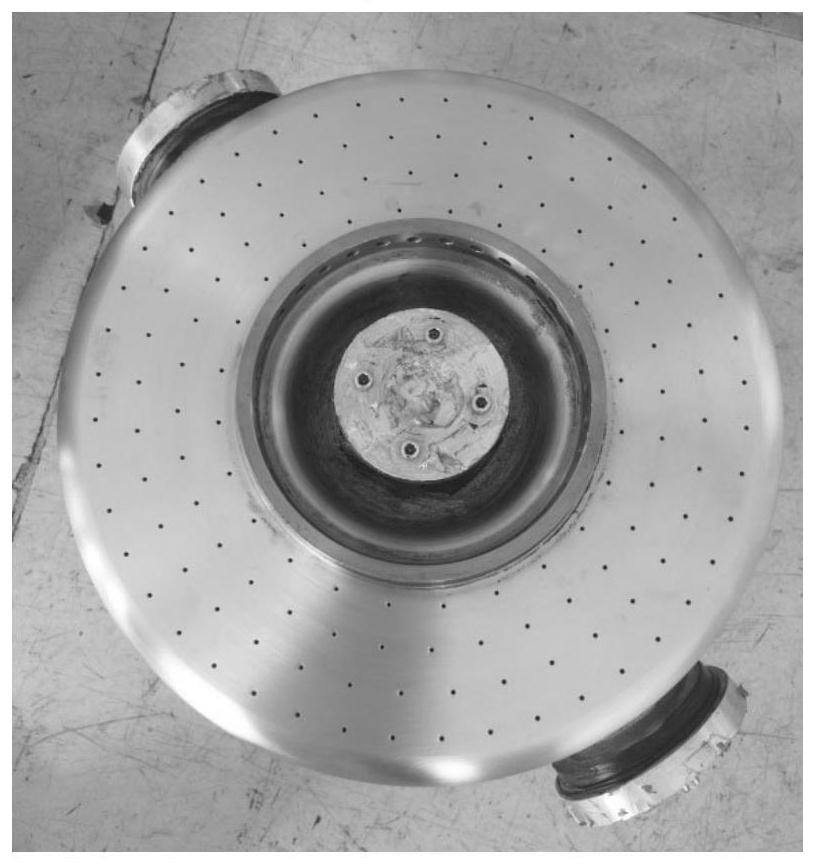

Long-service-life storage device and long-service-life storage method for superconducting quantum bits

The invention discloses a long-life storage device and a long-service-life storage method for superconducting quantum bits. The three-dimensional ellipsoid radio frequency superconducting thin film cavity with high quality factor is adopted, and compared with a currently used rectangular cavity, the three-dimensional ellipsoid radio frequency superconducting thin film cavity has the advantages that the quality factor reaches up to 1010; the superconductive quantum bits are coupled with the superconductive cavity, and the decorrelation time of the superconductive quantum bits is prolonged to a hundred milliseconds to second order, so that obstacles are cleared for realizing control and measurement of the quantum bits and quantum storage; according to the method, the superconducting quantum bits with long service life can be obtained, and the device method have important significance for quantum calculation, quantum storage, quantum information, quantum communication and other aspects; the three-dimensional ellipsoid radio frequency superconducting thin film cavity is applied to superconducting quantum calculation for the first time, a mature superconducting cavity technology and emerging superconducting quantum calculation are combined, and the superconducting quantum calculation is further extrapolated forwards.

Owner:PEKING UNIV

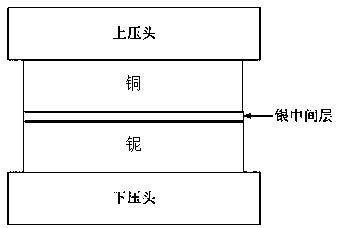

Copper and niobium connector and connecting method thereof

InactiveCN109604804AHigh strengthGood deformabilityNon-electric welding apparatusNiobiumHeating furnace

The invention relates to the technical field of copper niobium superconducting cavity making, in particular to a copper and niobium connector and a connecting method thereof. The copper and niobium connector is characterized in that the connector is composed of a copper plate, a silver intermediate layer and a niobium plate, and the upper and lower ends of the silver intermediate layer are connected with the copper plate and the niobium plate correspondingly. The connecting method includes the following steps that firstly, the to-be-connected surfaces of the niobium plate and the copper plateare ground to obtain the fresh metal surfaces, and acetone or ethyl alcohol are used for ultrasonic cleaning; secondly, metallic silver which can react eutectically with copper and form a solid solution with niobium is selected as the intermediate layer; and thirdly, the niobium plate, the silver intermediate layer and the copper plate are assembled together and put into a heating furnace, the mixture is pressurized, vacuumized and then heated for connection, and niobium silver copper connector is obtained after cooling and removing. The copper and niobium connector and the connecting method thereof have the advantages that the method is simple, the silver is used as the intermediate layer to connect the copper and the niobium, connection at the low temperature is realized, and good strength and deformation ability of a joint are ensured.

