Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Has heat and humidity resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

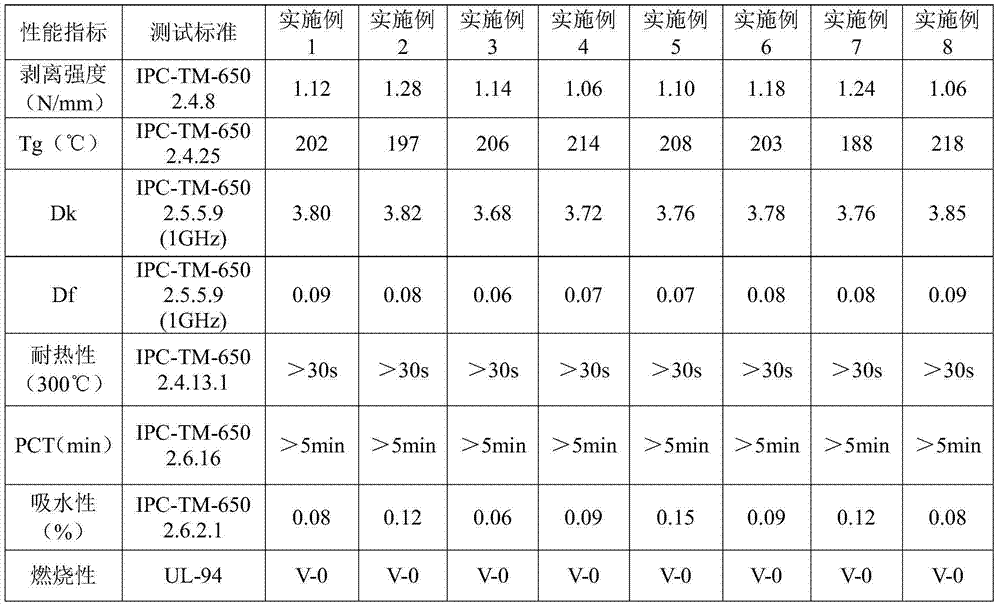

Thermosetting resin composition and method for manufacturing prepreg and laminated board by using thermosetting resin composition

InactiveCN103937156AGood dielectric propertiesImprove heat and humidity resistanceSynthetic resin layered productsMetal layered productsChemistryMetal foil

The present invention discloses a thermosetting resin composition and a method for manufacturing a prepreg and a laminated board by using the thermosetting resin composition. The thermosetting resin composition is prepared by dispersing the following components in an organic solvent, wherein the components comprise, by weight, 10-80 parts of an epoxy resin, 10-60 parts of cyanate, 10-60 parts of bismaleimide, 10-50 parts of polyphenylene oxide, 0.01-1.0 part of a curing accelerator, 1-40 parts of a fire retardation agent, and 0-100 parts of an inorganic filler, and the solid content of the resin composition is 30-70 wt%. The prepared prepreg and the metal foil-clad laminated board have characteristics of good heat resistance, good wet heat resistance, high glass-transition temperature, low water absorption rate, low dielectric constant, low dielectric loss factor and the like.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

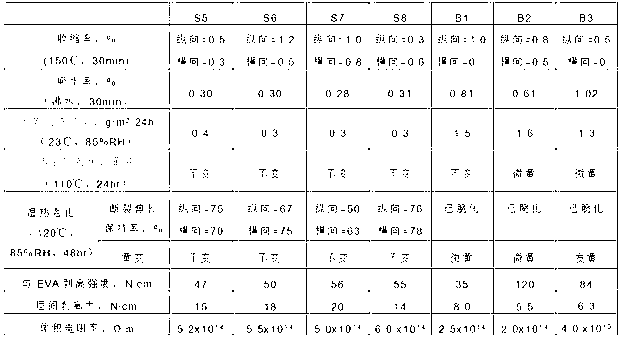

Modified polypropylene resin composition and solar energy rear panel made of the same

ActiveCN103066141AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesSurface layerWater vapor permeability

The invention discloses a solar energy rear panel and a preparation method of the solar energy rear panel. The solar energy rear panel comprises an inner surface layer, a core layer and an outer surface layer from inside to outside. By a mass rate, the inner surface layer is 10%-20%, the core layer is 20%-40%, and the outer surface layer is 40%-60%. The inner surface layer and the outer surface layer are made of polyamide resin, fillings and additive, and the core layer is made of the modified polypropylene resin composition. The modified polypropylene resin composition comprises the following components: 100 parts of polypropylene resin, 5-50 parts of graft polyethylene, 0-2.5 parts of additive and 0-100 parts of fillings. Meanwhile, the invention discloses the novel modified polypropylene resin composition used for the solar energy rear panel. Due to the novel modified polypropylene resin composition, a final product obtained has good low temperature resistance and impact resistance, meanwhile anti-aging performance and especially has performance of humidity resistance and resistance to aging. The solar energy rear panel prepared by the novel modified polypropylene resin composition is better than other rear panels in terms of water absorption, water vapor permeability, and interlaminar peeling and has excellent electrical insulating property. A shrinking rate, hot air aging and insulation property required by the solar energy rear panel are met, and the novel modified polypropylene resin composition can be used for solar energy battery components manufacturing .

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method, and using method of the same used as filling material of railway plate type dreg-free track convex block. The polyurethane resin composition is mainly used as filling material of railway plate type dreg-free track convex block, and mainly includes: polyether or polyester polyol, isocyanate or prepolymer of the same, pigment, filling and other auxiliary agent. Advantages of the prepared polyurethane resin are: construction manufacturability is better, bonding to cement of cured resin is good; the polyurethane resin is resistant of ultraviolet ray irradiation, moisture, heat, ageing and fatigue, and owns appropriate elasticity and integrated mechanical capability.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Composition of unsaturated resin, preparation method, and method of application

This invention provides an unsaturated resin composition, its preparation method, and its application as the filler of the slab-free track cam plate. The unsaturated resin composition is mainly composed of unsaturated resin, pigment, filler, peroxide initiator, and other additives. The unsaturated resin composition has such advantages as high processability, and high adhesiveness to cement after cured, appropriate elasticity, good comprehensive mechanical properties, and high UV, humidity, heat, aging and fatigue resistance.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

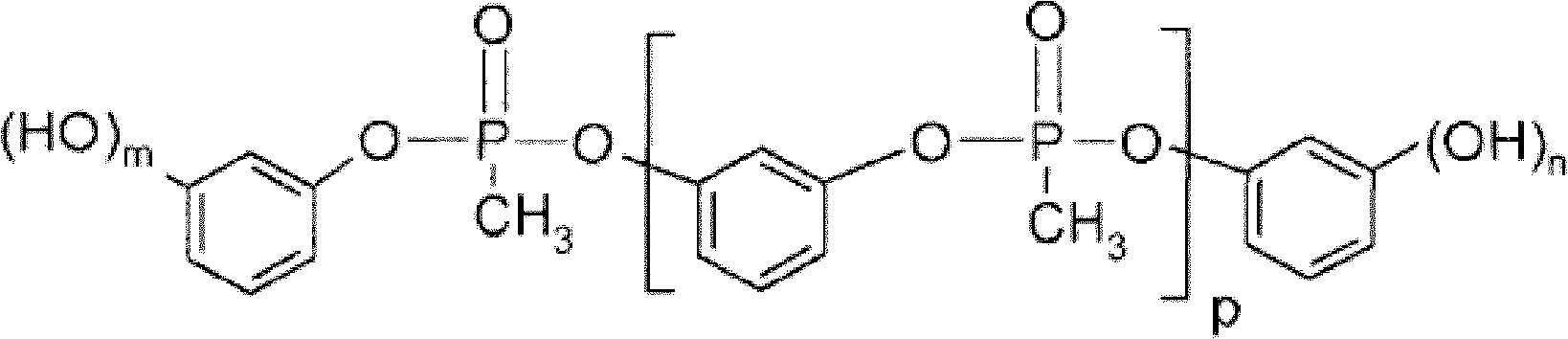

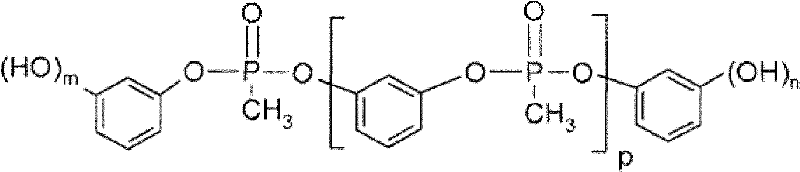

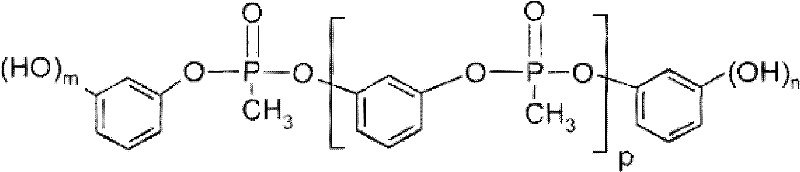

Halogen-free fire resistance resin composite and application thereof

InactiveCN102020830AGood heat resistanceSmall water absorptionPrinted circuit aspectsPrinted circuit manufactureMetal foilFlame resistance

