Construction of superconducting multi-core billet and method for manufacturing superconducting multi-core wires

A technology of superconducting blanks, applied in the field of physical structure of superconducting multi-core blanks, to achieve the effect of reducing manufacturing time and eliminating local concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] In an embodiment of the present invention, the multi-core superconducting blank is formed by preparing a plurality of vertical holes in a circular cross-section copper or copper alloy blank, wherein the vertical holes are filled with a superconducting material including Nb. The volume ratio of copper or copper alloy to the superconducting material used in the billet is called the copper ratio.

[0043] Typically, the customer sets requirements for the range of copper ratios (ie, the volume ratio of copper to NbTi), the diameter of the superconducting wire, the diameter of the superconducting filament, and other details. In most cases in this context, the manufacturer determines the detailed physical structure of the superconducting wire according to the requirements set by the customer. If you specify three parameters: wire diameter d, superconducting filament diameter d sc , Copper ratio m, then the number of divisions N is uniquely determined. Between them, the rela...

Embodiment approach 2

[0069] In the second embodiment, the number N of longitudinal holes on the inner layer of the blank 2 is determined to be a prime number. This embodiment applies a geometrically asymmetric structure based on prime numbers, the purpose of which is to determine the number of longitudinal holes on the inner layer, but this embodiment still uses a symmetrical structure in terms of plastic deformation. N 2 The reason for being a prime number is that the irregular deformation of the superconducting filament is suppressed during the drawing process.

[0070] Same as Embodiment 1, Embodiment 2 is applicable when the copper ratio is greater than 4. As in Embodiment 1, the number N of vertical holes on the inner layer 2 and the number N of longitudinal holes on the outer layer 1 The relationship between 2 =N 1 / 2 or N 1 / 4 or N 1 / 8 OK.