Owner:HARBIN INST OF TECH AT WEIHAI

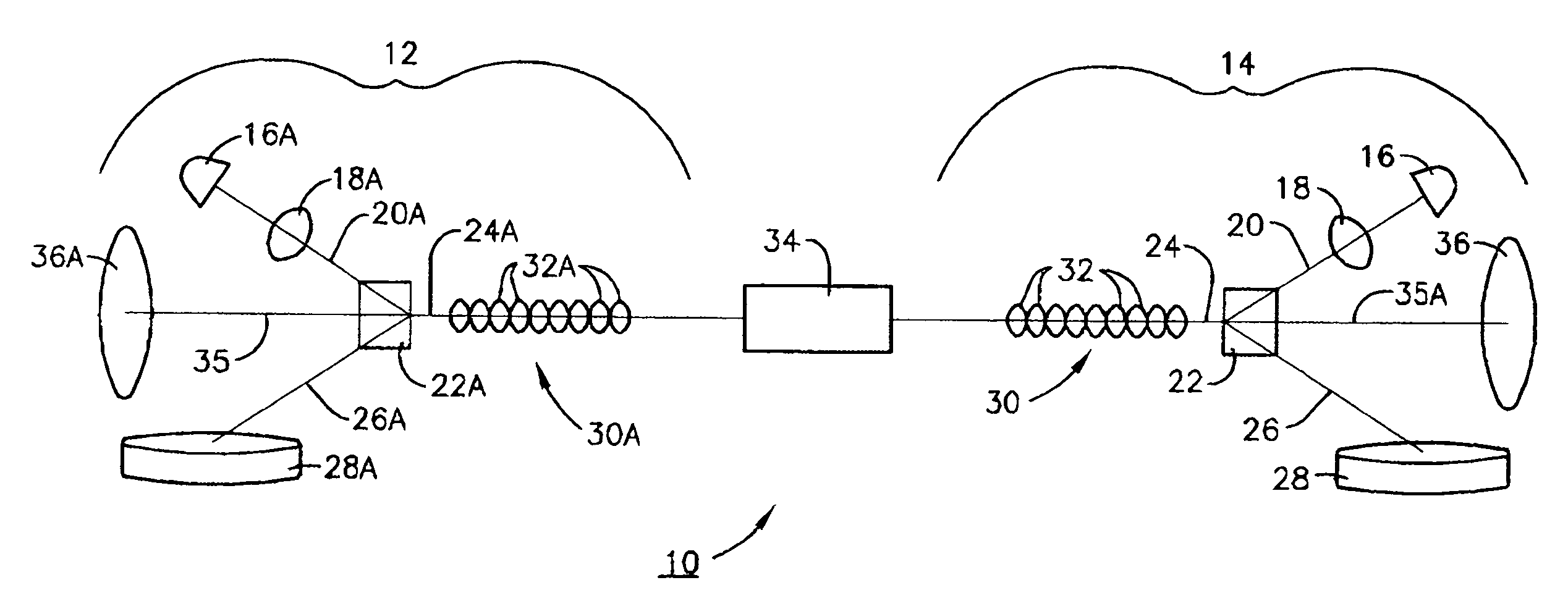

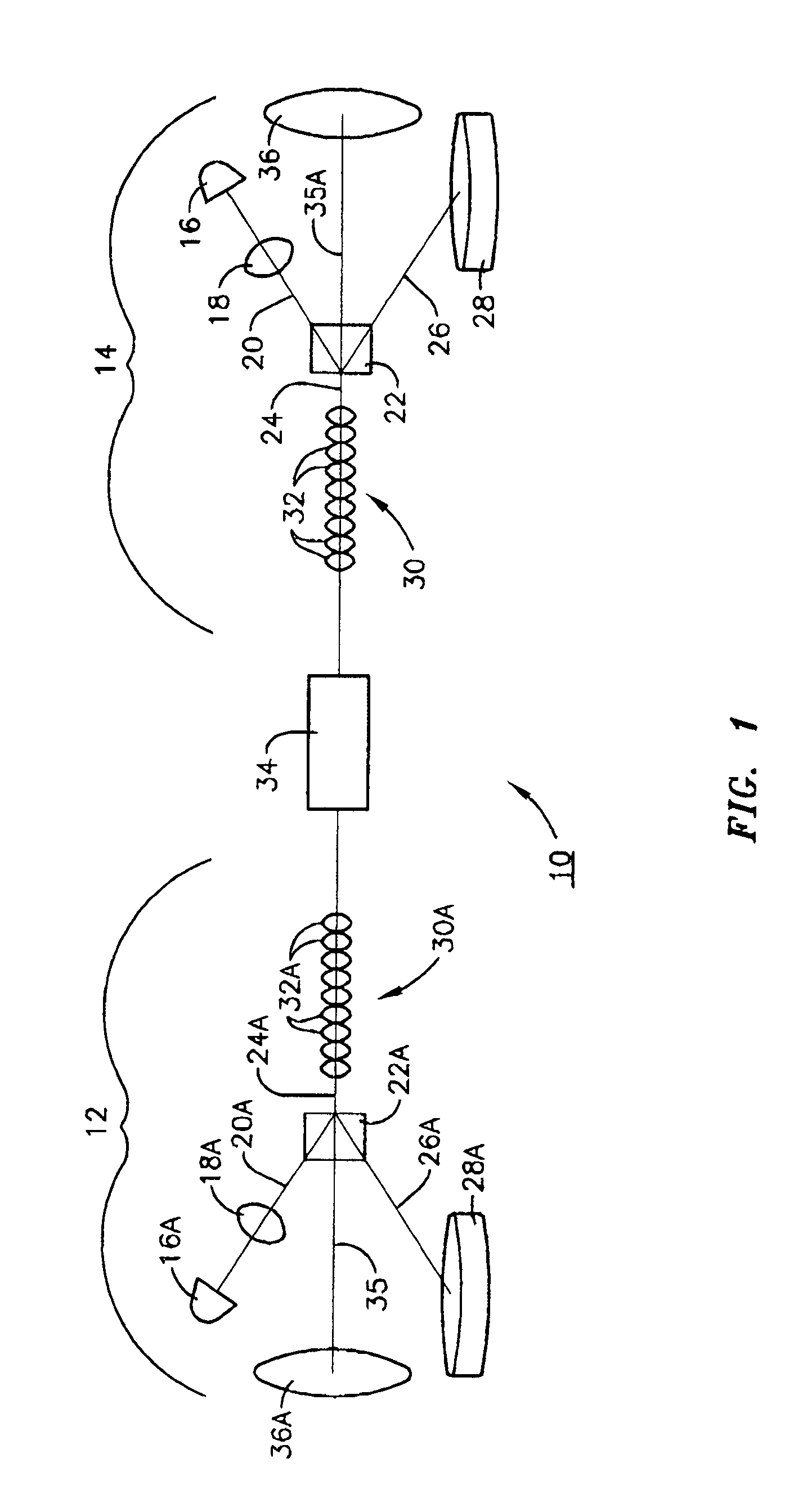

Compact two-beam push-pull free electron laser

InactiveUS7499476B1More compact and highly efficient apparatusExcitation process/apparatusAcceleratorsLight beamPush pull

An ultra-compact free electron laser comprising a pair of opposed superconducting cavities that produce identical electron beams moving in opposite directions such that each set of superconducting cavities accelerates one electron beam and decelerates the other electron beam. Such an arrangement, allows the energy used to accelerate one beam to be recovered and used again to accelerate the second beam, thus, each electron beam is decelerated by a different structure than that which accelerated it so that energy exchange rather than recovery is achieved resulting in a more compact and highly efficient apparatus.

Owner:JEFFERSON SCI ASSOCS LLC

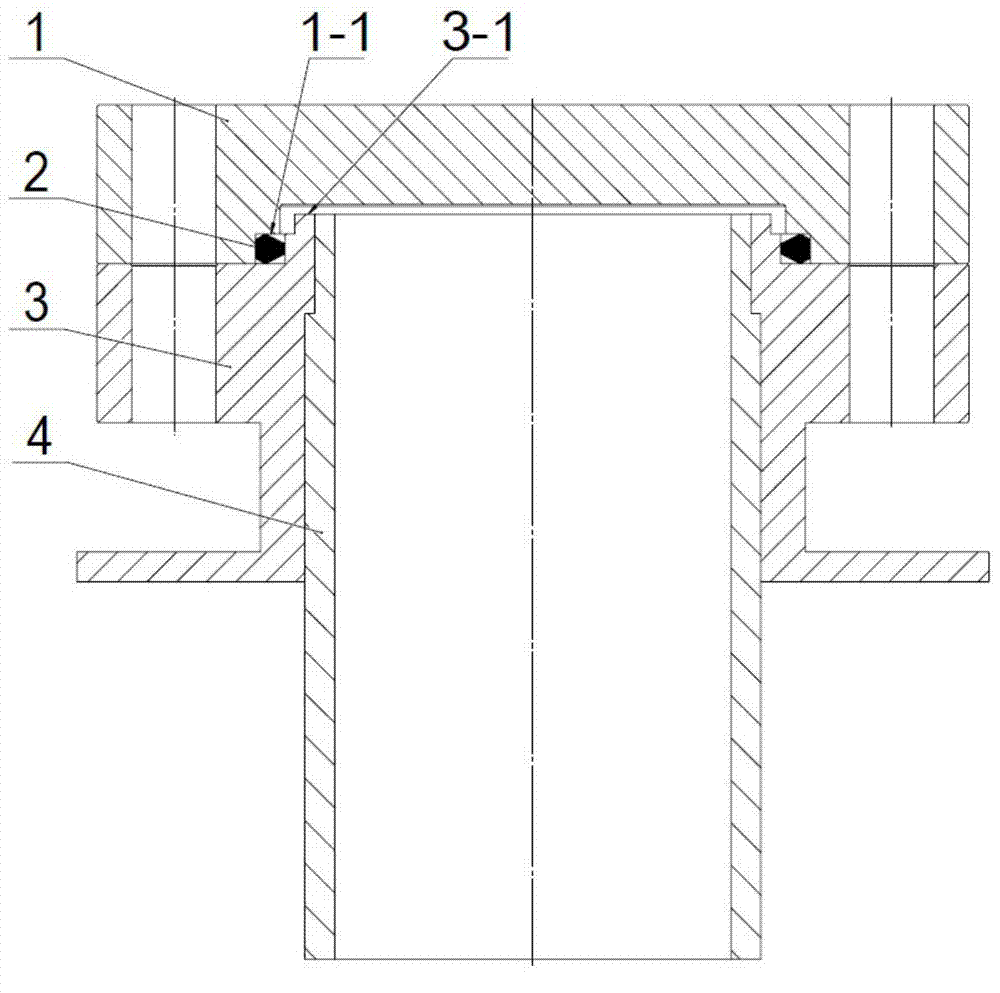

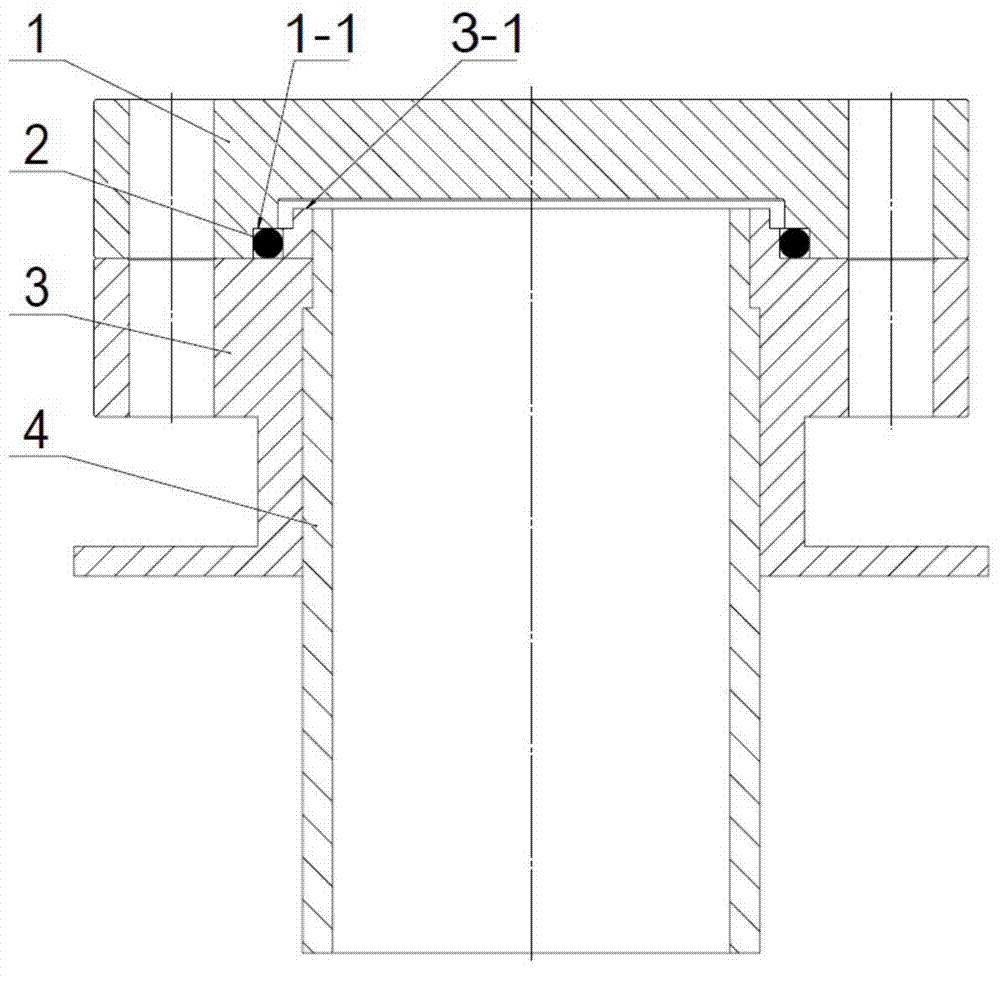

Niobium and titanium flange device with superconducting cavity suitable for two types of washers