The invention relates to a halogen-free fire resistance resin composite and application thereof. The halogen-free fire resistance resin composite comprises the following components: bifunctional or multifunctional halogen-free epoxy resin, reactive polyphosphonate and cyanate resin. The halogen-free fire resistance resin is applied to a prepreg; the prepreg comprises a base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite is applied to a plyboard for a printing circuit; the plyboard for the printing circuit comprises a plurality of stacked prepregs and single-surface or double-surface metal foil arranged on the stacked prepregs; each prepreg comprises the base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite has high heat resistance, fire resistance and dip soldering resistance, and thereby, the halogen-free fire resistance resin composite can be used for manufacturing the resin sheet, the resin composition metal foil, the prepreg, the plyboard and the printed wiring board.

Owner:GUANGDONG SHENGYI SCI TECH

Polyamide backplane for solar energy assembly

ActiveCN103057223AImprove water absorptionExcellent heat and humidity resistanceFinal product manufactureSynthetic resin layered productsSurface layerWater vapor

The invention discloses a polyamide backplane for a solar energy assembly. The polyamide backplane comprises an inner surface layer, a core layer, and an outer surface layer from the inside to the outside, wherein by mass, the ratio of inner surface layer to the core layer to the outer surface layer is 10-20:60-80:10-20. The inner surface layer and the outer surface layer are made from a polyamide resin, fillers and additives; the core layer is made from a modified polyamide resin composition; and the modified polyamide resin composition comprises a polyamide resin, grafted polyethylene, a polypropylene resin, fillers and additives. The novel polyamide backplane of the present invention is prepared by using coextrusion technology, the final product obtained has excellent adhesion and interlayer peeling force, anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and is easy in preparation and low in cost, suitable for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

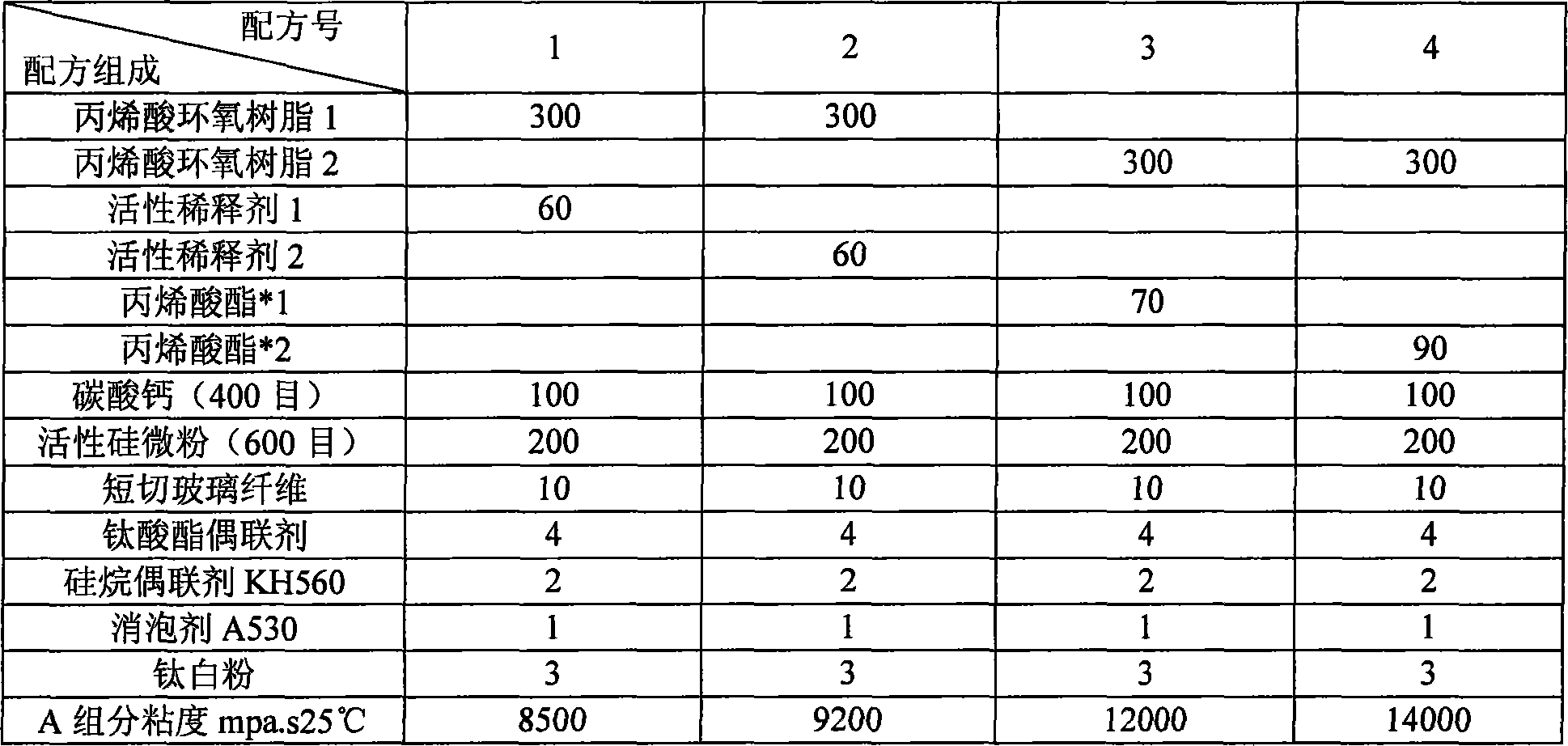

Preparation method and application of high temperature solvent resistant acrylate pressure sensitive adhesive

ActiveCN104449486AImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateCarvacryl acetate

The invention relates to a high temperature solvent resistant acrylate pressure sensitive adhesive which comprises the following components in parts by weight: 150-250 parts of 2-ethylhexyl acrylate, 50-100 parts of butyl acrylate, 3-10 parts of acrylic acid, 3-10 parts of hydroxyethyl acrylate, 10-20 parts of vinyl acetate, 15-35 parts of bornyl isoacrylate, 0.5-3 parts of azobisisobutyronitrile, 0.3-2 parts of N-hydroxymethyl acrylamide and 400-600 parts of ethyl acetate. The mechanical property, high temperature resistance and weather resistance of the emulsion type acrylate pressure sensitive adhesive are improved, so that the application range of the emulsion type acrylate pressure sensitive adhesive is widened, and the pressure sensitive adhesive has the characteristics of high viscidity, high temperature resistance, damp-heat aging resistance and low cost.

