Superconducting cavity surface chemical buffer polishing full-automatic acid liquor preparation device and method

A technology of surface chemistry and superconducting cavity, which is applied in the direction of chemical instruments and methods, mixing methods, mechanical equipment, etc., can solve the problems of toxic gas volatilization and strong corrosion, and achieve the goals of avoiding danger, ensuring preparation accuracy and improving preparation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

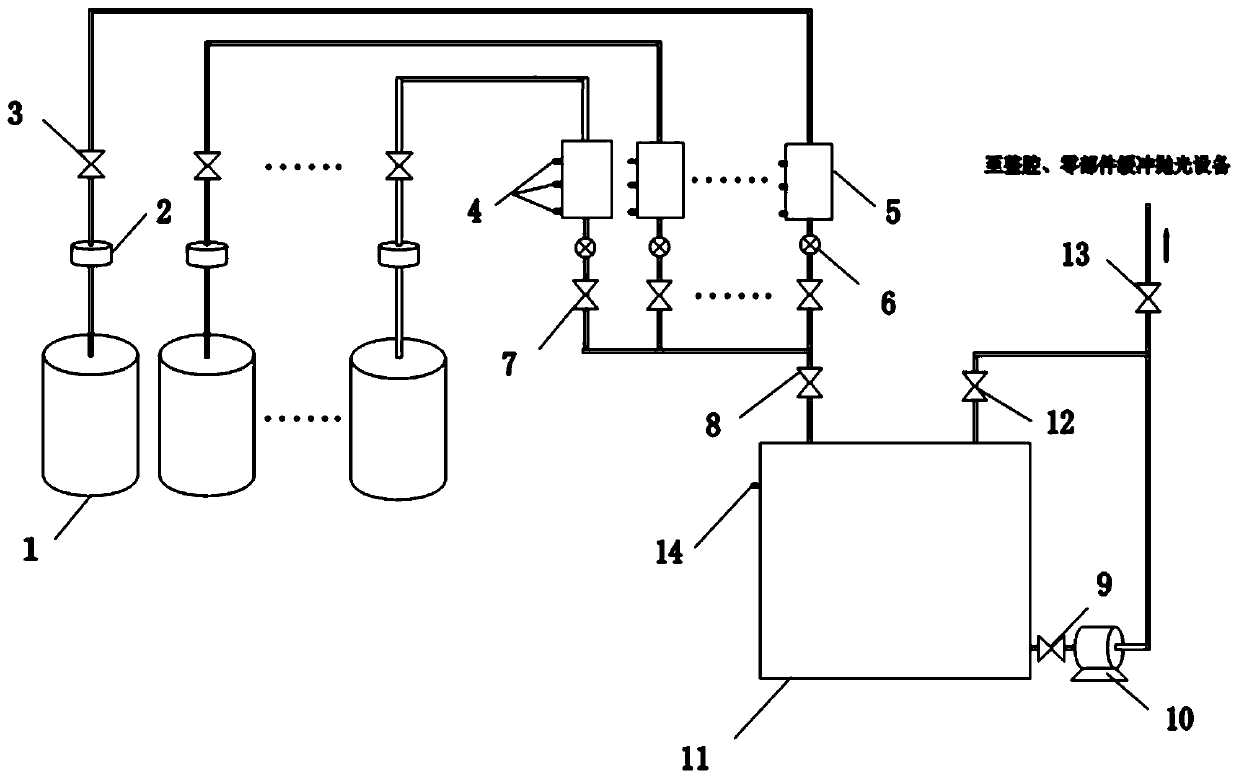

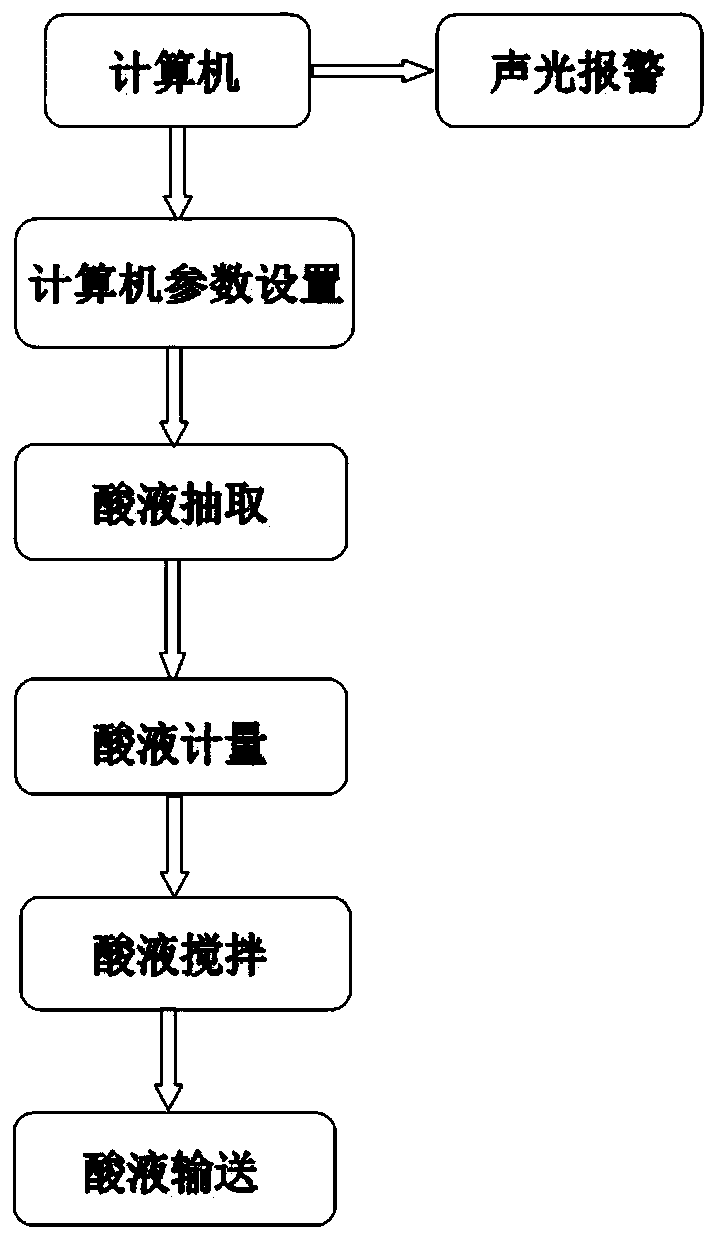

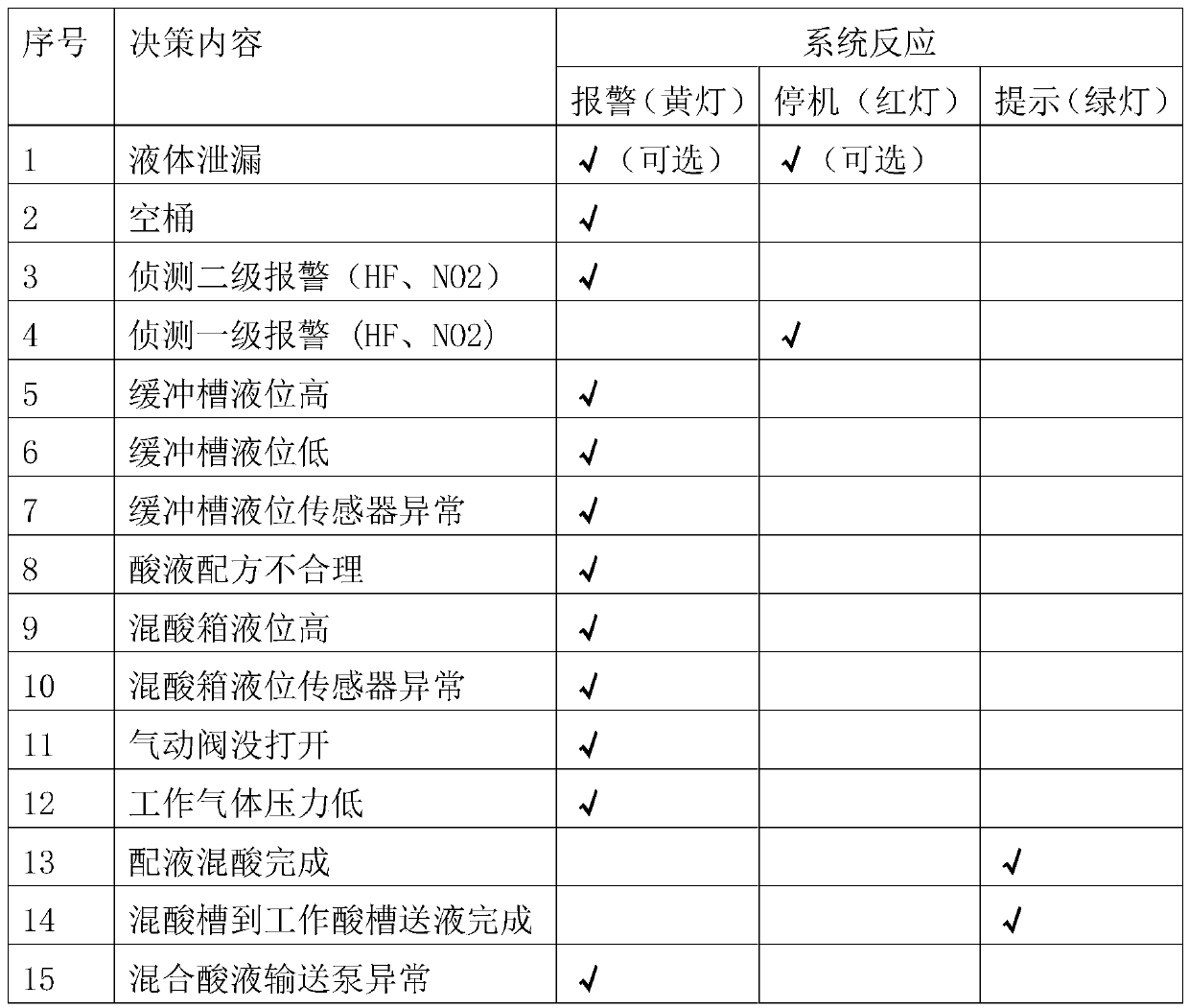

[0026] like figure 1 As shown, the present invention provides a superconducting cavity surface chemical buffer polishing automatic acid preparation equipment, which includes an acid mixing tank 11, an acid circuit control mechanism and a computer control display system (not shown in the figure). Wherein, the top of the mixed acid tank 11 is provided with a first mixed acid inlet and a second mixed acid inlet, the first mixed acid inlet is connected with the first acid liquid preparation pipeline, and the other end of the first acid liquid preparation pipeline is connected with more than one acid liquid extraction system arranged in parallel. The pipelines are connected, and the other ends of the acid extraction pipelines are connected to the original acid tank 1 containing different acid solutions; the second mixed acid inlet is connected to the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com