The invention belongs to the field of a superconducting acceleration cavity of an accelerator, and provides a niobium and titanium flange device with a superconducting cavity suitable for two types of washers. The device comprises an upper flange and a lower flange, wherein the lower flange is connected with a niobium pipe of a niobium cavity. The device is characterized in that the sealing surface of the upper flange is provided with a right-angled notch, the sealing surface of the lower flange is provided with a boss, a cavity which is formed by the right-angled notch, the sealing surface of the lower flange and the side surface of the boss is a sealing cavity, and the interior of the cavity is provided with a sealing ring. The device has the advantages that the device is suitable for both of the magnalium alloy washer and the indium washer; the vacuum sealing of the cavity is ensured, the usage amount of indium sealing flanges is reduced, the labor and time of installing and detaching the washers are saved, and meanwhile, the pollution to the cavity by the indium is effectively avoided.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

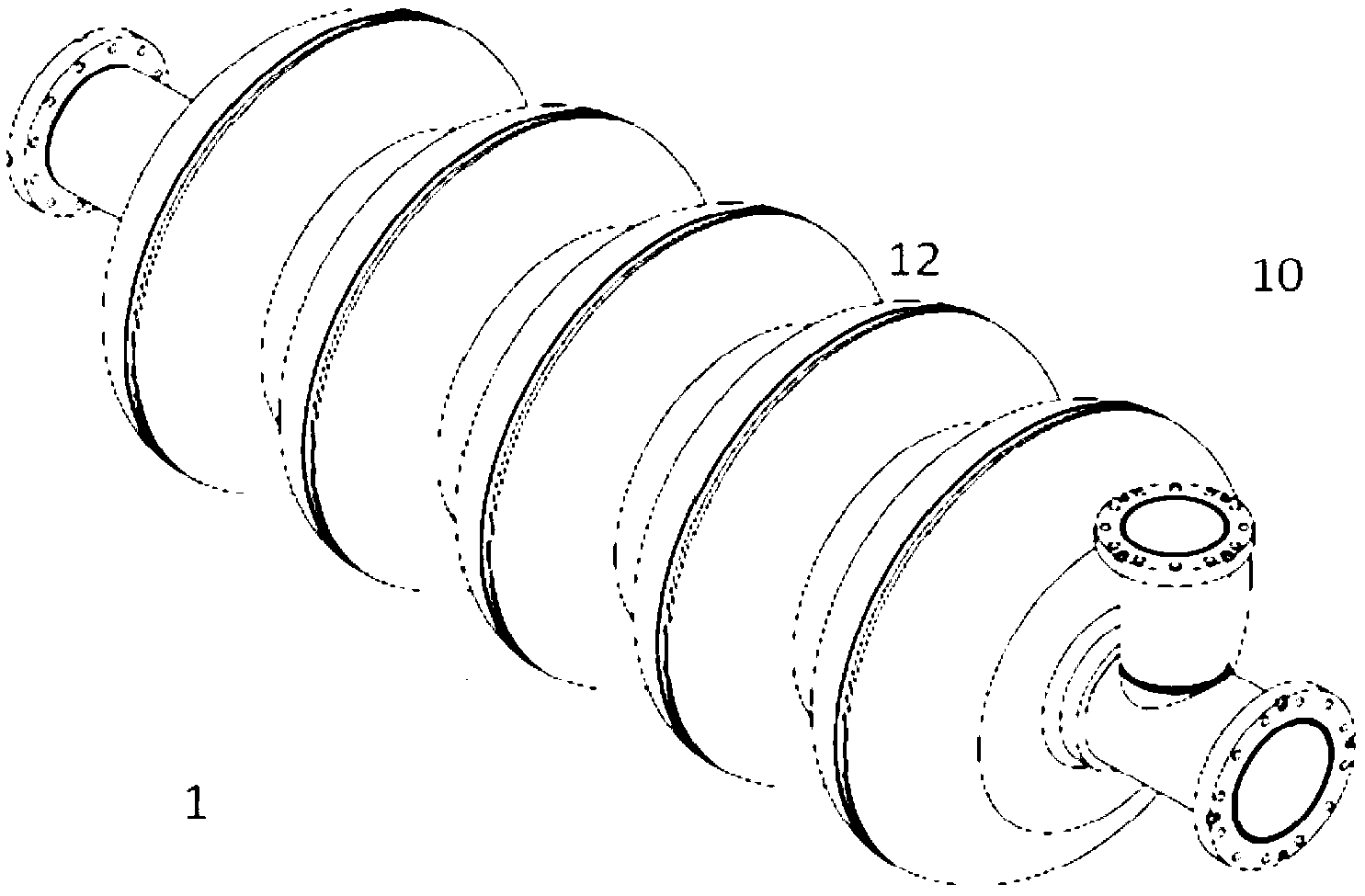

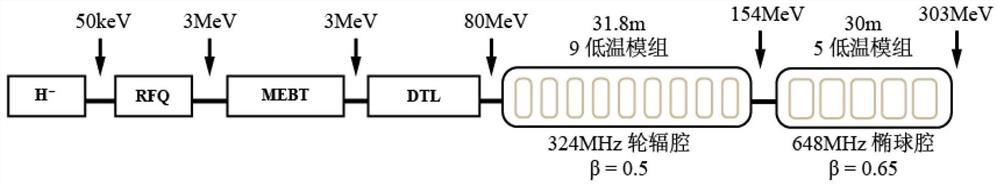

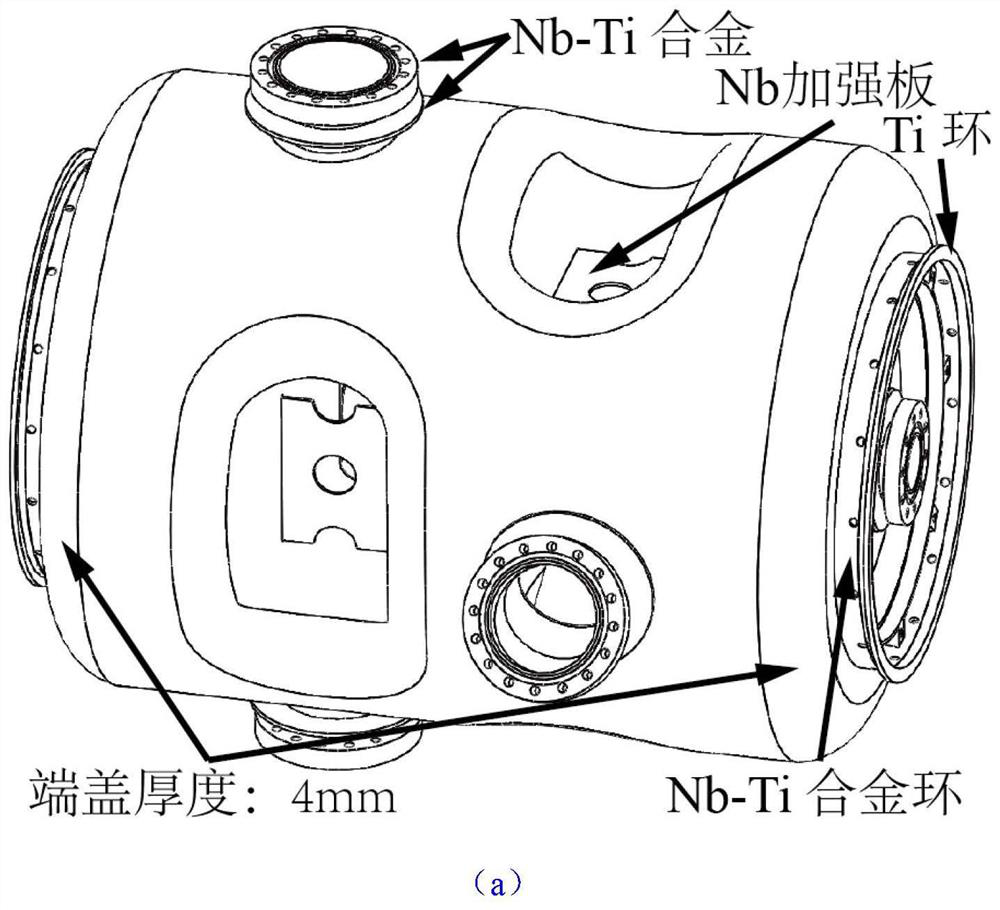

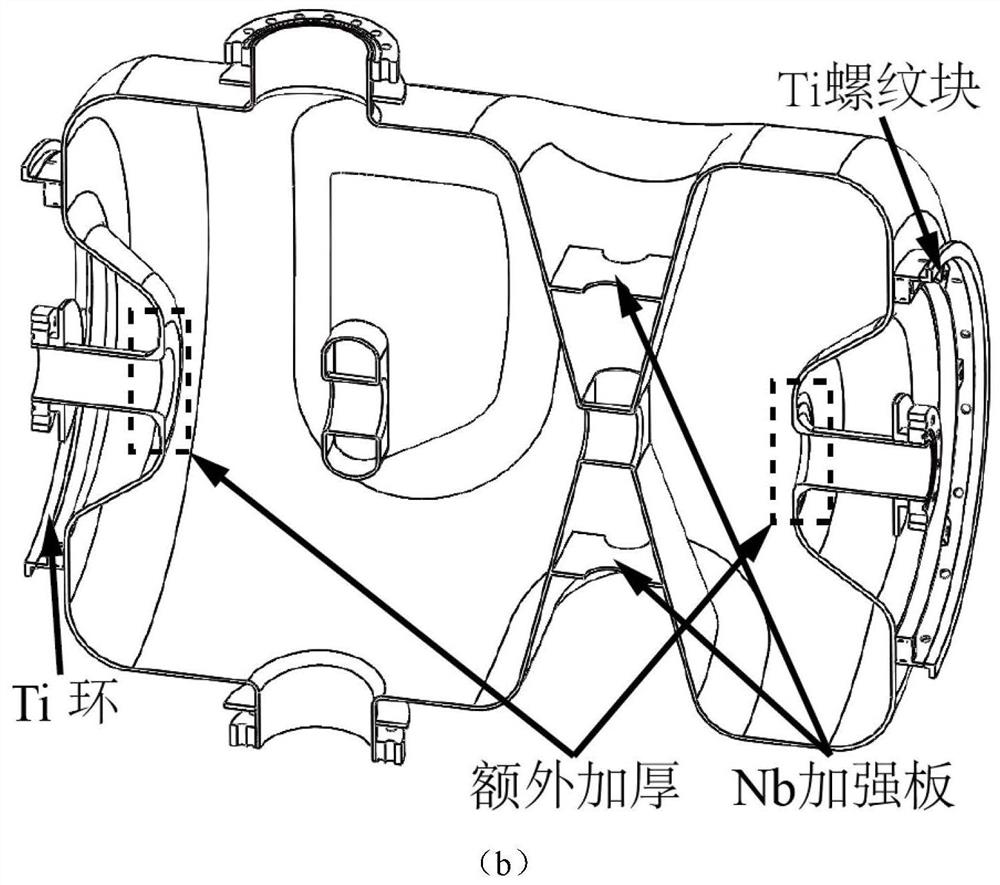

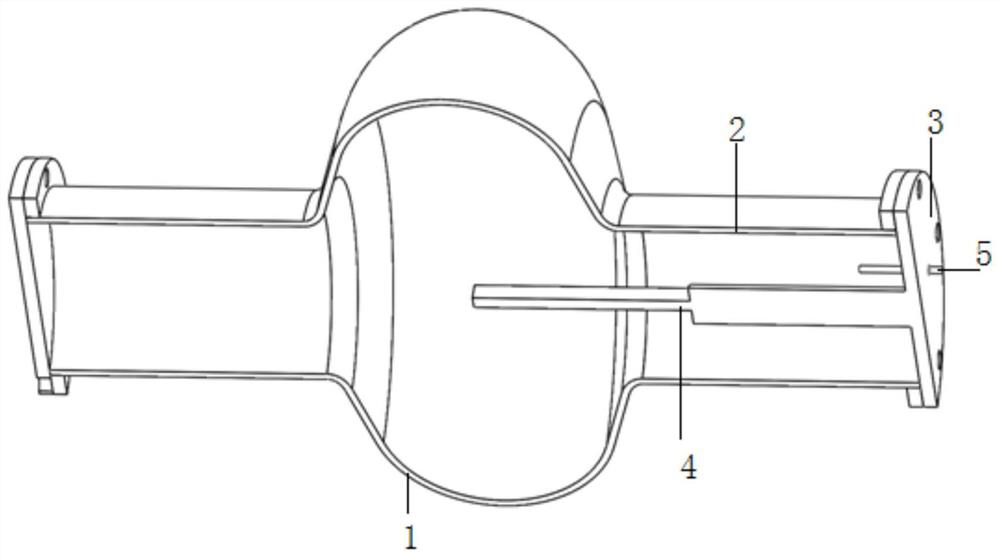

Double-spoke column spoke superconducting cavity and manufacturing method thereof

PendingCN113260132AAchieve preparationVerify operation processAcceleratorsElectrical conductorBeam tube

The invention discloses a double-spoke column spoke superconducting cavity and a manufacturing method thereof. The double-spoke column spoke superconducting cavity is characterized by comprising end covers, spoke columns and an outer conductor, wherein the two spoke columns are arranged in the outer conductor, and drift tubes of the two spoke columns are coaxial; a first opening matched with a cleaning observation port of the double-spoke column spoke superconducting cavity is formed in the outer conductor, and the first opening is connected with the cleaning observation port through a first adapter ring; a second opening matched with a coupler coupling port of the double-spoke column spoke superconducting