Owner:新丰杰力电工材料有限公司

Solar-powered back plate and manufacturing method thereof

ActiveCN103050563AHigh temperature resistanceImproved environmental stress cracking resistanceFinal product manufacturePhotovoltaic energy generationSurface layerAging resistance

The invention discloses a solar-powered back plate. The solar-powered back plate comprises an inner surface layer, a core layer and an outer surface layer in the mass ratio of (10-20):(20-40):(40-60) from inside to outside, wherein the inner surface layer is made from vinyl resin, a filler and an additive; the outer surface layer is made from polyamide resin, a filler and an additive; and the core layer is made from a modified polyethylene resin composition. The invention further develops a novel polyethylene resin composition, which comprises 100 parts of crosslinked polyethylene resin, 0-50 parts of grafted polyethylene, 0.1-0.5 parts of catalyst, 0-100 parts of filler and 0-2.5 parts of additive. The novel solar-powered back plate developed by the invention is prepared through a coextrusion process; and a prepared final product has the advantages of superior adhesion, high interlaminar peeling strength, aging resistance, particular damp-heat aging resistance, low saturated water absorptivity, low water vapor transmittance and superior electric insulating property, simple preparation process, low cost and suitability for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

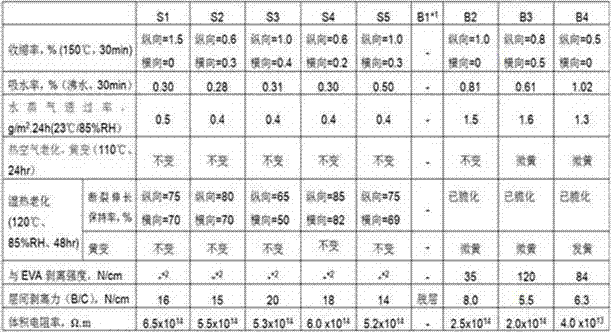

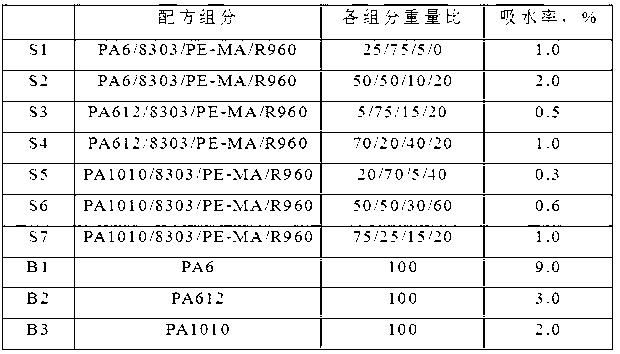

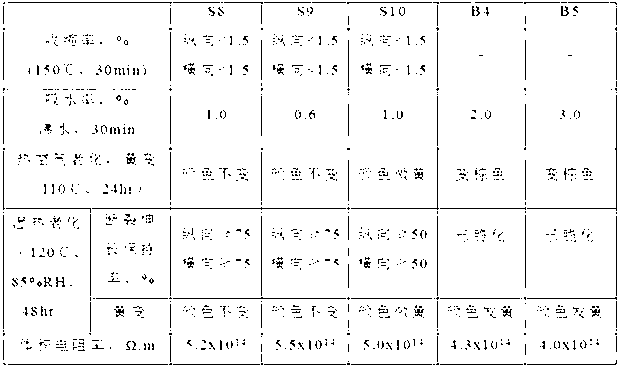

A modified polyamide resin composition and backplane substrate film prepared by the same

ActiveCN103059558AImprove heat resistanceImprove wear resistancePhotovoltaic energy generationSemiconductor devicesPolypropylenePolyamide

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Modified polypropylene composition for solar cell back panel and preparation method thereof

InactiveCN107151384AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesElastomerPolyolefin

The invention discloses a modified polypropylene composition for a solar cell back panel. The modified polypropylene composition comprises the following components in percentage by weight: 40 to 80 percent of polypropylene, 5 to 30 percent of polyamide, 2 to 15 percent of polyolefin elastomer, 0.1 to 1.0 percent of an initiator, 0.5 to 5.0 percent of a grafting monomer, 0 to 30 percent of reinforcing filler, and 0 to 5 percent of an additive. The composition provided by the invention has excellent low-temperature impact resistance and aging resistance, has low saturated water absorptivity, low water vapor permeability and excellent electrical insulating property, and can be used for manufacturing a solar back panel.

