Spoke superconducting cavity tuner

A superconducting cavity tuning and tuner technology, which is applied in the direction of accelerators, electrical components, etc., can solve the problems of limiting the displacement of the auxiliary arm, small tuning range, and difficult maintenance, so as to increase the tuning range and ensure The effect of stable operation and simplified complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

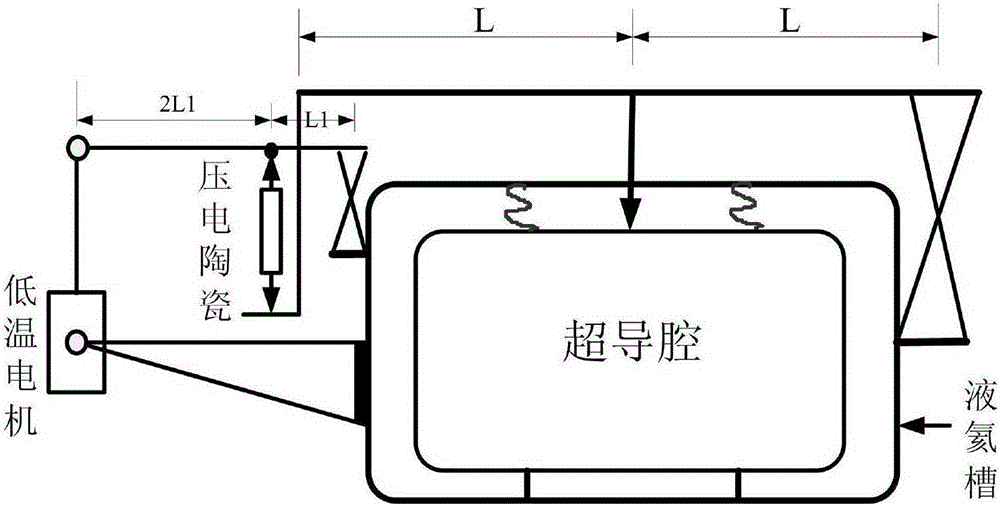

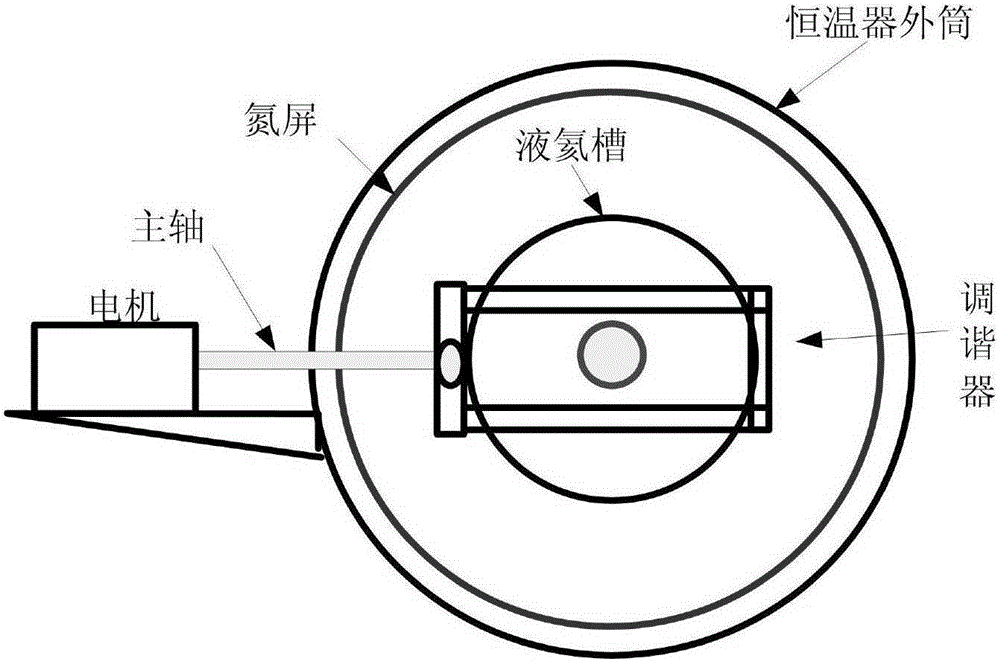

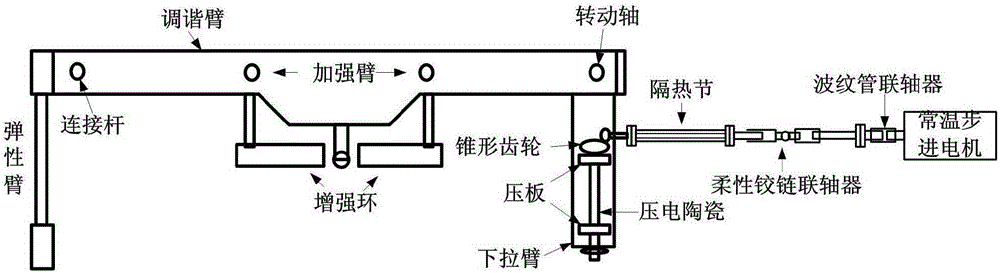

[0038] Such as figure 2The schematic diagram of the conceptual design of the tuner is shown. The mechanical actuator of the Spoke superconducting cavity tuner is placed inside the thermostat and directly connected to the liquid helium tank. In order to reduce the failure rate of the tuner and reduce the maintenance time of the superconducting cavity system, the motor of the tuner is placed outside the thermostat. This design requires the motor shaft to pass through the 80K nitrogen screen and the outer cylinder of the 300K thermostat, and the motor is fixed on the outer cylinder of the thermostat through an external bracket. The operating temperature of the mechanical actuator part of the tuner is about 5K to 10K, and the high vacuum is 1×10 -6 Pa, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com