cavity is formed in the outer conductor, and the second opening is connected with the coupler coupling port through a second adapter ring; two ends of the outer conductor are respectively connected with one end cover; and the drift tubes of the spoke columns are coaxial with beam tubes in the centers of the end covers. According to the double-spoke column spoke superconducting cavity, the design of the manufacturing and processing technology of the double-spoke column spoke cavity is solved, and the manufacturing of the double-spoke column spoke cavity applied to the accelerating section of the proton accelerator is successfully realized.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

Ultrahigh vacuum heat treatment furnace for high-frequency superconducting cavity

InactiveCN109594057ANo pollution in the processGuaranteed uptimeVacuum evaporation coatingSputtering coatingMetallic materialsEngineering

The invention discloses an ultrahigh vacuum heat treatment furnace for a high-frequency superconducting cavity. The ultrahigh vacuum heat treatment furnace comprises a machine frame and an ion pump, wherein the ion pump is installed on the machine frame; the ion pump comprises an ion pump shell, a heating inner container is arranged in the shell, and an outer vacuum chamber is formed between the heating inner container and the shell; an inner vacuum chamber is formed inside the heating inner container, a workpiece conveying pipe is arranged at the top of the shell, and the workpiece conveyingpipe is in communication with the inner vacuum chamber; and a workpiece is conveyed into the inner vacuum chamber from the workpiece conveying pipe, a heater and a heat shielding layer are installed in the outer vacuum chamber, the heat shielding layer surrounds a circle of the inner wall of the outer vacuum cavity, and the heater heats the heating inner container. The ultrahigh vacuum heat treatment furnace is a double-vacuum heat treatment device, the heater, the heat shielding and the like are arranged outside a furnace cavity, so that no other substances exist in the furnace except the metal material of the furnace shell, and an implementation possibility is provided for the environment with ultrahigh vacuum and non-pollution sources.