Owner:HUAZHONG AGRI UNIV

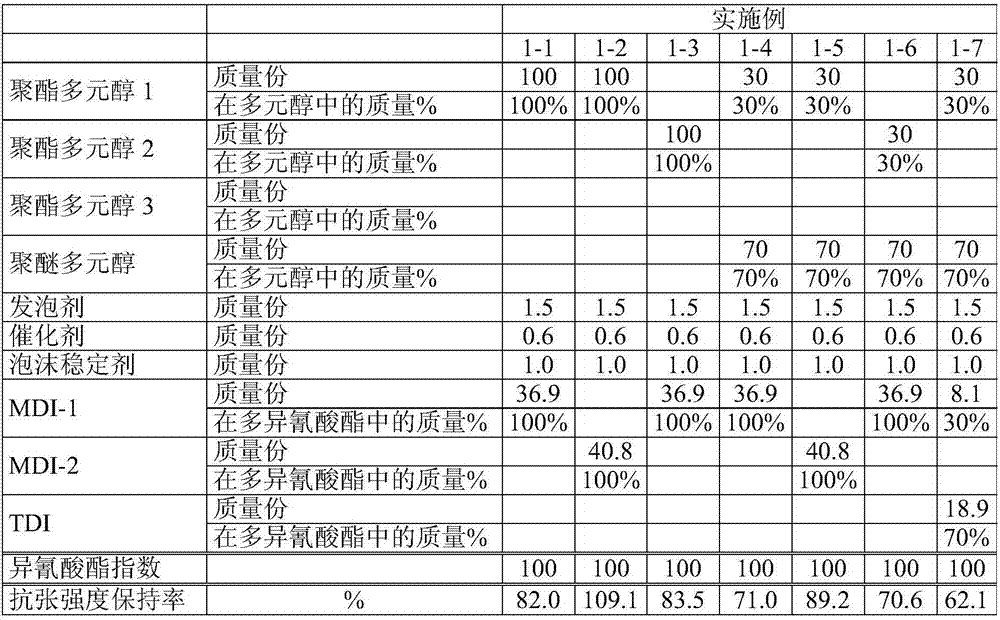

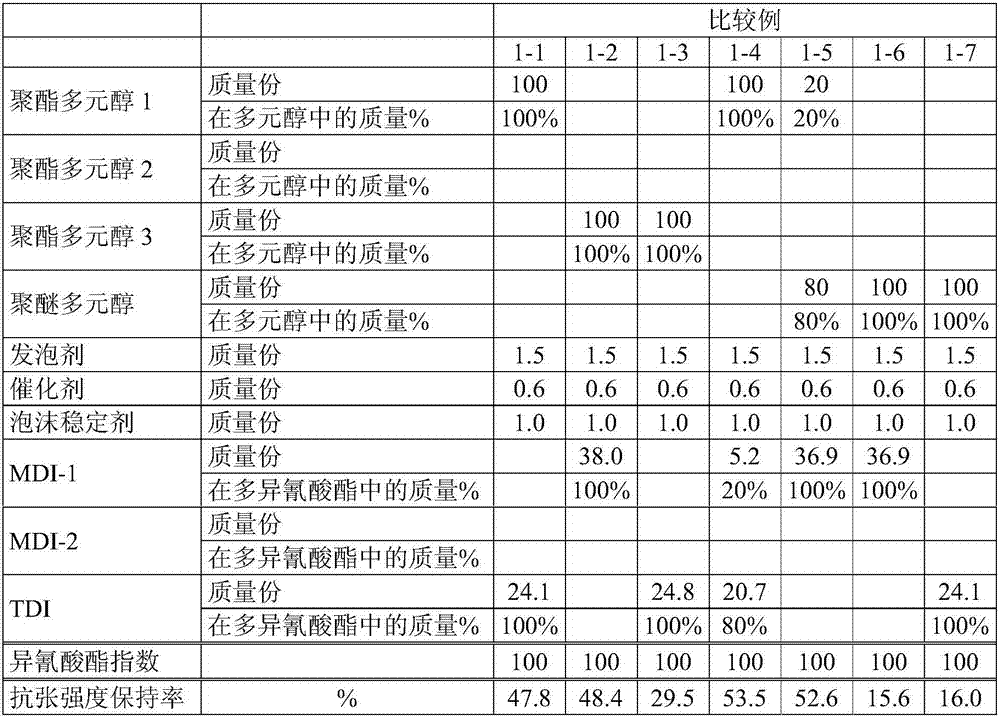

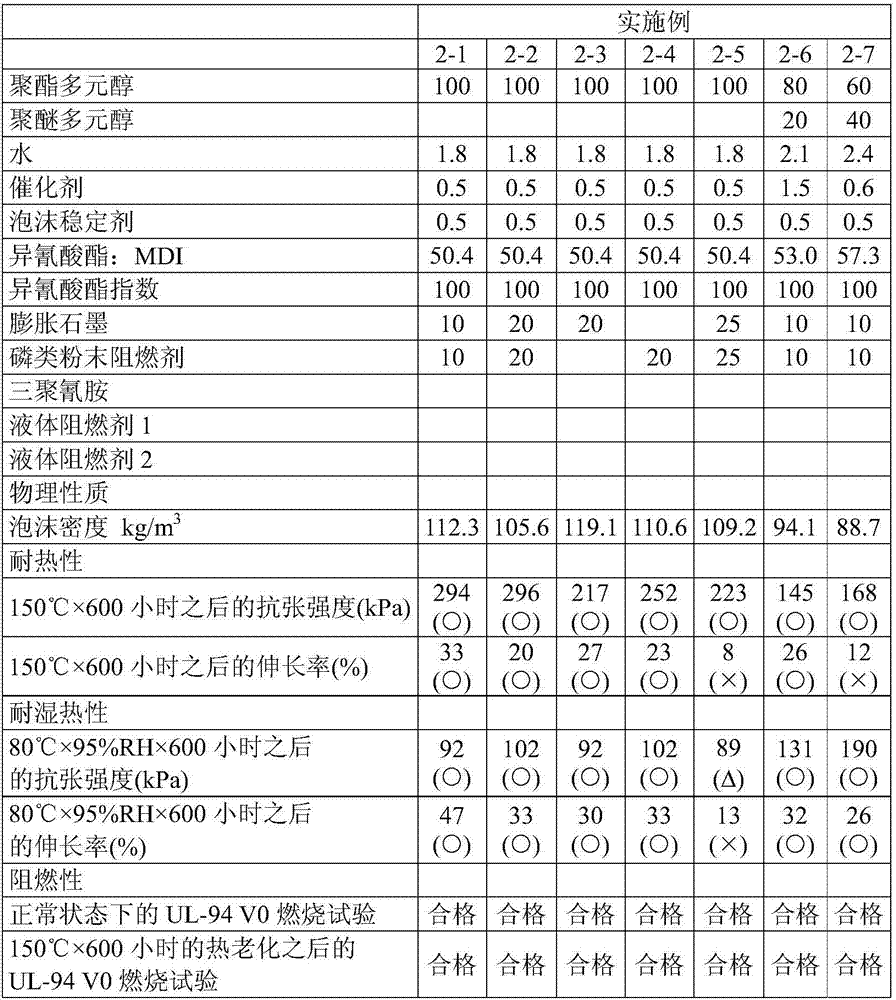

Polyurethane foam

Provided is a polyurethane foam which has excellent heat resistance and the like. This polyurethane foam is obtained from a material that contains a polyol and a polyisocyanate. The polyol contains a polyester polyol, and the polyisocyanate contains a diphenylmethane diisocyanate-based isocyanate. It is preferable that the polyester polyol has one or more side chains, each of which is composed of an alkyl group. This polyurethane foam is able to be used as a sound insulation material for vehicles.

Owner:INOAC CORP

Solar cell base film made from norbornene copolymer and processing technology thereof

ActiveCN102832347AGuaranteed reliabilityImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingElastomerPolyolefin

The invention discloses a solar cell base film made from norbornene copolymer, which is characterized in that the base film is a single-layer structure which is made from norbornene copolymer, PC (polycarbonate), EVA (ethylene vinyl acetate) and fillings, or norbornene copolymer, POE (polyolefin elastomer), EVA and fillings, or norbornene copolymer, PP (polypropylene), EVA and fillings, or norbornene copolymer, eutectics of PET (polyethylene terephthalate) and fillings; and the base film of the single-layer structure is obtained by processing by the melt extrusion technology. The solar cell base film made from norbornene copolymer disclosed by the invention has the characteristics of resistance to heat and humidity, ageing, tear and hydrolysis, high barrier property to water vapor, high insulating property, high strength, stable size and easiness in processing and shaping, is good for protecting a solar cell module, and is capable of prolonging the service life of the solar cell.

