Machining method of high-RRR-value high-purity niobium material and niobium material for radio frequency superconducting cavity

A processing method and high-purity technology, applied in accelerators, electrical components, etc., can solve the problems that the RRR of the finished sheet cannot reach more than 300, the gas elements cannot meet the corresponding requirements, the grain size is uneven, etc., and achieve large market promotion value. With the effect of protecting value, improving product direct yield, and improving isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

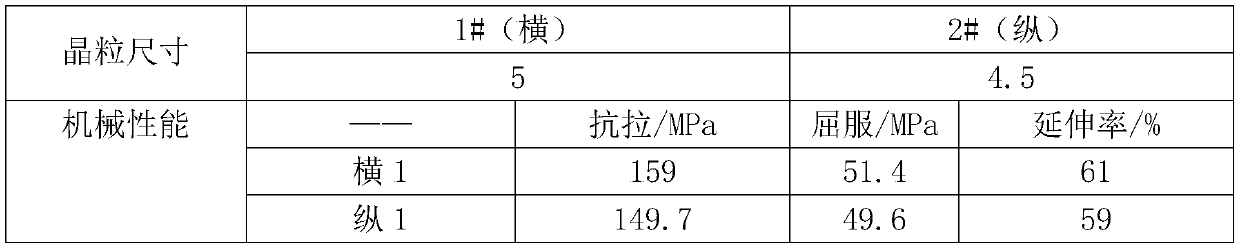

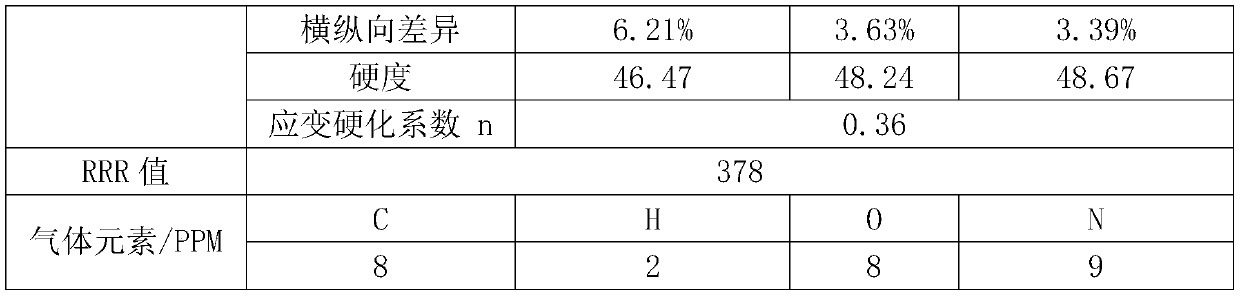

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a processing method for high-purity niobium material with high RRR value. The processing method for high-purity niobium material with high RRR value comprises the following steps:

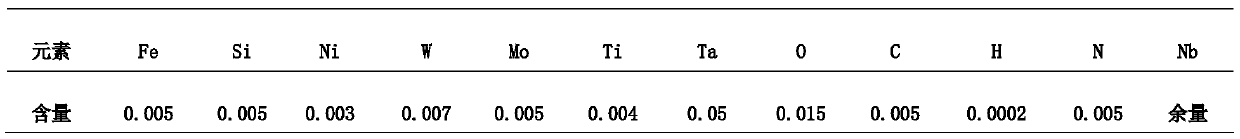

[0041] (1) The RRR300 superconducting niobium ingot is obtained by electron beam melting. The diameter of the superconducting niobium ingot is 285 mm and the length is 1250 mm. The composition of the ingot is shown in Table 1. Table 1 is the elemental composition of the superconducting niobium ingot data sheet;

[0042] Table 1 Elemental composition data table of superconducting niobium ingot

[0043]

[0044] (2) The superconducting niobium ingot obtained in step (1) is ultrasonically tested, and then the superconducting niobium ingot is radially squared, axially elongated, and rounded. The specific forging sequence and dimensional changes are as follows: first, the cast The ingot is forged into a square end face with a size of 240×Lmm→th...

Embodiment 2

[0059] (1) The RRR300 superconducting niobium ingot is obtained by electron beam melting. The diameter of the superconducting niobium ingot is 285 mm and the length is 400 mm. The composition of the ingot is shown in Table 2;

[0060] Table 2 Elemental composition data table of superconducting niobium ingot

[0061]

[0062] (2) The superconducting niobium ingot obtained in step (1) is ultrasonically tested, and then the superconducting niobium ingot is radially squared, axially elongated, and rounded. The specific forging sequence and dimensional changes are as follows: first, the cast The ingot is forged into a square end face with a size of 240×Lmm→the end face is an equilateral octagon with a size of 240×Lmm→the end face is a square with a size of 200×Lmm→the end face is an equilateral octagon with a size of 200×Lmm →The end face is square, the size is 170×Lmm→The end face is equilateral octagon, the size is 170×Lmm→The end face is square, the size is 160×Lmm→The end fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com