Dry treatment method for superconductor cavity

A technology for dry processing and superconducting cavity, which is applied in the field of dry processing the surface of superconducting cavity, can solve the problems of increasing power and increasing acceleration field strength, complicated device and high cost, and achieves good processing effect and simple structure. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

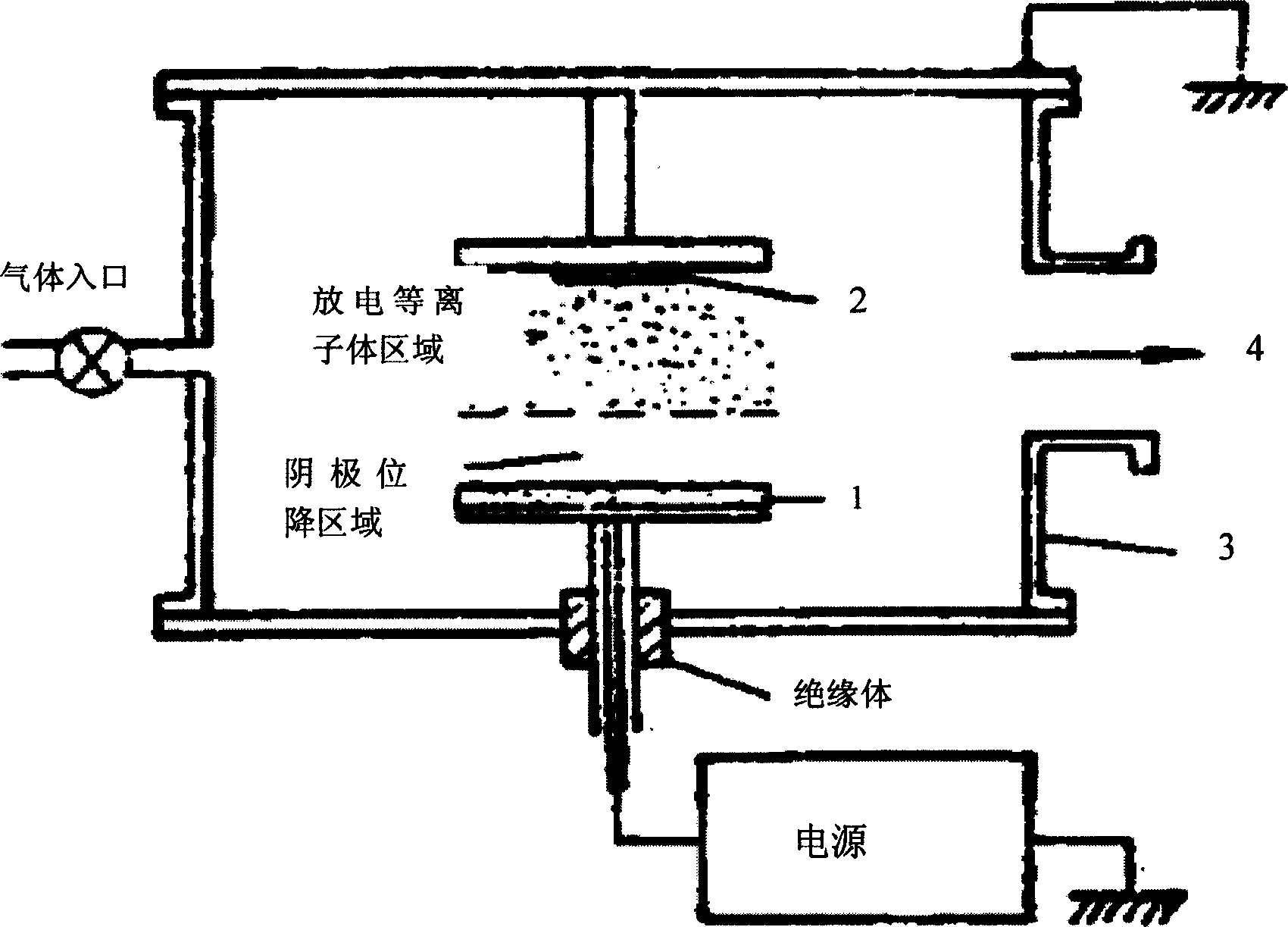

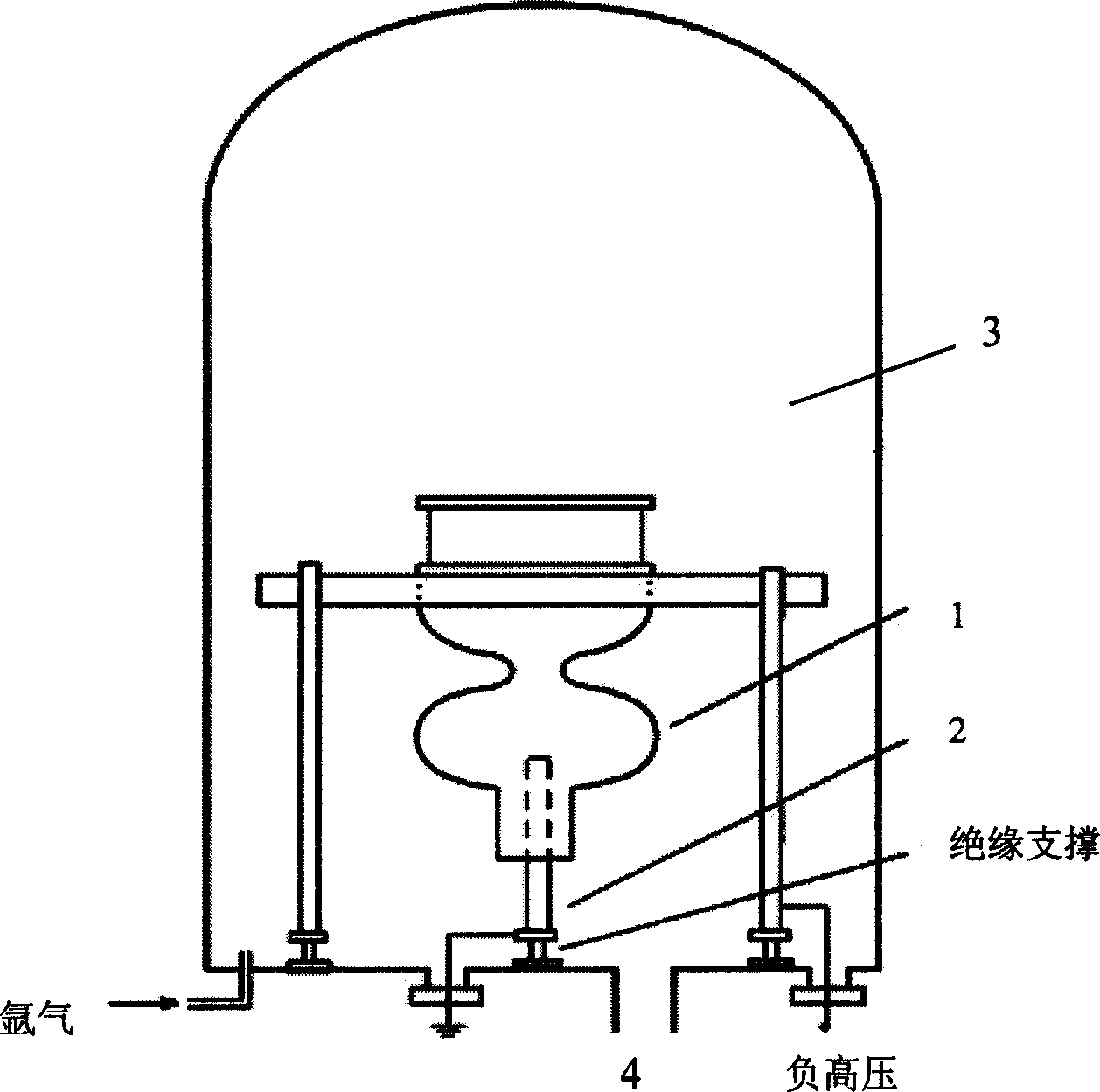

[0024] Such as figure 2 Shown is a schematic structural diagram of an implementation device of a preferred embodiment of the present invention. In one embodiment of the present invention, the substrate 2 uses a titanium rod as the anode and is grounded; the superconducting cavity 1 is used as the cathode and is connected to negative high voltage. Wherein, the superconducting cavity 1 selects the DC-SC photocathode injector designed and developed by the radio frequency superconducting laboratory of Peking University, and its main body is a 1+1 / 2 pure niobium superconducting cavity (Hao Jiankui et al.: for high average power FEL DC-SC Photocathode Injector. Intense Lasers and Particle Beams, Volume 14, Issue 3, May 2002), prior to sputter polishing, pure niobium superconducting cavities were subjected to conventional surface treatments, including: mechanical Polishing (rolling), high pressure water washing, chemical polishing, electropolishing and high temperature treatment at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com