Owner:JOLYWOOD SUZHOU SUNWATT

Epoxy resin composition and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

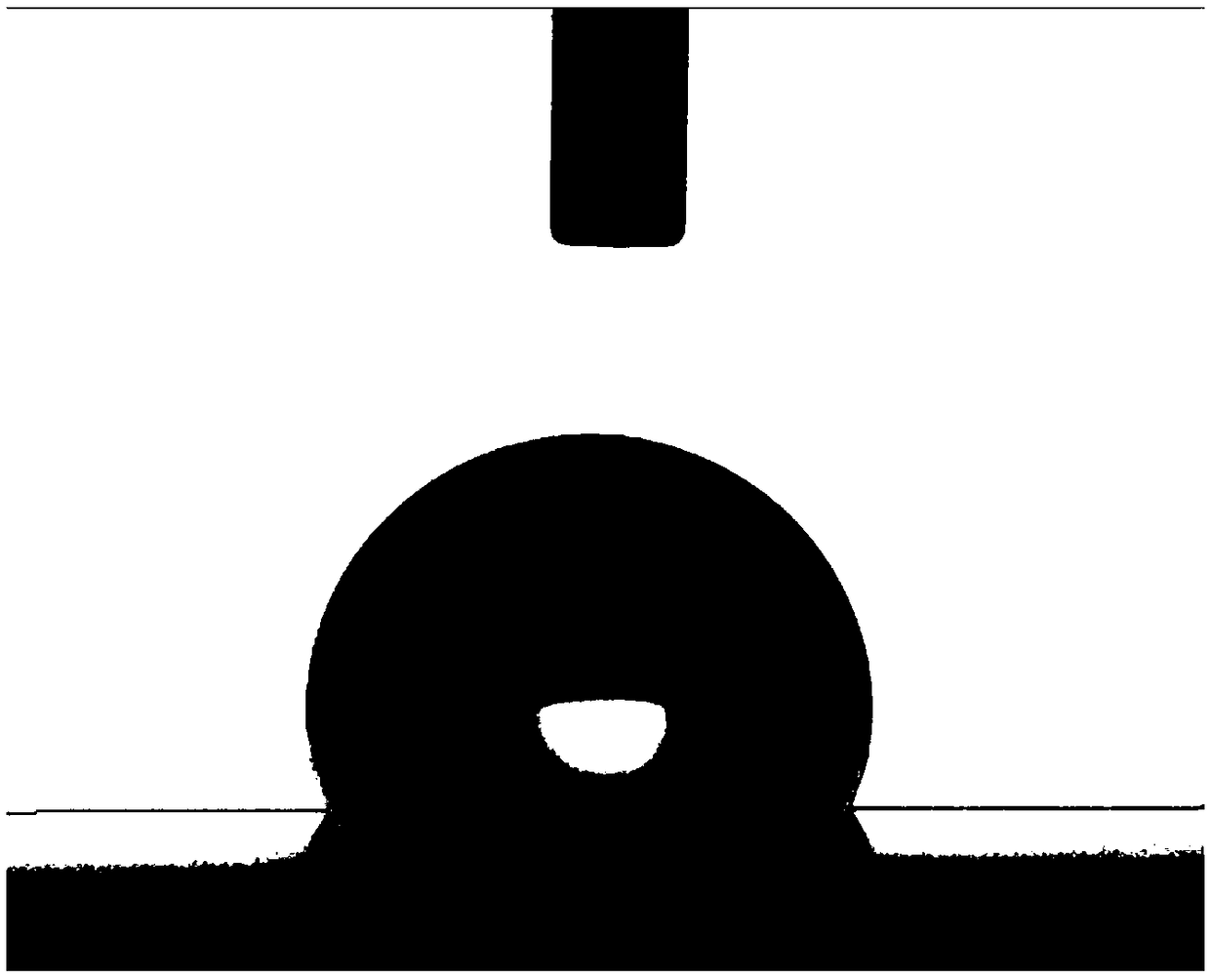

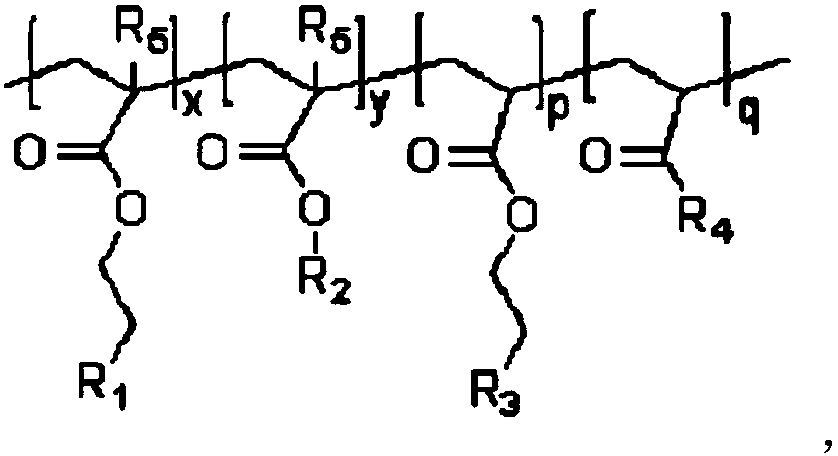

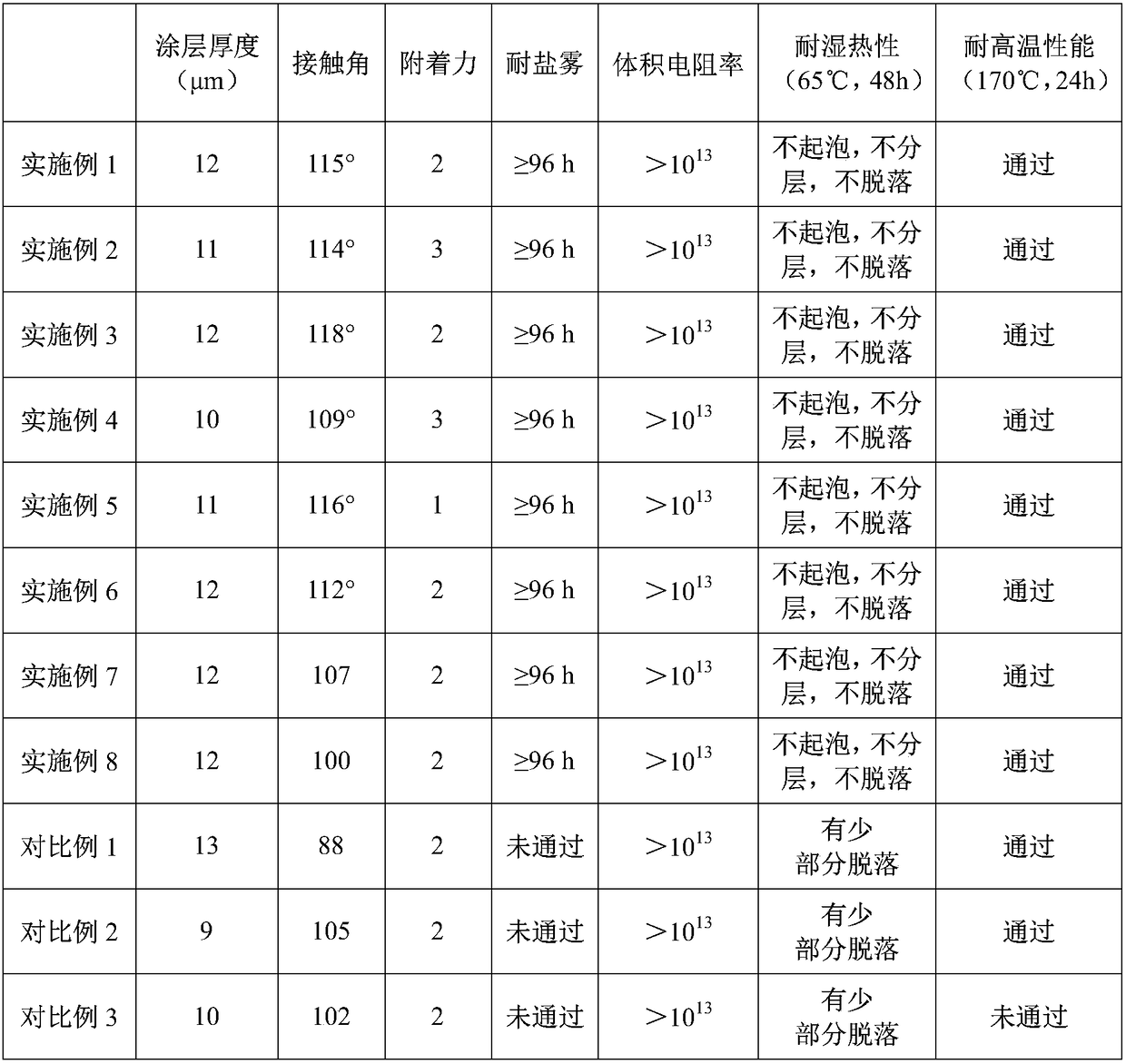

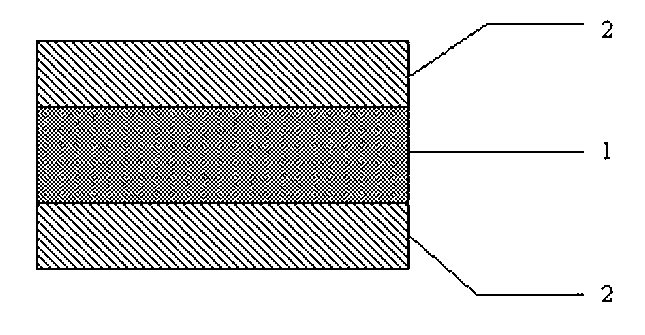

Micron-scale strong salt mist resistant and water repellent three-proof paint for circuit boards

ActiveCN108610868AStrong resistance to salt sprayHigh temperature resistanceFireproof paintsAlkaneMicron scale

The invention relates to a micron-scale strong salt mist resistant and water repellent three-proof paint for circuit boards, wherein the paint comprises a perfluoropolyether modified acrylate polymer.The perfluoropolyether modified acrylate polymer comprises the following structural units: (A) a structural unit provided by a perfluoropolyether derivative monomer and represented by the general formula I, (B) a structural unit provided by a fluorine atom-free acrylate derivative monomer, (C) a structural unit with a cyclic structure and (D) a structural unit with a polar group, wherein CF3CF2CF2O[CF(CF3)CF2O]nCF(CF3)-Y-C(R1)=CH2 (I), in the formula I, n is 5-50, R1 is hydrogen or 1-4 carbon saturated alkanes, and Y is a connecting group. According to the perfluoropolyether modified acrylatepolymer used for preparing the three-proof paint, a side chain as a perfluoropolyether-based chain is introduced to a polymer chain, a polar group, a cyclic group and other groups are introduced intothe polymer, and the prepared three-proof paint has strong salt mist resistance, high temperature resistance, moisture and heat resistance and excellent water repellency.

Owner:太仓中化环保化工有限公司

Polyolefin modified solar battery backplane and processing process thereof

ActiveCN103187469ADimensionally stableEasy to processSynthetic resin layered productsPhotovoltaic energy generationPolyolefinMicrometer

A polyolefin modified solar battery backplane comprises one hygrothermal-aging-resistant layer, a base layer and the other hygrothermal-aging-resistant layer. The base layer is made of hygrothermal-aging-resistant polyethylene terephthalate (PET) formed through blending modification. The range of the thickness of the base layer is 50-350 micrometers. The hygrothermal-aging-resistant layers are made of polyolefin materials formed by filling modification. The range of the thickness of each hygrothermal-aging-resistant layer is 10-250 micrometers. The polyolefin modified solar battery backplane has the advantages of being hygrothermal-aging-resistant, tear-resistant, hydrolysis-resistant, weather-proof, impact-resistant, stable in size and easy to process, and having a function of electrical insulation.

Owner:江苏中来新材科技有限公司

Compound wax emulsion

The invention discloses a composite wax emulsion, which is prepared by mixing the following components: wax, emulsifier and deionized water. The compounded wax emulsion of the present invention is compounded with three components of palm wax, liquid paraffin and beeswax, and emulsified by a high-performance emulsifier. The wax emulsion has the advantages of high stability, low viscosity, rust resistance, heat and humidity resistance, high and low temperature resistance, chemical medium resistance, water resistance and the like.

