Epoxy resin composition for vacuum introduction formation of fibre reinforced composite material and preparation method of epoxy resin composition

A technology of vacuum introduction molding and epoxy resin, which is applied in the field of epoxy resin composition and its preparation in the vacuum introduction molding process of fiber-reinforced composite materials, which can solve the problems of high viscosity, poor heat resistance and toughness, and achieve low viscosity, The effect of high heat resistance and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

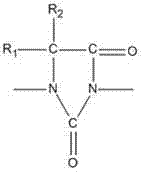

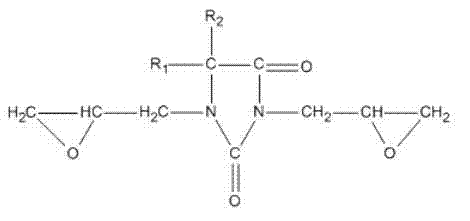

Method used

Image

Examples

Embodiment 1

[0027]Example 1: 50.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 50.0g bisphenol A glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value is 0.48-0.54) mechanically stir and disperse at 800 rpm at 30°C for 5 minutes, add 0.5g kaolin, 10.0 g 1,4-butanediol diglycidyl ether, 0.5g γ-glycidyl etheroxypropyl trimethoxysilane, mechanically stir and disperse at a speed of 800 rpm for 10 minutes, then stand at room temperature for use, and 20.0 1g polyetheramine D230 and 10.0g triethylenetetramine were mechanically stirred and dispersed at room temperature at a speed of 600 rpm for 5 minutes, and 0.5g 2,4,6-tris(dimethylaminomethyl)phenol was added while stirring , mechanically stirred at a speed of 600 rpm for 5 minutes at room temperature. Mix the above components at room temperature, mechanically stir and disperse at a speed of 3000 rpm for 3 minutes, v...

Embodiment 2

[0028] Example 2: 80.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 20.0g bisphenol A glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value 0.48-0.54) mechanically stir and disperse at 900 rpm at 40°C for 8 minutes, add 2.5g of kaolin, 20.0 g 1,4-butanediol diglycidyl ether, 2.5g γ-glycidyl etheroxypropyl trimethoxysilane, mechanically stirred and dispersed at a speed of 900 rpm for 10 minutes, then stood at room temperature for use, and 40.0 1g polyetheramine D230 and 5.0g triethylenetetramine were mechanically stirred and dispersed at room temperature at a speed of 600 rpm for 5 minutes, and 5.0g 2,4,6-tris(dimethylaminomethyl)phenol was added while stirring , at room temperature with mechanical stirring at a speed of 600 rpm for 10 minutes. Mix the above components at room temperature, mechanically stir and disperse at a speed of 3000 rpm for 5 m...

Embodiment 3

[0029] Example 3: 80.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 20.0g 4,5-epoxycycloethane-1,2- Diglycidyl dicarboxylate TDE-86 (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd., epoxy value 0.88) was mechanically stirred at 1000 rpm for 8 minutes at 40°C, and 5.0 g aluminum hydroxide, 10.0 g cyclohexanediol diglycidyl ether, 5.0 g γ-(methacryloyloxy) propyltrimethoxysilane, mechanically stir and disperse at a speed of 1000 rpm for 10 minutes at room temperature Stand still for use, 32.0g polyetheramine D230, 8.0g polyetheramine D2000 and 5.0g tetraethylenepentamine were mechanically stirred and dispersed at room temperature at a speed of 700 rpm for 10 minutes, and 2.5g three Boroethylamine fluoride was mechanically stirred and dispersed at room temperature at a speed of 700 rpm for 10 minutes. Mix the above components at room temperature, mechanically stir and disperse at a speed of 3500 rpm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com