Solar cell base film made from norbornene copolymer and processing technology thereof

A technology of norbornene and solar cells, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced bonding performance between the backsheet and EVA, complex bonding processing technology, poor bonding performance, etc. Ease of operation, ensuring reliability, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

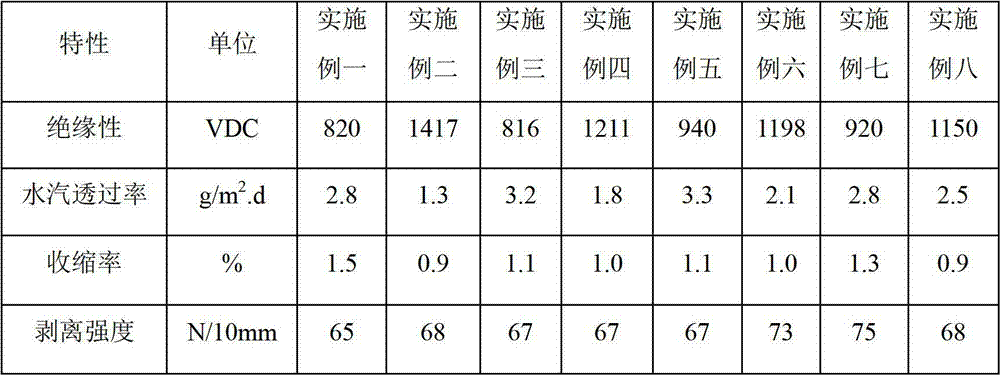

Examples

Embodiment 1

[0033] The thickness of solar cell base film is 0.15mm, and described base film is made of eutectic of norbornene copolymer, PC and EVA, filler, and the weight ratio of norbornene copolymer, PC and EVA, filler is respectively 10% :50%:10%:30%.

Embodiment 2

[0035]The thickness of solar cell base film is 0.35mm, and described base film is made of eutectic of norbornene copolymer, PC and EVA, filler, and the weight ratio of norbornene copolymer, PC and EVA, filler is 10%: 50%: 10%: 30%.

Embodiment 3

[0037] The thickness of solar cell base film is 0.15mm, and described base film is made of norbornene copolymer, POE and EVA, the eutectic of filler, and the weight ratio of norbornene copolymer, POE and EVA, filler is 15%: 50%: 15%: 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com