Owner:张耀忠

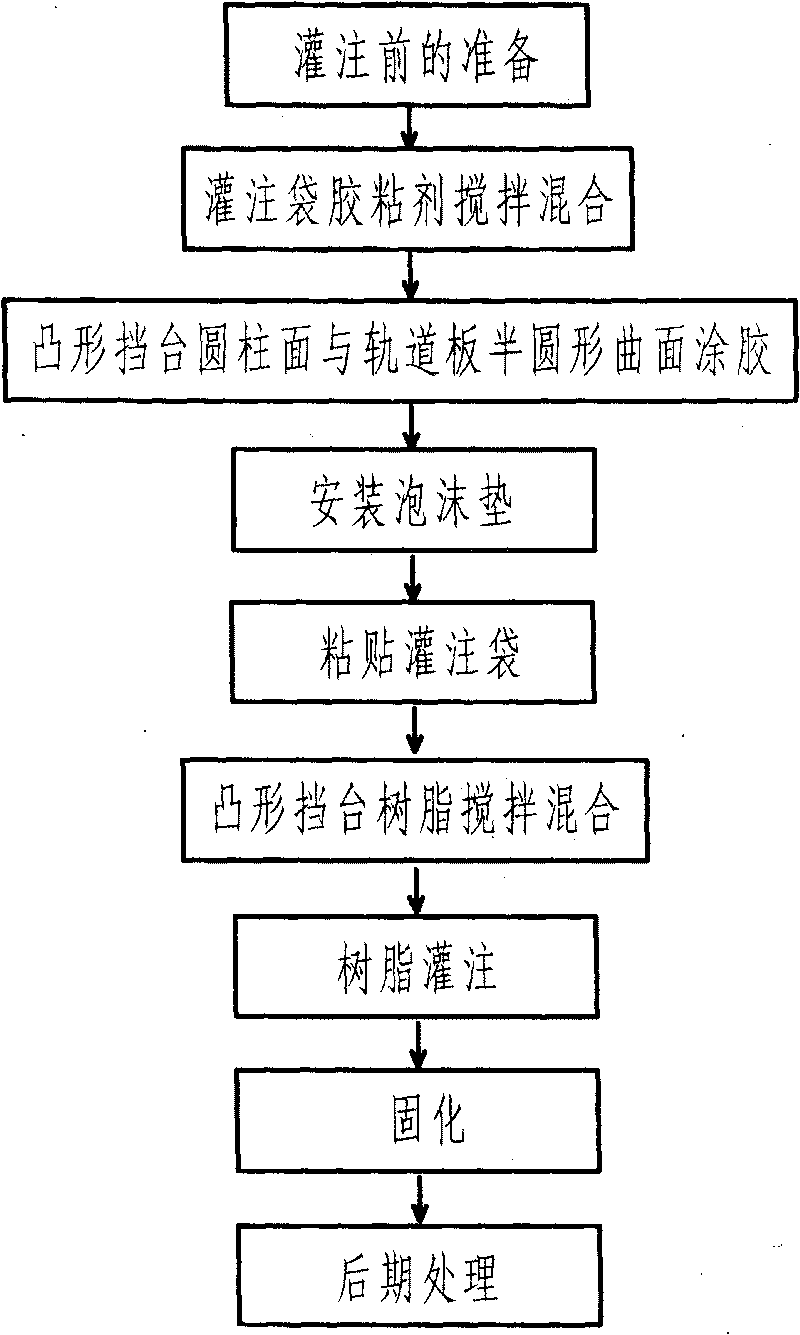

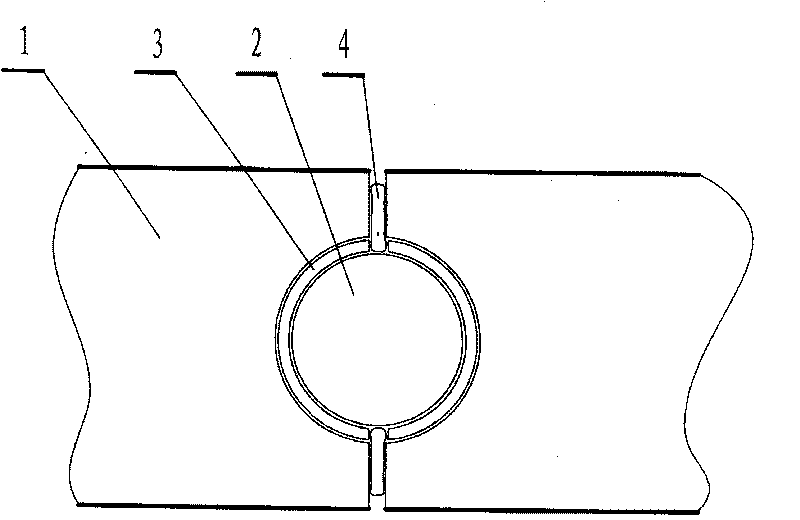

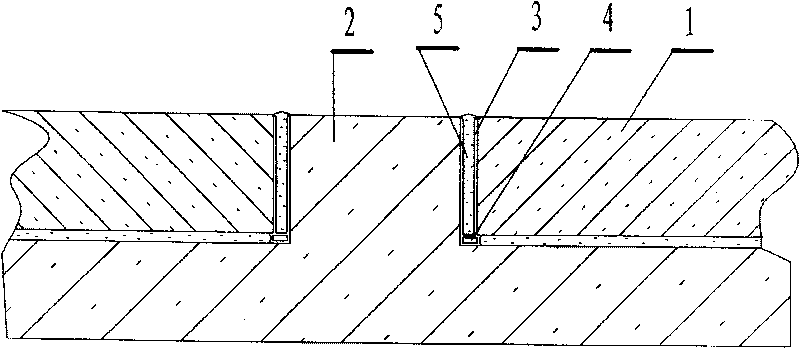

Construction method for filling resin in convex blocking platform of plate-type ballastless-free rail

InactiveCN101718068AImprove adhesionImprove low temperature resistanceBallastwayTrack maintainenceResistAdhesive

The invention discloses a construction method for filling resin in a convex blocking platform of a plate-type ballastless-free rail. An infusion bag is adhered between the convex blocking platform and a rail plate by using an adhesive and infused with filling resin so that the convex blocking platform and the rail plate are favorably adhered. The construction method comprises the following steps of: preparing before infusion; stirring and mixing the infusion bag and the adhesive; coating the adhesive on the cylindrical surface of the convex blocking platform and the semi-circular curve of the rail plate; mounting a foam cushion; adhering the infusion bag; stirring and mixing the convex blocking platform with the resin; and infusing the resin, solidifying and subsequently processing. The filling resin constructed between the convex blocking platform and the rail plate has favorable adhesive force to concrete members, resists UV irradiation, hydrothermal aging and chemical corrosion, and has a certain elasticity and mechanical strength. The construction method is simple and convenient to operate, thereby being suitable for the mass construction of plate-type ballastless-free rails.

Owner:CHINA RAILWAY 23RD BUREAU GROUP 2TH ENG +2

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method and its use as a filling material for the convex stopper of railway slab ballastless track, the composition is mainly used as the convex stopper of railway slab ballastless track Filler. The polyurethane resin composition is mainly composed of polyether or polyester polyol, isocyanate or its prepolymer, pigment, filler and other auxiliary agents. The prepared polyurethane resin has good construction technology, and the cured resin has good adhesion to cement, and has ultraviolet radiation resistance, damp heat aging resistance, fatigue resistance and suitable elasticity and comprehensive mechanical properties.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

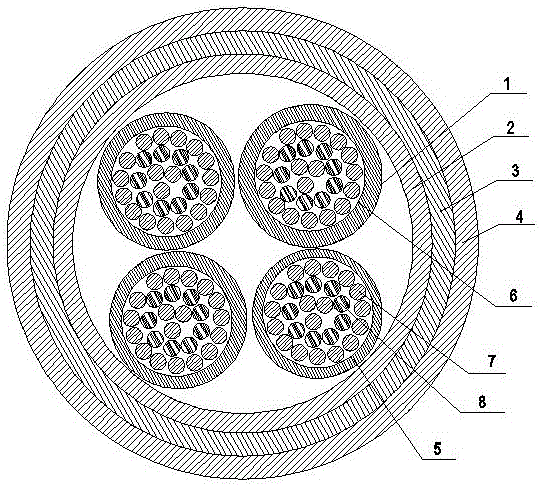

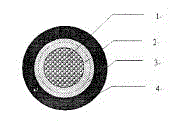

High-weather-resistant, torsion-resistant and bending-resistant control cable

InactiveCN106601345AImprove insulation performanceImprove combustion characteristicsQuad constructionsClimate change adaptationFiberInterference resistance

The invention provides a high-weather-resistant, torsion-resistant and bending-resistant control cable, and relates to the technical field of design of towline cables. The high-weather-resistant, torsion-resistant and bending-resistant control cable includes a cable core formed by mutual twisting of a plurality of reinforced insulating wire cores, an inner liner layer, a reinforced braided shielding layer and an outer sheath layer are arranged in sequence outside the cable core, each reinforced insulating wire core includes a conductor externally wrapped by an insulating layer, and the conductor is formed by intertwisting copper wires and Dupont fibers in the same direction; and the reinforced braided shielding layer is formed by braiding copper wires and Dupont fibers in a combined manner, each spindle of copper wires is provided with a piece of Dupont fiber, and the braiding density of the reinforced braided shielding layer is larger than 90%. The high-weather-resistant, torsion-resistant and bending-resistant control cable provided by the invention has the characteristics of excellent interference resistance, torsion resistance, bending resistance and the like, and can meet market requirements.

