Method for preparing compound 4-hydroxy butyl vinyl ether

A technology of hydroxybutyl vinyl ether and compounds, which is applied in the field of preparation of vinyl ether compounds, and can solve problems such as increasing the contact time of acetylene gas, low vinyl ether content, and high cyclic acetal by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Add 2000g of 1,4-butanediol and 180g of potassium hydroxide into a 3000ml three-necked bottle, start stirring, heat the oil bath to 140°C, distill under 0.05MPa vacuum, and slip out about 200g of colorless transparent liquid to obtain about 1980g of brown Viscous liquid, add 400g dimethyl sulfoxide, stir well and set aside.

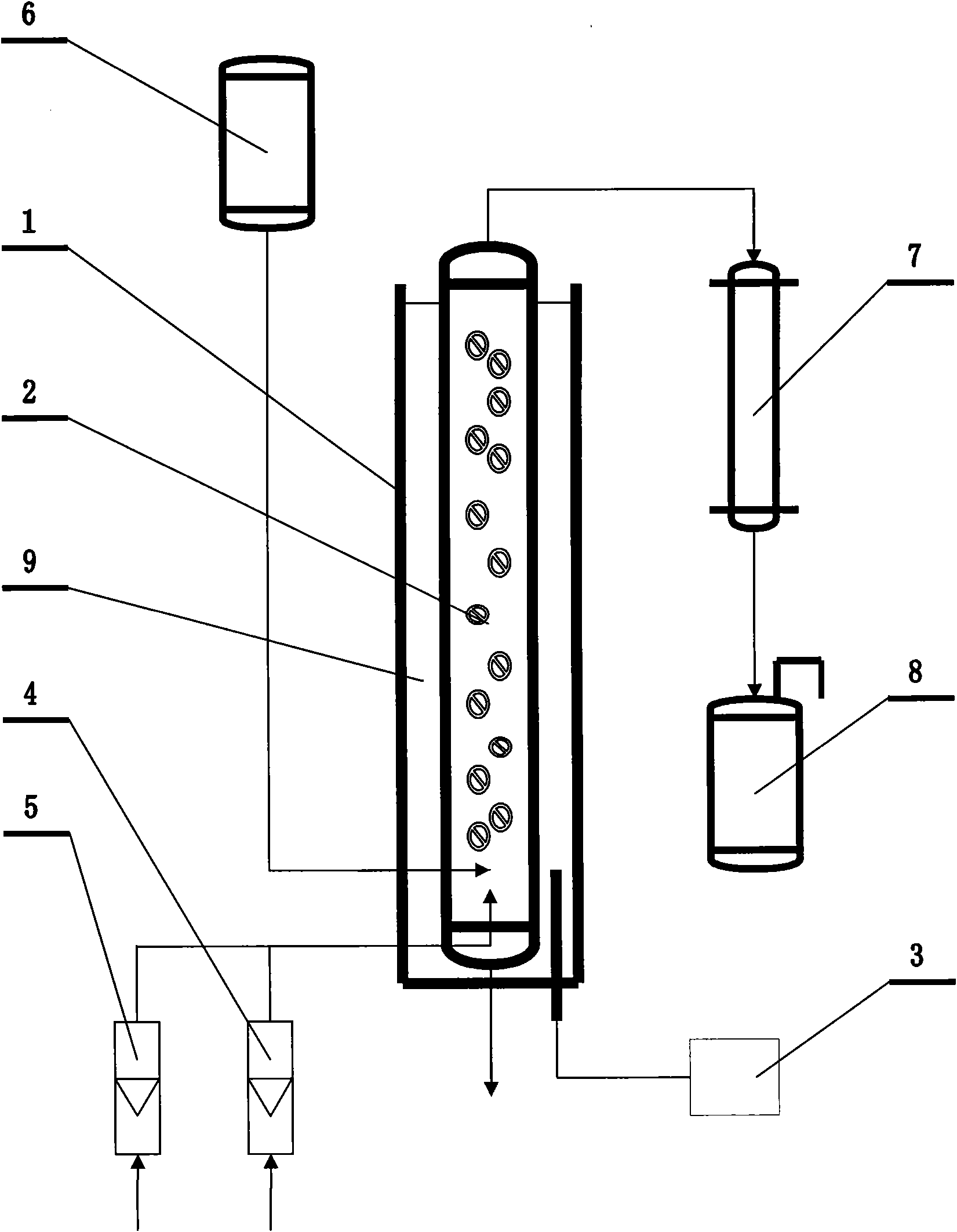

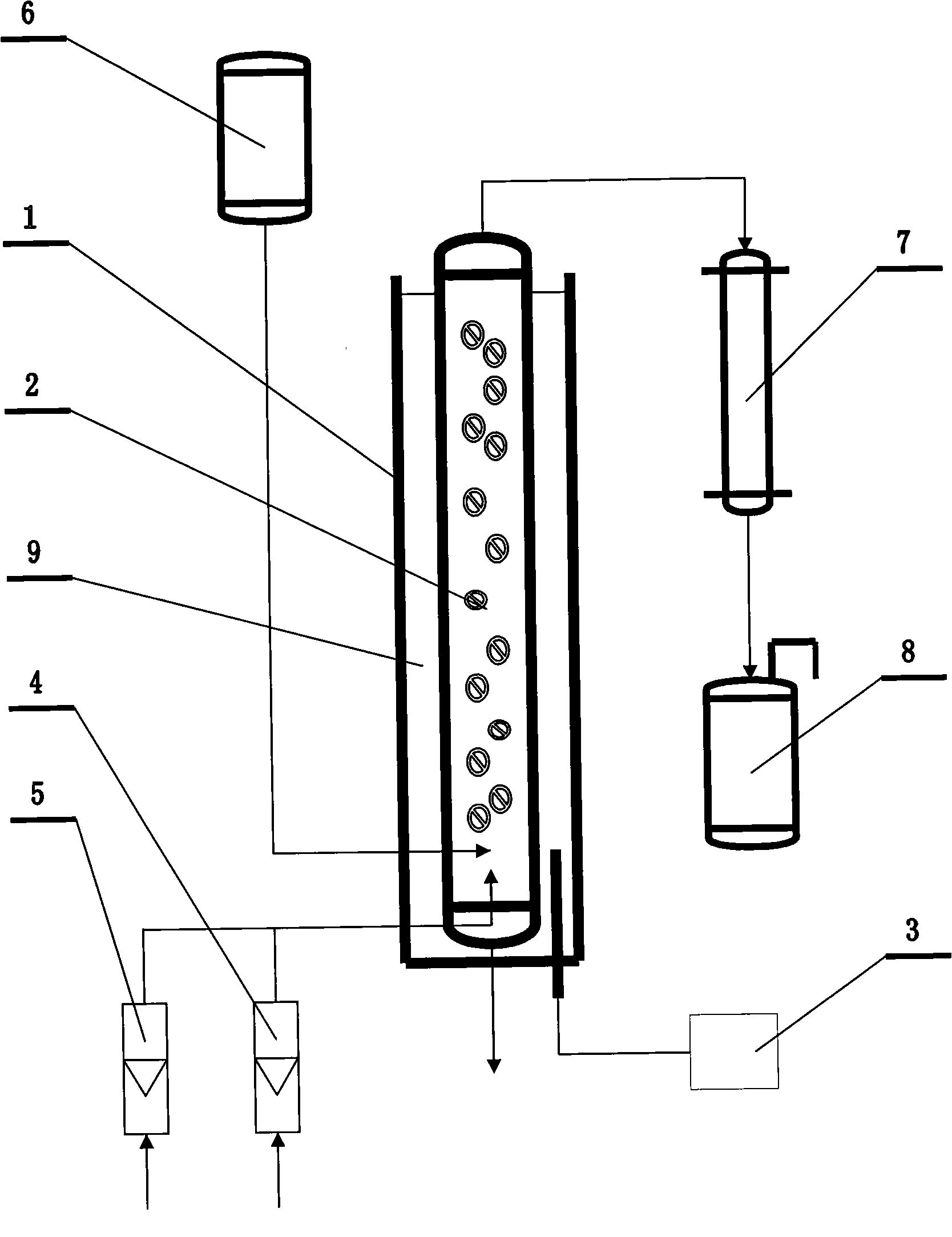

[0048] Such as figure 1 Shown: Weigh about 400g of the above raw materials and add them to the packing reaction tower 1. The packing reaction tower is 70cm high and 5cm in diameter (volume 0.9L, the actual volume after filling the ceramic ring is 0.6L), the packing is ceramic ring 2, open The heat supply control system 3 uses the heat transfer oil 9 oil bath to supply heat, and when the temperature reaches 170°C, open the acetylene gas valve 4 and the nitrogen gas valve 5, and pass the flowmeter, the acetylene gas: nitrogen = 60:40 (V / V) The ratio is passed into the tower, and the flow rate of the mixed gas is 15-20L / H. At the same time, the dropp...

Embodiment 2

[0050]Add 2000g of 1,4-butanediol and 180g of potassium hydroxide into a 3000ml three-necked bottle, start stirring, heat the oil bath to 140°C, distill under 0.05MPa vacuum, and slip out about 200g of colorless transparent liquid to obtain about 1980g of brown Viscous liquid, add 400g dimethyl sulfoxide and 10g octadecyltrimethylammonium chloride, stir well and set aside.

