Antibacterial high barrier food wrapping film and preparation method thereof

A high-barrier, packaging film technology, applied in the field of food packaging films, can solve the problems that it is difficult to completely prevent moisture and oxygen attack, the barrier performance is not very good, food is easy to spoil, etc., to achieve the improvement of comprehensive performance, barrier and other performance improvement, The effect of keeping food fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

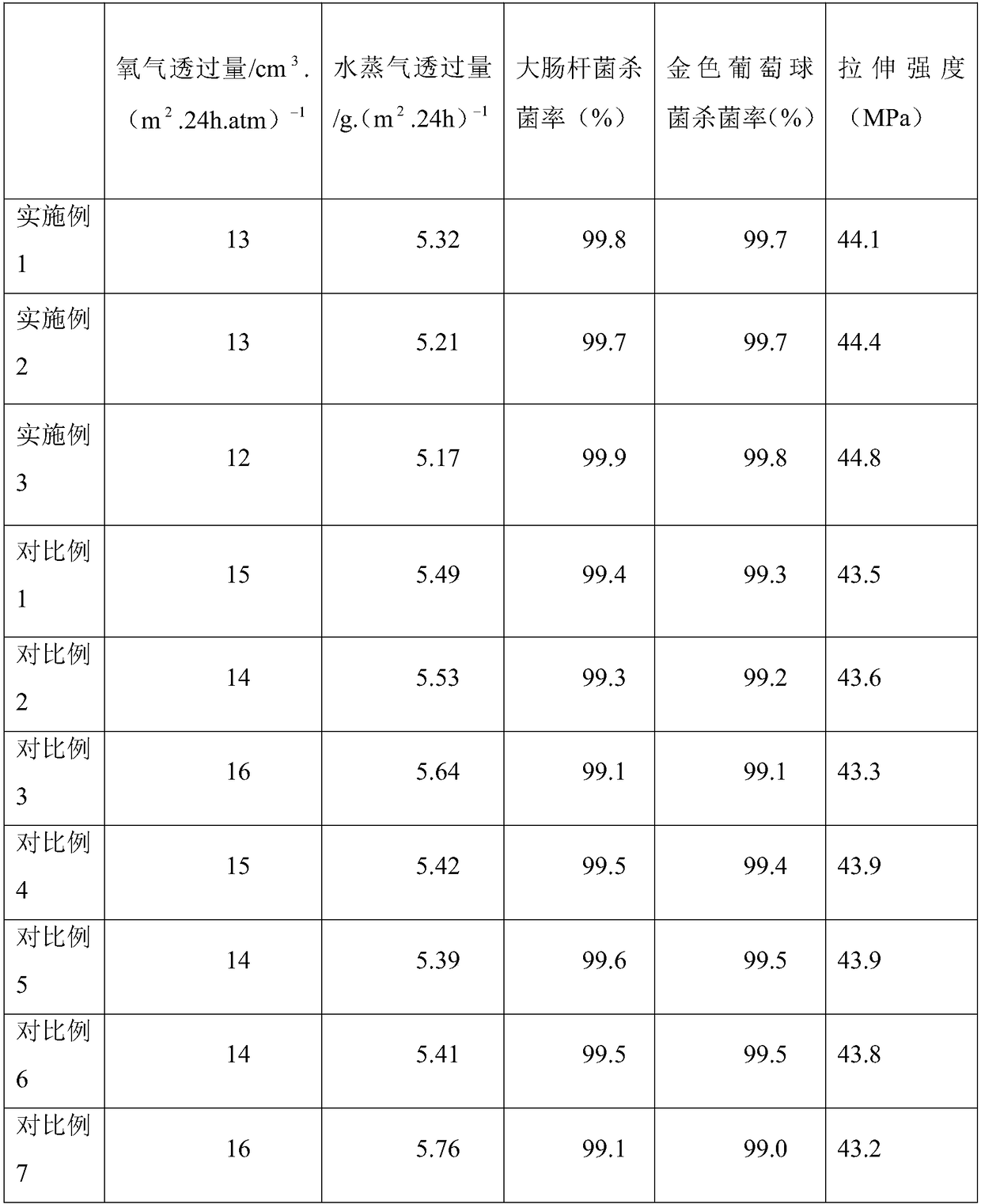

Examples

Embodiment 1

[0027] A kind of antibacterial high barrier food packaging film of the present embodiment comprises the following raw materials:

[0028] Ethylene-vinyl alcohol copolymer, polyurethane, polyvinyl acetal, composite silicate mineral additive, silane coupling agent KH-550.

[0029] The antibacterial high barrier food packaging film of this embodiment also includes an antibacterial enhancer.

[0030] The antibacterial enhancer of the present embodiment comprises following raw materials in parts by weight:

[0031] 22 parts of methylparaben, 14 parts of polyethylene terephthalate, 12 parts of ethyl p-hydroxybenzoate, 8 parts of novolac resin, 4 parts of silver ion composite antibacterial agent, 3 parts of polyether ether ketone resin, 2 parts of sucrose fatty acid ester, 1 part of monoglyceride.

[0032] The silver ion composite antibacterial agent of the present embodiment comprises silver ion antibacterial agent, ceramic powder, cerite powder, sepiolite powder, tourmaline powde...

Embodiment 2

[0041] A kind of antibacterial high barrier food packaging film of the present embodiment comprises the following raw materials:

[0042] Ethylene-vinyl alcohol copolymer, polyurethane, polyvinyl acetal, composite silicate mineral additive, silane coupling agent KH-550.

[0043] The antibacterial high barrier food packaging film of this embodiment also includes an antibacterial enhancer.

[0044] The antibacterial enhancer of the present embodiment comprises following raw materials in parts by weight:

[0045] 28 parts of methylparaben, 18 parts of polyethylene terephthalate, 16 parts of ethyl p-hydroxybenzoate, 12 parts of novolac resin, 10 parts of silver ion composite antibacterial agent, 5 parts of polyether ether ketone resin, 6 parts of sucrose fatty acid ester, 3 parts of monoglyceride.

[0046] The silver ion composite antibacterial agent of the present embodiment comprises silver ion antibacterial agent, ceramic powder, cerite powder, sepiolite powder, tourmaline powd...

Embodiment 3

[0055] A kind of antibacterial high barrier food packaging film of the present embodiment comprises the following raw materials:

[0056] Ethylene-vinyl alcohol copolymer, polyurethane, polyvinyl acetal, composite silicate mineral additive, silane coupling agent KH-550.

[0057] The antibacterial high barrier food packaging film of this embodiment also includes an antibacterial enhancer.

[0058] The antibacterial enhancer of the present embodiment comprises following raw materials in parts by weight:

[0059] 25 parts of methylparaben, 16 parts of polyethylene terephthalate, 14 parts of ethyl p-hydroxybenzoate, 10 parts of novolac resin, 7 parts of silver ion composite antibacterial agent, 4 parts of polyetheretherketone resin, 4 parts of sucrose fatty acid ester, 2 parts of monoglyceride.

[0060] The silver ion composite antibacterial agent of the present embodiment comprises silver ion antibacterial agent, ceramic powder, cerite powder, sepiolite powder, tourmaline powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com