Owner:江苏安胜电缆有限公司

High-performance single-component dealcoholization room temperature vulcanized silicone rubber sealant and preparation method thereof

ActiveCN105838317AGood compatibilityHigh strengthNon-macromolecular adhesive additivesFiberPolymer science

The invention relates to the technical field of sealing materials, in particular to a preparation method of a high-performance single-component dealcoholization room temperature vulcanized silicone rubber sealant .The sealant is prepared from, by weight, 150-200 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 5-40 parts of a crosslinking agent, 80-300 parts of functional filler, 2-10 parts of a catalyst and 0-20 parts of a plasticizer .The functional filler is composite particles prepared by adopting nano calcium carbonate as the nucleus and adopting polydivinylbenzene as a shell through a dispersion polymerization method, wherein the particle size is 50-90 nm; the functional filler shell is polydivinylbenzene, has the good hydrophobicity and can be wound around chain segments of a matrix or embedded in the matrix in an anchored mode, the composite particles on a micelle interface has the fiber-bridge effect on the matrix, and the effect of increasing the capacity of the single-component dealcoholization room temperature vulcanized silicone rubber sealant is achieved .The rubber sealant is good in adhesiveness, and the surface drying time is shorter than 10 min; due to the fact that the price of the filler is low, the comprehensive material cost can be lowered .

Owner:勃乐氏密封系统(太仓)有限公司

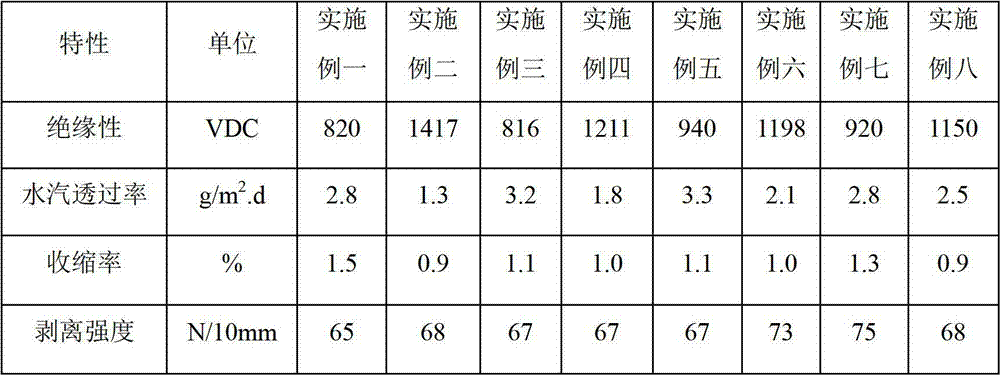

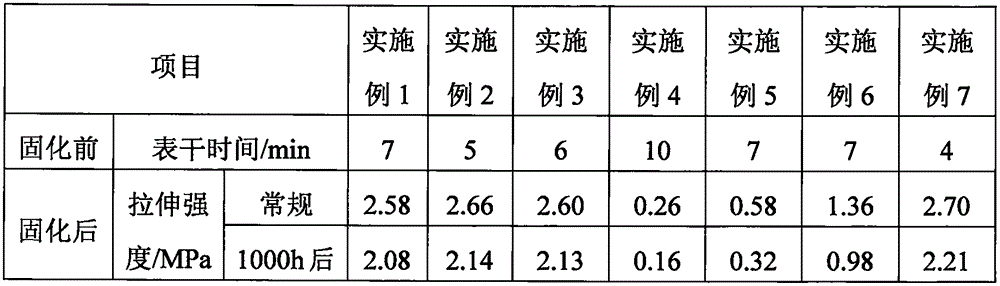

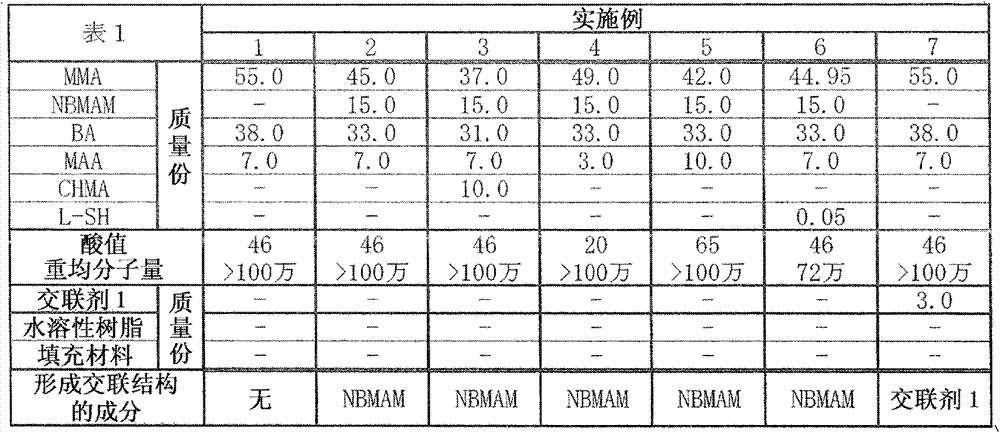

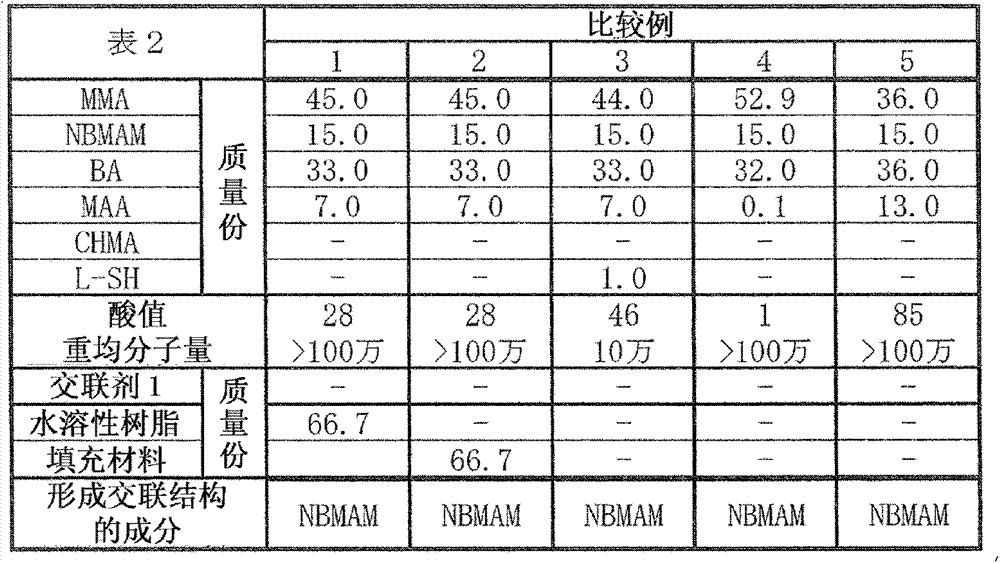

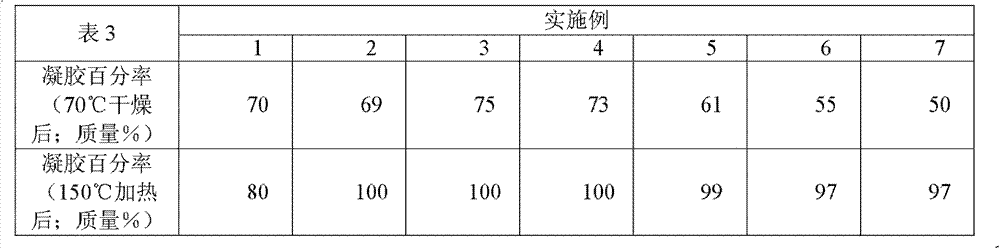

Resin composition for forming receiving layer, receiving substrate obtained using same, printed matter, conductive pattern, and electrical circuit

InactiveCN103249571AExcellent adhesionHas heat and humidity resistanceDuplicating/marking methodsPrinted circuit manufactureFine lineWater based

The present invention addresses the problem of providing a resin composition for forming a receiving layer, the resin composition being capable of forming a highly adhesive receiving layer, of ensuring water resistance and the ability to form fine lines both with water-based conductive inks and solvent-based conductive inks, and of forming conductive patterns or the like that have wet heat resistance. This invention is related to a resin composition for forming a receiving layer, characterized in that: the resin composition contains a vinyl resin (A) having a weight-average molecular weight of at least 100,000 and an acid value of 10-80, an aqueous medium (B), and, as necessary, at least one component (C) selected from the group consisting of a water-soluble resin (c1) and a filler (c2);the vinyl resin (A) being dispersed in the aqueous medium (B); and the amount of the component (C) being 0-15% by mass with respect to the total amount of the vinyl resin (A).