[0051] Such as figure 1 Shown: Weigh about 400g of the above raw materials and add them to the packing reaction tower 1. The packing reaction tower is 70cm high and 5cm in diameter (volume 0.9L, the actual volume after filling the ceramic ring is 0.6L), the packing is ceramic ring 2, open The heat supply control system 3 uses the heat transfer oil 9 oil bath to supply heat, and when the temperature reaches 170°C, open the acetylene gas valve 4 and the nitrogen gas valve 5, and pass the flowmeter, the acetylene gas: nitrogen = 60:40 (V / V) The ratio is passed into the tower, and the flow rate of the mixed g...

Embodiment 3

[0053] Add 2000g of 1,4-butanediol and 180g of potassium hydroxide into a 3000ml three-necked bottle, start stirring, heat the oil bath to 140°C, distill under 0.05MPa vacuum, and slip out about 200g of colorless transparent liquid to obtain about 1980g of brown Viscous liquid, add 300g dimethyl sulfoxide and 8g octadecyltrimethylammonium chloride, stir well and set aside.

[0054] Such as figure 1 Shown: Weigh about 400g of the above raw materials and add them to the packing reaction tower 1. The packing reaction tower is 70cm high and 5cm in diameter (volume 0.9L, the actual volume after filling the ceramic ring is 0.6L), the packing is ceramic ring 2, open The heat supply control system 3 uses the heat transfer oil 9 oil bath to supply heat, and when the temperature reaches 170°C, open the acetylene gas valve 4 and the nitrogen gas valve 5, and pass the flowmeter, the acetylene gas: nitrogen = 55:45 (V / V) The ratio is passed into the tower, and the flow rate of the mixed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com