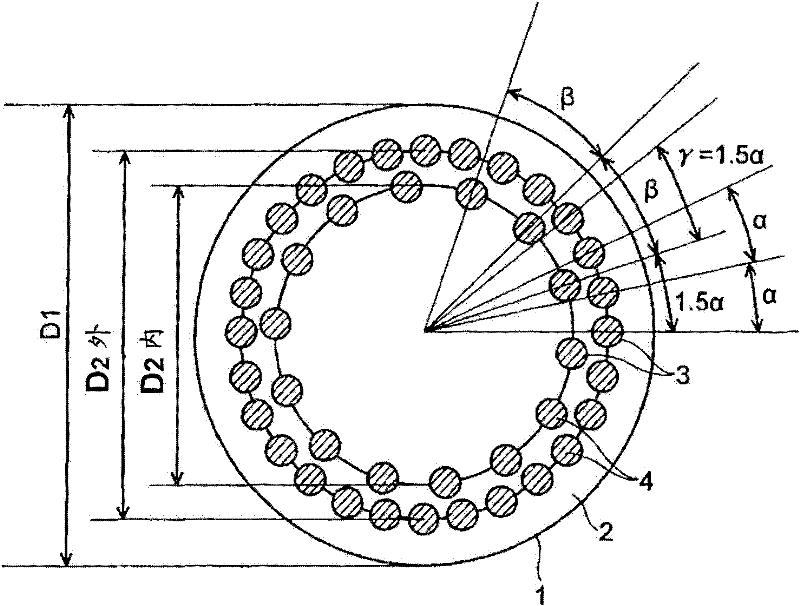

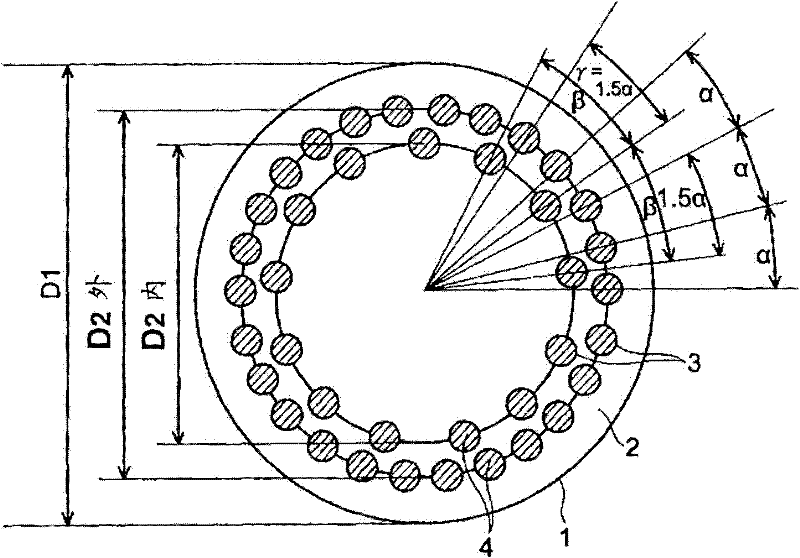

[0071] exist figure 2 In the illustrated embodiment, the longitudinal holes 3 are arranged in the outer concentric circles (D 2外 ) and inn...

Embodiment approach 3

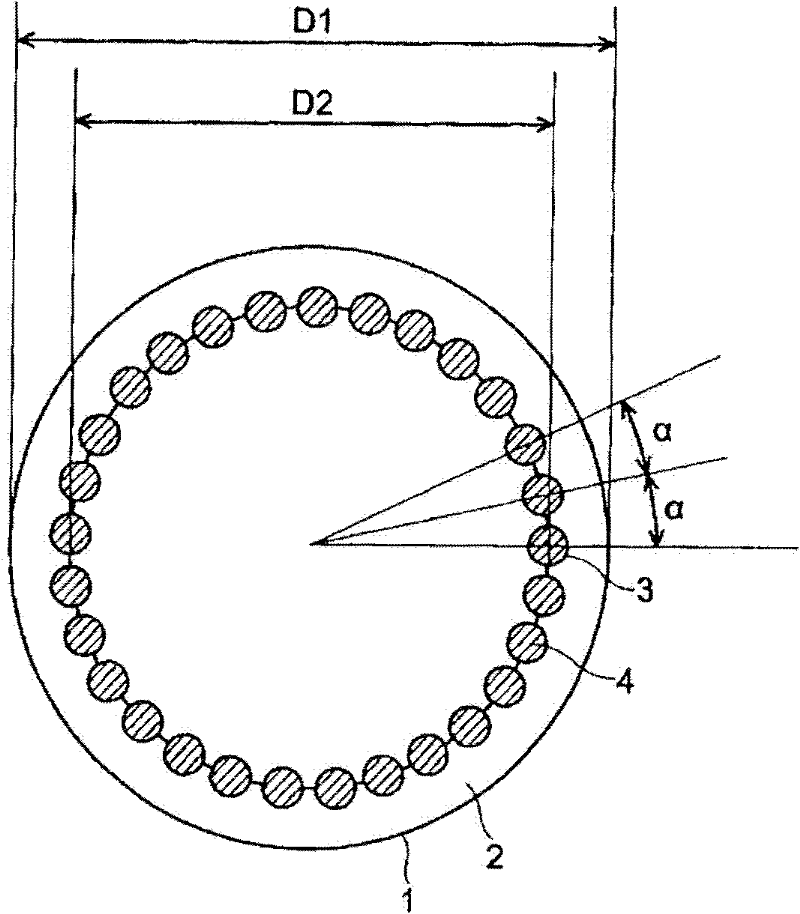

[0089] In the third embodiment, longitudinal holes are prepared in the blank so that each longitudinal hole will be arranged on a layer of concentric circles concentric with the center of the blank, the number N of holes being 29. As in Embodiments 2 and 3, the longitudinal holes are drilled at equal intervals, ie at equal angles α. In this embodiment, where the number N is 29, the equal angle α is 360 / N, ie 12.4°.

[0090] exist Figure 3A and 3B Among them, the numeral symbol 1 denotes a superconducting multi-core blank, 2 denotes a copper or copper alloy blank, 3 denotes a vertical hole 3 prepared in the blank 1, 4 denotes a superconducting material inserted into the vertical hole 3, and 5 denotes a process by A superconducting multi-core wire obtained from a superconducting multi-core blank 1 is processed.

[0091] Figure 3A The structure in the case where N is 29, where N should preferably be an integer of 17 to 53, will be described. In addition, it is preferable t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com