Preparation method of stripping boron nitride anticorrosive coating, coating obtained by preparation method and application of coating

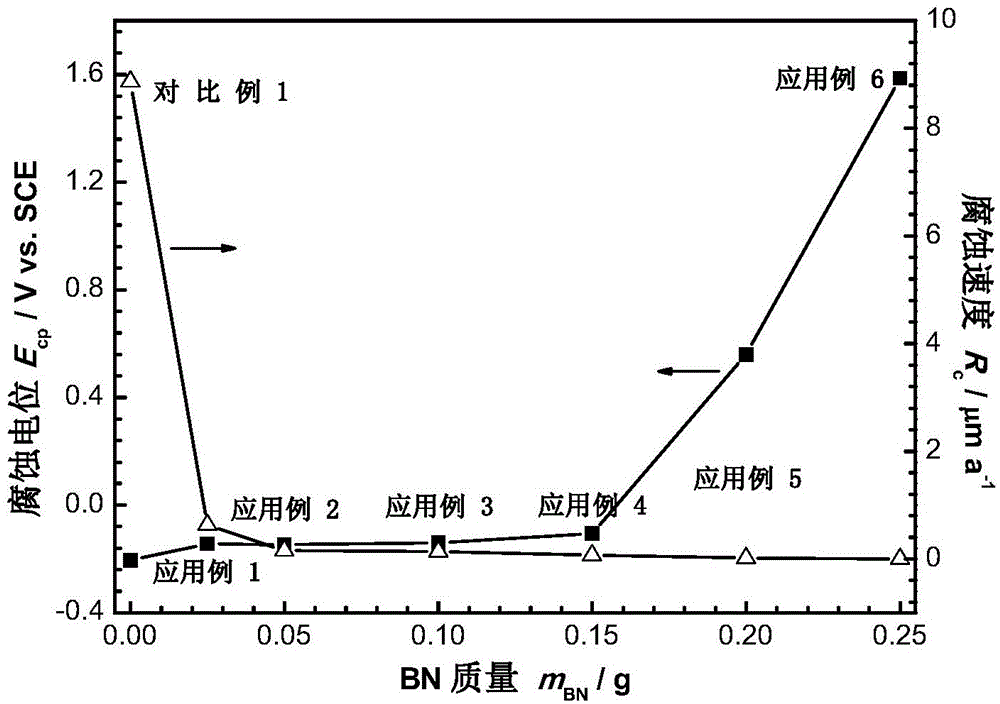

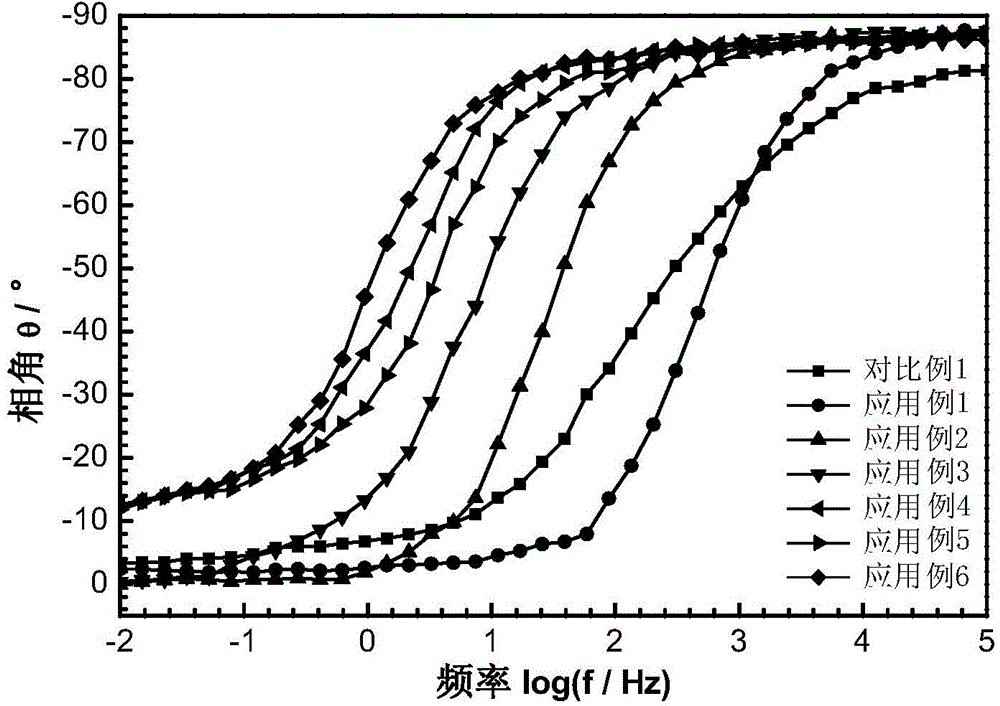

A technology of anti-corrosion coatings and boron nitride, applied in anti-corrosion coatings, coatings, etc., can solve problems such as restricting applications, and achieve the effects of increasing anti-corrosion performance, reducing dosage, and extending diffusion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of exfoliated boron nitride: Add 1 g of hexagonal boron nitride to 80 mL of isopropanol, ultrasonicate for 24 hours to form an exfoliated boron nitride dispersion with a concentration of 12.5 mg / mL, and then centrifuge the dispersion at 10,000 rpm for 20 min , after washing with distilled water for 3 times, freeze-dry the obtained solid (freezing temperature is -37°C, vacuum degree is 13Pa) to obtain exfoliated boron nitride.

Embodiment 2

[0046]Preparation of exfoliated boron nitride: Add 1 g of hexagonal boron nitride to 100 mL of N-methylpyrrolidone, ultrasonicate for 48 hours to form an exfoliated boron nitride dispersion with a concentration of 12.5 mg / mL, and then centrifuge the dispersion at 10,000 rpm After 20 minutes, the obtained solid was washed with distilled water for 3 times, and then freeze-dried (freezing temperature was -45° C., vacuum degree was 17 Pa) to obtain exfoliated boron nitride.

Embodiment 3

[0048] Preparation of exfoliated boron nitride: Add 1 g of hexagonal boron nitride to 80 mL of dimethyl sulfoxide, ultrasonicate for 48 hours to form an exfoliated boron nitride dispersion with a concentration of 12.5 mg / mL, and then centrifuge the dispersion at 9000 rpm After 20 minutes, the obtained solid was washed with distilled water for 3 times, and then freeze-dried (freezing temperature was -20° C., vacuum degree was 10 Pa) to obtain exfoliated boron nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com