Owner:深圳四维高科技术有限公司

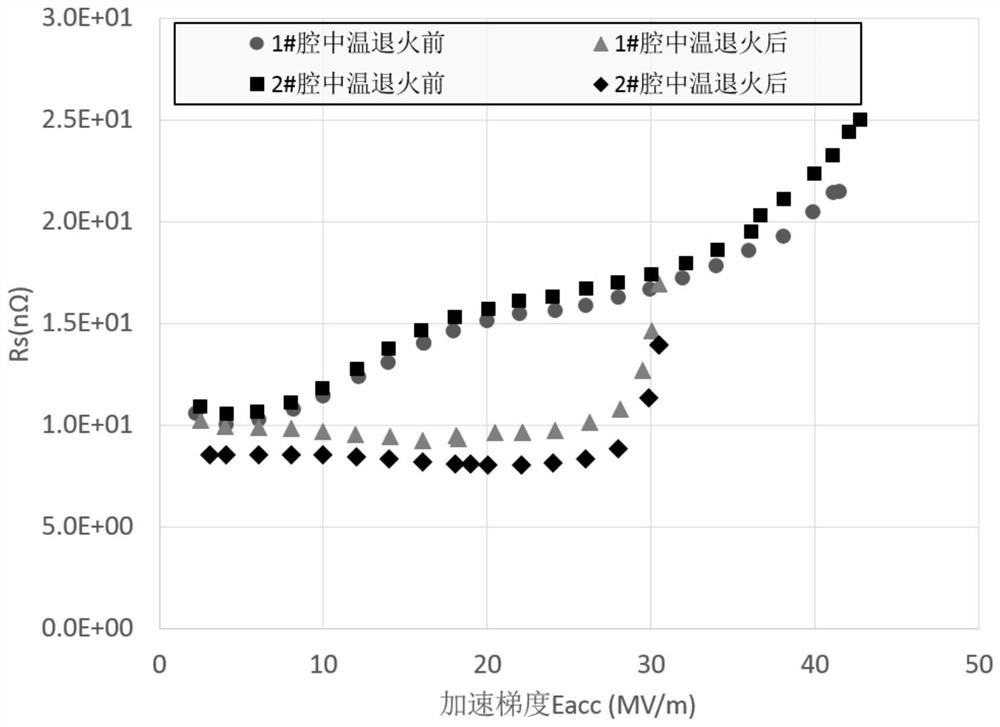

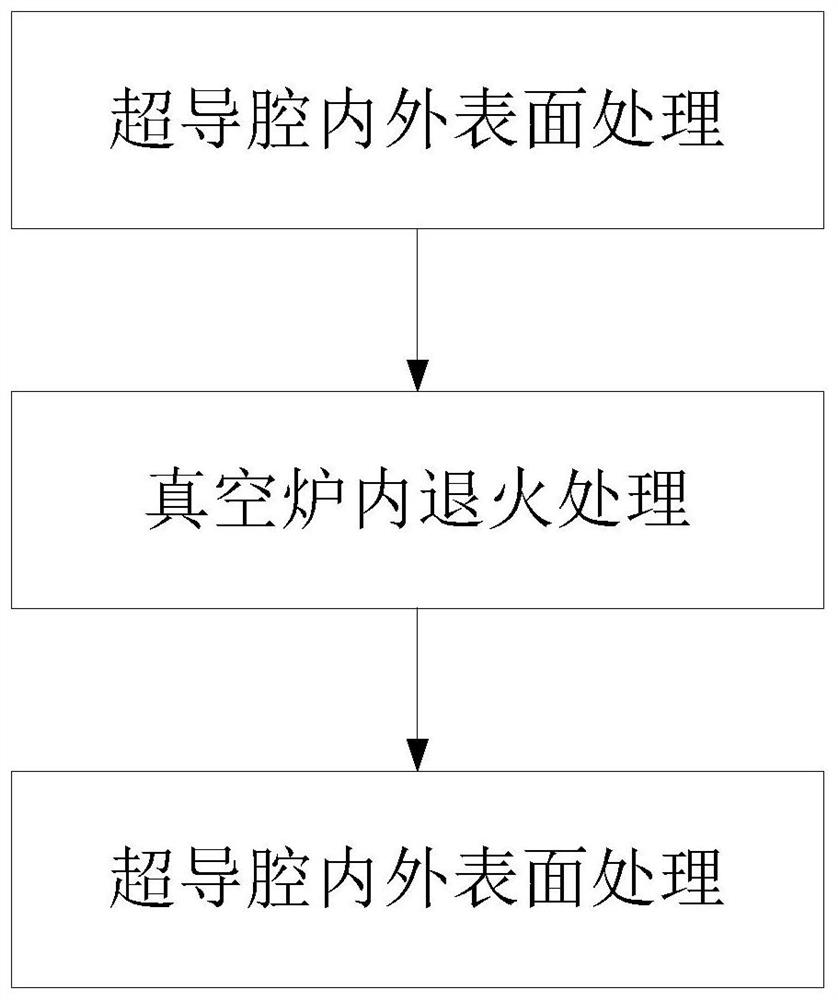

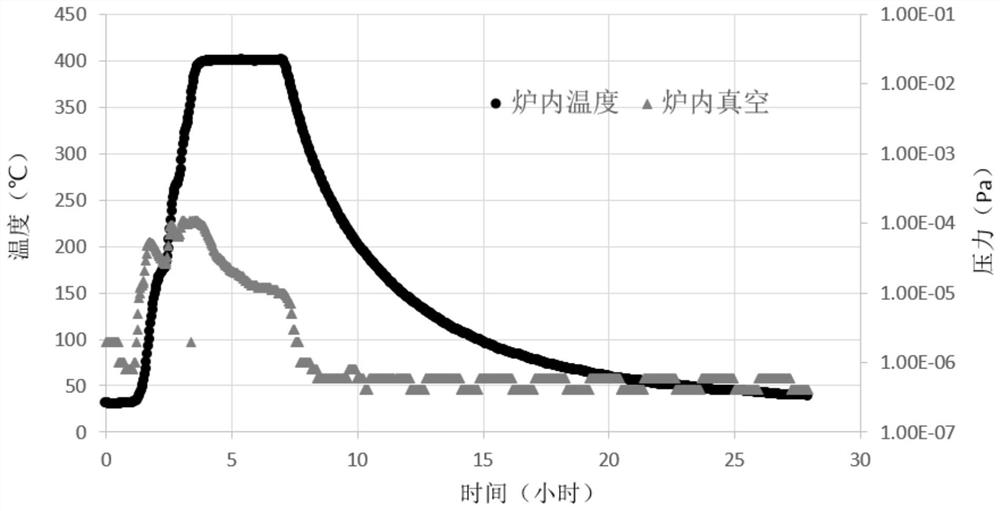

Medium-temperature annealing method for superconducting cavity

ActiveCN111800933AReduce surface resistance RsReduce power consumptionAcceleratorsElectrochemistryPumping vacuum

The invention discloses a medium-temperature annealing method for a superconducting cavity. The method comprises the following steps: 1) carrying out electrochemical polishing and cleaning on the inner surface of the superconducting cavity; 2) if the superconducting cavity is a dehydrogenated superconducting cavity, carrying out the step 3); otherwise, carrying out high-temperature annealing on the superconducting cavity, and then carrying out the step 3); and 3) placing the superconducting cavity in a vacuum furnace, vacuumizing, heating to a medium-temperature area, and carrying out medium-temperature annealing after maintaining the temperature for a period of time. Compared with the traditional superconducting cavity treatment process, the surface resistance of the superconducting cavity can be further reduced, so that the power consumption of the superconducting cavity is reduced, and the process flow can be simplified.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

