Preparation method of high-strength fine-diameter ultra-thin tubular fabric

A tubular fabric and thin-diameter technology, which is applied in fabrics, textiles, textiles, and papermaking, can solve the problems of tubular fabrics with small diameters and small tube walls, which cannot meet the requirements of light weight and super tensile strength, and achieve product adaptability Good, dimensional stability, and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

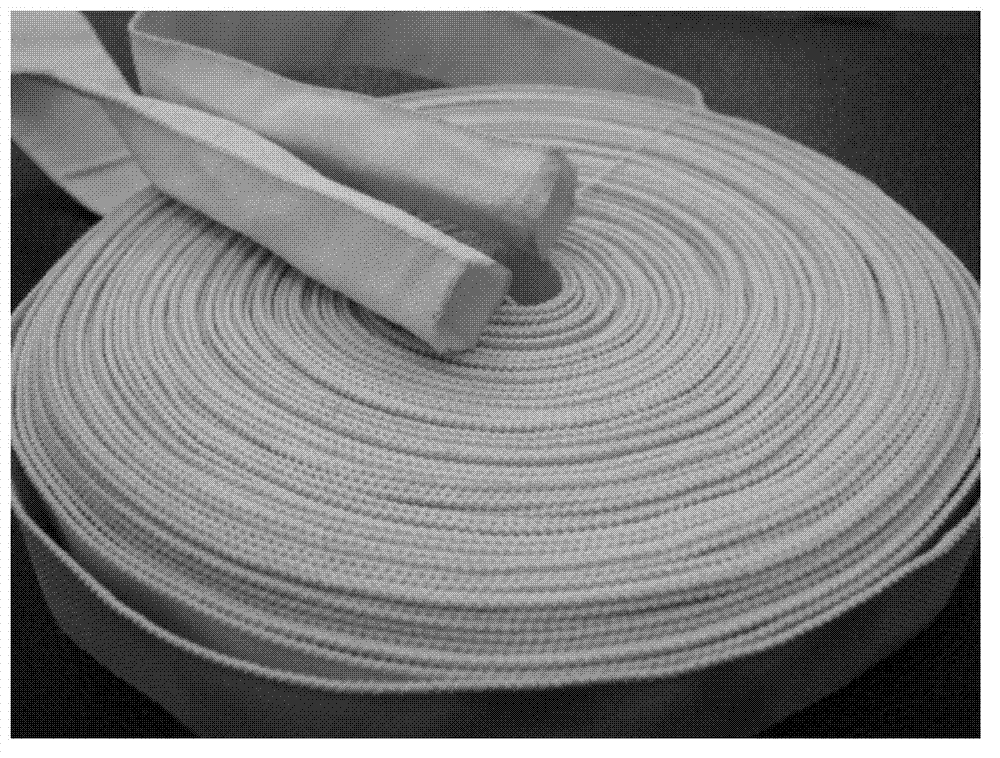

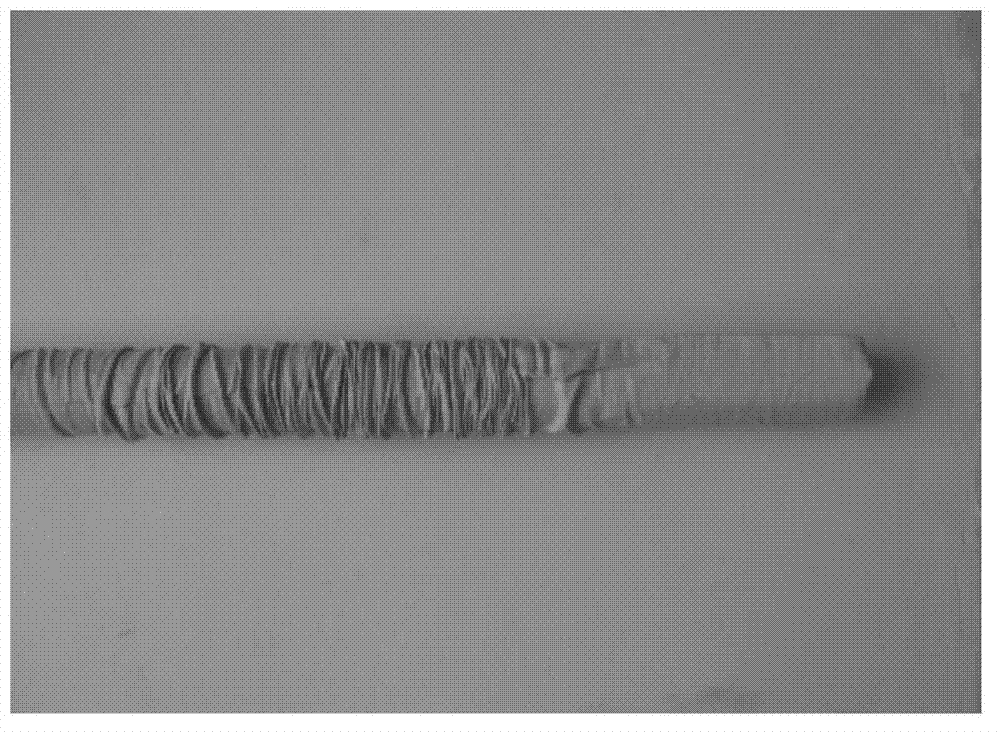

[0016] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the specific steps of the preparation method of a high-strength fine-diameter ultra-thin tubular fabric described in this embodiment are as follows:

[0017] Step 1. Select PBO fiber as the warp and weft of the tubular fabric, and the fiber linear density of the PBO fiber is 100-300D;

[0018] Step 2, twisting the PBO fiber filament yarn, as twisting is 230 twists / meter;

[0019] Step 3, the weft yarn is not twisted, and the weft yarn is wound into a yarn suitable for the size of the shuttle of the shuttle loom;

[0020] Step 4, adopting the weaving method of the fabric that is interwoven according to certain rules on the loom by mutually vertically arranged yarns that are horizontal and vertical two systems, that is, adopts plain weave structure;

[0021] Step 5. Start to weave the tubular fabric. The specific weaving steps are:

[0022] Step 5 (1), carry out winding, draw 50~200 bobbi...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in step 1 of the method for preparing a high-strength fine-diameter ultra-thin tubular fabric described in this embodiment, 75-200D aramid fibers can be used as the warp and weft of the tubular fabric. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To illustrate this embodiment, in the third step of the preparation method of a high-strength fine-diameter ultra-thin tubular fabric described in this embodiment, a rapier loom without a shuttle loom is used to weave the tubular fabric, and the yarn needs to be wound to prepare the weft yarn into the bobbin required by the shuttleless loom. In addition to the characteristics of high speed, high degree of automation, and high-efficiency production, the shuttleless loom selected in this embodiment also has a positive weft insertion method, that is, the weft yarn is transferred to the center of the weaving fell without any guiding device, and has strong variety adaptability. , Small footprint, uniform reed width control, there will be a needle hook edge. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com