Ceramic aggregate biological filler and preparation method thereof

A technology of biological filler and ceramsite, which is applied in the field of waste slag utilization, can solve the problems of resource waste and no comprehensive utilization, and achieve long-term stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

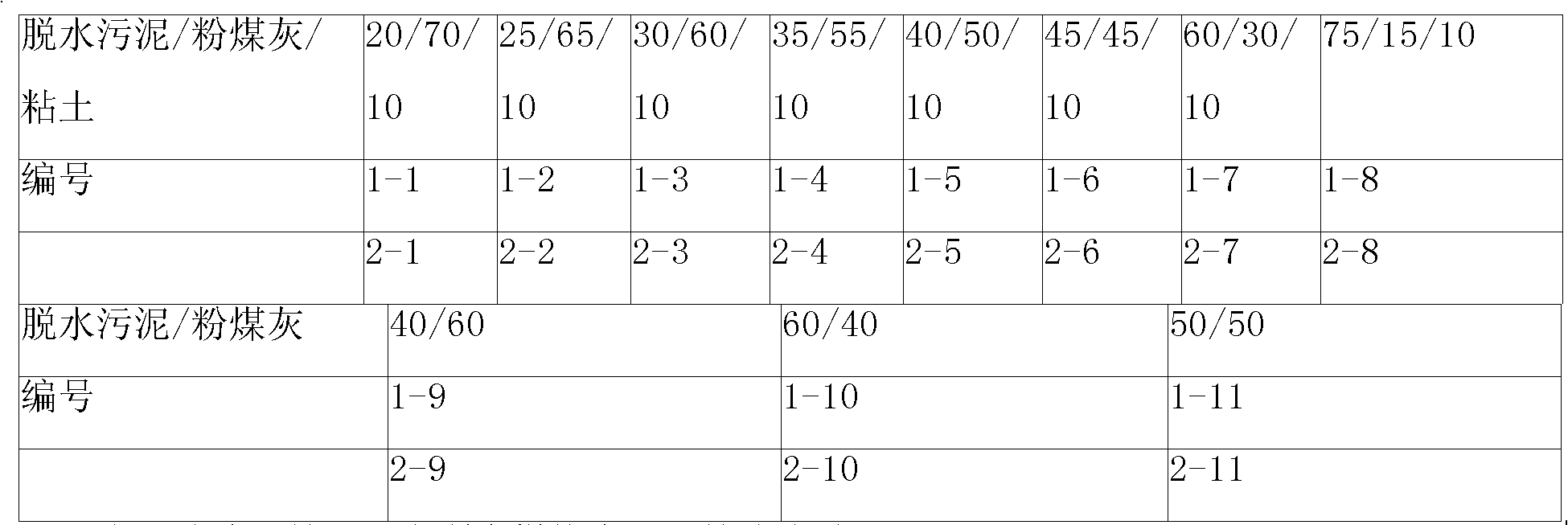

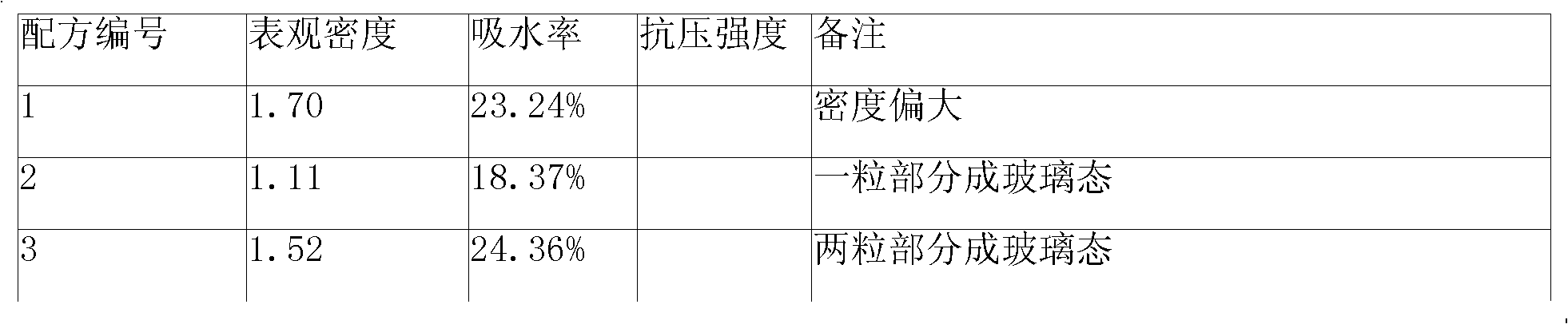

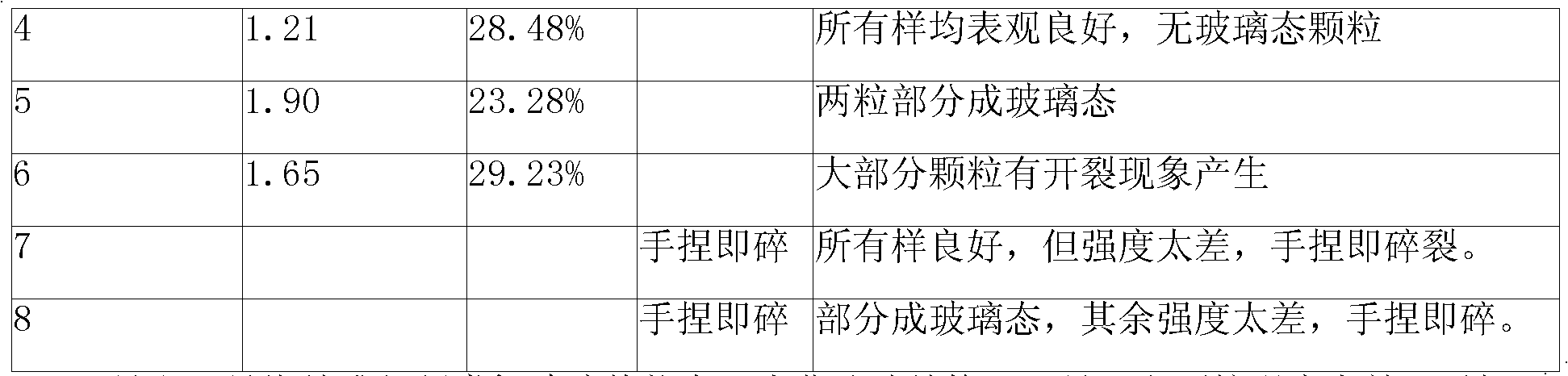

[0111] Embodiment 1 of the present invention: preparation of ceramsite biological filler:

[0112] (1) Weigh respectively 50g of fly ash (collected from the flue gas of coal combustion), 174g of dewatered sludge (moisture content is 77%, dry weight is 40g) of sewage treatment plant, clay (true density is 1.65g / cm 3 ) 10g and aluminum sulfate octadecahydrate 3g, add water and stir evenly to make 8-10mm particles;

[0113] (2) Dry the particles at a constant temperature of 100°C for 70 minutes;

[0114] (3) Put the dried particles into a muffle furnace and heat to 450°C, preheat for 13 minutes, then raise the temperature to 900°C for 5 minutes to prevent the particles from being heated unevenly due to excessive heating, and then heat up to 1100°C for 20 minutes minutes, cool in the furnace to 300-400°C and take it out to obtain yellow ceramsite biological filler.

Embodiment 2

[0115] Embodiment 2 of the present invention: preparation of ceramsite biological filler:

[0116] (1) Weigh the dried and pulverized clay (true density is 1.65g / cm 3 ) 10g in a 500ml beaker, add about 10ml of water and stir into a paste; then weigh 175g of sewage treatment plant sludge with a water content of 80% (dry weight is 35g, directly used without drying) into the beaker, and stir slightly; Then weigh 55g of fly ash (collected by the chimney of the power plant) and 4g of aluminum sulfate octadecahydrate and add them into the beaker together, stir evenly, and it is advisable to make some 8mm spherical particles with no yellow clay on the beaker wall.

[0117] (2) Put the spherical particles into a constant temperature oven at 105°C and dry for 60 minutes;

[0118] (3) Put the dried particles into the muffle furnace and heat to 400°C (heating rate 35°C / min), preheat for 10 minutes, then raise the temperature to 800°C for 2 minutes to prevent the particles from being hea...

Embodiment 3

[0119] Embodiment 3 of the present invention: preparation of ceramsite biological filler:

[0120] (1) Take by weighing fly ash 60g, sewage treatment plant sludge 176.5g (moisture content is 83%, dry weight is 30g), clay 10g and aluminum sulfate octadecahydrate 6g, add water and stir to make granules;

[0121] (2) Dry the particles at a constant temperature of 110°C for 80 minutes;

[0122] (3) Put the dried particles into an electric heating furnace and heat to 500°C, preheat for 12 minutes, then heat up to 1200°C and burn for 25 minutes, then cool in the furnace to 500-600°C and take it out to obtain ceramsite biological filler .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com