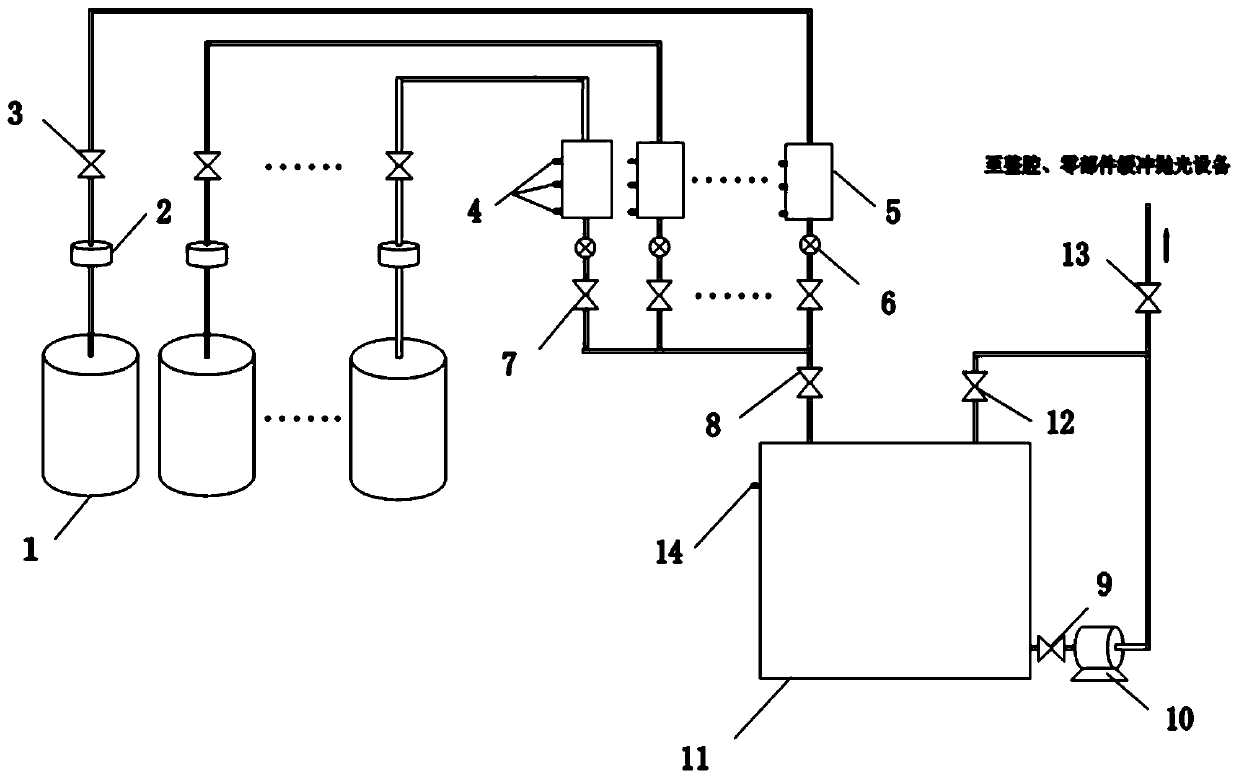

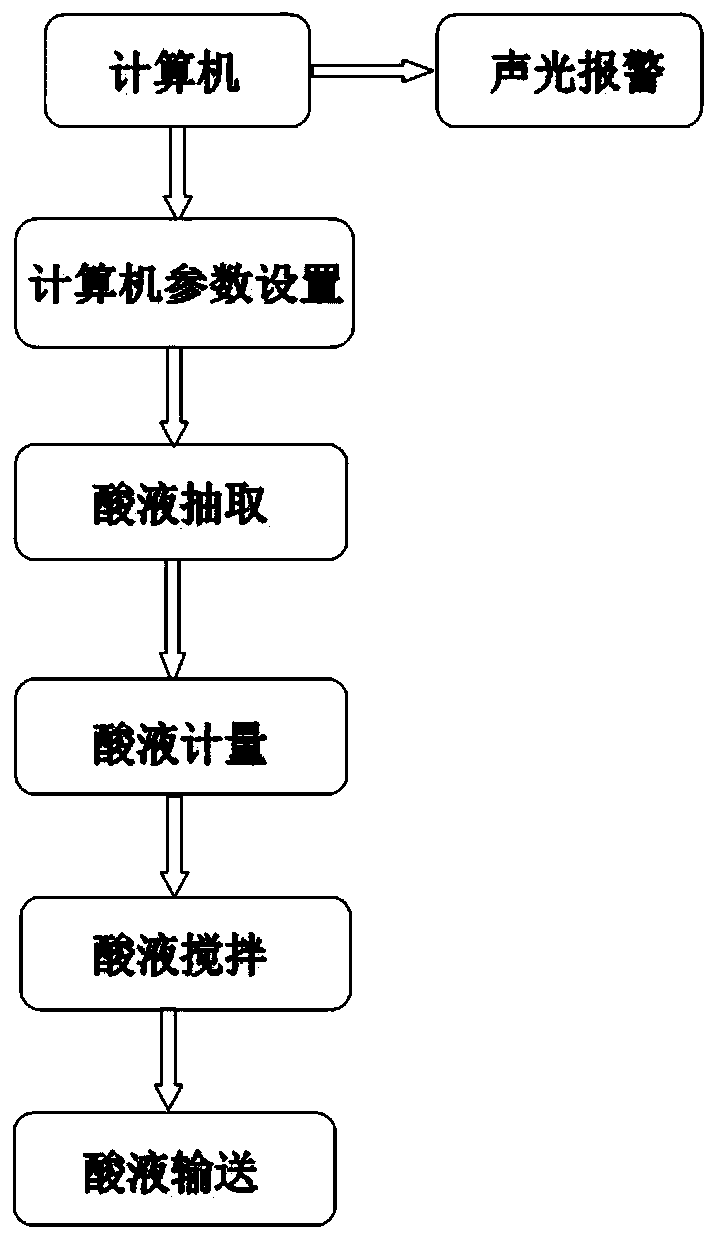

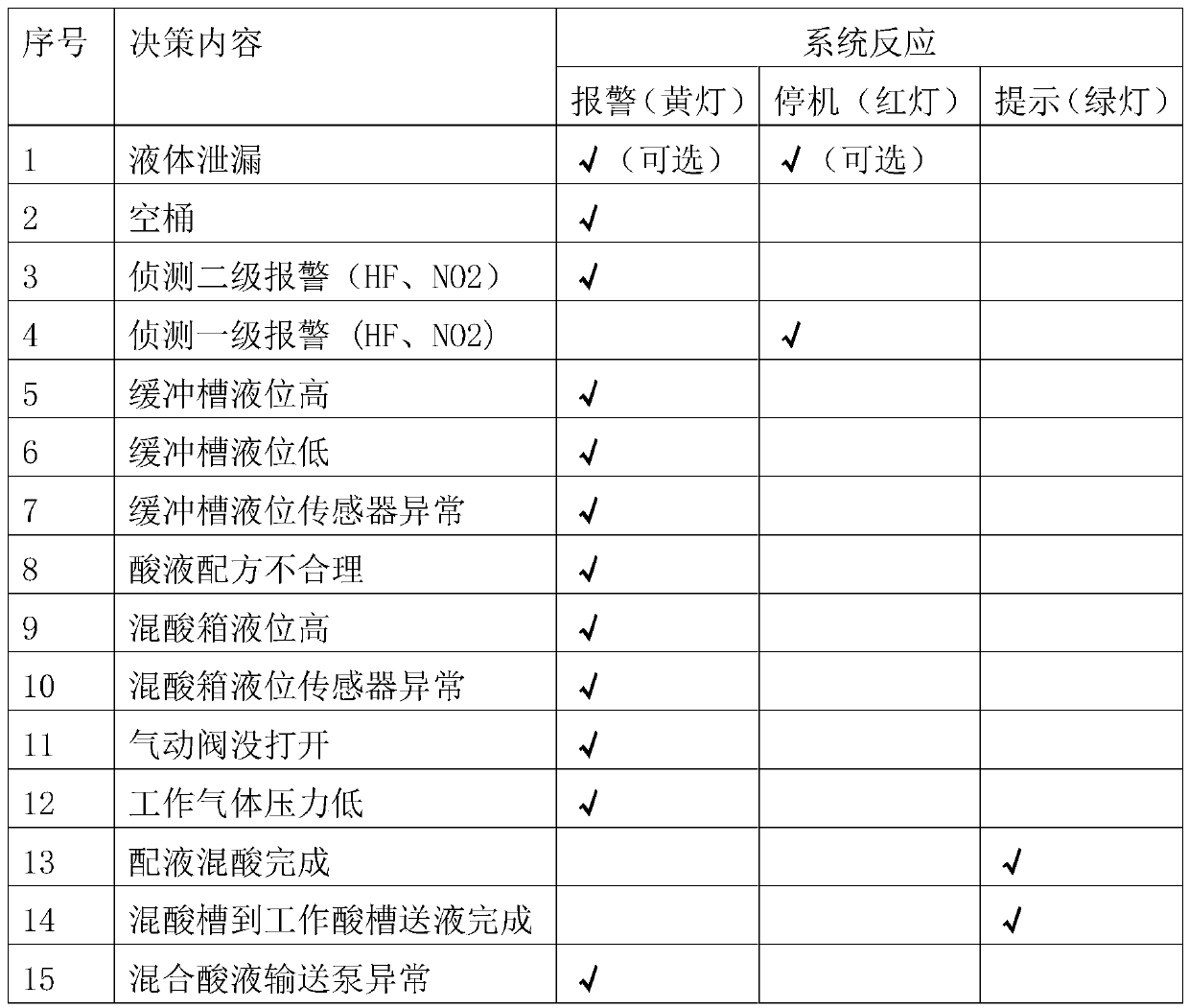

Superconducting cavity surface chemical buffer polishing full-automatic acid liquor preparation device and method

InactiveCN110124545AActual capacity monitoringGuaranteed preparation accuracyTransportation and packagingMixing methodsLoop controlAcid preparations

The invention relates to a superconducting cavity surface chemical buffer polishing full-automatic acid liquor preparation device and method, and the superconducting cavity surface chemical buffer polishing full-automatic acid liquor preparation device comprises an acid mixing box, an acid liquor loop control mechanism and a computer control display system. The top of the acid mixing box is provided with two acid mixing inlets, one acid mixing inlet is connected with a first acid preparation pipeline, the first acid preparation pipeline is connected with more than one acid extraction pipelineswhich are arranged in parallel, and the other ends of acid extraction pipelines are connected with raw acid barrels which are filled with different acid solutions. The other mixed acid inlet is connected with a mixed acid conveying pipeline through a second acid preparation pipeline. The low part of the acid mixing box is provide with a liquid outlet which is connected with the acid mixing conveying pipeline through a liquid outlet pipeline. The other end of the mixed acid conveying pipeline is connected with whole cavity chemical buffer polishing equipment or component chemical buffer polishing equipment. The acid liquor loop control mechanism is arranged on each pipeline and may control acid liquor in each pipeline under the control of the computer control display system. The superconducting cavity surface chemical buffer polishing full-automatic acid liquor preparation device can be widely applied to the accelerator manufacturing field.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

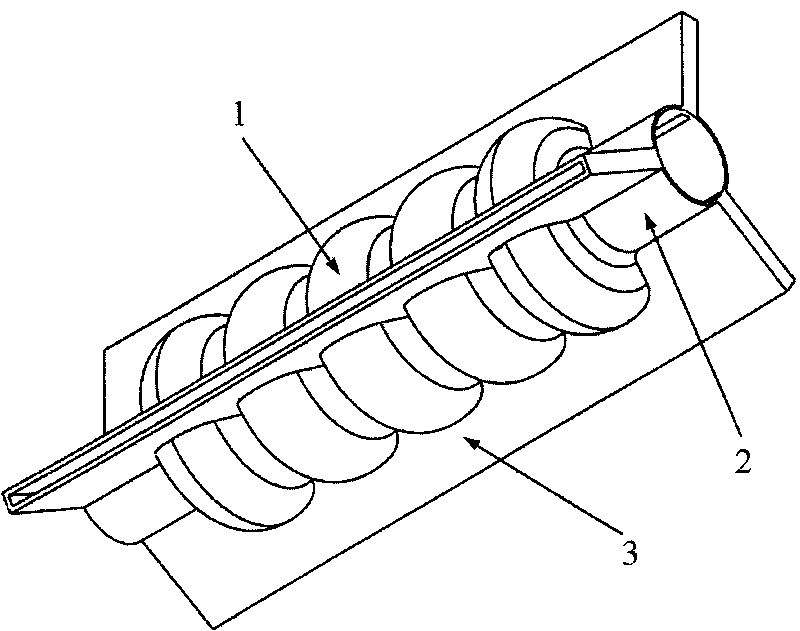

Electromagnetic induction structure for locally heating tin source in superconducting cavity

PendingCN113817990AAchieve localized heatingRealize local heating and individual temperature controlVacuum evaporation coatingSputtering coatingTemperature controlCrucible

The invention discloses an electromagnetic induction structure for locally heating a tin source in a superconducting cavity. The electromagnetic induction structure comprises the superconducting cavity with a plurality of acceleration units, an electromagnetic induction heating coil, a tin source crucible, a supporting straight rod and a temperature thermocouple. The superconducting cavity is of a substrate structure for Nb3Sn film growth; one end of the electromagnetic induction heating coil is connected with the positive electrode of an alternating power supply, the other end of the electromagnetic induction heating coil is connected with the negative electrode of the alternating power supply, and the electromagnetic induction heating coil is used for heating the tin source placed in the coil; one tin source crucible is placed in each acceleration unit of the superconducting cavity, and the tin source crucible is a container for containing tin metal particles; the supporting straight rod is used as a supporting structure of the tin source crucible; and the temperature thermocouple is used for measuring the temperature in the superconducting cavity. According to the electromagnetic induction structure for locally heating the tin source in the superconducting cavity, local heating can be carried out on a plurality of tin sources in the superconducting cavity of the multiple acceleration units, and independent temperature control of the superconducting cavity and the tin sources is realized in each acceleration unit, so that each acceleration unit has the same'superconducting cavity-tin source 'temperature combination.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