Owner:DIC CORP

Triphenyl borate modified melamine flame-retardant and sound-absorption foam material for cranes and preparation method of foam material

InactiveCN106147128AWith thermal insulationHas heat and humidity resistanceHexamethylenetetraminePolyethylene glycol

The invention relates to a triphenyl borate modified melamine flame-retardant and sound-absorption foam material for cranes. The foam material is characterized by being prepared from the following raw materials in parts by weight: melamine, a 37% formaldehyde solution, paraformaldehyde, ammonium polyphosphate, aluminum oxide, zinc borate, polyethylene glycol, 1,4-butanediol, 1,1-bis(t-butylperoxy)cyclohexane, diisopropyl disulfide xanthate, vinyl acetate, toluene, ethanol, sodium ethoxide, 4-hydroxybenzohydrazide, chloroform, cupric chloride, n-pentane, phosphoric acid, triethylhexyl phosphoric acid, a hydrochloric acid solution with a pH value equal to 1-2, a proper amount of hexamethylenetetramine and a proper amount of water. The foam material provided by the invention has excellent flame retardance and good sound absorption capacity, and the noise can be reduced by above 10dB.

Owner:侯明

A modified polyamide resin composition and backplane substrate film prepared by the same

ActiveCN103059558BImprove water absorptionGood moisture and heat aging resistancePhotovoltaic energy generationSemiconductor devicesWater vaporGraft reaction

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Insulated rail with nano-ceramic coating

InactiveCN106939534AEliminate stray currentSimplify track laying processRailsInsulation resistanceNanometre

The invention relates to an insulated rail with a nano-ceramic coating. The surface of a rail (1) comprises a rail top surface (3) and rest rail outer surfaces (4), wherein the rail top surface (3) refers to the surface in contact with the rolling of wheels and the nearby upper surface part; the rest rail outer surfaces (4) comprise the upper, lower and side surfaces of a rail foot, the two side surfaces of a rail web and the upper, lower and side surface of a rail head along the longitudinal direction of the rail; a nano-ceramic insulated coating (2) is evenly coated on the rest rail outer surfaces (4); and the materials of the nano-ceramic insulated coating (2) comprise an adhesive material, a reinforcing material and an active hardener. Compared with the prior art, the insulated rail with the nano-ceramic coating has the functions of high insulation resistance, corrosion resistance, water resistance, aging resistance, friction resistance, damp and heat resistance, atmospheric aging resistance and strong adhesion; in addition, the insulated rail with the nano-ceramic coating has the advantages of fundamentally eliminating the occurrence of stray currents of a rail system and avoiding the electrochemical corrosion, and the cost is low.

Owner:SHANGHAI UNIV OF ENG SCI

Solar photovoltaic cable

InactiveCN103824623AHigh mechanical strengthGood flexibilityInsulated cablesPower cablesCross-linkPolyolefin

The invention belongs to the field of a cable and especially provides a solar photovoltaic cable applied to a photovoltaic solar system. The solar photovoltaic cable mainly comprises a conductor, an insulating layer and a sheath. The insulating layer comprises an inner insulating layer and an outer insulating layer. The inner insulating layer is made of a -40 DEG C-125 DEG C low-smoke zero-halogen radiation cross-linking polyolefin material, of which the volume resistance is 1.0*1014-9.0*1017 Omega.cm when the temperature is 20 DEG C. The outer insulating layer is made of a -40 DEG C-125 DEG C low-smoke zero-halogen anti-flaming radiation cross-linking polyolefin material, of which the volume resistance is 1.0*1012-9.0*1015 Omega.cm when the temperature is 20 DEG C and the oxygen index is 24-46. The thickness of the inner insulating layer is 0.1 mm-1.3 mm. The thickness of the outer insulating layer is 0.2 mm-1.3 mm. The advantages lie in that the external diameter of the finished product is reduced by 16.7%; weight is reduced by 49.1%; the decrease amount of the thickness of the insulating layer is 42.5% of the prior art; working performances, such as acid and alkali resistance, humidity and heat resistance, ozone resistance and ultraviolet resistance and the like are improved; and the service life of the cable is prolonged.

Owner:QINGDAO YUTAI NEW ENERGY SCI & TECH

Norbornene copolymer modified polyolefin solar cell rear film and processing technology thereof

ActiveCN102800725AHas heat and humidity resistanceTear resistantFinal product manufactureSynthetic resin layered productsPolymer sciencePolyolefin

The invention provides a norbornene copolymer modified polyolefin solar cell rear film. The norbornene copolymer modified polyolefin solar cell rear film comprises a base layer, a surface layer and a bottom layer, wherein the base layer is formed by PET (Polyethylene Glycol Terephthalate) or a norbornene copolymer or PP (Propene Polymer); the surface layer is positioned on the upper surface of the base layer and formed by an eutectic based on the norbornene copolymer and a copolymer of vinylidene fluoride and crylic acid; and the bottom layer is positioned on the lower surface of the base layer and formed by the eutectic based on the norbornene copolymer and an EVA (Ethylene vinyl acetate Copolymer). The norbornene copolymer modified polyolefin solar cell rear film provided by the invention has the characteristics of heat and humidity resistance, aging resistance, tearing resistance, hydrolysis resistance, high barrier property to steam, high insulating performance, high strength, stability in dimension, and easiness in processing and forming, is beneficial to the protection of a solar cell module, and prolongs the service life of a solar cell.

Owner:江苏中来新材科技有限公司

Halogen-free fire resistance resin composite and application thereof

InactiveCN102020830BExcellent dielectric propertiesExcellent heat and humidity resistancePrinted circuit aspectsPrinted circuit manufactureDip solderingMetal foil

Owner:GUANGDONG SHENGYI SCI TECH

Solar cell module support member and machining process thereof

ActiveCN102931252BReduce weightRigid hardnessPhotovoltaic supportsFinal product manufactureNorbornenePolyamide

The invention discloses a solar cell module support member which comprises a surface layer of a support member, and a bottom layer of the support member, wherein a surface layer formed by a norbornene copolymer, PA (polyamide) or PP (Propene Polymer) or PVDF (Polyvinylidene Fluoride), MAH-g-POE and eutectic of a filler is used as the surface course of the support member, the bottom layer is formed by a POE layer arranged on the lower surface of a base layer, and the POE layer can be one or two. The solar cell module support member provided by the invention has better mechanical property, has the characteristics of humidity and heat ageing resistance, tearing and hydrolysis resistance, high water vapor barrier property, high insulation property, high strength, size stability and fatigue resistance, and is beneficial to protection of a solar cell module and prolonging of the service life of the solar cell module.

Owner:JOLYWOOD SUZHOU SUNWATT

Preparation method and application of high temperature resistant solvent-type acrylate pressure-sensitive adhesive

ActiveCN104449486BImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEthyl acetateTemperature resistance

The invention relates to a high temperature solvent resistant acrylate pressure sensitive adhesive which comprises the following components in parts by weight: 150-250 parts of 2-ethylhexyl acrylate, 50-100 parts of butyl acrylate, 3-10 parts of acrylic acid, 3-10 parts of hydroxyethyl acrylate, 10-20 parts of vinyl acetate, 15-35 parts of bornyl isoacrylate, 0.5-3 parts of azobisisobutyronitrile, 0.3-2 parts of N-hydroxymethyl acrylamide and 400-600 parts of ethyl acetate. The mechanical property, high temperature resistance and weather resistance of the emulsion type acrylate pressure sensitive adhesive are improved, so that the application range of the emulsion type acrylate pressure sensitive adhesive is widened, and the pressure sensitive adhesive has the characteristics of high viscidity, high temperature resistance, damp-heat aging resistance and low cost.

Owner:新丰杰力电工材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com