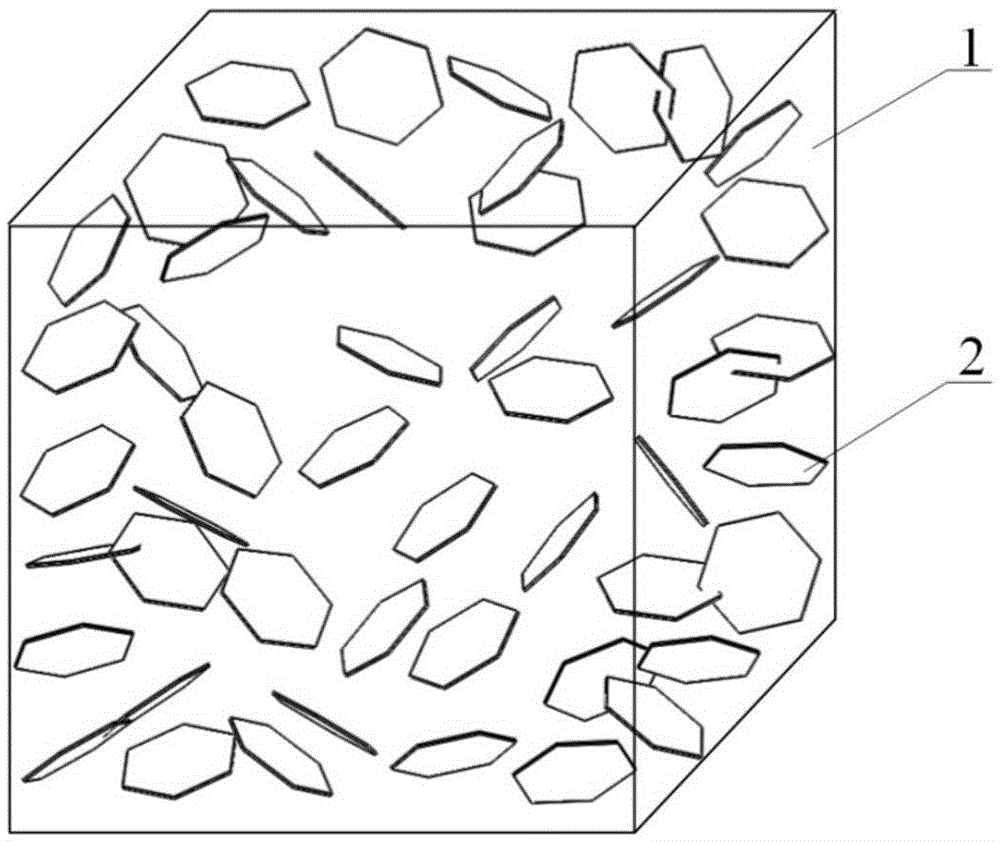

Polypropylene composite material with high thermal conductivity and preparation method thereof

A composite material and high thermal conductivity technology, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of low thermal conductivity, low density, and low cost of polymers, so as to improve thermal conductivity, ensure mechanical properties, thermal The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

