Room-temperature liquid metal high-flux sample preparation device

A liquid metal and sample preparation technology, applied in the field of liquid metal at room temperature, can solve problems such as slow preparation progress, affecting the accuracy of material sample test data, and deviations between content and theoretical values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

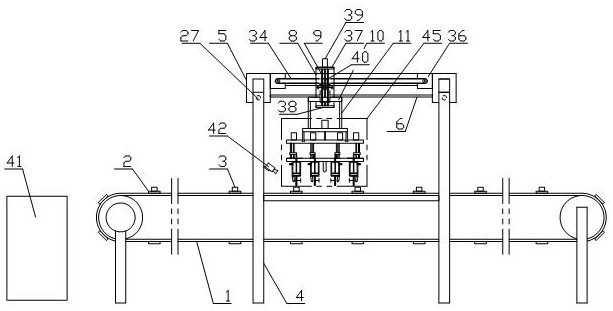

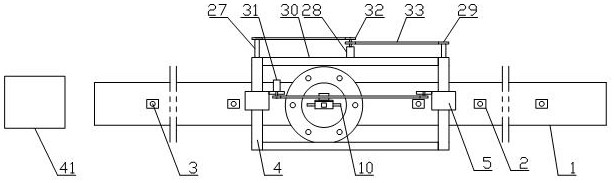

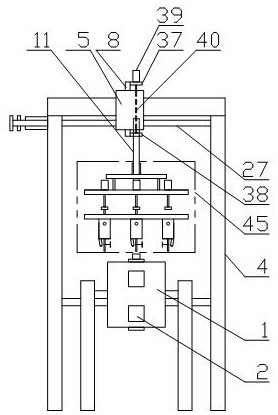

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the present invention belong to the protection scope of the present invention.

[0023] like Figure 1~5 Shown, the present invention comprises belt conveyor 1 and a plurality of stock plate 2, and belt conveyor 1 is existing structure, can directly purchase and use on the market as required, because belt conveyor in this device 1 is an intermittent working mode. In order to facilitate operation, the driving motor of the belt conveyor 1 can be a stepper motor. 2 is placed with a sample dish 3, the sample dish 3 is used to contain the liquid metal sample, before it is placed on the material plate 2, in order to facilitate the distinction between each sample dish 3, each sample dish 3 can be numbered , and paste the numbered label on the sample dish 3, two gantry frames 4 are ere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com