Coating method for wire or electrical insulator with teflon coating

An insulator and Teflon technology, applied in the direction of conductor/cable insulation, insulator, cable/conductor manufacturing, etc., can solve problems such as lowering insulation performance, grounding accidents, and tower breakage, and achieve excellent heat resistance and low temperature resistance. The effect of prolonging the life of the lead wire and reducing the permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail;

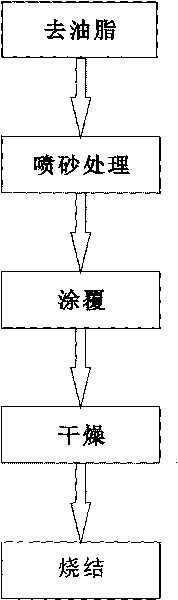

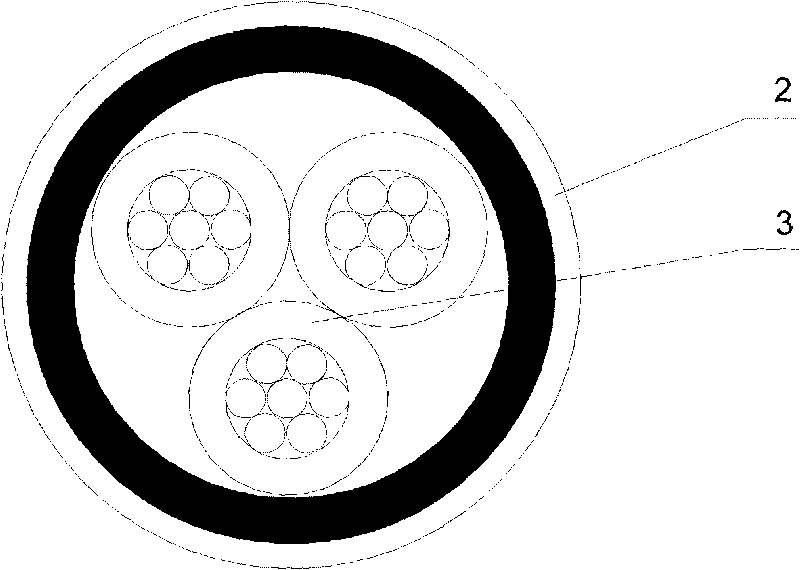

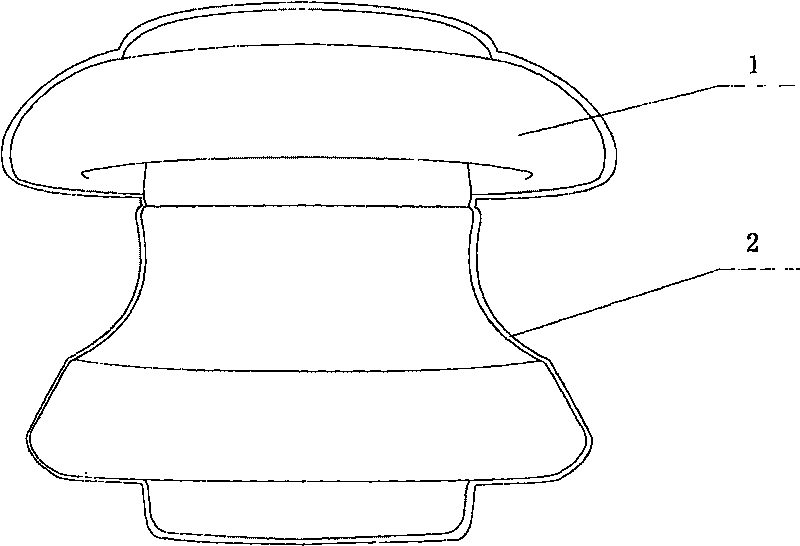

[0042] Such as figure 1 , 2 , a kind of coating method of the wire that is coated with Teflon coating, the coating method of insulator shown in 3, at first prepare the organic solvent of alcohols or ketones, wire is arranged in a straight line, insulator is strung into row; Insulator is coated with The method includes the following steps:

[0043] a), degrease

[0044] In order to obtain sufficient surface adhesion on the surface of the insulator, all the grease on the surface of the insulator 3 to be coated must first be removed; first use acetone to dissolve the grease on the surface of the insulator 3, and then use a heating device to heat the insulator 3 to 420-450°, so that the surface of the insulator 3 remains Alcohol or ketone organic solvents are completely volatile;

[0045] b), sandblasting

[0046] A sandblasting machine is used to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com