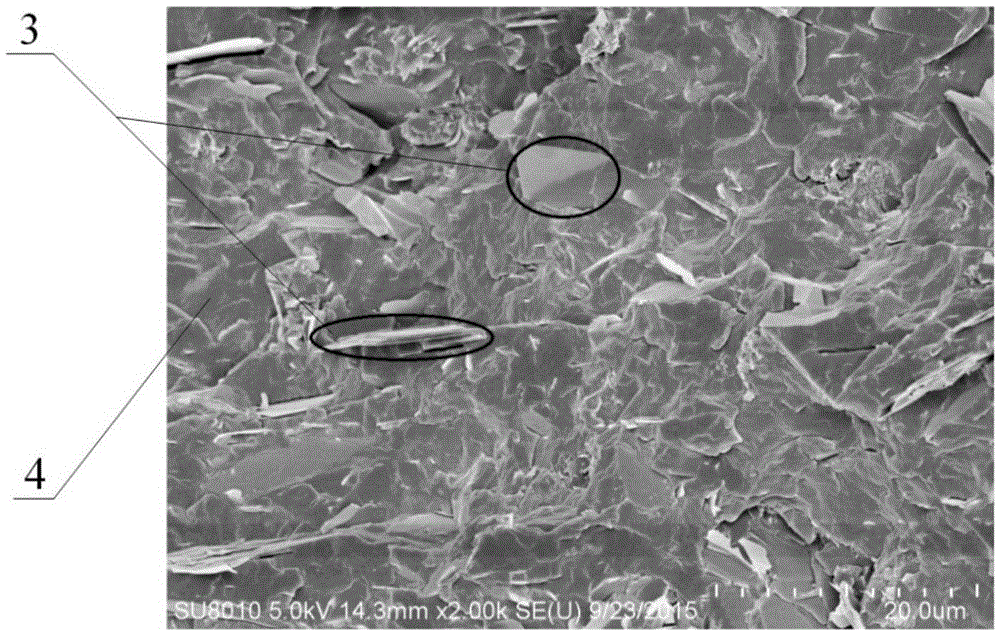

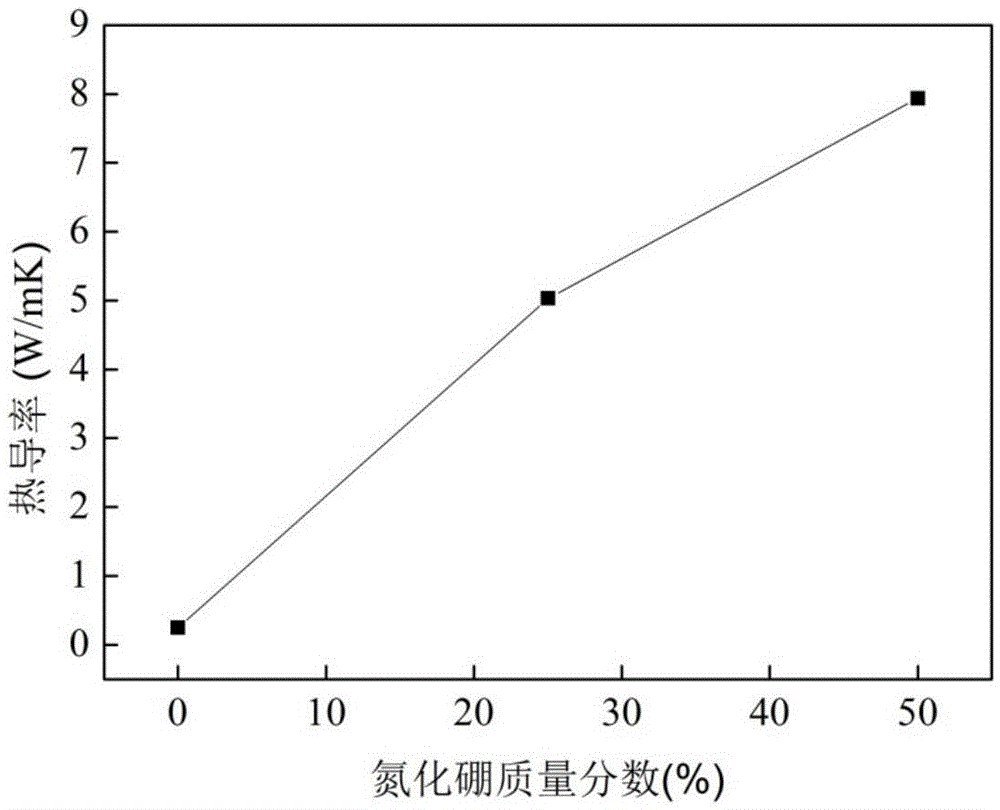

[0023] Composite materials with different dopamine-modified boron nitride mass fractions were prepared by the following melt blending method:

[0024] 1) Dry all the raw materials in a vacuum drying oven, the drying time is 8-15 hours, and the drying temperature is 80-100°C.

[0025] 2) Disperse 200-300g of boron nitride in 6000-10000ml of deionized water, sonicate for 30-60min, add 5-10g of tris(hydroxymethyl)aminomethane, and then add 10-20g of dopamine hydrochloride to adjust the pH of the solution to 8.5, stirring for 4 to 8 hours, ultrasonically centrifuging the reacted solution with deionized water for 5 to 10 times at a speed of 2000 to 4000 r / min, and drying to obtain dopamine-modified boron nitride.

[0026] 3) Add 8775g polypropylene, 225g maleic anhydride grafted polypropylene, and 3000g / 9000g dopamine-modified boron nitride prepared by the method described in step 2) into the extruder evenly, and extrude the sample after adjusting the temperature and rotating speed...

Embodiment 2

[0031] Composite materials with different dopamine-modified alumina mass fractions were prepared by the following melt blending method:

[0032] 1) Dry all the raw materials in a vacuum drying oven, the drying time is 8-15 hours, and the drying temperature is 80-100°C.

[0033] 2) Disperse 200-300g of alumina in 6000-10000ml of deionized water, sonicate for 30-60min, add 5-10g of tris(hydroxymethyl)aminomethane, and then add 10-20g of dopamine hydrochloride to adjust the pH of the solution to 8.5 , stirred for 4 to 8 hours, and the reacted solution was ultrasonically centrifuged for 5 to 10 times with deionized water at a speed of 2000 to 4000 r / min, and dried to obtain dopamine-modified alumina.

[0034] 3) 8775g polypropylene, 225g maleic anhydride grafted polypropylene, 3000g / 9000g dopamine-modified alumina prepared by the method described in step 2) are evenly added to the extruder, and the extruder is extruded after adjusting the extruder temperature and rotating speed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com