Composite cathode material, preparation method and lithium ion battery

A technology for compounding positive electrode materials and positive electrode materials, applied in the field of battery materials, can solve the problems of poor thermal stability of positive electrode materials, decreased capacity retention rate, uneven distribution of PTC, etc., achieves good thermal stability, improves thermal stability, and avoids side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment approach 1

[0058] In order to further illustrate technical effect of the present invention, design experimental scheme one is:

[0059] A thin layer of MgAl was formed on the surface of the ternary cathode material by sol-gel method 2 o 4 Nanomaterials, ternary materials and MgAl 2 o 4 The mass ratio of MgAl is 80~100:0.5~5. During heat treatment, MgAl 2 o 4 It is possible to form a Li-Al-Co-O eutectic with the positive electrode material. With this structure, the corrosion of the electrolyte to the ternary material is reduced, the collapse of the material structure is avoided, and the cycle stability of the material is improved. At the same time MgAl 2 o 4 It has good high temperature resistance, can improve the high temperature stability of the material, and has a simple preparation method and is convenient for large-scale production. The synthesis steps are:

[0060] Step 1: Preparation of core-shell positive electrode material precursor: Weigh a certain amount of soluble Ni, ...

experiment approach 2

[0066] The second experimental design is:

[0067] Step 1: The nickel-cobalt-manganese ternary material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Mixed with lithium source, calcined to obtain ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 .

[0068] Step 2: MgAl with commercially purchased spinel structure 2 o 4 Nanomaterials and the ternary cathode material LiNi prepared in Step 1 0.6 co 0.2 mn 0.2 o 2 Mix in a ball mill.

[0069] Step 3: Calcining the mixture obtained in Step 2 to obtain a composite cathode material.

[0070] According to above-mentioned experimental design scheme, enumerate specific embodiment below, verify technical effect of the present invention:

Embodiment 1

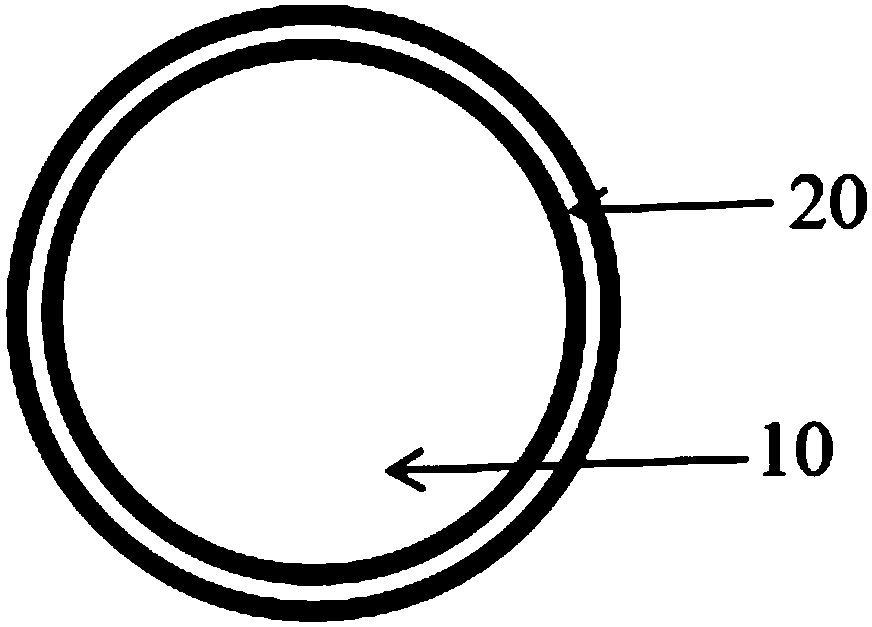

[0072] In this example, MgAl is loaded with ternary material 2 o 4 As an example, the composite positive electrode material is described, the inner layer is LiNi 0.6 co 0.2 mn 0.2 o 2 , the outer layer is MgAl 2 o 4 . Among them LiNi 0.6 co 0.2 mn 0.2 o 2 with MgAl 2 o 4 The mass ratio of is 100:2, and its preparation method comprises the following steps:

[0073] Step 1: The commercialized layered high-nickel material Ni 0.6 co 0.2 mn 0.2 (OH) 2 Mixed with lithium acetate at a molar ratio of 1:1, mixed in a ball mill for 30 minutes, and calcined at 900°C for 6 hours to obtain the ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 .

[0074] Step 2: Taking magnesium salt and aluminum salt as starting raw materials, using water as solvent, configuring n(Mg 2+ ):n(Al 3 + ) = 1:2 mixed solution of metal ions, after mixing thoroughly, add an appropriate amount of citric acid as a complexing agent, and then heat at 70-100°C to form a complex sol.

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com