Resin composition for forming receiving layer, receiving substrate obtained using same, printed matter, conductive pattern, and electrical circuit

A technology of resin composition and accommodating layer, applied in the directions of printed circuit, printed circuit manufacturing, printing, etc., can solve the problems of disconnection, the heat and humidity resistance of the conductive pattern cannot be said to be sufficient, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0215] Example 1

[0216] 350 parts by mass of deionized water and 4 parts by mass of LATEMUL E-118B (manufactured by Kao Co., Ltd.: active ingredient 25% by mass) were added to a reaction container equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, a thermometer, and a dropping funnel, The temperature was raised to 70° C. while blowing nitrogen gas.

[0217] Under stirring, a vinyl monomer mixture containing 55.0 parts by mass of methyl methacrylate, 38.0 parts by mass of n-butyl acrylate and 7.0 parts by mass of methacrylic acid, Aqualon KH- A part (5 parts by mass) of the monomer pre-emulsion obtained by mixing 4 parts by mass of 1025 (made by Daiichi Kogyo Pharmaceutical Co., Ltd.: active ingredient 25 mass %) and 15 parts by mass of deionized water, and then adding potassium persulfate 0.1 It was made to polymerize for 60 minutes, maintaining the temperature in the reaction container at 70 degreeC.

[0218] Then, while maintaining the tempera...

Embodiment 2~6

[0225] Examples 2 to 6

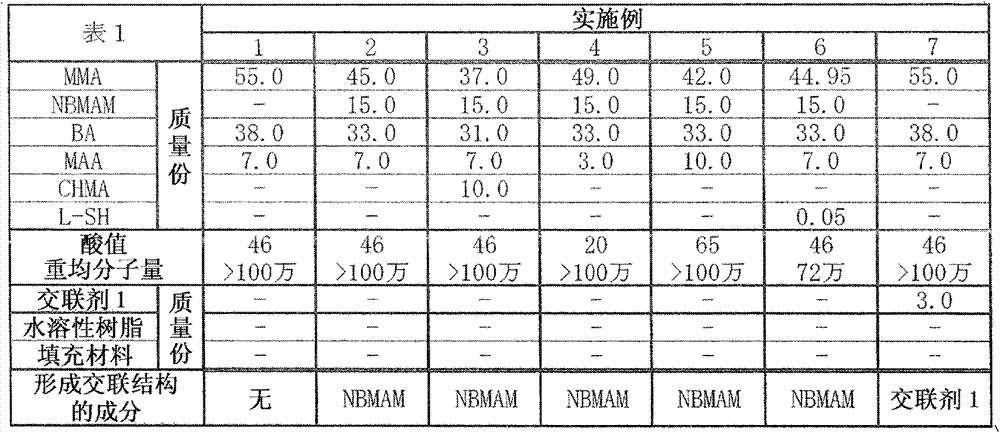

[0226] Except for changing the composition of the vinyl monomer mixture to the composition described in the following Table 1, a resin combination for forming a receiving layer with a non-volatile content of 20% by mass was prepared by the same method as that described in Example 1. Objects (I-2) ~ (I-6).

[0227] In addition, the resin compositions (I-2) to (I-6) for forming an accepting layer were respectively used instead of the resin composition for forming an accepting layer (I-1), using the same method described in Example 1. In the same way as above, the receiving substrates (II-2) to (II-6) were produced.

Embodiment 7

[0228] Example 7

[0229]350 parts by mass of deionized water and 4 parts by mass of LATEMUL E-118B (manufactured by Kao Co., Ltd.: active ingredient 25% by mass) were added to a reaction container equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, a thermometer, and a dropping funnel, The temperature was raised to 70° C. while blowing nitrogen gas.

[0230] Under agitation, a vinyl monomer mixture containing 55.0 parts by mass of methyl methacrylate, 38.0 parts by mass of n-butyl acrylate, and 7.0 parts by mass of methacrylic acid, Aqualon KH-1025 (Daiichi Kogyo Pharmaceutical Co., Ltd. Co., Ltd.: a part (5 parts by mass) of the monomer pre-emulsion obtained by mixing 4 parts by mass of active ingredient 25 mass %) and 15 parts by mass of deionized water, then add 0.1 parts by mass of potassium persulfate, and react Polymerization was carried out for 60 minutes while maintaining the temperature in the container at 70°C.

[0231] Then, while maint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com