Superconducting accelerator, superconducting cavity for same and manufacturing method of superconducting accelerator

A superconducting cavity and accelerator technology, applied in cooling/ventilation/heating transformation, electrical components, accelerators, etc., can solve the problems of superconducting cavity gradient cannot be increased, liquid helium evaporation, quenching, etc., to achieve quench suppression The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0015] The applicant found that for the currently applied superconducting cavities, as the acceleration gradient increases, a quench phenomenon (quench) often occurs, that is, due to local defects on the inner surface of the superconducting cavity (which can be impurities, cracks, lattice defects, etc. ) generates a large amount of heat under high-intensity electromagnetic field, and the heat cannot be quickly transferred to the liquid helium in the cooling system, resulting in an increase in the temperature of the defect site, and at the same time, the cavity wall in the superconducting state around the defect is transformed into a non-superconducting state, and the surrounding The cavity wall in the non-superconducting state will generate a large amount of heat under the high-intensity electromagnetic field, which makes this process continue a vicious cycle, and finally causes the entire superconducting cavity to instantly change from a superconducting state to a non-supercond...

no. 2 approach

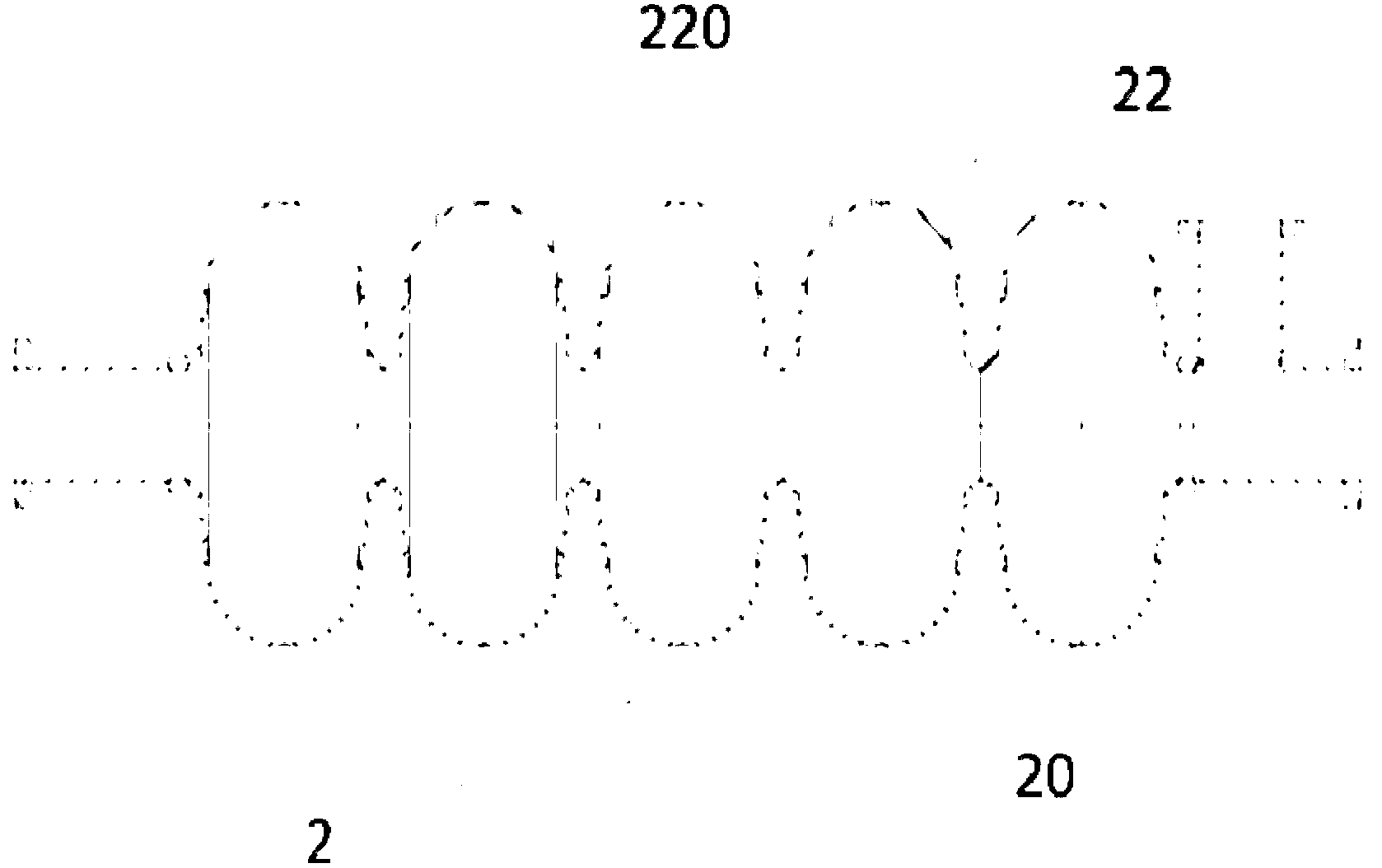

[0022] Such as figure 2 As shown, in this embodiment, the superconducting cavity 2 of the present invention includes an outer surface 20, which is a non-smooth surface, that is, the outer surface 20 of the superconducting cavity 2 is provided with a heat dissipation structure. In this embodiment, the heat dissipation structure is a heat dissipation device 22 , and the heat dissipation device 22 is directly attached to the outer surface 20 of the superconducting cavity 2 . The heat sink 22 is made of a material with good heat dissipation performance, such as niobium, aluminum, copper or a mixture of niobium, aluminum and copper, and the like. The heat dissipation device 22 includes a plurality of heat dissipation fins 220 through which the heat dissipation surface area of the outer surface 20 of the superconducting cavity 2 can be effectively increased. The heat dissipation device 22 can effectively increase the heat dissipation surface area of the outer surface 20 of the...