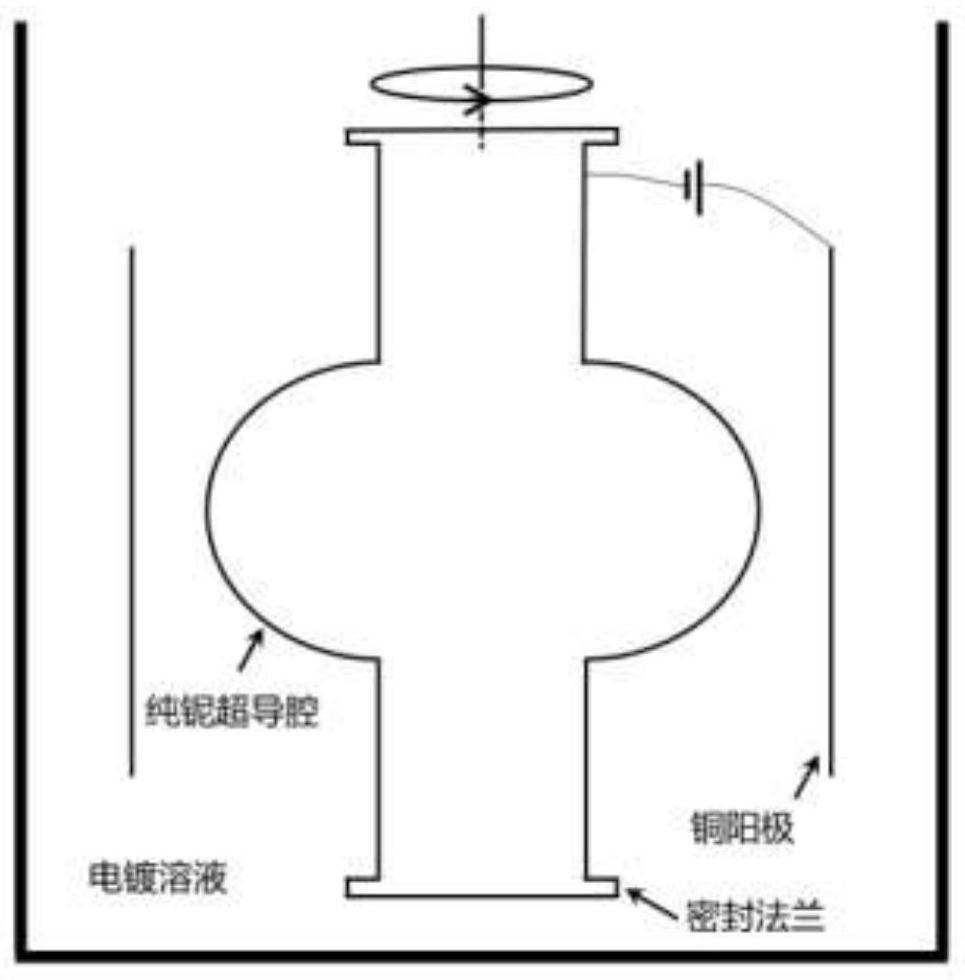

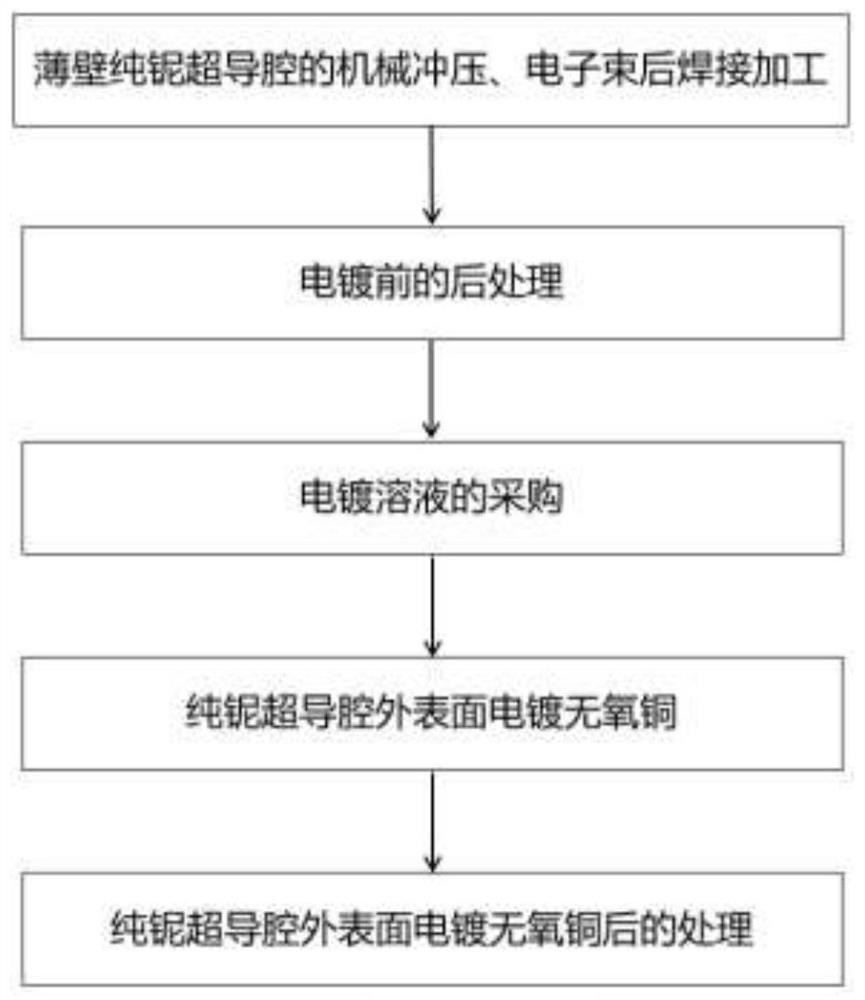

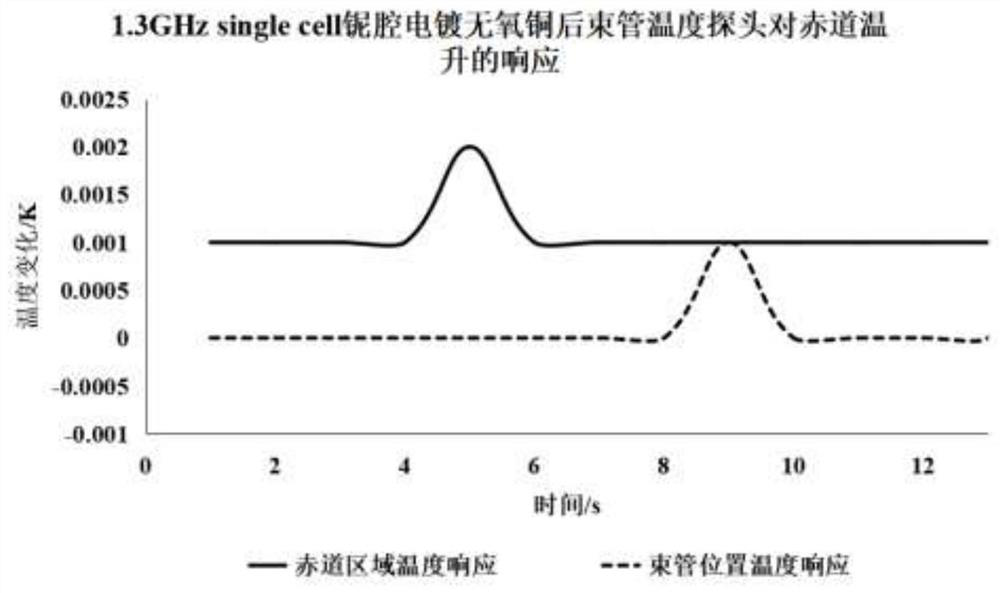

Preparation method of copper-based thick-wall niobium-based superconducting cavity

The invention discloses a preparation method of a copper-based thick-wall niobium-based superconducting cavity by electroplating oxygen-free copper on the outer surface. The method comprises the following steps: 1) carrying out mechanical stamping and electron beam welding processing on the thin-wall pure niobium superconducting cavity; 2) pretreating before electroplating of a pure niobium superconducting accelerating cavity, such as high-temperature degassing, inner and outer surface BCP polishing and ultrasonic cleaning; (3) preparing an oxygen-free copper electroplating solution; 4) electroplating oxygen-free copper on the outer surface of the pure niobium superconducting accelerating cavity; and (5) post-processing after electroplating the oxygen-free copper on the outer surface of the pure niobium superconducting accelerating cavity. The copper-based thick-wall niobium-based superconducting cavity developed by the invention is high in oxygen-free copper layer density, low in porosity, small in thermal reaction, large in copper wall thickness tolerance, low in batch production cost, capable of remarkably improving the mechanical stability and the thermal stability of the superconducting cavity on the premise of ensuring that the radio frequency performance of the copper-based thick-wall niobium-based superconducting cavity is not lower than the level of a pure niobium superconducting cavity; and suitable for large scientific devices based on the radio frequency superconducting accelerator technology.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

A long-life storage device and storage method for superconducting qubits

The invention discloses a superconducting qubit long-life storage device and a storage method thereof. The present invention adopts a three-dimensional ellipsoid radio frequency superconducting film cavity with a high quality factor, which has great advantages compared with the currently used rectangular cavity: the quality factor is as high as 10 10 ; and the superconducting qubit is coupled with the superconducting cavity, and the decoherence time of the superconducting qubit is increased to the order of hundreds of milliseconds to seconds, thereby clearing the way for the realization of the manipulation, measurement and quantum storage of the qubit; The invention will be beneficial to obtain long-life superconducting qubits, which are of great significance to quantum computing, quantum storage, quantum information and quantum communication; the invention is the first to apply a three-dimensional ellipsoidal radio frequency superconducting thin film cavity to superconducting quantum In computing, the mature superconducting cavity technology is combined with the emerging superconducting quantum computing to push superconducting quantum computing a step forward.

