High-performance single-component dealcoholization room temperature vulcanized silicone rubber sealant and preparation method thereof

A room temperature vulcanization, one-component technology, used in non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problem of poor wettability of polysiloxane, affecting the high temperature resistance of materials, and surface hydrophilicity difficult problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

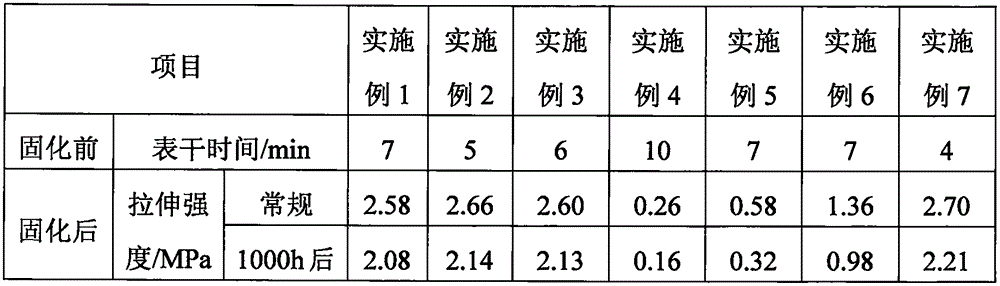

Examples

Embodiment 1

[0030] The high-performance one-component dealcoholized room temperature vulcanized silicone rubber sealant of this embodiment is prepared from the following raw materials in parts by weight: 200 parts of α, ω-dihydroxypolydimethylsiloxane with a dynamic viscosity of 5000 cps , 15 parts of crosslinking agent, 200 parts of functional filler, 4 parts of catalyst and 20 parts of plasticizer;

[0031] Wherein, the preparation method of described functional filler is:

[0032] (1) Mix nano-calcium carbonate and deionized water to form an aqueous suspension with a mass fraction of 6%, then add polyvinylpyrrolidone accounting for 0.5% of divinylbenzene mass, stir and disperse for 80min at 1500r / min, and disperse The pH of the homogeneous suspension was adjusted to 6.5;

[0033] (2) Stir and heat the suspension under the condition of 450r / min and heat up to 78°C, then stabilize it for 12 minutes, then add ammonium persulfate accounting for 0.8% of the mass of divinylbenzene;

[0034...

Embodiment 2

[0039] The high-performance one-component dealcoholized room temperature vulcanized silicone rubber sealant of this embodiment is prepared from the following raw materials in parts by weight: 150 parts of α, ω-dihydroxypolydimethylsiloxane with a dynamic viscosity of 20000 cps , 5 parts of crosslinking agent, 150 parts of functional filler, 2 parts of catalyst and 0 parts of plasticizer;

[0040] Wherein, the preparation method of described functional filler is:

[0041] (1) Mix nano-calcium carbonate and deionized water to form an aqueous suspension with a mass fraction of 6%, add polyvinylpyrrolidone accounting for 1% of divinylbenzene mass, stir and disperse for 60min under the condition of 1800r / min, and disperse The pH of the homogeneous suspension was adjusted to 7.0;

[0042] (2) Stir and heat the suspension under the condition of 600r / min and heat up to 80°C, then stabilize it for 10min, then add ammonium persulfate accounting for 1.0% of the mass of divinylbenzene; ...

Embodiment 3

[0048] The high-performance one-component dealcoholized room temperature vulcanized silicone rubber sealant of this embodiment is prepared from the following raw materials in parts by weight: 180 parts of α, ω-dihydroxypolydimethylsiloxane with a dynamic viscosity of 50000 cps , 40 parts of crosslinking agent, 180 parts of functional filler, 10 parts of catalyst and 0 parts of plasticizer;

[0049] Wherein, the preparation method of described functional filler is:

[0050] (1) Mix nano-calcium carbonate and deionized water to form an aqueous suspension with a mass fraction of 10%, add polyvinylpyrrolidone accounting for 1% of the mass of divinylbenzene, stir and disperse for 40min under the condition of 2000r / min, and disperse The pH of the homogeneous suspension was adjusted to 6.5;

[0051] (2) Stir and heat the suspension under the condition of 750r / min and heat up to 82°C, stabilize it for 8 minutes, and then add ammonium persulfate accounting for 0.8% of the mass of diviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com