no. 3 approach

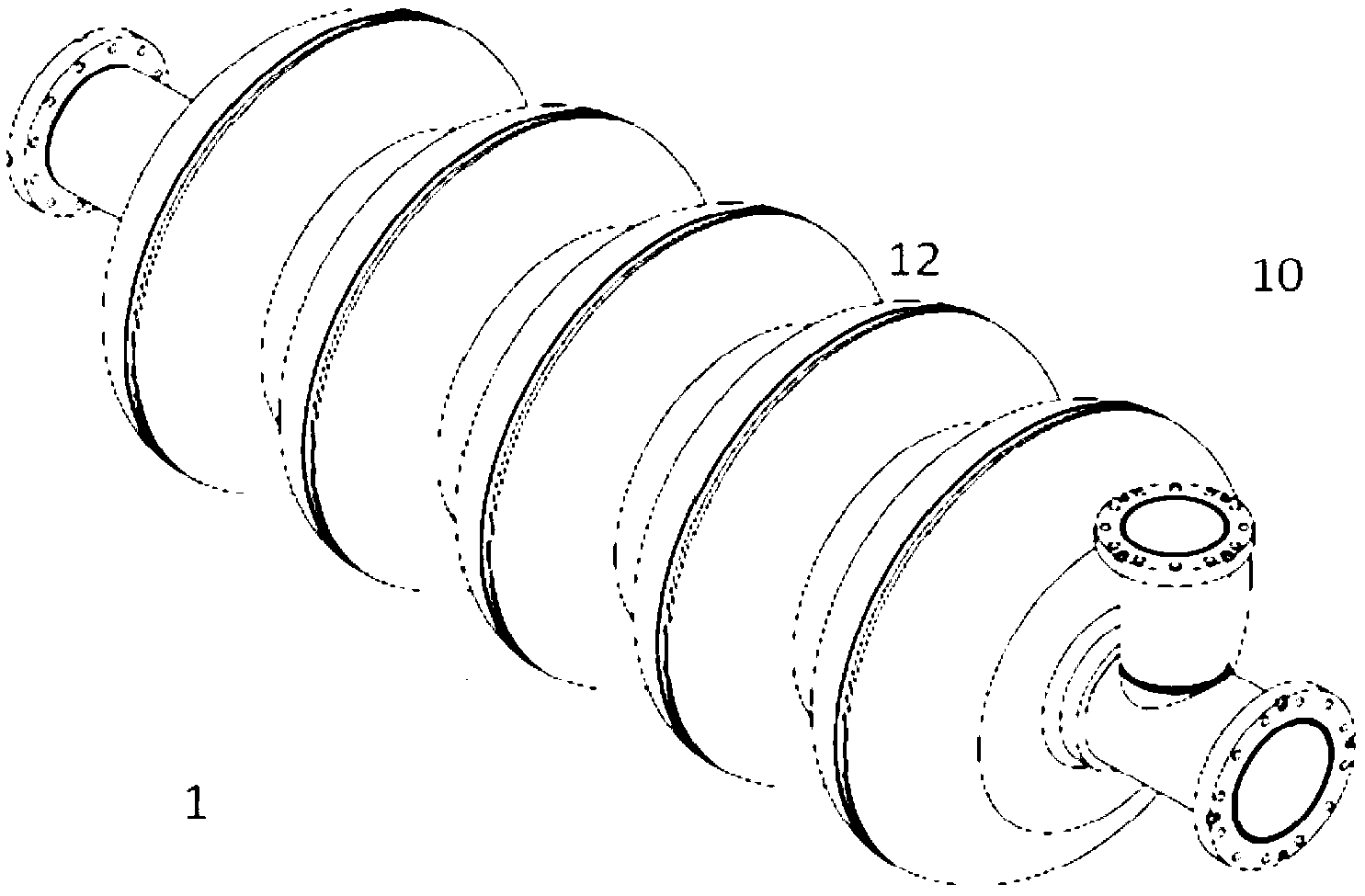

[0028] The difference between the preparation method of the superconducting cavity 1 in the above-mentioned first embodiment and the traditional superconducting cavity is the processing steps of the outer surface of the superconducting cavity 1, that is, the preparation method of the superconducting cavity 1 of the present invention is different from that of the traditional superconducting cavity. The cavity preparation method is different in that it includes the step of: performing groove or drilling on the outer surface 10 of the superconducting cavity 1 to form grooves 12 or depressions.

[0029] The specific process steps of processing the outer surface 10 of the superconducting cavity 1: 1. Groove or punch the outer surface of the half cavity before welding the half cavity; 2. After the processing is completed, it can be carried out according to the conventional superconducting cavity manufacturing process welding. Specifically, in the first step, since the niobium cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com