Owner:PEKING UNIV

Preparation method of copper-niobium composite radio frequency superconducting resonant cavity

ActiveCN113973419ARealize developmentGood low temperature radio frequency superconducting propertiesAcceleratorsWaveguide type devicesNiobiumRadio frequency

The invention discloses a preparation method of a copper-niobium composite superconducting resonant cavity. The method comprises the following steps: 1) preparing a pure niobium superconducting cavity; 2) sequentially carrying out mechanical polishing, cleaning solution cleaning, ultrasonic ultrapure water cleaning and acid solution polishing on the inner and outer surfaces of the pure niobium superconducting cavity prepared in the step (1), removing residual acid on the surface of a material, and sequentially carrying out sand blasting and reverse plating electrocleaning treatment on the outer surface of the superconducting cavity after the residual acid is cleaned; 3) preparing a niobium-copper eutectic bond bonding structure on the outer surface of the pure niobium superconducting cavity: a, electroforming a transition metal layer on the outer surface of the pure niobium superconducting cavity; b, electroforming copper on the metal surface of the transition metal layer; and c, enabling the niobium-transition layer metal-copper layer to be subjected to vacuum high-temperature annealing, and generating inter-atomic eutectic bond bonding is generated on the copper and niobium layers through transition metal; 4) electroforming a thick copper layer on the copper layer on the outer surface of the superconducting cavity prepared in the step 3); and 5) performing finish machining on the outer surface of the superconducting cavity prepared in the step 4) to obtain the copper-niobium composite superconducting resonant cavity.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI +1

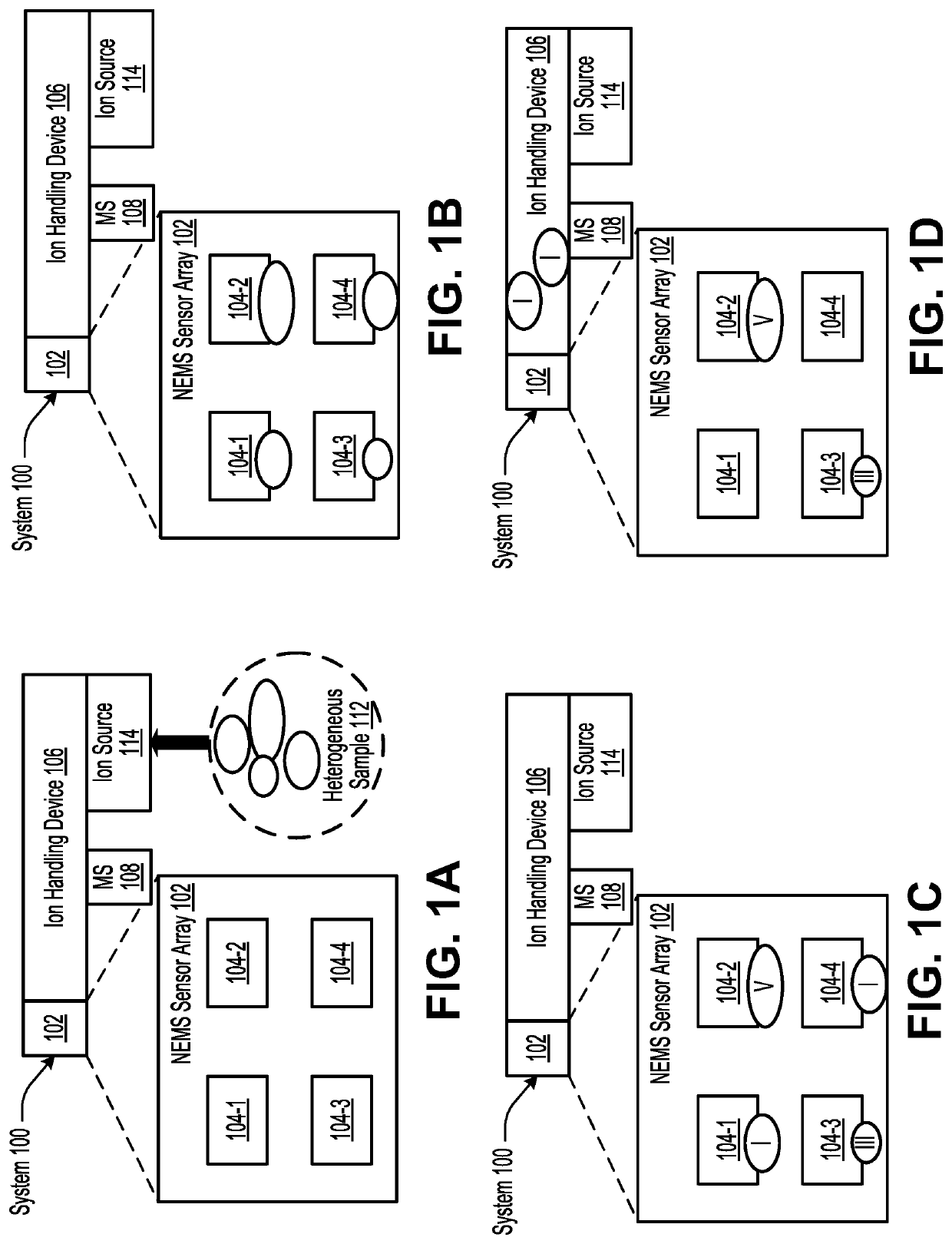

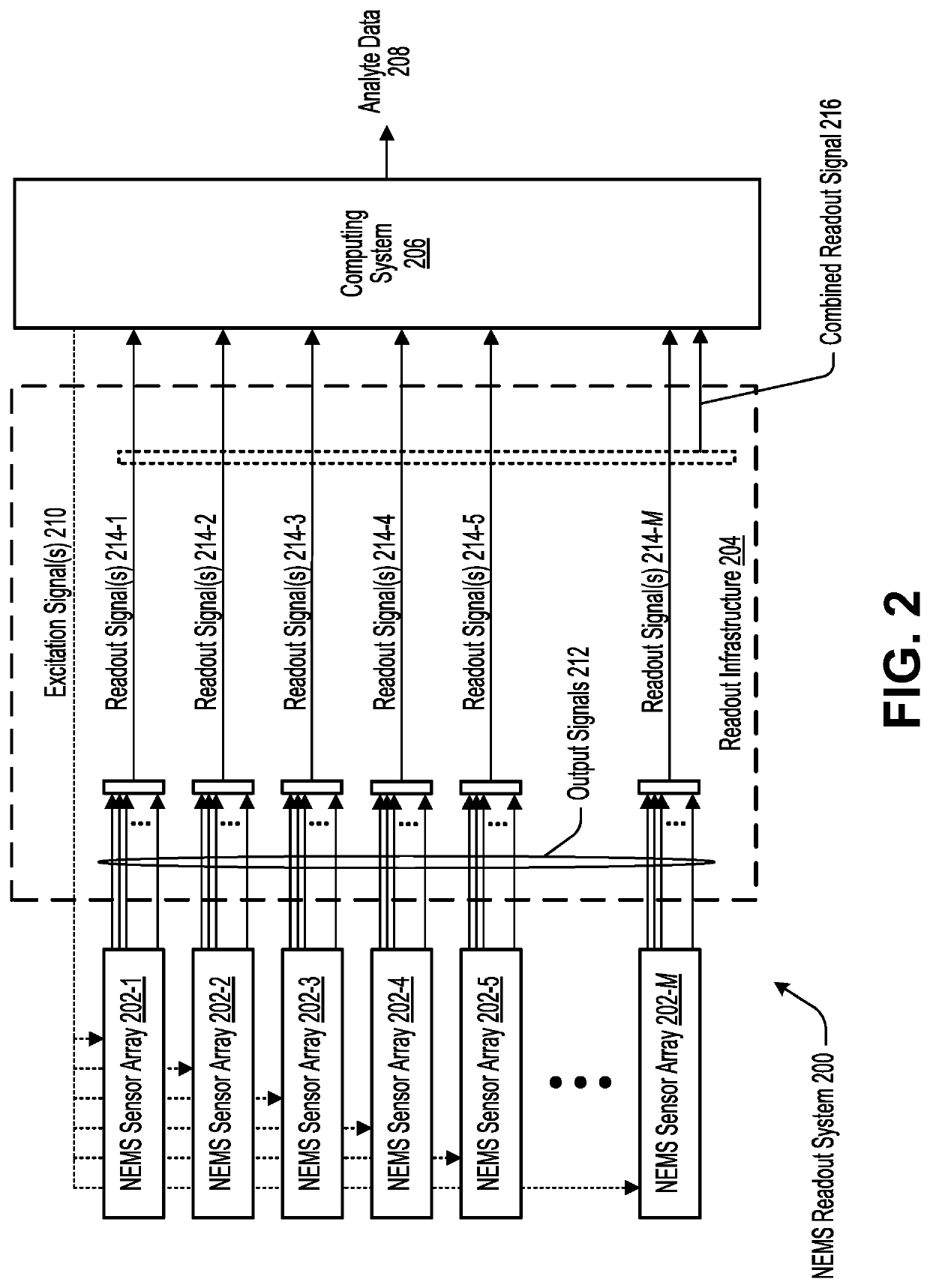

Highly-multiplexed NEMS-array readout system based on superconducting cavity optomechanics

ActiveUS11187663B2Efficient readoutImprove adsorption capacityMaterial analysis using microwave meansResponse signal detectionSensor arrayEngineering

Owner:CALIFORNIA INST OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com